Kingroon is a rather inconspicuous 3D printer manufacturer that has, nonetheless, maintained significant popularity over a commendable stretch of time. The brand’s systems stand out as something of an oddity in the market, offering desirable hardware at a pretty much unbeatable entry-level price. Their most notable series is the KP3S lineup: tiny cantilever 3D printers boasting linear rails and a Titan-style direct extruder.

The series started with the KP3S 3.0, the most affordable in the lineup and the focus of this review, but Kingroon has kept the popular machine growing and now offers four variants of the machine with marginal improvements until you hit the KP3S Pro V2 – which might as well be an entirely different machine with its triple linear rails, networkable Klipper firmware, auto-bed leveling, and larger interface for under $300.

We’ve been sleeping on this series a bit. The KP3S 3.0 was released some time ago and has maintained its popularity today, with plenty of users complimenting the system. We’re finally here to see what all the fuss is about. Read on to hear our thoughts about the Kingroon KP3S 3.0.

The Verdict

Pros

- Extremely affordable & delivers great quality

- X & Y axis linear rails

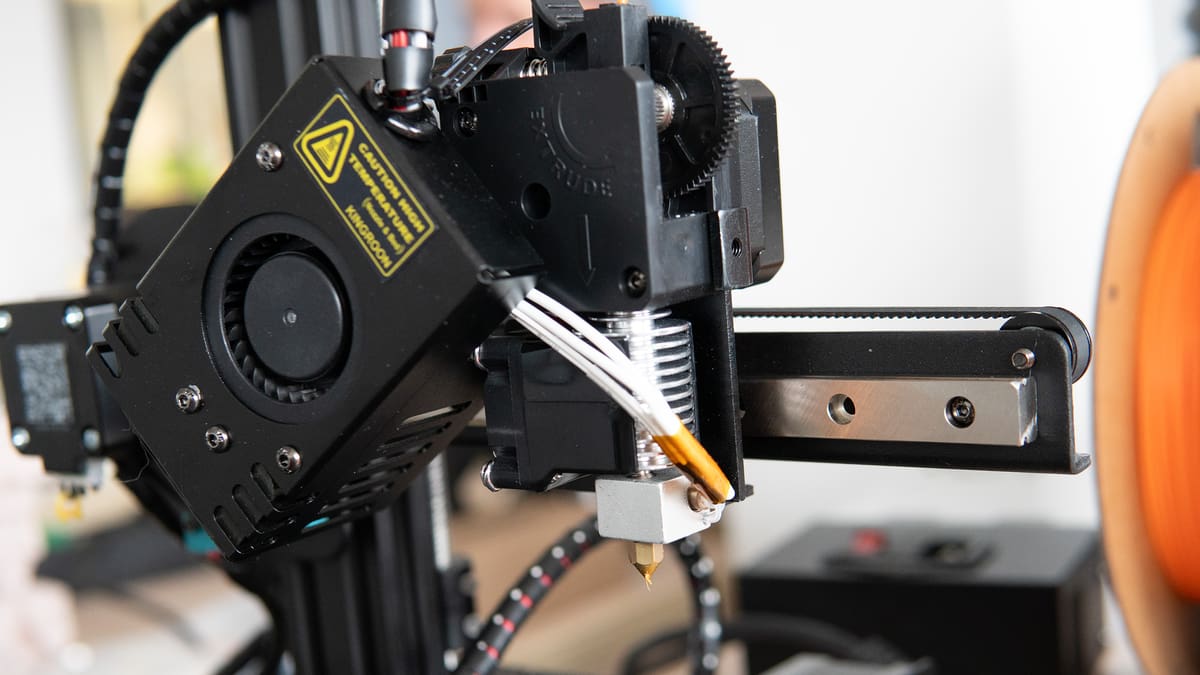

- Direct extruder handles a variety of filament well

Cons

- Misaligned X-axis start position

- Cumbersome external power brick

- Soft magnetic print surface feels cheap and sticks too well

We had a great experience with the Kingroon KP3S 3.0. Its linear rail motion feels smooth and results in parts with clean layer uniformity, while the Titan-style direct extruder handled every material we threw at it with ease. Being a simple thing, the machine has plenty of potential for mods – some simple ones offered by Kingroon itself – and a fair amount of printable files offered by the community, all for an extremely accessible price point of $159.

We did find the printer’s external power supply to be cumbersome, especially in the mini 3D printer format. Competing mini, cantilever-style machines – like the Ender 2 Pro – manage to integrate a PSU into the 3D printer’s base just fine, and so do other entries in the KP3S series. The power brick limits portability in a form factor that otherwise has the advantage of being easily moved and stowed away for occasional use.

Still, we think the Kingroon KP3S 3.0 is an ideal budget choice for those taking their first steps into 3D printing or who want a cheap and cheerful machine around to try their hands at modding. It’s an affordable system that we found simple to use and to produce great quality parts. Though we did find some small oversights on the machine, like needing an X-axis offset to start in the build volume, we ultimately feel they are within reason for a machine at the KP3S 3.0’s price point.

At A Glance

- Price: $159

- Build Volume: 180 x 180 x 180 mm

- Max. Hot End/Heated Bed Temperatures: 260 ℃ / 110 ℃

- Print Bed Material: Magnetic sticker sheet

- USP: Affordable and compact with linear rails.

- They say: “The linear guide rails of both the X-axis and Y-axis highly increase the print accuracy.”

- We say: “Sure seems that way.”

The Tech

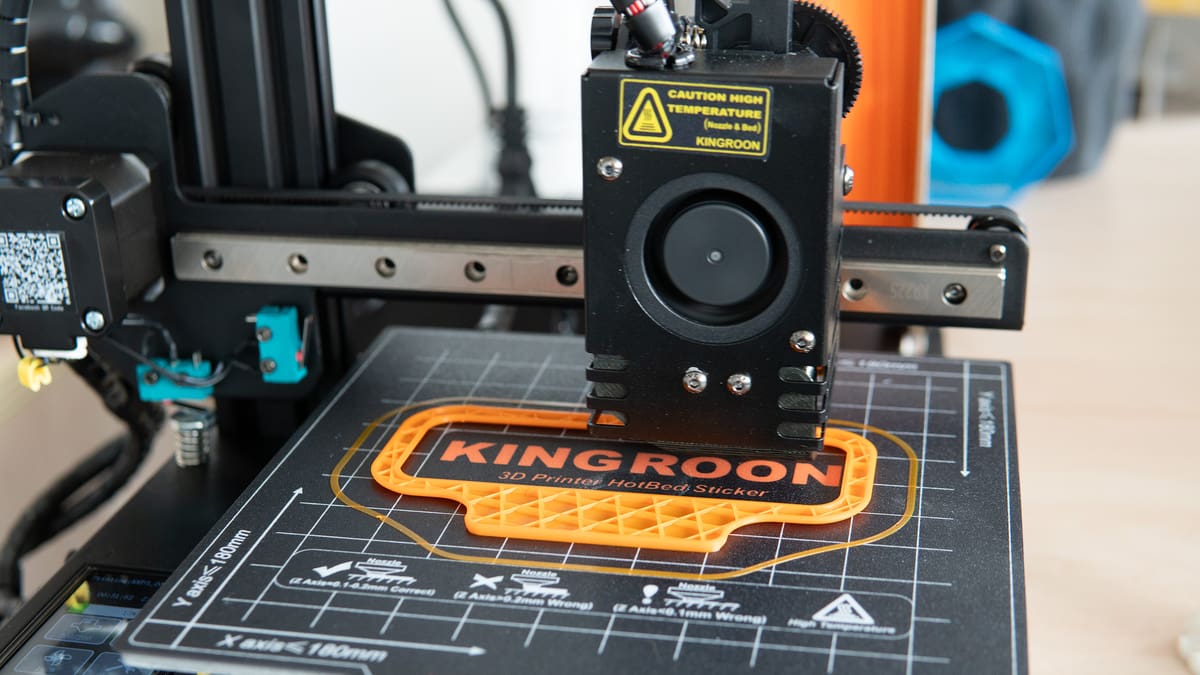

Kingroon’s KP3S 3.0 is a small Cantilever 3D printer with a build volume of just 180 x 180 x 180 mm. The little machine stands out from the crowd with its atypical hardware, boasting linear rails along its X and Y axes and a direct, PTFE-lined Titan-style extruder with a 3:1 gear ratio. And, still, Kingroon manages to keep the system’s price low at just $159 – beating the price of All3DP’s current budget pick for small 3D printers, the Ender 2 Pro, by $10.

Better yet, the KP3S has a tiny 2.4-inch touchscreen integrated into the base, as opposed to clip-on 12864 screens with a rotary encoder on competing machines. Surprising finish for such an affordable machine, the only compromise being the cumbersome external power supply that severely limits this little machine’s portability.

If you’ve been turned onto the KP3S, it’s probably due to the linear rails that serve as the system’s standout feature. Linear rails are generally considered more reliable and longer lasting than V-slot wheels but require more maintenance in the form of reapplying lubricant.

Ample Addons

Kingroon’s offering may also be attractive for the upgrades the manufacturer offers – somewhat unusual for the relatively limited printer offerings. Users can easily upgrade the included direct extruder to be all metal with Kingroon’s stainless steel or titanium heat break, replace the magnetic print surface to remedy one of the machine’s weak points, or even attach a 1.6W laser engraver to the system (though we would advise caution when using a laser on an unenclosed system such as the KP3S series – it’s best to avoid).

The printer’s 32-bit mainboard with removable TMC2225 stepper drivers also has a free slot to add auto bed-leveling, such as the BLtouch-like “3D Touch” offered by Kingroon, should you want to give your mini machine a bit more automation.

Compromises

Though the KP3S is very impressive for its price, it’s not a perfect system. Some of the choices that we found interesting, like the spring-tensioned screw acting as a Z-endstop (that likely helps the machines to pass QA a little easier), call the machine’s longevity into question. Is an endstop that moves fine over time, or will it cause problems?

We can’t answer these questions because we’re not spending an extended period of time working with the machine, but it’s a safe assumption that you’ll need to replace things like springs on a 3D printer this inexpensive. But, with that said, nothing on this machine appears difficult or expensive to replace, and points of failure will likely just become your first upgrades.

Printing

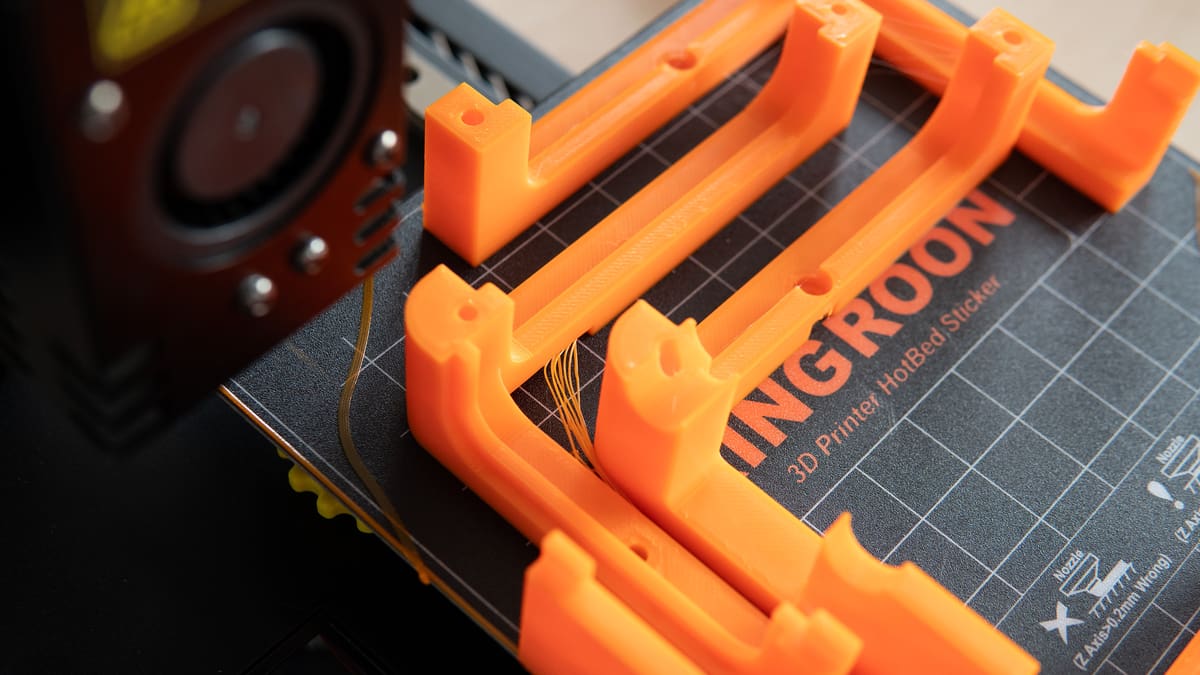

When it came to the quality of prints out of the box, the KP3S 3.0 performed great. Off-brand linear rails can be treated with skepticism, but we found the machine’s motion to be smooth – the excellent layer uniformity of the KP3S 3.0 is a testament to the rails’ performance.

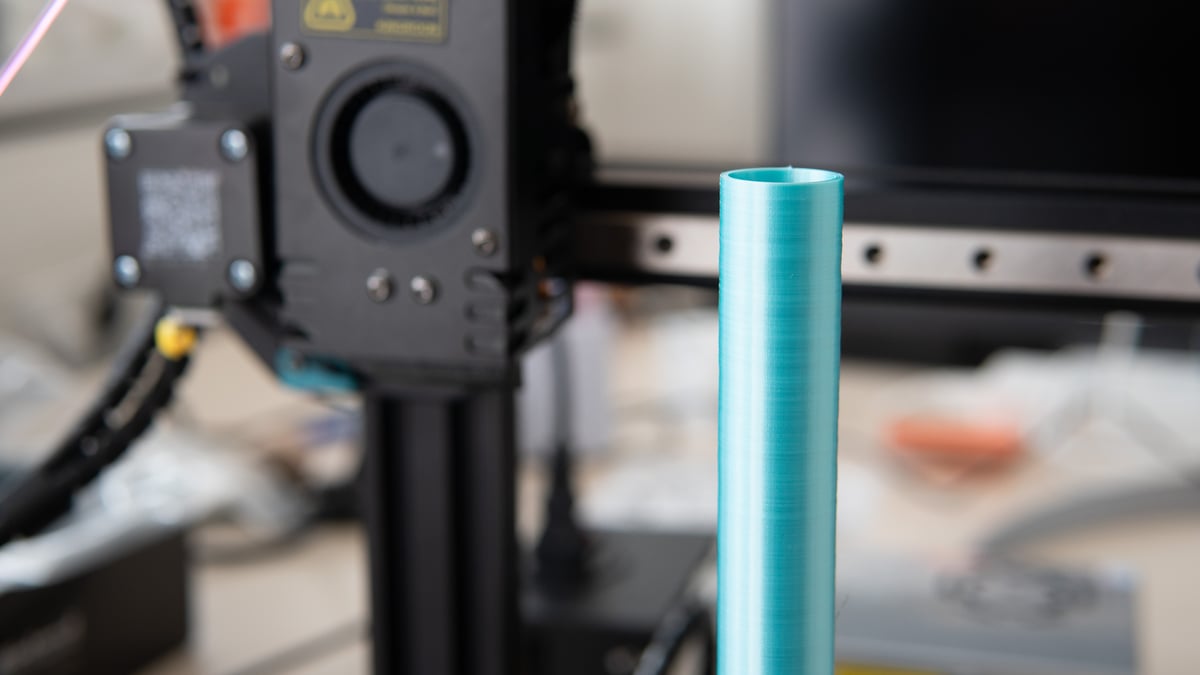

The KP3S ships with the leadscrew packaged separately in a rigid tube – unusual in the era of pre-assembled 3D printers. This helps to protect it from bending during shipping. Still, assembly was simply a matter of attaching the Z and X-axis assembly to the base via bottom screws, slotting in the leadscrew, and tightening the coupler. Easy.

We found the little machine to print its full Z volume with admirable stability. There’s a little bit of wobble at the very top, but it’s barely noticeable – surpassing expectations. If you really want to reduce it further, opting for the slightly more expensive KP3S Pro, which swaps the Y-axis linear rails for a smooth-riding Z, would be a good bet.

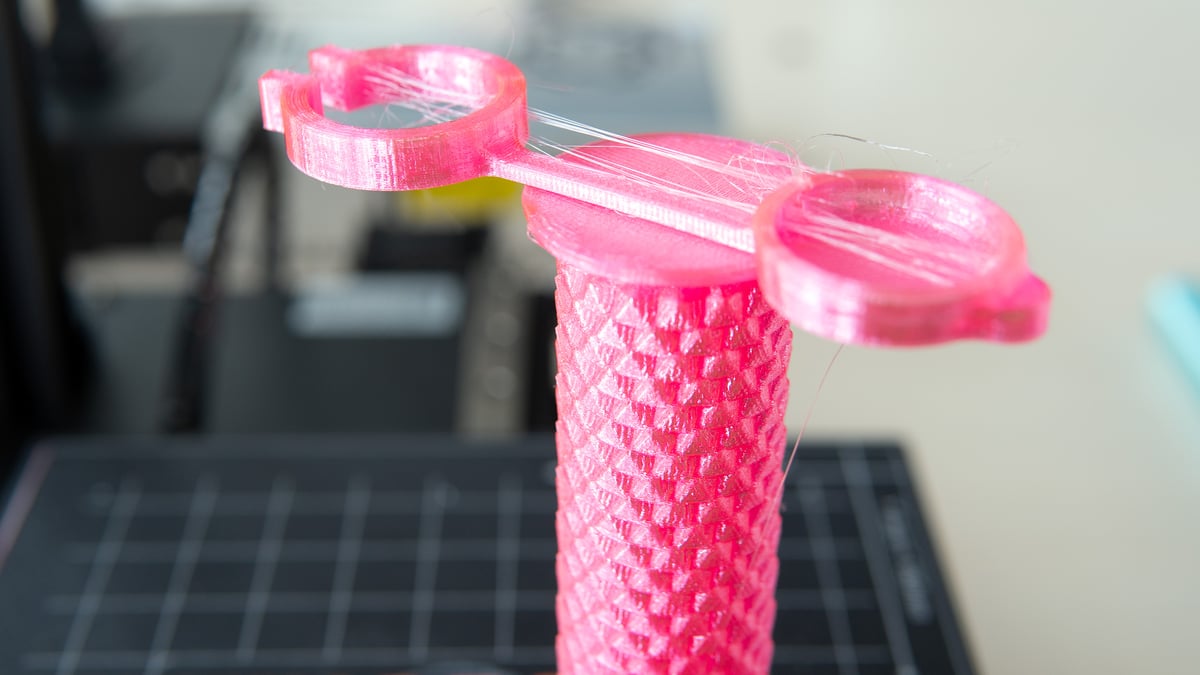

Other materials produced similarly pleasing results on the KP3S, with TPU being a notable success – partly thanks to the little machine’s direct extruder. The bike handle and bottle cap prints we ran both completed with uniform layers for a quality part. We saw a fair bit of stringing, but well within reason before dialing in a material profile.

Offsets

When we kicked the Kingroon KP3S 3.0 into action, we started off by leveling. Shocking, we know, but there’s an interesting part to this on the KP3S 3.0: the Z-endstop hits against a simple spring-tensioned screw that can be adjusted to change the Z-height manually rather than through an offset. Typically, a Z endstop is mounted to a printer’s Z axis and is adjusted through more complicated means. It’s neat to see an easily adjusted screw, but we do wonder if the tensioned spring could be a point of failure in the future. Easily replaced if so, at least.

We did see one flaw involving offsets, too. When homing the print head, the X-axis was a few millimeters shy of the print bed. Unlike the Z-axis, the X endstop is fixed and would need to be modded for a physical adjustment. When we went to use the whole bed, the first layers on the very left of the printer missed it entirely.

You could not use the first 3 mm of the X axis, which was too much to skip over with the already limited space on a 3D printer of this size. A permanent fix here requires a hardware change to make the endstop trigger earlier – sticking a material of appropriate thickness to where the X-endstop triggers would work.

Instead, we opted to program a simple offset into Cura’s start G-code that moved the printer’s X0 after homing 3 mm to the right. It works, but we’ll run back into the issue if we ever need to download a new slicer. If you want to do the same, add two simple lines after G28 in the start G-code:

G1 X3; move to bed G92 X0; custom offset

Over Adhesion

Another weak point on KP3S 3.0 is the print surface: parts stick to the magnet-backed sticker surface too well. We had to forcibly peel prints off and expect this to eventually cause some damage to the bed material. You could always replace it with magnetic spring steel or tempered glass bed – a trivial fix, but one that’ll cost you extra.

We suggest adding some glue while you’re using the stock print bed. It will create a layer between the print bed and should make part removal easier.

Should You Buy One?

We would usually say that a 3D printer in this price range is an excellent introduction to the hobby – a way to dip your toes in before an inevitable upgrade – but the Kingroon KP3S series deserves more recognition than that. It has some interesting features, performs great out of the box, and has ample opportunity to upgrade with parts from the manufacturer or beyond.

A first step into 3D printing is undoubtedly one reason to consider the Kingroon KP3S 3.0, especially when one can be picked up for ~$160. But, even if you already have a 3D printer or two, maybe you’re curious about linear rails. That hardware can be pricey, but the KP3S offers a good experience with them for little investment. If you want a new 3D printer to mod, the barebones KP3S gives you plenty of options without much initial investment and some interesting add-ons from Kingroon itself for a smooth transition into tinkering with your machines.

And, honestly, if you only have larger 3D printers, a mini machine is a practical solution for the tiny parts you will inevitably print. Why waste energy heating a large print bed for your next chip clip? Even if it’s not your daily driver, it’s small enough to tuck away without eating into your space.

The Kingroon KP3S 3.0 is a great little machine, and we recommend it wholeheartedly.

Alternatives

If the Kingroon KP3S 3.0 isn’t quite what you’re looking for, you should first consider the alternatives in the KP3S series. The KP3S Pro encloses the power supply, making the machine easier to pick up and store away, and swaps the Y-axis linear rail for a Z-axis rail for $179. The series inches up from there all the way to the latest KP3S Pro V2, which has linear rails on all axes, an inductive leveling sensor, and stock Klipper firmware for $279.

If you’d rather go with a larger name, Creality has a very similar machine in the Ender 2 Pro. It uses the more familiar V-slot rails on all its axes and a Bowden extruder instead of the KP3S 3.0’s direct, but it is more portable with its enclosed power supply. Though its MSRP is $10 higher than the KP3S 3.0, it can often be found on sale for a fair bit less.

Featured Prints

Shout out to the talented folks who designed the models featured in this review’s photos:

Tech Specs

- Technology: Fused deposition modeling (FDM)

- Year: 2022

- Assembly: Partially assembled, simple

- Mechanical Arrangement: Cantilever

- Build Volume: 180 x 180 x 180 mm

- Feeder System: Direct

- Nozzle: 0.4 mm brass

- Max. Hot End Temp.: 260 ℃

- Max. Heated Bed Temp.: 110 ℃

- Print Bed Material: Magnetic sticker sheet

- Bed Leveling: Manual

- Connectivity: SD card, USB

- Filament Sensor: No

- Filament Diameter: 1.75 mm

- Frame Dimensions: 280 x 285 x 370 mm

License: The text of "Kingroon KP3S 3.0 Review: Mighty Mini" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.