When it comes to 3D printing, CAD (computer-aided design) is often the most critical – and also the most challenging – part of the process. Turning an idea into a printable digital model requires both technical know-how and creativity. Plus, CAD for 3D printing is unique in many ways.

Computer-aided design isn’t just about making something look good, it’s about understanding the constraints of the specific 3D printing method you’re using and ensuring the design works in the real world. Although certain designs may look simple, there could be a whole host of factors as to why a design is more complicated or more time intensive than it might seem. Just designing a product is one thing, designing something to be 3D printed is completely different.

This is often the critical distinction when it comes to the cost of having your product designed. To better understand what you designer might be charging you, first understand what’s involved in CAD for 3d printing.

Why Is CAD Design Crucial for 3D Printing?

CAD design is the foundation of any 3D printing project. Designers transform a concept into a precise 3D model and consider factors like material properties, dimensional accuracy, and the capabilities and pitfalls of the chosen printing method. Good CAD designers understand the limitations and advantages of materials and manufacturing methods. They will know whether something is 3D printable or not, whether one process of 3D printing is superior or overkill for your part, and how your product can be made lighter, smaller, stronger, more efficient, or more appealing through any of the various 3D printing technologies.

A poorly designed file can lead to print failures, wasted material, and expensive delays. Whereas, a well-crafted CAD model will save you a lot of time, money, and headaches.

Understanding your Budget and your Design

Before hiring someone for CAD services for 3D, it’s essential to understand your budget as it aligns with your project’s goals. Start by determining how much you’re willing to spend and the complexity of your design.

Simple projects with straightforward geometries might be achievable with budget-friendly freelancers, while more intricate or technical designs may require mid-tier or professional services. Don’t forget to also account for potential revisions, as iterative improvements can add to the overall cost. By clearly defining your financial limits, you’ll be better equipped to evaluate service providers and choose one that offers the right balance of quality and affordability for your specific needs without having any sticker shock when you get the final bill.

Factors Influencing CAD Design Costs

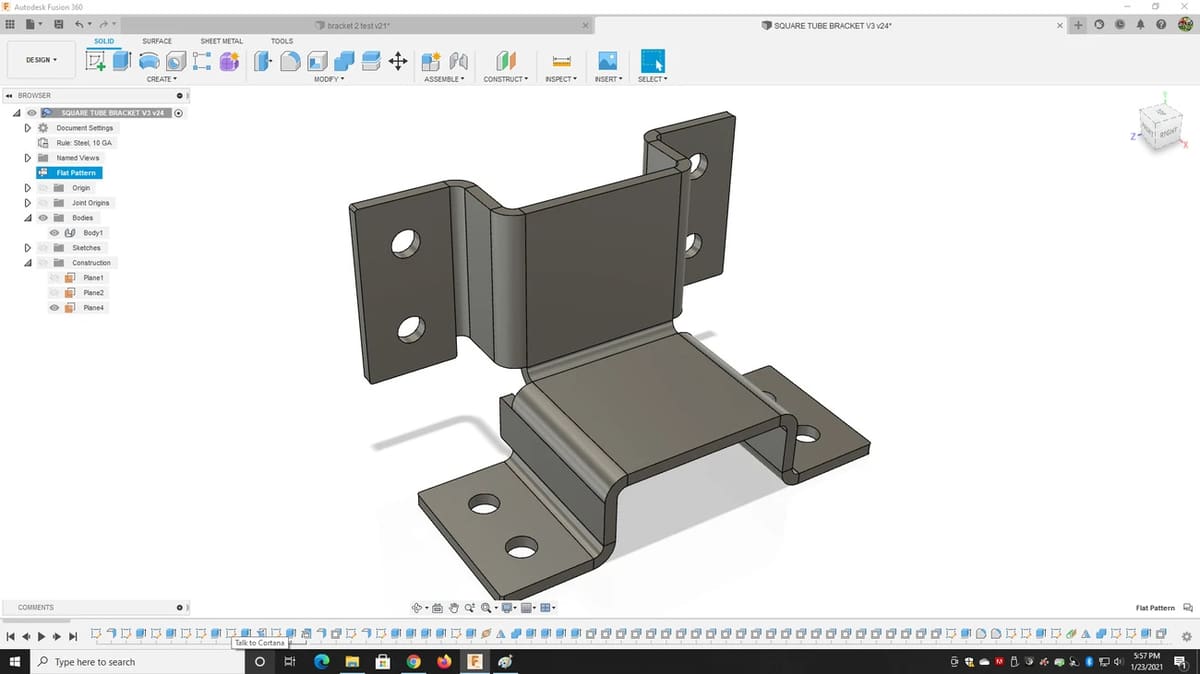

The complexity of a design is a major factor in determining its cost. Simple geometries such as basic brackets are quick and affordable to create, while intricate designs—think: organic shapes, lattice structures, or multi-part assemblies—require significantly more time and expertise, and will drive up costs. Functional designs that need to meet specific performance criteria adds complexity, and therefore, you guessed it, more costs. Whether your project is simple or advanced, the effort required to translate it into a manufacturable model will almost always impact the price.

Other factors to remember are that things like the number of revisions and the level of the designer’s expertise also influence fees. Most CAD projects involve multiple iterations, with each revision adding to the overall expense. Some designers include a set number of revisions in their packages, but exceedingly this will often incur additional markup. Make sure you clarify this with your designer before the work commences. Additionally, the level of the designer’s experience plays a critical role. Beginners may offer affordable rates for simple projects but may lack the skills for more technical designs. Mid-level freelancers or studios provide a balance of cost and quality, while professional firms bring extensive expertise at premium rates, making them ideal for complex or business-critical projects.

Additional services, such as design optimization for 3D printing, stress analysis, and file preparation, can further increase costs but add significant value. Larger projects or tight deadlines also tend to incur higher expenses due to the time and resources required. By understanding these factors—complexity, revisions, expertise, and additional services—you can better plan your budget and choose a CAD design solution that meets your needs. Whether you need a basic design or a high-precision model, aligning your goals with these cost drivers ensures a smoother and more successful 3D printing process.

Budget-Friendly CAD Design Services

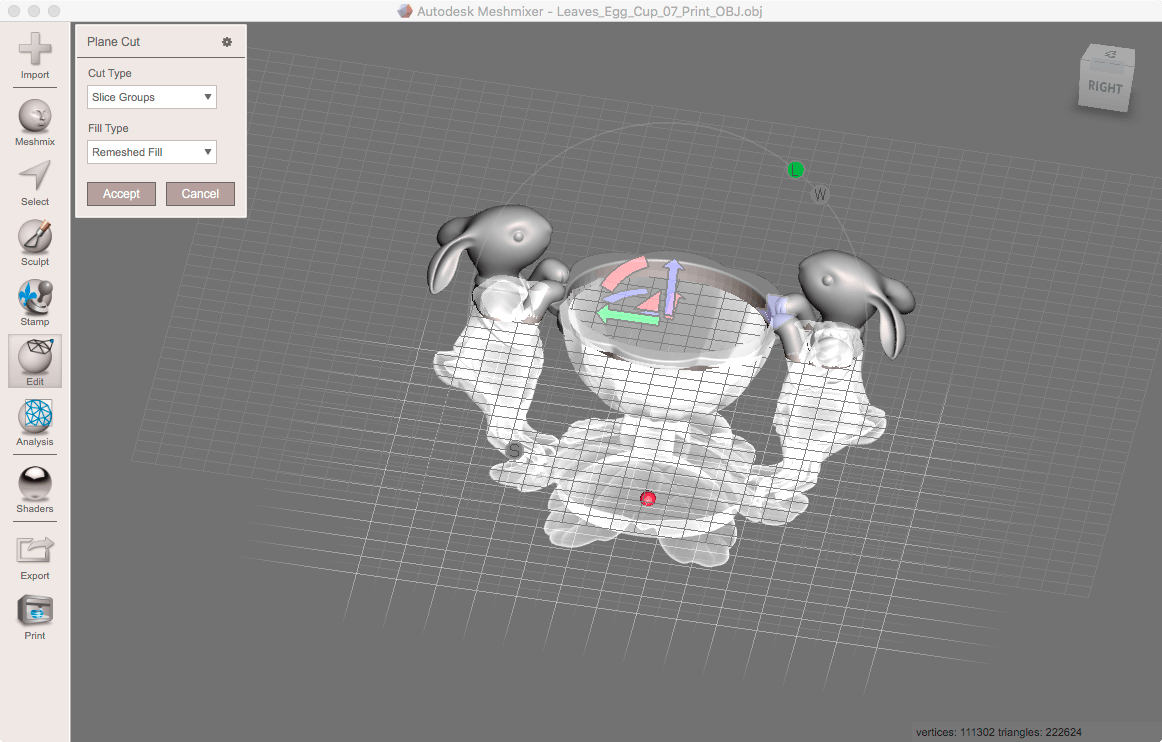

If you’re working on a simple project or have a tight budget, budget-friendly CAD design services might be a good solution for you. These options are often provided by freelancers and can be found on platforms like Fiverr or Upwork, making them easily accessible to hobbyists or professionals with straightforward needs. Perfect for things like a basic bracket or decorative figurines, these services can help bring your ideas to life without costing you an arm and a leg.

When opting for budget-friendly CAD design though, it’s important to set realistic expectations. Many designers in this range have basic experience, which means they can handle simple design projects but may not have in-depth knowledge of advanced 3D printing constraints. Additionally, these services often include minimal revisions, so you’ll need to be clear about your requirements from the start. Costs typically range from $50 to $500, depending on the complexity of your design.

The biggest advantage of budget-friendly services is, obviously, affordability, but also generally a quick turnaround time. Great for small-scale projects or amateurs. However, these types of services do come with limitations—customization options may be limited, and less experienced designers might not fully optimize your model for 3D printing. This can sometimes lead to additional adjustments before printing. So, while they’re a great choice for straightforward designs, more complex or precision-driven projects may require a higher level of expertise.

- What to Expect:

- Designers with basic experience who can handle simple projects.

- Limited understanding of advanced 3D printing constraints.

- Minimal revisions included in the price.

- Cost Range: $50 to $500, depending on the design’s complexity.

- Pros and Cons:

- Pros: Affordable, quick turnaround, accessible for hobbyists.

- Cons: Limited customization, less expertise with complex designs, may require additional adjustments before printing.

- Conclusion:

- Budget-friendly services are ideal for simple designs like basic brackets or figurines but may not be sufficient for projects requiring precision or optimization.

Middle-Tier CAD Design Services

If you’re looking for a sweet spot between affordability and expertise, middle-tier CAD design services are an excellent choice. These services are typically offered by experienced freelancers or small design studios, perfect for individuals or small businesses. Whether you need a high-quality design for a product prototype or a moderately complex project – a design that involves multiple parts that interlock together, for example – middle-tier services provide more value without the hefty price tag of professional-grade solutions, but with more expertise than one of our budget-friendly picks.

With middle-tier services, you can expect designers who have a solid understanding of 3D printing constraints and materials. They often provide a higher level of customization and support compared to budget options, giving you more flexibility to fine-tune your design. Most providers in this range include a reasonable number of revisions and can handle minor optimizations to ensure your model is print-ready from the get go. Prices typically range from $300 to $1500, depending on the complexity of the project.

One of the key advantages of middle-tier services is the balance they strike between cost and quality. Designers in this range generally work with their clients more closely and have a deeper understanding of 3D printing requirements, making them a reliable choice for moderately complex designs. However, it’s important to note that they may lack the advanced tools or capabilities of top-tier professional firms – so no high level precision or specialized materials here. With that said, middle-tier services offer great value for money and are a dependable option.

- What to Expect:

- Designers with moderate experience who understand 3D printing constraints.

- A higher level of customization and support compared to budget services.

- Options for revisions and minor design optimization

- Cost Range: $300 to $1500, depending on complexity.

- Pros and Cons:

- Pros: Better understanding of printing requirements, good value for money, more thorough communication with client.

- Cons: May lack the advanced capabilities or resources of top-tier professional firms.

- Conclusion:

- Middle-tier services are ideal for moderately complex projects that need more precision and expertise than budget designers can offer but don’t justify the cost of professional-grade services.

Professional CAD Design Services

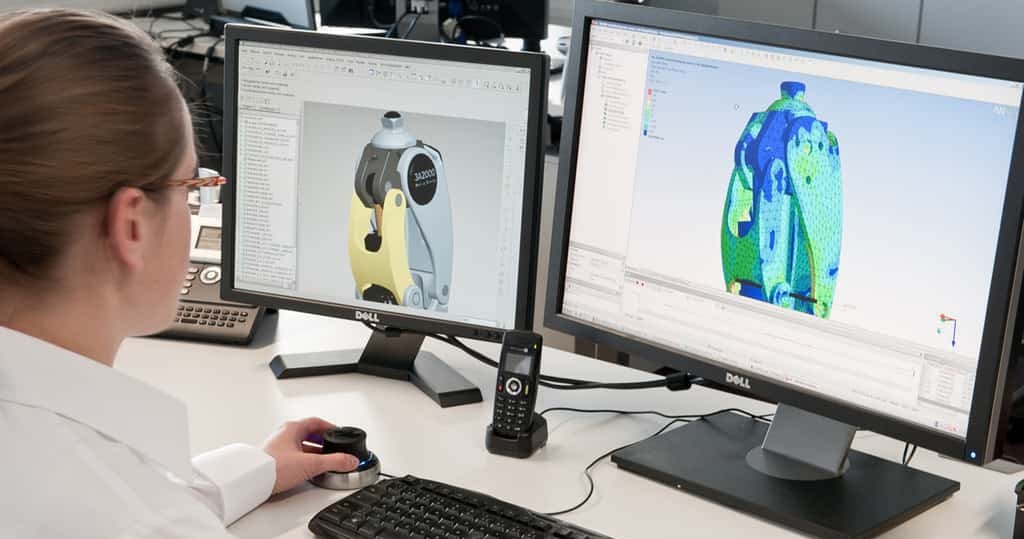

For high-quality, precise 3D CAD design, professional services are the best option. These services are provided by experienced designers or specialized firms equipped with the expertise and resources needed for demanding projects. Professional CAD services deliver tailored solutions to meet the highest standards of accuracy and functionality.

With professional services, you can expect designers who have extensive experience in both 3D printing methods and materials. They offer advanced capabilities, such as stress analysis, multi-material optimization, and complex multi-part assemblies, ensuring that your design is not only functional but also optimized for production. These services will also include comprehensive support services, making sure your design aligns perfectly with your specific needs. Depending on the complexity of the project, costs typically range from $500 to $5000 or more.

The key advantage of professional CAD design is the superior quality it delivers. These services offer customized designs, advanced expertise, and detailed optimization, and high precision that hobbyists or mid-tier options may not equal. However, on the flip side, they do come with higher costs and potentially longer lead times, particularly for complex projects. Professional services are ideal for businesses or individuals who need reliable, high-precision models where there’s no room for error and have a budget to match

- What to Expect:

- Designers with extensive experience in 3D printing methods and materials.

- Advanced capabilities such as: stress analysis, multi-material optimization, and multi-part assemblies.

- Full support, high attention to detail, and compatibility with specific printing processes.

- Cost Range: $500 to $5000 or more, depending on the project’s complexity.

- Pros and Cons:

- Pros: Superior quality, tailored designs, access to advanced expertise, and detailed optimization.

- Cons: Higher costs, longer lead times for complex projects.

- Conclusion:

- Professional services are ideal for businesses or individuals working on mission-critical designs where precision, reliability, and functionality are essential.

The Growing Market for CAD Design Services

The demand for CAD design services is growing alongside the popularity of 3D printing. More companies now offer CAD as part of their 3D printing services. Platforms like Craftcloud, Shapeways, and 3D Hubs even bundle CAD design with printing, making it easier for customers to turn ideas into physical products. Freelance marketplaces have also expanded, providing accessible options for hobbyists and startups.

CAD design costs can range from $50 for basic models to over $5000 for professional, high-end solutions. Whether you’re a hobbyist or a business, investing in a well-designed model is crucial for a successful 3D printing project. With so many options available, choosing the right service ensures your design is not only functional but optimized for manufacturing, saving time and money in the long run.

You May Also Like:

Lead image source: Autodesk

License: The text of "How Much Should CAD Design Cost?" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.