Aleph Objects’ LulzBot line of 3D printers has a high reputation amongst prosumers, makers, and 3D printing professionals alike. Not without good reason is the LulzBot Taz 6 our awarded Workhorse 3D Printer of Spring 2019. And the LulzBot Mini 2 is an evergreen machine in All3DP’s printing department, with an Editor’s Choice award to its name.

In short: we’ve had positive experiences with Aleph Objects’ machines. They are open source, can handle most materials and deliver outstanding printing results — but will the new Taz Workhorse, based on the Taz 6, live up to its predecessor? It boasts a 14% larger build volume and some additional improvements, however only by testing it out ourselves can we know for sure.

Read on as we review the first 10 hours of 3D printing with the Workhorse.

Feature Check

In terms of pricing, the Taz Workhorse costs $2,950. Its fancier counterpart, the Pro, will set you back a cool $4,950 and offers upgrades like dual extrusion and a touchscreen.

Like other machines in the Taz line, it has a heated borosilicate glass PEI-coated print bed traveling in the Y-axis, with belt-driven X and Z-axes, all housed within an open beam frame with left-mounted electronics and control box. And, also like other machines in the line, it lacks some handy features like WiFi connectivity (a decision Aleph Objects made in order to stay true to keeping everything in the printer open-source).

But, the Workhorse also boasts several other notable features.

Bigger Build Volume

The LulzBot Taz Workhorse boasts a 14% bigger build volume than the Taz 6, giving it the same printing size as the Taz Pro.

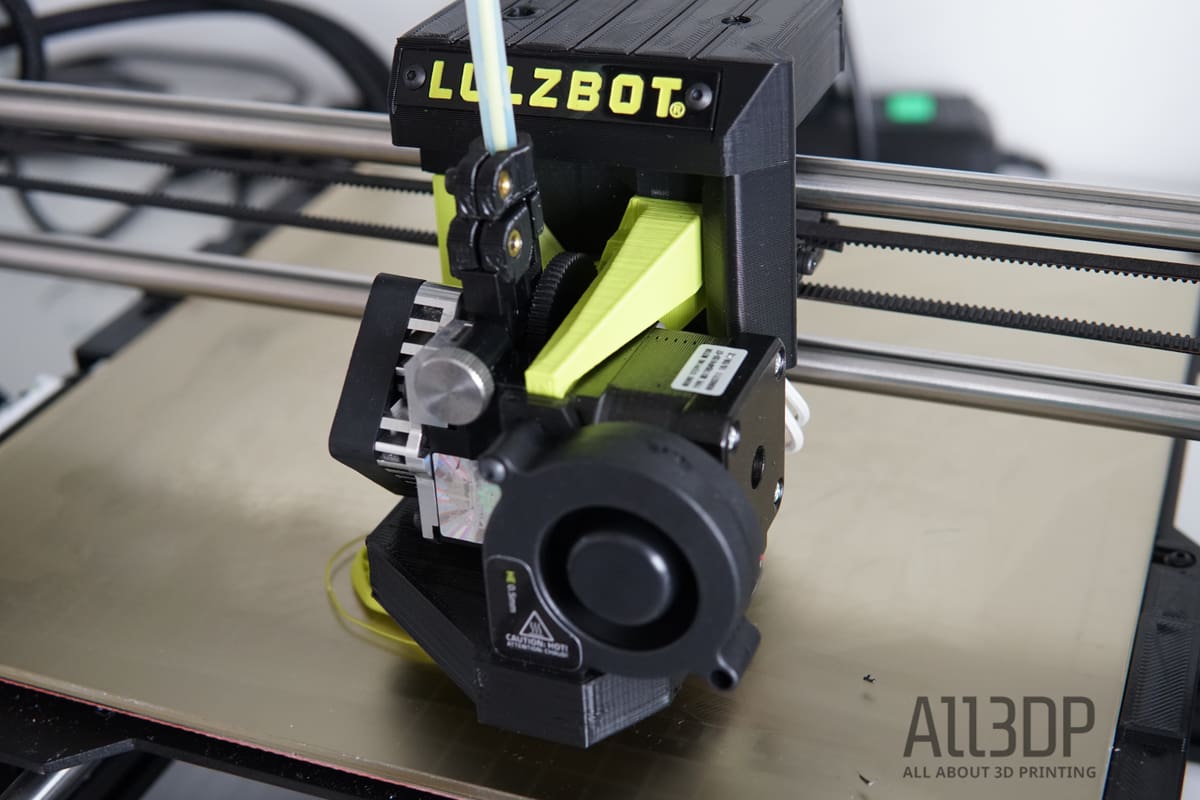

Thanks to a new belt-driven Z-axis and a new, lightweight tool head design, prints should also be more precise. However, we didn’t necessarily find this to be the case.

Strengthened Frame

The Taz 6 was already built like a tank, but it seems Aleph Objects made the Workhorse even sturdier. The frame is now reinforced. Also, the electrical connectors were upgraded.

More Available Materials

With the Taz 6, you already could venture into new 3D printing material regions. The Taz Workhorse is supposed to handle an ever wider range of materials, including high-heat and high-strength composite polymers. This should be possible straight out of the box due to its hardened-steel tool head components.

To get to better printing results, the Workhorse introduces automatic X/Y/Z backlash compensation for improved print accuracy. However, as you’ll see further down in the benchmarking section, we did not find the print results with this machine to be very impressive.

Swappable Toolheads

The Workhorse uses Lulzbot’s next generation of tool heads. It comes with the HE tool head made of hardened steel with a 0.5 mm nozzle, but you can also buy these additional models:

- SL Tool Head: Made for small layers with a 0.25 mm nozzle. Use this to print with more detail and higher resolution.

- HS Tool Head: For high-strength end-use parts. The hardened steel nozzle is 0.8 mm wide. Also usable for composite materials like carbon-filled filament.

- HS+ Tool Head: The widest nozzle. Also comes in hardened steel with a diameter of 1.2 mm. Use this if you want to print fast and big.

Benchmarking

Given the Workhorse’s name, one could assume it’s dependable and produces consistent results. But is the machine truly a workhorse or is it workshy?

To get a good first impression for this Lulzbot Taz Workhorse review, we took the machine for a test ride using the 0.5 mm nozzle the machine comes with by printing the two most popular torture tests. If you’re interested, you can read more about how All3DP benchmarks 3D printers here.

Setting up and calibrating the machine was a breeze; we ran into absolutely no problems. Tools were provided aplenty; they even come in a nice bag. Then we started with the benchmarking our test objects.

For printing the test objects, we make sure to get a vanilla-state machine, normal PLA filament, and middle-of-the-road slicer settings.

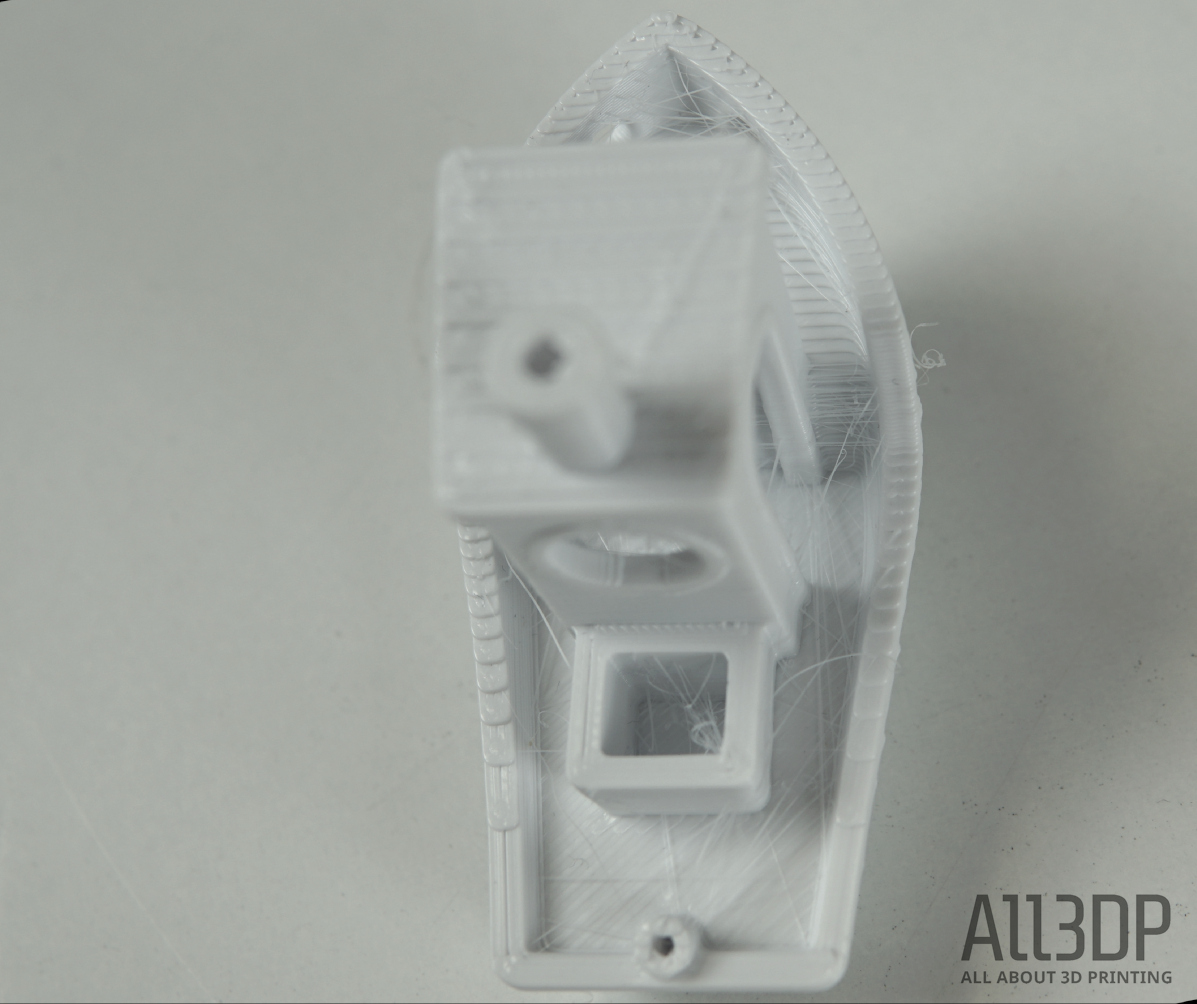

Benchmarking Object 1: Benchy

Our 3DBenchy (STL file here) was completed on the first try but was extremely stringy. We used white eSun PLA+ filament. To prepare the needed G-code, we used the Cura Lulzbot Edition that comes with the Lulzbot Taz Workhorse. We set the temperature to 215°C, the bed heated up to 60°C.

We measured the tolerances of the print and also did a visual inspection. Overall the Benchy was solid, but it suffered from massive stringing. We also found zits and layer lines.

Ultimately, in the Benchy torture test, the Lulzbot Taz Workhorse achieved 13 out of 15 points.

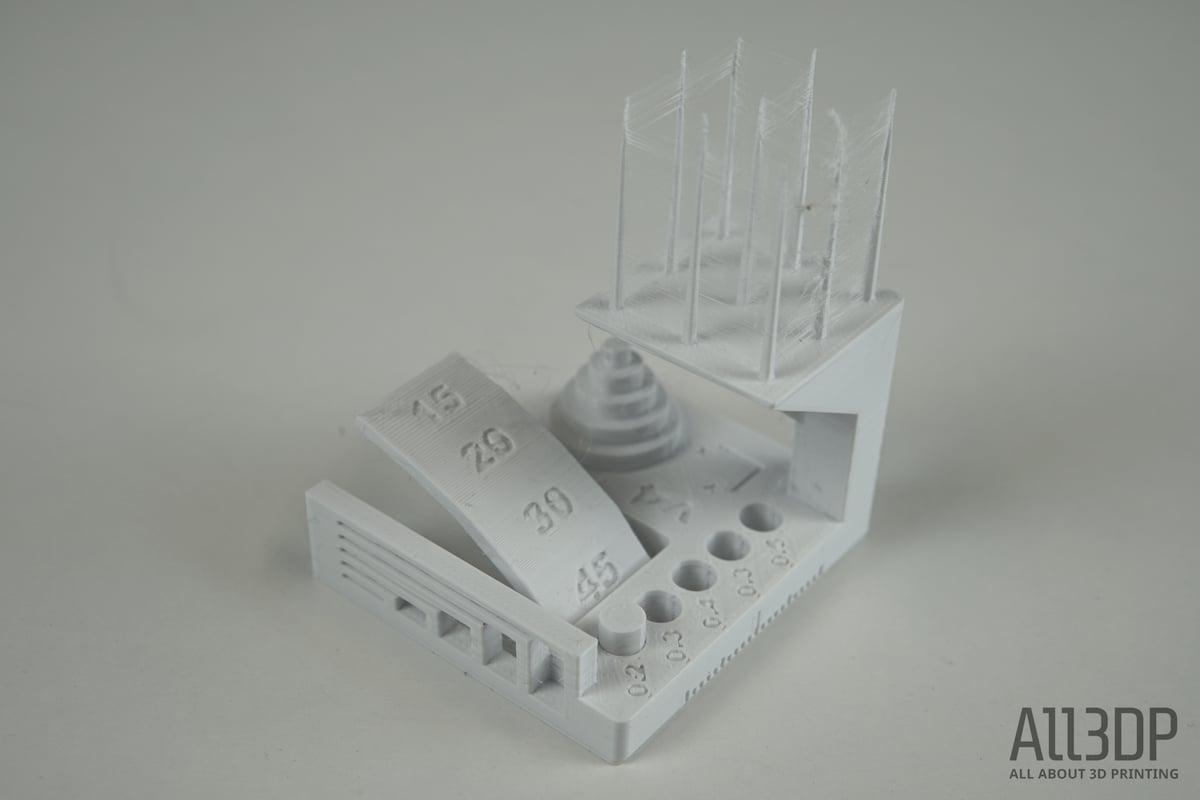

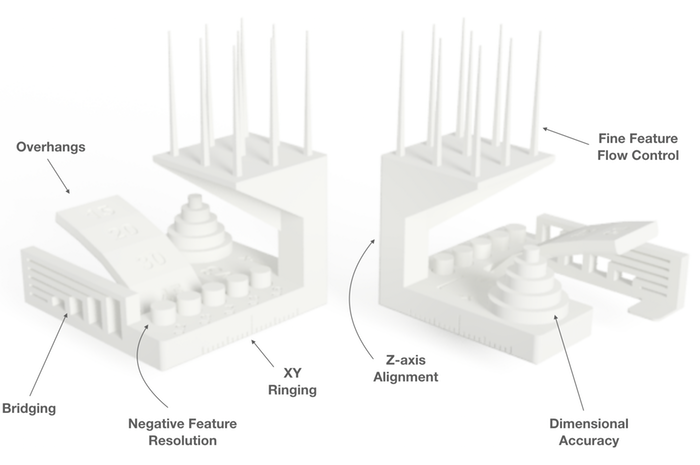

Benchmarking Object 2: Kickstarter Autodesk Test

The Autodesk Kickstarter test model looks at an FDM printer’s precision. You can find the file and read more about it here. We used the same Amazon white eSun PLA+ filament and the same temperature settings (215 / 60).

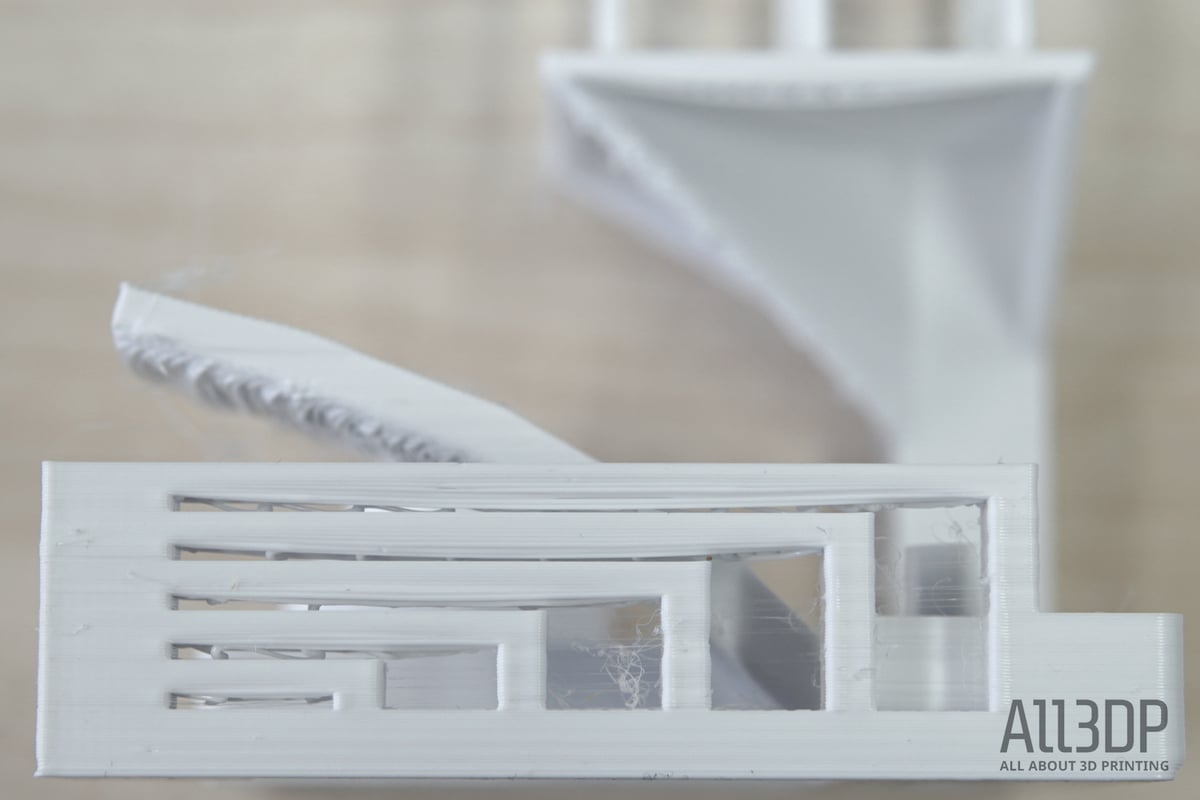

The Lulzbot Taz Workhorse did well in dimensional accuracy, overhangs, XY-resonance and Z-alignment. However, we found some problems with fine flow control and bridging.

Overall, the Lulzbot Taz Workhorse scored 20.5 of 30 points in this test.

Benchmarking Verdict

Our benchmarking prints put the Lulzbot Taz Workhorse on the same level as the Artillery Sidewinder X-1.

Overall, the printing process was easy. Although we had some initial problems getting the extruder tensioned just right.

After approximately 10 hours printing with the Lulzbot Taz Workhorse, we’re slightly underwhelmed, we just expected better bridges and less stringing due to the newly designed duct and the extruder being direct drive. Both problems might be an easy fix when playing with the slicer settings, but for this first test, we stuck to Lulzbot’s recommendations. We will try to find better ones for further tests.

Stay tuned for our longer-term impressions and final verdict on the Lulzbot Taz Workhorse. It’s going to be interesting to see if the printer is the workhorse we expected it to be.

Tech Specs

GENERAL SPECIFICATIONS

- Technology: FDM

- Build Size: 280 x 280 x 285 mm

- Layer Resolution: 0.05-0.4 mm

- Positioning Accuracy: (X/Y/Z) 0.01/0.01/<0.001 mm

- Extruder Quantity: Single

- Nozzle Diameter: 0.5 mm (plus optional tool heads, ranging from 0.25 mm to 1.20 mm)

- Filament Diameter: 2.85 mm

- Materials: PLA, ABS, Nylon 645, Polycarbonate, Carbon Fiber Reinforced Blends, TPU 85A & 95A (flexible), PETG, PETT, Copolyester, PVB, PVA, HIPS

TEMPERATURE

- Max. Extruder Temperature: 290°C

- Max. Print Bed Temperature: 120°C

SOFTWARE

- Slicer Software: Cura LulzBot Edition

- Software Input Formats: STL, OBJ, G, GCODE, X3D, 3MF, PNG, JPG

- Connectivity: USB serial, USB flash drive

ELECTRICAL

- Input rating: 110VAC – 240VAC

- Output: 24V DC, 500 watts, 21 amps

- Power supply: Auto-switching MeanWell RSP-500-24

PHYSICAL DIMENSIONS & WEIGHT

- Printer Dimensions: 832 x 510 x 520 mm

- Net Weight: 16.78 kg

Where to Buy

The LulzBot TAZ Workhorse is available directly from the manufacturer or at these online stores:

Benchmarking Results

Here you find the detailed results of our initial testing of the LulzBot Taz Workhorse. Our benchmarking procedure can be found below.

Benchy

- Overall length (60 mm ±1 % tolerance): 59.62 mm, 1 point given

- Overall width (31 mm ±1 % tolerance): 31.24 mm, 1 point given

- Bridge Roof length (23 mm ±1 % tolerance): 22.98 mm, 1 point given

- Chimney roundness inner diameter (3 mm ±10 %): 2.64 mm, 0 points given

- Chimney roundness outer diameter (7 mm ± 5 % tolerance): 7.07 mm, 1 point given

- Vertical overall-height (48 mm ±1 % tolerance): 48.67 mm, 0 point given

- Box depth (9 mm ± 5 % tolerance): 9.02 mm, 1 point given

- Box inner length (7 mm ± 5 % tolerance): 6.85 mm, 1 point given

- Box outer length (10.81 ± 5 % tolerance): 10.47 mm, 1 point given

- Box outer width (12 mm ± 5 % tolerance): 12.11 mm, 1 point given

- Box inner width: (8 mm ± 5 % tolerance): 7.88 mm, 1 point given

- Hawsepipe inner diameter left (4 mm ±10 % tolerance): 3.86 mm, 1 point given

- Hawsepipe inner diameter right (4 mm ±10 % tolerance): 3.74 mm, 1 point given

- Bridge front window width (10.5 mm ±5 % tolerance): 10.47 mm, 1 points given

- Rear window inner diameter (9 mm ±5 % tolerance): 8.95 mm, 1 point given

Overall, the LulzBot Taz Workhorse scored 13 out of 15 points.

Kickstarter x Autodesk Test

- Dimensional Accuracy: 5 of 5 points (24.82 / 19.90 / 15.08 / 10.11 / 4.95)

- Fine Flow Control: 2.5 of 5 points (all spires were printed correctly but stringy)

- Fine Negative Features: 4 of 5 points (4 pins were removable)

- Overhangs: 3 points (surface quality got worse at the 20° overhang)

- Bridging: 1 points (4 bridges contacted the surfaces beneath them)

- XY Resonance: 2.5 points (no ringing detectable)

- Z-axis alignment: 2.5 points (not visible)

Overall, the LulzBot Taz Workhorse scored 20.5 out of 30 points in this test.

How We Benchmark

For the benchmarking element of our review, we use the following guidelines:

Unbox the printer: We unbox the printer and assemble it according to the manufacturer’s instructions. Deficiencies and errors are noted and build around according to the consensus online for the printer.

Filament: We use white eSun PLA+ filament. Temperature settings are 215 °C for the nozzle and 60 °C for the bed.

Printing: We print two test models — Benchy and the Kickstarter x Autodesk FDM 3D Printer Assessment — using the manufacturer-provided/recommended slicer and settings. If the printer ships without a dedicated slicer and profile, we generate a generic Cura profile using the essential information of the printer.

After the first print, we inspect the object for easily fixable problems (i.e., a loose belt or a poorly leveled print bed) and then print again. If the printer can’t provide a decent result after three attempts, we stop. Printers that fail to produce a test object receive zero points for the respective test object.

1. Benchy

The Benchy 3D printer torture test is one of the world’s most popular prints. It helps to measure the dimensional accuracy capabilities of your printer and helps highlight other visible print nastiness.

We measure our best Benchy print using digital calipers, scoring 15 criteria against their target value. A total of 15 points are available.

- Overall length: 60 mm

- Overall width: 31 mm

- Bridge Roof length: 23 mm

- Chimney roundness inner diameter: 3 mm

- Chimney roundness outer diameter: 7 mm

- Vertical overall-height: 48 mm

- Box depth: 9 mm

- Box inner length: 7 mm

- Box outer length: 10.81

- Box outer width: 12 mm

- Box inner width: 9 mm

- Hawsepipe inner diameter left: 4 mm

- Hawsepipe inner diameter right: 4 mm

- Bridge front window width: 9.5 mm

- Rear window inner diameter: 9 mm

To accommodate the difficulty and inaccuracies when measuring small features, we have implemented a sliding scale of tolerance in our scoring. The smaller the feature, the greater our allowance for deviation:

- 60 mm to 23 mm: 1 percent tolerance allowed

- 23 mm to 7 mm: 5 percent tolerance allowed

- 7 mm to 0 mm: 10 percent tolerance allowed

Finally, we do a visual inspection and note any flaws and problems we encounter.

2. Kickstarter x Autodesk FDM 3D Printer Assessment

The Kickstarter x Autodesk print exposes an FDM printer’s precision via six distinct tests in one object.

By pushing a printer’s hardware and software the system to the point of failure, the print reliably visible imperfections that can be used to assess the performance of the slicer, the extruder, and the motion system together.

Here’s what’s getting measured.

- Dimensional Accuracy

- Fine Flow Control

- Fine Negative Features

- Overhangs

- Bridging

- XY Resonance

- Z-axis alignment

The tolerances and measurements are very detailed. You can find the exact measuring procedure on Github. The highest possible score is 30, indicating a very well-calibrated system.

It’s worth noting that these benchmarking tests are not a definitive measure of a printer’s worth. More an indication of a printer’s state out of the box with no-tinkering, it’s only after a full evaluation and in-depth review that we fully judge a 3D printer.

License: The text of "LulzBot Taz Workhorse Review: 10-Hour Testing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.