Going hands-on with the new Bambu Lab H2D over the past few weeks, imagining that we’re running a small business or an engineering department in a large enterprise, was an eye-opening experience in many ways. It left us thinking of some professional FDM 3D printer makers we may see exiting the industry in the coming years.

In fact, what you can get from this $2,200 machine should have a lot of printer manufacturers worried, but not all of them, which we’ll get into below.

For as good as the H2D is, it is not aiming to be your company’s next workhorse for jigs and fixtures. It’s billed as a “multifunctional manufacturing hub” for people who want to 3D print, laser engrave, cut fabric, and draw. Yet, strip away these optional accessories and what you have is a dual-nozzle, high-temperature, composite-material-ready printer that is capable of handling your jigs and fixtures, replacement parts, functional prototypes, and much more, with a few caveats.

This is the duality of the H2D: aimed at power-hobbyists and prosumers alike. Is it trying to do too much?

This review ignores a lot of the new features of the H2D that we think most professionals will have no use for (drag knife, pen plotter) and focuses on the advances, such as those that enable it to boost accuracy to levels not seen on previous Bambu Lab printers and its engineering-grade-material-enabling features that are well above hobby level. Throughout, we compare it to the Bambu Lab X1E, which was released in 2024 and billed as the company’s professional machine.

My colleague Matt Mensley and I put the H2D through its paces over the course of several weeks. Matt focuses on the bulk of its features and innovations here, while, below, I look specifically at the business case for purchasing this machine.

So now, let’s dive into why your company may or may not want to buy a few H2Ds.

It's Twice as Fast, Sort Of

As with any business purchase, one of the main questions is: What problem will this machine fix? Is the 3D printing hurdle at your company: speed, materials, part quality, or ease of use?

If you said speed, the H2D would tick that box.

Bambu Lab has moved the goalposts again with its 1,000 mm/s print speed. The X1E has a top speed of 500 mm/s. Realistically, however, print speed is more hype than feature since it depends on your part geometry, material, and other printing conditions. No part will actually print at 1,000 mm/s and nothing we printed came close to sustained 1,000 mm/s. Although impressive, it certainly would be misleading to say the H2D is twice as fast as the X1E. Or that this figure alone would make it a better choice than the 500 mm/s print speed you’ll find on an UltiMaker S8 or a Raise3D Pro3 HS.

That said, we were impressed with how fast our parts printed while exhibiting (mostly) excellent quality.

Why You Want Dual Nozzles

The primary aspect that makes the H2D faster than the Bambu Lab X1E is its new dual nozzles.

Dual nozzles have long been a distinguishing feature of professional FDM 3D printers. The main reason for having dual nozzles is that one prints with a support material while the other prints with a base material. You’ll find dual extruders on UltiMaker, Stratasys, BCN3D, and many others for this purpose.

3D printing supports in the same material as the main part can be a waste of expensive filament when you could be printing the supports in a much lower-cost filament. Often, for more complex parts, water-soluble support material is the best solution, especially for hard-to-reach or internal supports.

Although dual material 3D printing is possible with material changers, such as the Automatic Material Station on the single-extruder X1E, the printing took much longer. For each material to print, the machine had to retract one filament, extrude “poop” to clean the nozzle, load the second filament, extrude a bit more material, then print the support layer. This would repeat hundreds of times for each print.

We’d venture to guess that one of the main reasons professionals opted against the X1E was its single extruder. And while the H2D doesn’t eliminate the need to prime the nozzle – you do still get a slim priming tower print alongside such multi-material prints — the difference is stark compared to a single-nozzle multi-material print on the X1E when it comes to print time.

For example, a digital file of a manifold that we printed using a base material through one extruder and a support material through the other took half the time on the H2D than it would have taken using two materials through a single extruder on the X1E. So, going back to speed, the H2D can be twice as fast as the X1E when it comes to dual-material printing.

Although most professional FDMs enable dual-material printing, the H2D goes far beyond just two materials. Although we didn’t print with more than four materials on a single print, theoretically you could attach up to four AMS Pro 2 material changers simultaneously for a 16-material print — not that most businesses have a need for such prints.

The dual nozzles are the completely tool-less quick-swappable type like you’ll find on an UltiMaker or a BCN3D. The H2D comes with dual 0.4 mm nozzles but is compatible with optional 0.2 mm, 0.6 mm, and 0.8 mm quick-swappable nozzles.

Accuracy & Reliability

Professional FDM manufacturers boast their solid steel frames and other quality components that contribute to reducing the level of drift or deviation in the print head as it prints. Bambu Lab says candidly that “using high-end parts on every axis of the motion system could improve its accuracy, but the cost would be excessive.” This cost is some of the reason other professional FDMs are in the $10,000 to $30,000 range.

To get around the limitations of its components, Bambu Lab has a new approach: a sensor system that adjusts for imperfections in the motion systems. Called a Vision Encoder, this calibration solution achieves a distance-independent 50-micron motion accuracy by measuring the dimensions at the last axis of the motion system and uses algorithms to compensate for drift. In other words, when calibrated using this Vision Encoder plate, which is an optional accessory, Bambu Lab says that pretty much 95% of the time, your print will be in a +/- 50 micron accuracy to the digital file.

This is not the type of live laser scanning of parts as they’re printing for the purpose of adjusting on the fly, like you’ll find in the Markforged FX10, however, but it’s a step in the right direction for a desktop unit. All3DP’s Vision Encoder got lost in shipping, but as soon as we get our hands on one, we’ll put it to the test.

To be sure, Bambu Lab is not coming out and claiming that the H2D has an accuracy of +/- 50 microns — like UltiMaker claims a +/- 150 microns accuracy for the S8 and Roboze’s claims a +/- 15-25 micron accuracy on its Pro Plus. Most desktop FDM 3D printer manufacturers stop short of listing a general accuracy, but what Bambu Lab is offering is the opportunity to have a higher level of accuracy than its other printers for users who need it.

Materials also play a big role in accuracy, so for this aspect, Bambu Lab says its temperature-controlled chamber and filament-specific thermal expansion calibration, among other features, “enable precise components without post-processing.”

Reliability and repeatability have been the buzzwords for a few years when it comes to professional and industrial FDMs. 3D printer manufacturers, such as 3D Systems and Stratasys, conduct studies where the same part is printed X amount of times and each measured and compared to the digital file to generate a statistical percentage of accuracy to be used as a general repeatability claim. Stratasys says its F190CR composite printer has a “verified 99% uptime and a 99% dimensional repeatability performance.”

Not many 3D printer manufacturers, including Bambu Lab, provide these “verified” performance numbers, but as repeatability becomes more central to purchasing decisions, we may see more of it.

Engineering-Grade Materials

Most companies looking to print durable parts lean toward more robust materials, like carbon-fiber-infused nylons that require a nozzle that can reach higher than 300ºC, a heat-controlled chamber, and, ideally, a temperature- and moisture-controlled filament bay. The H2D has all of these things.

Sealed & Heated Filament Bays

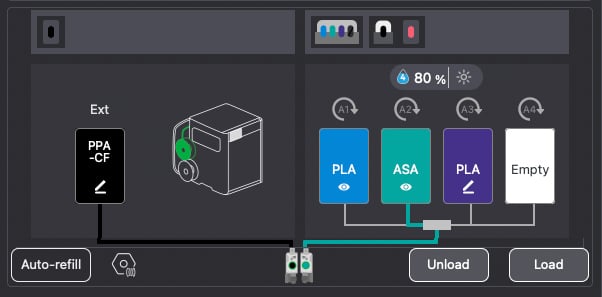

The H2D offers two new external Automatic Materials Systems that dry filament; the AMS 2 Pro and the AMS HT (price and availability yet to be announced).

It’s one thing to dry your moisture-sensitive material, but to maintain stable material mechanical properties during printing you’ll want to print directly from an environmentally controlled and sealed box. Professional FDMs from UltiMaker, Stratasys, Markforged, and Roboze have integrated sealed and heated material chambers. The external Bambu Lab AMS does essentially the same.

The AMS 2 Pro both heats (to 65 ºC) and dries the materials in its four slots. With electromagnetic vents, the AMS expels moist air during drying cycles. Once the drying is complete, it seals the vents airtight for low-moisture storage, saving you from having to unload the spools to house in airtight containers or cabinets.

For your most moisture-sensitive materials, like nylon, the new single spool AMS HT is similar to stand-alone filament dryers, like the Creality Filament Dry Box, the PrintDry Pro 3, or the PolyDry from Polymaker. It can heat up to 85 ºC, auto-rotate while drying, and keep the filament dry as you’re printing with it directly from the box.

The AMS HT is not only hotter (85 ºC) than the AMS Pro 2 but it’s a better choice, Bambu Lab says, when feeding fiber-reinforced rigid filaments and soft TPU into the machine because there’s a more direct path from the AMS HT unit directly to the printer. These materials are not recommended for use with the AMS Pro 2, since, in our experience with the X1E and its AMS, they tend to get stuck in the loading and retracting process.

Like the X1E, the H2D is compatible with a wide range of materials including engineering-grade carbon-fiber-reinforced PPA and PPS. The H2D’s maximum nozzle temperature of 350 °C and its 65 °C maximum chamber temperature just skirt the lower limit of the requirements to print with Ultiem (PEI), yet most brands of this engineering grade material says a 410 ºC nozzle is optimal.

Connectivity & Security

You can connect your H2D to your PC and mobile devices through the cloud or wall it off completely in three offline modes. The H2D has Wi-Fi authentication but not the same WPA2-Enterprise Wi-Fi as the X1E, and it does not have ethernet or a physical network kill switch like the X1E. Why? Could have been a cost-trimming measure.

Wi-Fi protocol (IEE 802.11 a/b/g/n) connection should be secure enough for business customers. Bambu Lab has removed the microSD card slot that was a feature on the X1E and instead has a USB port, so you’re not strictly limited to sending all printing over Wi-Fi.

If enterprise-level security is a top priority (for government, defense, or large-scale manufacturing) and you need security compliances (such as NIST, ISO 27001), these are found in professional 3D printers from manufacturers such as Stratasys.

The H2D’s Cloud Mode comes with the advantages of being able to start or monitor prints outside of the local network, use Bambu Handy, and the Print History function, plus, easy software updates. LAN Mode is the same as you’ll find with the X1E and we’ve covered it in-depth here. LAN Mode restricts third-party software from access and control to important printer functions, such as remote access, but the new “Developer Mode in LAN,” released in January, essentially opens it up again if you wish.

This mode is essential for business users since third-party software is your only option for efficiency-friendly, workflow features like networking several Bambu Lab printers and establishing a print queue for jobs from various users.

It may not be fair to list the things the H2D doesn’t do or isn’t designed to do, but if you’re considering it against other professional desktop FDMs for a print farm or an enterprise environment, there are some features you won’t find, which are, more or less, common on many other professional FDMs. Chief among them is the print queue.

If you’re looking for software to manage your 3D printing operation that involves organizing the incoming orders from several users with features like establishing user permissions, pulling machine and project print logs that track print success, failures, and abandoned jobs, you’ll need to look elsewhere for now. In the same orbit, hardware and price-wise is Prusa, which offers this kind of oversight and control with its Prusa Connect service. Ultimately, for what we’d consider enterprise usage nothing here compares to the workflow software of UltiMaker’s Digital Factory, Markforged’s Digital Forge, or Stratasys’ GrabCAD.

Bambu Lab is working on farm management software, but it’s unclear when or in what form this will release, nor which printers it will support.

For our printer testing, we shared one login and password, but we expect, like the X1E, multiple users to be able to sync with one machine.

Tech Specs & Alternatives

As the H2D is put to use over the coming months, its accuracy, durability, and reliability will become apparent, but, on paper, out of the box, this Bambu Lab machine is on par with many of the industry’s professional FDM solution in terms of size, speed, temperature, and materials.

Our hands-on experience over the past few weeks has swung towards positive, though it hasn’t been as fire-and-forget for large-volume prints or mixing tricky materials as we’d like.

As amazing as it is on paper, we’ve had difficulty getting any large-size perfect prints. It’s difficult to know this early if software updates will smooth this over — updates should follow thick and fast as more users get their hands on the machine — or maybe there’s a bigger issue at hand. Still, for the time and material savings alone, it’s a worthwhile investment over the company’s smaller machines.

What Does the H2D Compete With?

Which professional FDM 3D printers to compare the H2D to isn’t easy. Certainly, other 3D printer manufacturers can make legitimate claims for superior components, more robust overall construction, and higher-quality electronics. These “presumably” would indicate solid repeatability, longer lifespan, and fewer repairs and replacement parts.

There’s also, as we mentioned, more business-focused workflow software from the competition aimed at tracking, and in many ways justifying, your 3D printing program’s ROI. All of this harkens back to the question we started with on the problem your 3D printer needs to solve, influenced by the resources you have to invest.

We’ve gone hands-on with the H2D, but have never had the opportunity to put a Stratasys to the test, or, frankly any of the professional printers we mention in this article, except the UltiMaker S5, which is excellent. So, yes, it’s unfair to compare the reality of the H2D to the claims of the other manufacturers, which is why, below we give you a comparison in facts and figures.

H2D vs. X1E

Having printed with both of these machines, we found the H2D is quieter compared to the X1E, and we had overall fewer failed prints and defects. Plus — and, this may be a little thing, but — we didn’t have to prop open the door and fume up the office when printing with materials that didn’t need the trapped heat of the enclosed chamber.

Air-quality-conscious businesses should appreciate the H2D’s internal air recirculation via particulate filter and heater. It opens a top flap to intake fresh air while maintaining filtered exhaust.

Overall, it isn’t much of a comparison if you’re deciding which one to buy. The new H2D is faster, bigger, and might be cheaper (depending on the number of options and upgrades you select to buy). There’s no feature of X1E that isn’t on the H2D.

What We Printed

Many of our H2D print projects for this review were large, requiring 24+ hours. We wanted to evaluate full-bed part production as well as large part accuracy and quality. Our other review has even more parts to check out.

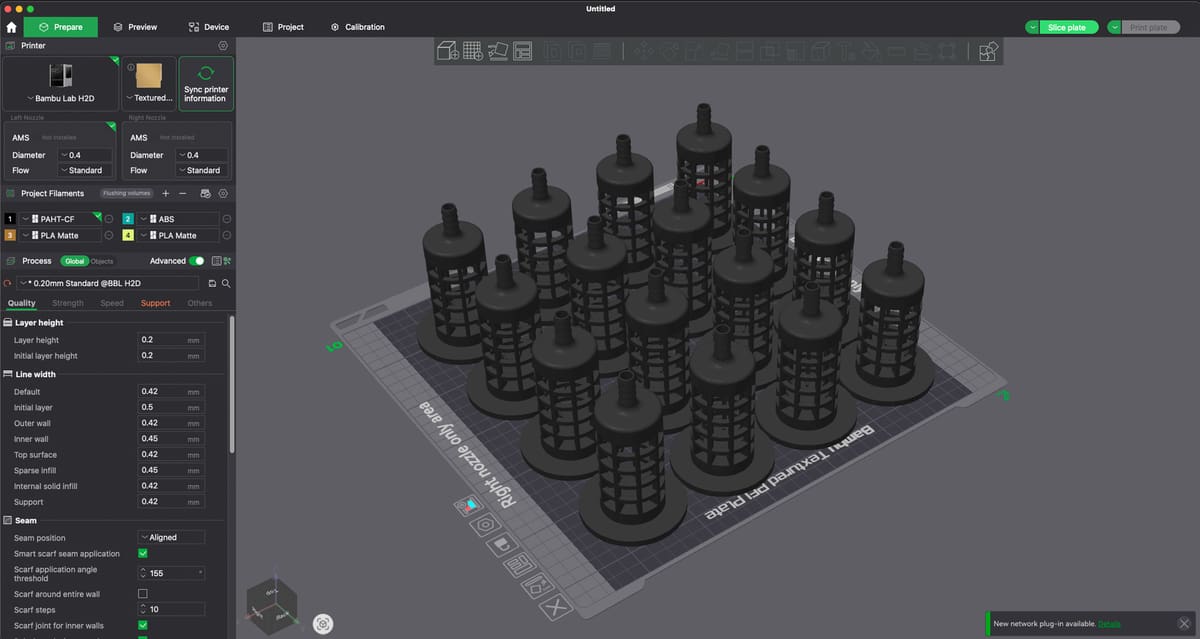

Pictured above (and as our main image to this article at the top) is a set of valves (part by @drimacl_87515 via Printables). Printed in PAHT-CF, Bambu Lab’s high-temperature carbon-fiber-filled nylon, with ASA supports, this 36-hour print impressed. Every part was the same even down to the exact same print flaws, which we’ll admit, are probably user errors from insufficient support. We went for the minimum amount of ASA tree supports thinking that support removal would be time-consuming. To our delight, the ASA trees quickly and cleanly popped off in a second, leading us to think that more supports would have fixed the surface flaws. Structurally, though, each part is solid and unbreakable by hand.

Next, we looked at using the H2D’s full volume with PPA-CF material. This manifold by @Maciej_2413918 via Printables is not a truly functional part but could stand in for one. It was an impressive print, except for the fact that it suffers from defects at various points, most notably a support tree breaking beneath what was supposed to be a fully supported overhang.

This would be a minor inconvenience for a personal print in inexpensive material, but PPA-CF is not cheap, and the day and a half lost to printing it compounds the pain.

Putting this into perspective, though, where this model has been printed is flawless. At this scale, it would not even be possible on the X1E.

What Would You Test Print?

Our multi-day printing didn’t leave us a lot of time for a wide variety of projects before the official launch of the H2D, which is where you come in. If you’re considering the H2D and have a specific print that’s typical of what you need at your business, send the STL or 3MF to us at Pro@All3DP.com along with the requested material and your preferred print settings. We’ll pick 10 reader parts to showcase.

You May Also Like:

License: The text of "Bambu Lab H2D Review for Business Users: Good for Production Parts, Struggles With Large Parts" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.