The sub-industrial market for 3D printers is possibly more competitive than it has ever been. Low-cost 3D printer kits have gutted the hobbyist market, leaving manufacturers of what one might consider premium products in this arena to double down on the professional dollar.

It is here that the historic imaging company Kodak is throwing its chips. Revealed at formnext 2018, Kodak’s debut 3D printer, the Kodak Portrait, is ready for its close up.

The printer was not developed by Kodak itself, however. Indeed, the Portrait is the work of Argentinian startup Smart International, which successfully pitched for the rights to use Kodak’s illustrious name.

Folding into Kodak’s new image as a brand for creative professionals, the Kodak Portrait is a flagship debut for the company, bringing with it an ecosystem of materials, quality of life features including cloud-connectivity and control, plus manufacturer material profiles for plug-and-play operation.

We saw the printer up close at formnext and can confirm that it looks the business. There are few printers that you encounter without any visible or immediate flaw, and the Kodak Portrait is one of them.

Here’s the full skinny on the specs and features.

Feature Check

The Kodak Portrait is a professionally pitched dual extrusion fused deposition modeling (FDM) 3D printer. Priced at $3,499, it sits squarely amongst the likes of the MakerGear M3-ID and BCN3D Sigma R19 concerning price and capability.

Dual Print Cores

Multi-material printing is handled on the Kodak Portrait via a dual print-core style print head that’s similar to Ultimaker’s “Print Core” concept, introduced in the Ultimaker 3.

Accepting any combination of PTFE and all-metal hot ends to meet a wide variety of material requirements, it’s interesting to see such a system gain traction. Despite their similarities, Kodak’s implementation requires a little more manual work in removing the print head housing to make the switch.

The inactive nozzle is mechanically retracted clear of the print to assist in preventing oozing and create clean transitions between materials and colors. Through our testing, we found the system to work well, although printing an ooze shield on multi-material prints is still a good idea.

Filament Cartridges

Feeding this versatile print head is a dual Bowden extruder arrangement, which is in turn fed from one of the more interesting inclusions of the Kodak Portrait — reusable moisture-resistant filament cartridges.

Not the most high tech of features — essentially two lockable clear plastic cases with compartments for silica pouches — these Kodak filament-compatible units mean that it’s possible to load up hygroscopic filaments such as Nylon (which is part of Kodak’s ecosystem of materials for the printer) and print for days without fear of moisture-induced misery. It’s not revolutionary, but a thoughtful rarity nonetheless.

We found that these filament cartridges are just slightly too small for some of our filament reels, notably our white benchmarking filament. While perfectly sized for Kodak’s own 0.75-kg spools, the cartridges are just not wide enough to fit a full-sized spool.

Print Area & Temperatures

The Kodak Portrait has a 200 x 200 x 235mm print volume, with a removable glass bed that snaps into place using magnets. Heating to 105 and 295 degrees Celsius respectively, the bed and hot ends are just so to aid the machine in tackling a wide range of materials including HIPS, PETG and multiple grades of Nylon.

Our one complaint is the bed leveling: In order to level the bed, one must use the touchscreen interface. While this might sound fine at first, we found it very frustrating and slow, especially as the preset increments are so small that it is difficult to tell in which direction the bed is actually moving.

There is no bed level sensor to speak of, and the almost comical design features no way to physically level the bed — no knobs, no nuts, no levers, nothing. In short, you are at the mercy of the software to dial in a good first layer.

Closed Frame and CoreXY Kinematics

A rigid all-steel frame with clear acrylic sides and ceiling completely enclose the print chamber, creating a friendly environment for printing temperature sensitive materials. A HEPA and activated carbon air filter tackles the VOCs released during the printing process, up to a point.

The locomotion system features linear rails for stability in the X and Y axes and a precision ball screw for the Z axis, in a CoreXY arrangement.

Cloud-Based Printing & Control

Pitching for effortless operation, Smart International opted to use the experience of 3DPrinterOS for print job generation, printer control, and farm management. Skinned in Kodak’s distinctive yellow color and branded as Kodak 3D Cloud, the resulting software and printer UI prioritizes simplicity, with Kodak material profiles removing the guesswork and trial-and-error often required in printing.

Operable via a web browser from anywhere with an internet connection, this cloud approach to print management allows the Portrait to slot into a network of machines with no load on the machine itself. An inbuilt Raspberry Pi 3 keeps things humming along, with direct operation possible via the printer’s 5-inch color touchscreen.

Offline operation is also possible via the Kodak 3D Slicer for print preparation, shifting print jobs to the Portrait using LAN or USB.

Overall the Kodak Portrait is an intriguing proposition. Including a suite of quality of life features that the direct competition lack for a similar price point sends a clear message, and with a bankable household name slapped across the front of the machine it is, without doubt, one of the more interesting 3D printers to launch in the past year.

Benchmarking

For a first look at the Kodak Portrait, we printed the two most popular torture tests on a new, freshly unboxed and unaltered machine, using PLA filament and averaged slicer settings for the ranges specified for the material.

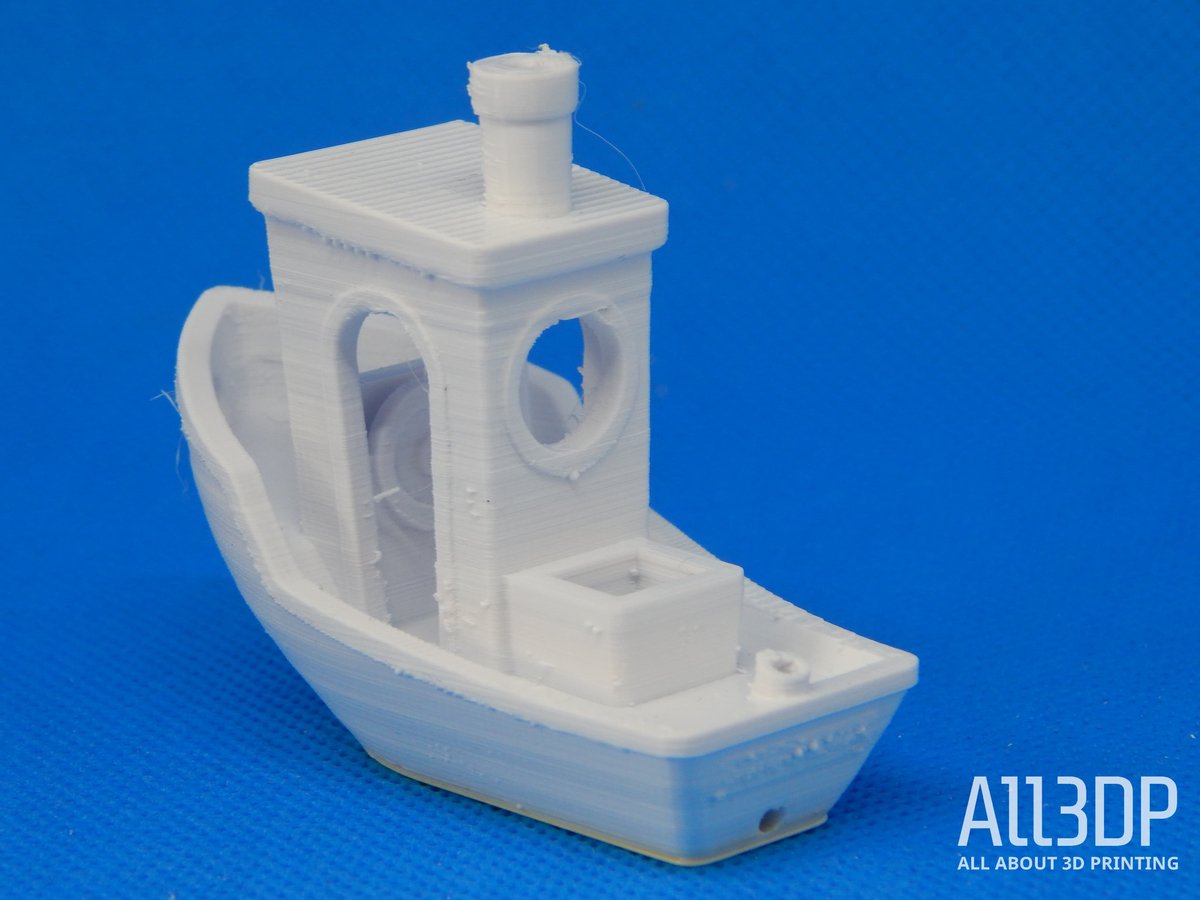

Benchmarking Object 1: Benchy

We used white eSun PLA+ filament. To prepare the G-code, we used Kodak’s rebranded 3DPrinterOS cloud slicer, adapting the existing profiles for PLA+. The temperature was set to 215 °C and the bed to 60 °C.

It took us one attempt to 3D print a Benchy.

We got decent results on the first try, so we measured the physical dimensions of the print (jump to the detailed results here).

The Benchy overall turned out decently, the Kodak Portrait achieved 13 out of 15 points. However, the visual inspection revealed some other underlying problems.

- Surfaces: The main problem was zits and blobbing, which is a sign that the retraction may need tuning. The overall surfaces were well-printed with no signs of under extrusion, but there was some z-axis banding.

- Details: The details were all fairly well defined, despite some small dropped loops in the windows and hawsepipes. The plaque on the rear of the Benchy was nearly readable, which is quite impressive for a first go at printing.

- Overall consistency: The print had minor inconsistencies, especially associated with the zits in the surface quality. Yet, the Benchy had fairly good Z-axis alignment overall.

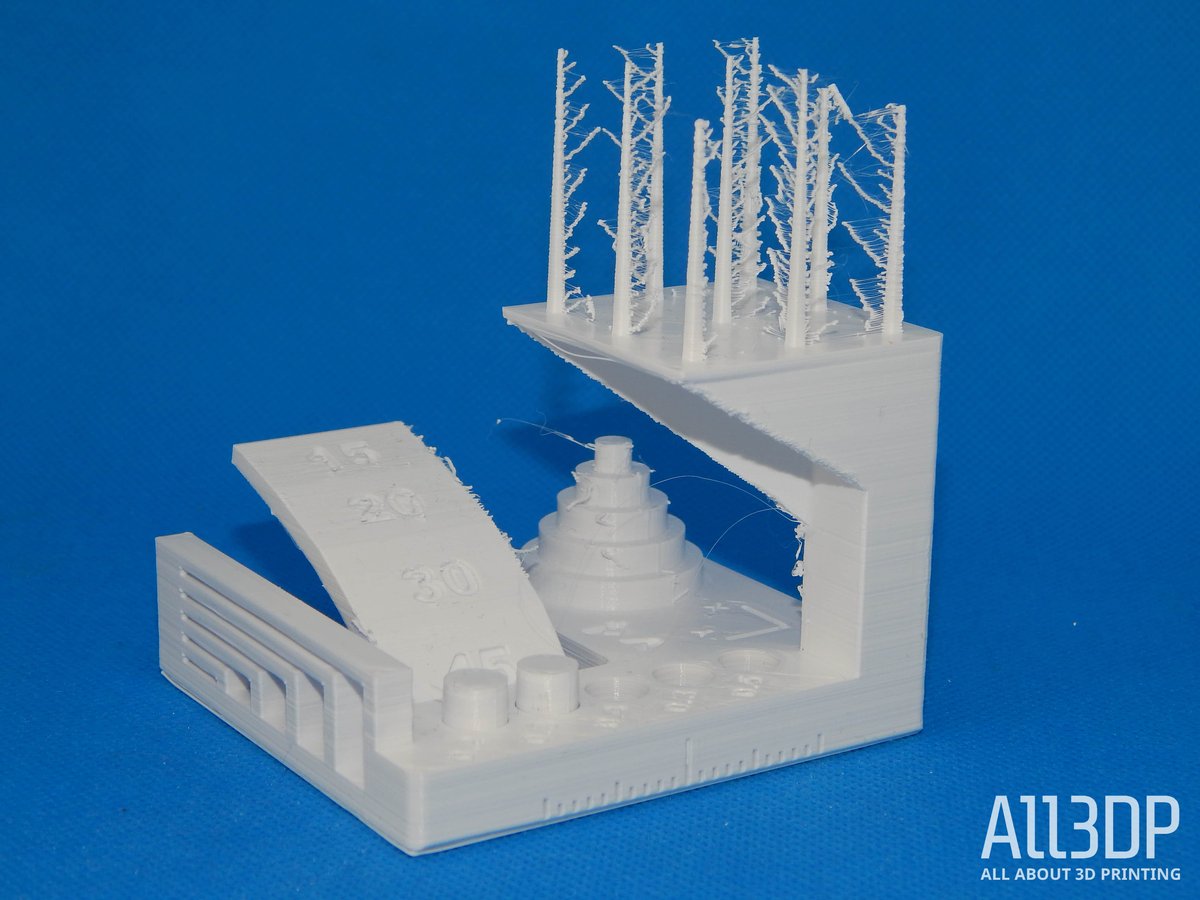

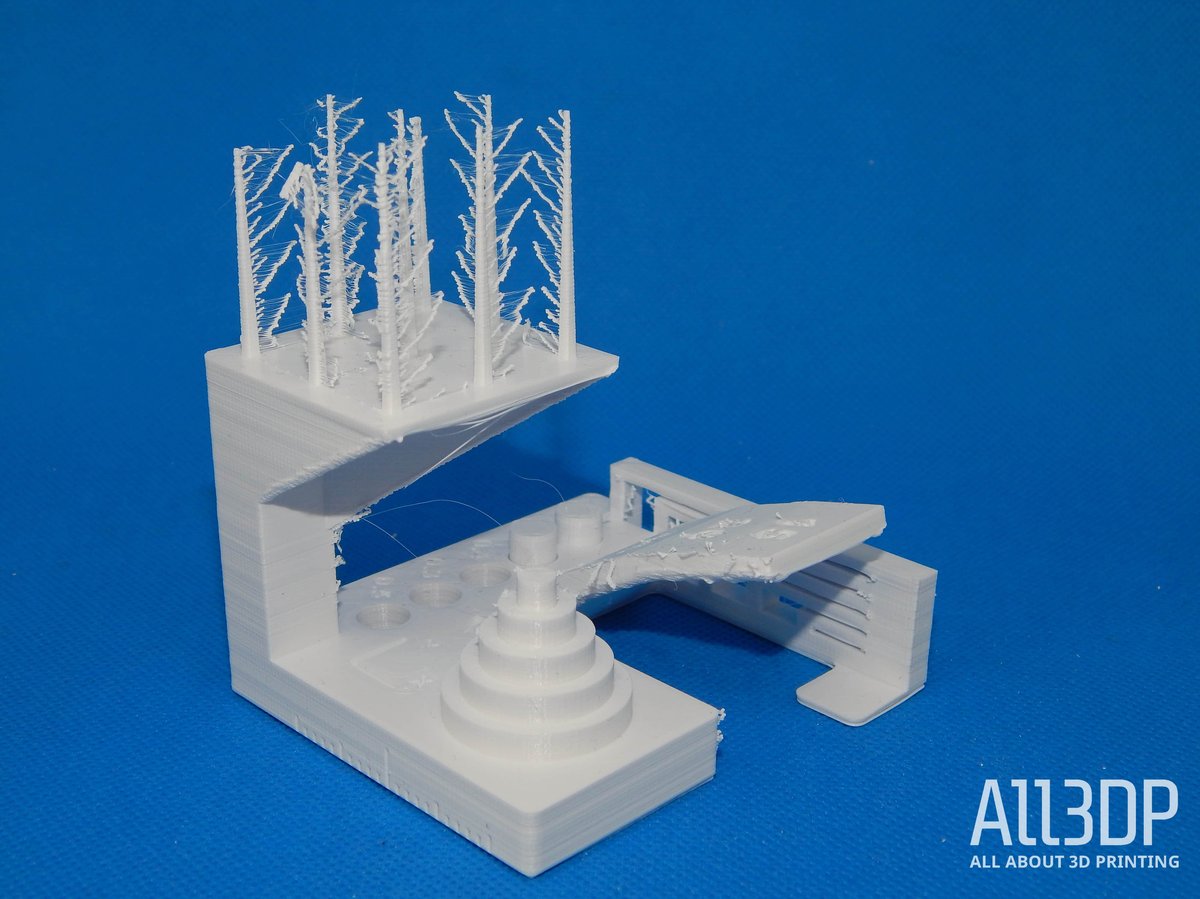

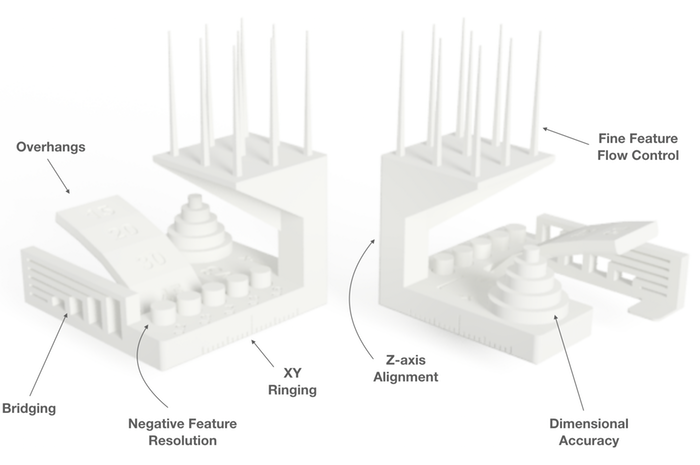

Benchmarking Object 2: Kickstarter-Autodesk Test

The Kickstarter-Autodesk test model looks at an FDM printer’s precision. We used the same white eSun PLA+ filament and the same temperature settings (215 / 60).

With a score of 19 out of 30 points, the Kodak Portrait did okay, but not outstanding. Regardless, the dimensional accuracy was excellent. We found problems with fine flow control, fine negatives, and XY resonance.

- Surfaces: Again, the test object had a bit of stringing and blobbing on the surface, the result of insufficient retraction during travel moves. Other than that and some slight ghosting, the surfaces of the print turned out fine.

- Details: The spikes were a bit short and fragile due to intense stringing, as you can see above.

- Consistency: The overall consistency was mediocre. You can see thick stringing between all the spikes, some of which were broken, the bridges for the most part failed, and the first layer was inconsistent.

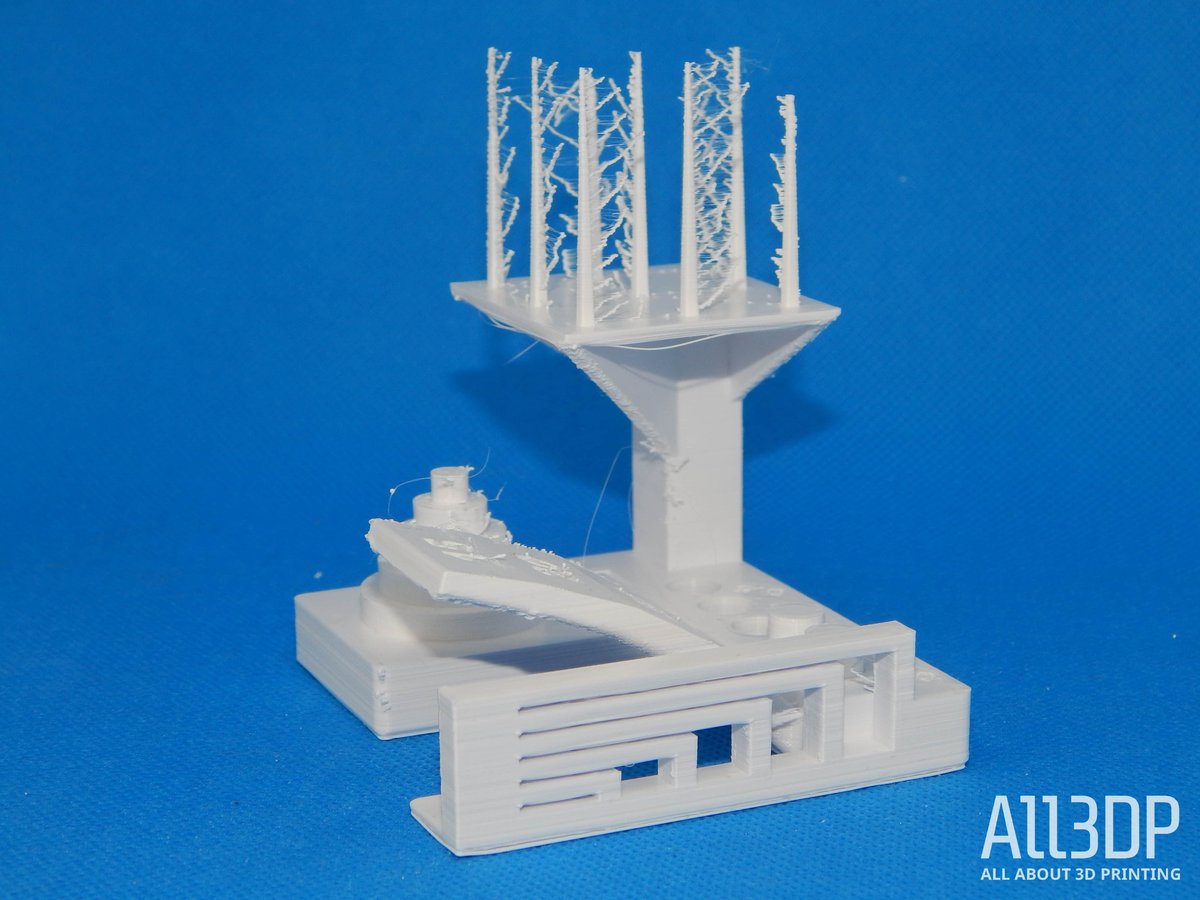

Benchmarking Verdict

While the measurements of our benchmarking test prints are pretty middle-of-the-road, a visual inspection of the prints points to a small number of issues, mostly related to extruder calibration (applicable to the specific conditions of our benchmarking prints).

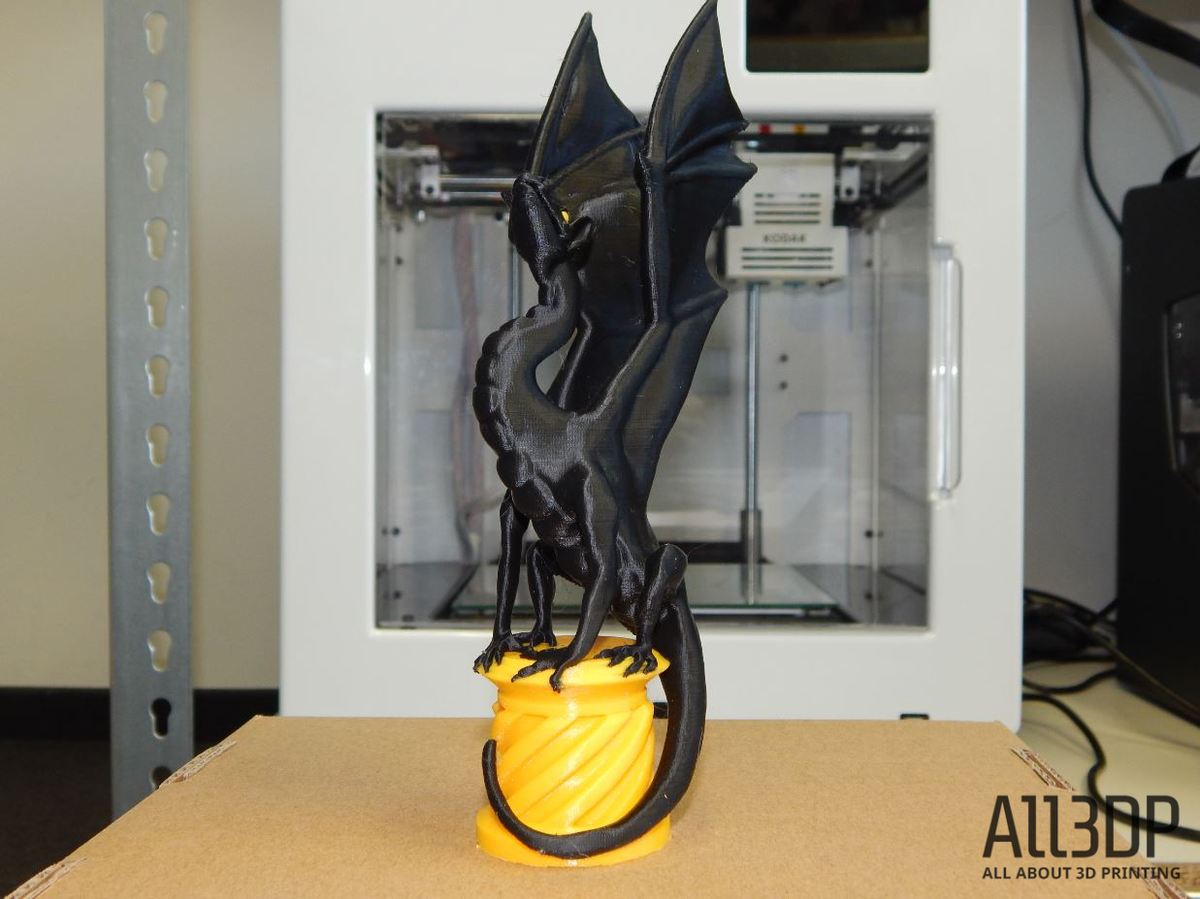

An additional print (see above) turned out exceptionally: Using the provided profiles for dual-extrusion in the cloud slicer, with no extra calibration or tweaking, we were able to achieve a stunning two-color print. With only some very light stringing and a very slight amount of color cross-contamination, the model was nearly devoid of issues worth complaining about.

Using Kodak’s own materials and corresponding presets, we did not run into any problems while printing. This leads us to the conclusion that for those who want to stay within Kodak’s ecosystem, printing should be quite easy and straightforward with good results. However, for those looking to print with other brands of materials, some extra tweaking will be required.

If you want to know in detail how we benchmark, please continue here.

Specifications

General Specs

- Technology: FDM

- Year: 2018

- Assembly: Fully assembled

- Mechanical arrangement: CoreXY

- Manufacturer: Kodak (Smart International)

Materials

- Filament diameter: 1.75mm

- 3rd party filaments: Yes

- Compatible materials: Kodak ABS, Flex 98, HIPS, Nylon 6, Nylon 12, PETG, PLA+, PLA Tough, PVA, other 3rd-party

3D Printing Properties

- Accuracy: XY +/-12.5 micron, Z +/- 2.5 micron

- Layer height: 20 – 250 micron

- Feeder system: Bowden

- Extruder type: Single print head – dual hot end

- Nozzle size: 0.4mm

- Max. extruder temperature: 295 °C

- Max. heated bed temperature: 105 °C

- Max. print speed: –

- Closed print chamber: Yes

- Bed leveling: Assisted Manual

- Print bed: Heated

- Display: 5-inch color touchscreen

- Connectivity: WiFi, LAN, USB

- Built-in camera: Yes

- Extras: HEPA + activated carbon air filter, moisture-blocking filament cartridges

Where to Buy

The Kodak Portrait has a list price of $3,499. It is available from the retailers listed below.

Benchmarking Results

Here you find the detailed results of our initial testing of the Kodak Portrait. Our benchmarking procedure can be found below.

Benchy

- Overall length (60 mm ±1 % tolerance): 59.52 mm, 1 point given

- Overall width (31 mm ±1 % tolerance): 31.00 mm, 1 point given

- Bridge Roof length (23 mm ±1 % tolerance): 23.02 mm, 1 point given

- Chimney roundness inner diameter (3 mm ±10 %): 2.60 mm, 0 points given

- Chimney roundness outer diameter (7 mm ± 5 % tolerance): 7.10 mm, 1 point given

- Vertical overall-height (48 mm ±1 % tolerance): 48.17 mm, 1 point given

- Box depth (9 mm ± 5 % tolerance): 9.6 mm, 0 points given

- Box inner length (7 mm ± 5 % tolerance): 6.91 mm, 1 point given

- Box outer length (10.81 ± 5 % tolerance): 10.82 mm, 1 point given

- Box outer width (12 mm ± 5 % tolerance): 11.84 mm, 1 point given

- Box inner width: (8 mm ± 5 % tolerance): 7.90 mm, 1 point given

- Hawsepipe inner diameter left (4 mm ±10 % tolerance): 3.80 mm, 1 point given

- Hawsepipe inner diameter right (4 mm ±10 % tolerance): 3.82 mm, 1 point given

- Bridge front window width (10.5 mm ±5 % tolerance): 10.43 mm, 1 point given

- Rear window inner diameter (9 mm ±5 % tolerance): 8.92 mm, 1 point given

Overall, the Portrait scored 13 out of 15 points.

Kickstarter x Autodesk Test

- Dimensional Accuracy: 5 of 5 points (24.91, 24.94 / 20, 19.99 / 15.1, 15.02 / 10.08, 10.08 / 5.03, 5.03)

- Fine Flow Control: 2.5 of 5 points (all spires were printed with intense stringing)

- Fine Negative Features: 3 of 5 points (3 pins were removable)

- Overhangs: 3 points (surface quality got worse at the 20° overhang)

- Bridging: 3 points (only three bridges were not touching the surface beneath it)

- XY Resonance: 0 points

- Z-axis alignment: 2.5 points (not visible)

Overall, the Portrait scored 19 out of 30 points in this test.

How We Benchmark

For the benchmarking element of our review, we use the following guidelines:

Unbox the printer: We unbox the printer and assemble it according to the manufacturer’s instructions. Deficiencies and errors are noted and build around according to the consensus online for the printer.

Filament: We use white eSun PLA+ filament. Temperature settings are 215 °C for the nozzle and 60 °C for the bed.

Printing: We print two test models — Benchy and the Kickstarter x Autodesk FDM 3D Printer Assessment — using the manufacturer-provided/recommended slicer and settings. If the printer ships without a dedicated slicer and profile, we generate a generic Cura profile using the essential information of the printer.

After the first print, we inspect the object for easily fixable problems (i.e., a loose belt or a poorly leveled print bed) and then print again. If the printer can’t provide a decent result after three attempts, we stop. Printers that fail to produce a test object receive zero points for the respective test object.

1. Benchy

The Benchy 3D printer torture test is one of the world’s most popular prints. It helps to measure the dimensional accuracy capabilities of your printer and helps highlight other visible print nastiness.

We measure our best Benchy print using digital calipers, scoring 15 criteria against their target value. A total of 15 points are available.

- Overall length: 60 mm

- Overall width: 31 mm

- Bridge Roof length: 23 mm

- Chimney roundness inner diameter: 3 mm

- Chimney roundness outer diameter: 7 mm

- Vertical overall-height: 48 mm

- Box depth: 9 mm

- Box inner length: 7 mm

- Box outer length: 10.81

- Box outer width: 12 mm

- Box inner width: 9 mm

- Hawsepipe inner diameter left: 4 mm

- Hawsepipe inner diameter right: 4 mm

- Bridge front window width: 10.5 mm

- Rear window inner diameter: 9 mm

To accommodate the difficulty and inaccuracies when measuring small features, we have implemented a sliding scale of tolerance in our scoring. The smaller the feature, the greater our allowance for deviation:

- 60 mm to 23 mm: 1 percent tolerance allowed

- 23 mm to 7 mm: 5 percent tolerance allowed

- 7 mm to 0 mm: 10 percent tolerance allowed

Finally, we do a visual inspection and note any flaws and problems we encounter.

2. Kickstarter x Autodesk FDM 3D Printer Assessment

The Kickstarter x Autodesk print exposes an FDM printer’s precision via six distinct tests in one object.

By pushing a printer’s hardware and software the system to the point of failure, the print reliably visible imperfections that can be used to assess the performance of the slicer, the extruder, and the motion system together.

Here’s what’s getting measured.

- Dimensional Accuracy

- Fine Flow Control

- Fine Negative Features

- Overhangs

- Bridging

- XY Resonance

- Z-axis alignment

The tolerances and measurements are very detailed. You can find the exact measuring procedure on Github. The highest possible score is 30, indicating a very well-calibrated system.

It’s worth noting that these benchmarking tests are not a definitive measure of a printer’s worth. More an indication of a printer’s state out of the box with no-tinkering, it’s only after a full evaluation and in-depth review that we fully judge a 3D printer.

License: The text of "Kodak Portrait 3D Printer Review: 10-Hour Testing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.