Through Chinese 3D printer maker Flashforge, All3DP had a rare opportunity to conduct a Q&A with JinQi Toys owner Zeng Hao about his massive printing operation. Naturally, he had wonderful things to say about Flashforge — which the company put in its own promotional video — but he also provided insights on how to run a competitive 3D printing operation where every penny counts.

According to JinQi’s profile on the Chinese business-to-business e-commerce platform 1688.com under the Alibaba Group, which is designed primarily to connect domestic Chinese manufacturers, JinQi (officially Yiwu Jinqi Technology Co., Ltd.) was founded just over a year ago in September, 2023. Its factory floor area is 2,657-square-meters (28,600 square feet) and it employes 41 people.

Q. What type of products do you produce and do you have a niche or specialty?

“JinQi primarily operates in two main business segments: printing services and filaments. These two segments complement each other. The finished products fall into three categories: toys, accessories, like keychains and small trinkets, and large-scale crafts exclusively for offline sales, measuring up to 45-50 cm in size.

“Currently, JinQi’s business consists of 80% exports and 20% domestic sales. Domestic customers tend to be more price-sensitive, even a difference of a few cents can make a big difference. If we can save on these costs with an affordable 3D printing, it will give us a competitive edge. For example, with an initial investment of 1 million yuan, we can produce significantly more products each month, more than double the current output. We plan to purchase more printers specifically for the domestic market this year.

“We stay ahead of the competition with our original design capabilities. Originality is the key to success. Without original design capabilities or collaboration with original designers, it will be difficult to survive in this market. If we simply remain a traditional manufacturer without original design capabilities, we could easily be eliminated from the market within half a year. Those who have already secured copyrights and IPs will have a significant advantage.”

Q. What's one of your biggest hurdles today?

“Currently, the biggest challenge with domestic designers is their limited understanding of 3D printing. As a result, their designs may not fully leverage the advantages of 3D printing. More communication is needed during the creative process.

“For instance, earlier this year, we worked with a Chinese designer whose model required a lot of supports. We gave him some suggestions, like making the four corners movable. If the model was rigid, it could easily be replaced by injection molding, and even if it became popular, it wouldn’t be profitable due to pricing. He then designed a new version of the model that requires minimal support. For example, this model contained an open mouth, and he inserted a pre-built module inside so supports didn’t need to be added from the base. All the limbs, tail, and head were movable. This design is highly sought after in 3D printing. Combined with our latest silk-like filaments, these products have a significant advantage over traditional injection-molded ones.

“As for our own IP series, like the Chinese dragons, you can see the level of details, even in the overhangs, is quite impressive. This dragon design is exclusive to us; we have a licensing agreement with the creator. We place a strong emphasis on copyright. Even for basic designs like common Chinese dragons in the market, we pay royalties to the creators. We have excellent relationships with these creators, especially after our year-end project last year. We planned to scale up their products, standardize them, and make them into finished goods.

“We have accumulated a vast library of models. Our local model library alone has over 10,000 different designs, including over 600 dragon designs and over 500 egg designs. However, due to the explosive domestic demand since May, we haven’t launched most of these yet. We plan to release them gradually throughout this year.”

Q. What's your top advice for operating a successful print farm?

“Invest in reliable and efficient 3D printers that offer faster speeds, easy operation, and superior print quality.

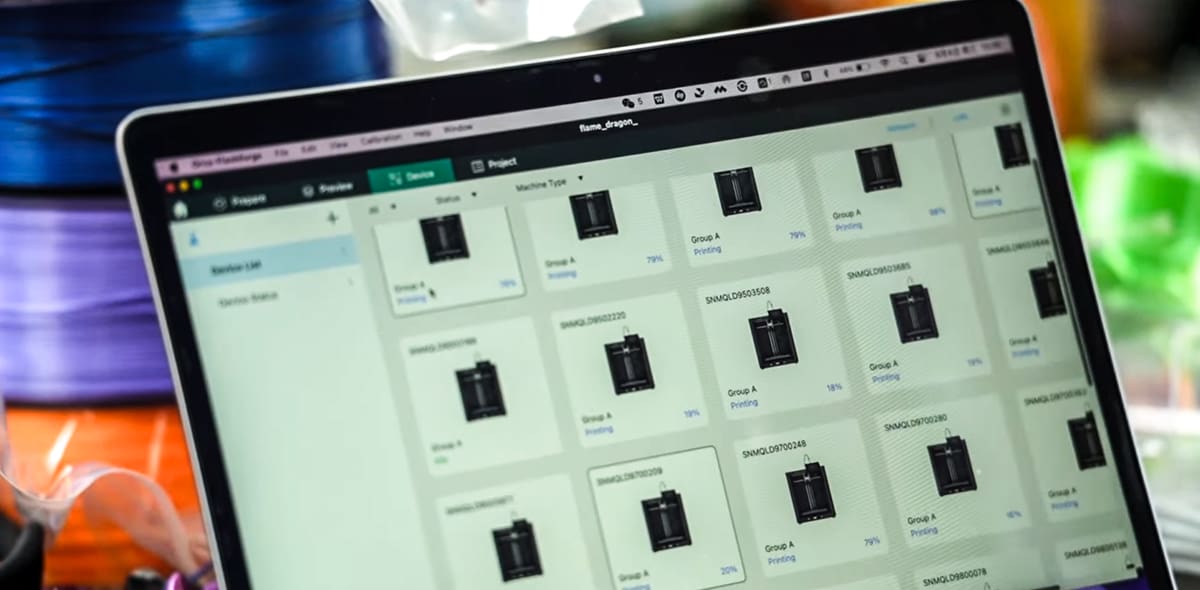

“Currently, one worker manages 500 devices. With 2,500 devices, we have five operators for both day and night shifts. One operator can manage hundreds of devices on one computer or smartphone. This significantly reduces labor costs and improves management efficiency.

“In China, having printers with a loss recovery feature is essential. In Jinqi, we experienced two power outages, and over 90% of prints on our Flashforge Adventurer 5Ms could be resumed with no visible seams. This saved Jinqi from significant losses, unlike other brands whose prints were completely ruined after power outages, requiring reprints and wasting both materials and time.”

Q. How many machines do you have and what materials do you use?

“JinQi has a fleet of 2,500 printers including 500 Flashforge AD5Ms. We plan to add more units of Flashforge Adventurer 5M. We use various types of PLA and work closely with Flashforge filament factory to create unique colors.”

(Flashforge has released a white paper on 3D printing farms to help entrepreneurs quickly understand the key actions involved in preparing for the 3D printing farm business.)

You May Also Like:

License: The text of "Inside China’s Largest 3D Print Farm" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.