US-based 3D printer manufacturer, Markforged shook up the 3D printing industry when it launched affordable and easy-to-operate professional-grade 3D printers in 2013 with the idea that manufacturers could use high-grade plastics to replace metal parts. Enabling shop floors around the globe to save billions of dollars by 3D printing their own tools, fixtures, and replacement parts, Markforged made waves with the Mark One continuous carbon-fiber printer it said could print “aluminum-strength parts on your desktop”.

Since then, the company has expanded with printers that create even stronger composite material parts, continuous Kevlar and fiberglass reinforced Nylon parts, and now with its newest printer, the FX20, fiber reinforced Ultem parts.

Markforged moved into metal 3D printing in 2019 with the launch of the Metal X system bringing the technology to the desktop for the first time. Metal X Gen Two, refining the technology to make it even faster, was launched in 2021.

Tying it all together is the company’s Eiger and Eiger Fleet software, which connects printers into a production factory, and Blacksmith, the adaptive manufacturing platform that connects part design, production, and inspection with an artificial intelligence.

If you’re thinking of investing in a Markforged, read on for our unbiased overview of all you need to know.

| Printer | Tech | Materials | Size | Approx. Price |

|---|---|---|---|---|

| Onyx One (Gen 2) | FDM | carbon-fiber filled Nylon | 320 x 132 x 154 | $4,500 |

| Onyx Pro (Gen 2) | FDM | continuous fiberglass-reinforced Nylon, carbon-fiber filled nylon | 320 x 132 x 154 mm | $10,000 |

| Mark Two (Gen 2) | FDM | continuous fiberglass-reinforced Nylon, continuous carbon-fiber filled nylon, continuous Kevlar filled nylon, continuous HSHT fiberglass-reinforced Nylon | 320 x 132 x 154 mm | $14,500 |

| X3 | FDM | carbon-fiber filled Nylon, flame resistant carbon-fiber filled Nylon, EDS safe carbon-fiber filled Nylon | 330 x 270 x 200 mm | $44,000 |

| X5 | FDM | carbon-fiber filled Nylon, flame resistant carbon-fiber filled Nylon, EDS-safe carbon-fiber filled Nylon, continuous fiberglass-reinforced Nylon | 330 x 270 x 200 mm | $49,900 |

| X7 | FDM | carbon-fiber filled Nylon; flame resistant and EDS-safe carbon-fiber filled Nylon; continuous fiberglass-, HSHT fiberglass-, Kevlar-, and carbon fiber-reinforced Nylon | 330 x 270 x 200 mm | $70,000 |

| FX20 | FDM | Ultem, carbon fiber reinforced Ultem, carbon-fiber filled Nylon, flame resistant and EDS-safe carbon-fiber filled Nylon. Continuous fiberglass-, HSHT fiberglass-, Kevlar-, and carbon fiber-reinforced Nylon | 525 x 400 x 400 mm | |

| Metal X System (Gen 2) | FDM | 17-4 PH stainless steel, copper, H13 tool steel, Inconel 625 A2, D2 tool steel | 300 x 220 x 180 mm | $99,500 |

Why Markforged’s Printers?

The appeal of Markforged printers can be boiled down to a combination of technology, materials, and price. Throw in really solid construction, intuitive software, and a global support network, and you have a lot of satisfied customers.

All3DP featured a Markforged customer in a case study detailing how one automotive parts company replaced their traditionally tooled aluminum parts with Nylon carbon-fiber parts. The result was a 70% cost savings plus weeks in time. The Markforged X7 was the printer selected over the competition because it could produce parts that rival cast aluminum, but was more affordable than other solutions.

Another attraction to Markforged is the company’s Onyx material, which is a proprietary Nylon filled with micro bits of carbon fiber. It’s a reliable and well-researched material and all Markforged printers except the Metal X are tuned to print with it. However, despite the convenience, being locked into using only proprietary materials can be a drawback depending on your intended use. A spool of Onyx is about $200.

Stronger than Onyx is the company’s continuous carbon fiber reinforced material available on the Mark Two and the X7 that’s considered to be about 20% stronger than aluminum.

The Metal X printer is attractive to a non-industrial crowd because it is one of the only metal 3D printers that costs around $100,000, doesn’t use hazardous loose metal powders, and can print completely sealed yet hollow parts. It uses a type of metal powder rod the company calls atomic diffusion additive manufacturing (ADAM). The rods are used basically the same way polymer filament is. The metal parts, after printer, need to be washed and sintered in a furnace, but fortunately Markforged sells both a washer and a sintering machine. Pair this with the company’s software, and you have full mini metal factory in your shop capable of making prototypes and end-use parts.

All Markforged machines come equipped with Eiger Software, which enables you to print from your browsers and control multiple devices simultaneously. In addition, Eiger gains updates in real-time, offers additional innovations, and even suggests settings and designs based on what you are trying to print.

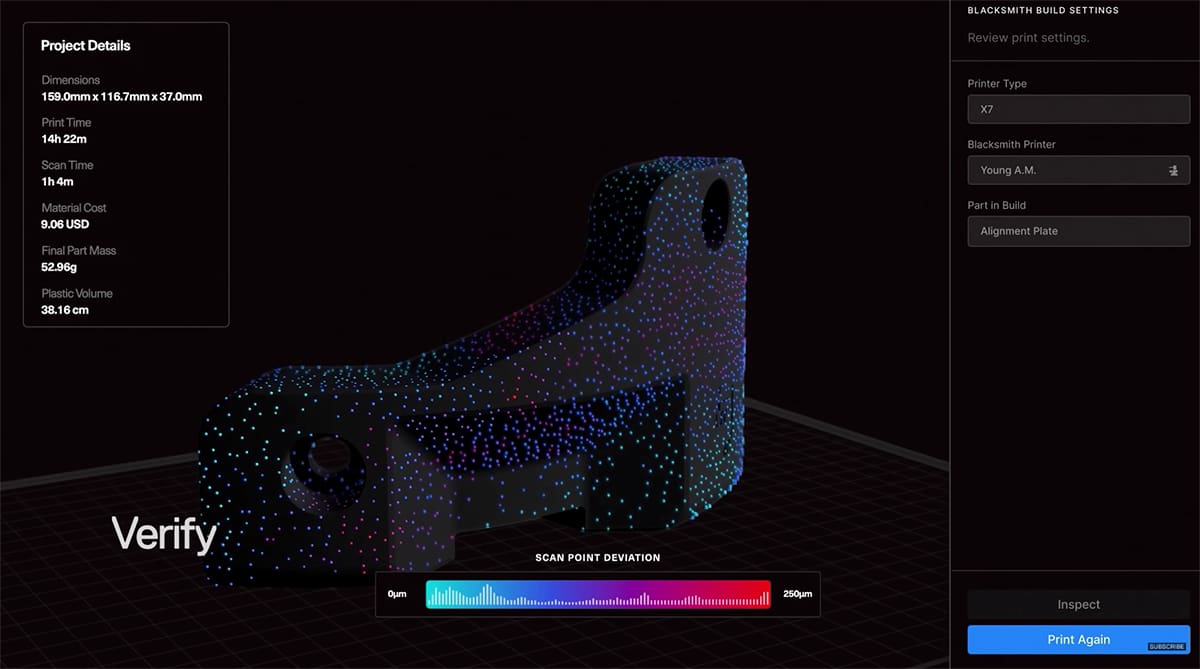

The last bit of software that Markforged uses is known as Blacksmith, released in March 2021, which is on the cutting edge when it comes to industrial level additive manufacturing production.

With Blacksmith, your X7 3D printer (it currently only work with the X7) can print and scan a part simultaneously to track how close the printed part is to the original digital design. This can alert you to any printing errors, saving potentially hours of printing time plus materials. Better yet is that Blacksmith continuously learns from each print ensuring, Markforged says, that parts can be printed accurately and precisely every time. Blacksmith calibrates machines, prints, scans, analyzes data, and generates field reports for any errors so you work is traceable and repeatable. This helps improve the output and reliability of their printers.

One of the benefits of buying a Markforged printer is that this technology won’t be available to competitors for quite a few years. This is because Markforged has patents on many of the unique parts of their printers, and even the Onyx material, consisting of nylon and carbon fiber, is a proprietary blend.

Markforged was very busy in 2021, with software and hardware launches, plus tweaks to its already popular machines that we cover under each product below.

Brand new for the company, however, is the FX20 just launched in November 2021, which is the company’s first venture into high-temperature polymer 3D printing with the ability to reinforce Ultem with continuous carbon fiber. The industrial machine aims to meet growing demand for high-performance 3D printed parts in aerospace, military, and heavy industry.

Below we break down each Markforged product in more detail. Check back here for all Markforged updates.

Onyx One (Gen 2)

Markforged’s desktop printers start with the Onyx One at about $4,500. It uses only the company’s Onyx material, which is a chopped carbon fiber reinforced Nylon, which offers far more strength and stiffness than commonly used thermoplastics, such as PLA or ABS. On top of that, the material provides a sleek carbon black surface finish that makes it ideal for end-use applications or even aesthetically pleasing prototypes.

Another intriguing feature of the Onyx One 3D printer is scalability. Those looking to produce even stronger 3D printed parts can upgrade to the Onyx Pro (priced at about $10,000), which uses their patented dual print head technology for continuous fiberglass reinforcement.

From there, customers can trade up even further to the Mark Two industrial 3D printer, which is capable of delivering metal-strength composites that are 10 times stronger than other thermoplastics.

Markforged has established the Onyx One as an entry point for beginners and businesses that may someday transition into their more advanced machines.

Onyx Pro (Gen 2)

Featuring the same bells and whistles as the Onyx One, the Pro version goes one step further with its ability to print not only with the Onyx materials but also continuous fiberglass reinforced Nylon making it one of the most affordable continuous fiber 3D printers on the market. Markforged says the fiberglass Onyx material is extremely durable and capable of replacing some machined aluminum parts.

Looking virtually identical to the Onyx One, the Pro version has a second spool holder for the continuous fiber.

Mark Two (Gen 2)

The Markforged Mark Two (Gen 2), again offers all the features of the two Onyx printers and looks almost identical, but this 3D printer can also print with continuous carbon fiber reinforced Nylon, continuous Kevlar reinforced Nylon, and continuous High Strength High Temperature (HSHT) fiberglass reinforced Nylon.

The machine is also designed to optimize precision. The print bed snaps into place with 10-micron accuracy so you can pause a print, remove the bed, add components, click the bed back in and then carry on with the print as if nothing ever interrupted it.

The machine has a touchscreen interface and uses Eiger, a cloud-based software, to track the materials being used and optimize print settings accordingly. Eiger can also work within most browsers, easily importing CAD drawings without the need of cumbersome software.

X3

Markforged’s X series is characterized by a larger print volume than the Onyx or Mark Two.

The X3 doesn’t print continuous fibers like the Mark Two, instead printing with the company’s Onyx carbon-fiber filled Nylon, also in flame resistant and ESD versions. Essentially the X3 is like a larger version of the Onyx One, but it can print in a higher resolution (Z layer resolution of 50 microns vs Onyx One’s 100 microns).

Designed for industrial and continuous use, each piece of hardware in the filament extrusion system — from the nozzles to the extruder hobs — can resist wear from micro carbon fiber-filled nylon filaments and maintain print quality over thousands of hours, the company says. Out-of-material sensors ensure that you’re always printing while a scanning laser on the printhead enables the printer to dynamically adjust the first layers of a print to achieve ideal bed adhesion.

X5

So if the X3 is the industrial version of the Onyx One, the X5 is the industrial version of the Onyx Pro. The X5 prints with the same materials as the Onyx Pro but like the X3, is larger than its desktop little brother and can print in finer detail.

Markforged markets this printer for commercial use boasting more precision-machined hardware for better accuracy and advanced sensors than the Onyx series. The X5 also features micron-level laser scanning for closed-loop calibration, reliably yielding parts with high repeatability and high surface finish.

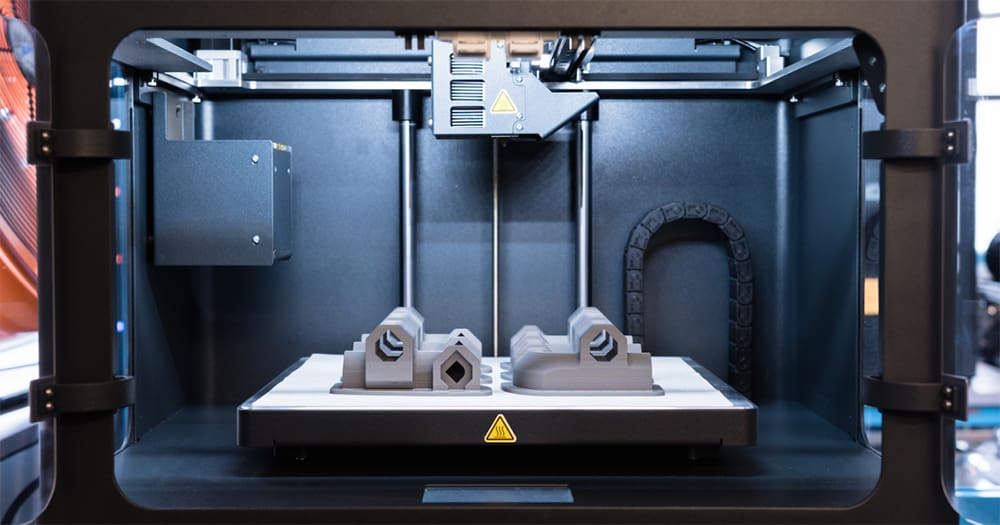

X7

Featuring all the bells and whistles of the X5, the X7 is Markforged most popular 3D printer. It can print with all of the company’s carbon fiber-filled and continuous fiber materials, but it’s more than materials that sets the X7 apart.

Early in 2021, Markforged announced the availability of its Blacksmith machine learning software for the X7. Blacksmith uses AI to help the 3D printing system to adapt and account for variables so it produces parts that are accurate and precise first time, the company says.

Blacksmith can harness data from each individual printer set-up as well as across fleets of X7 printers to learn with every print. With the support of Blacksmith, the X7’s integrated laser micrometer and a patented smart scanning process can compare parts as they’re printed against the design file loaded into the machine.

In 2021, Mark forged introduced the Markforged X7 Field Edition, which is essentially the X7 in a cool military-grade travel case.

If it wasn’t for the price tag you might want this for luggage, but the case that makes the X7 a “Field Edition” is a timely response to the increasing use of metal additive manufacturing on site at remote locations in either the oil and gas industry, or for deployed military. In fact, the U.S. Marine Corps XFAB program has field-tested the Markforged X7 in the field.

The main difference between an X7 and an X7 Field Edition is the outer case, custom foam inserts, and included tools, consumables, and spare parts, such as print head and extruder. The printer also substitutes the lower material storage cabinet found on the standard X7, opting for a simplified drybox setup like the Mark Two.

The X7 FE starts at $89,500

Markforged says you can “drop” – presumably by aircraft – the unit directly into harsh environments like combat zones and exploration sites and be printing in less than two minutes. The high-impact polyethylene Pelican case will protect the printer inside.

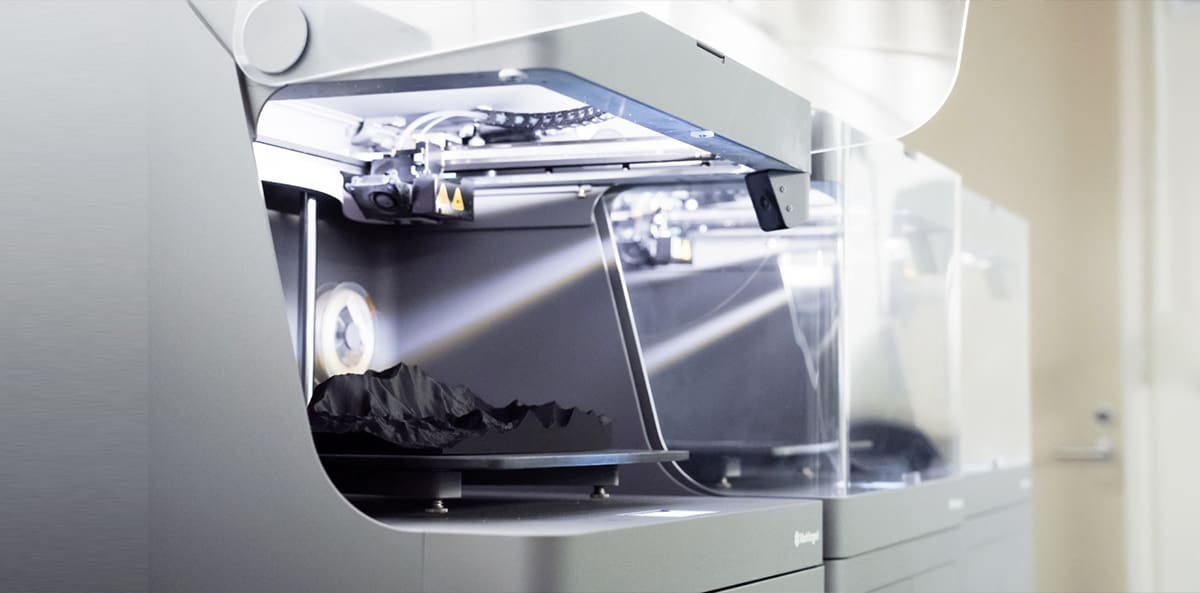

FX20

The new FX20 is by far Markforged most ambitious industrial-grade 3D printer. It’s bigger, faster, and the company says “more sophisticated” than the rest of the Markforged family. Setting it apart is its ability to print with high-temperature Ultem 9085, a flame-retardant, high-performance thermoplastic used to create tools and end-use parts in aerospace, automative, and heavy industry.

Although you have several options on the market if you’re looking to print with Ultem filament, the FX20 may be the only one that can reinforce the already strong Ultem with continuous carbon fiber. Ultem has a lower impact strength relative to other high-performance plastics, such as PEEK and PEI, but is generally less expansive, so reinforcing this material with continuous fibers should solve the strength issue while remaining affordable. An extra large spools of Markforged’s Ultem 9085 filament is about $1,400 (still less than the same amount of PEEK).

The FX20 can print with the full line of Markforged materials.

Markforged says the FX20 is the most precise machine the company has ever produced and it’s massive compared to the rest of its family. Its turbo mode builds parts faster than any other Markforged machine. New XL spools offer four times the material without spool changeover.

The FX20 features a 7-inch touchscreen from which users can control every aspect of the printer. Automated calibration and leveling reduce operator input, while a wide variety of sensors give live feedback on machine performance. A material bay contains two active XL spools and can store two more with precise moisture control.

The FX20 runs on the Eiger software and there’s no news yet if Markforged’s Blacksmith software is available for the FX20.

The FX20 and Ultem 9085 filament are expected to ship worldwide in the first half of 2022 and we should hear a market price for the unit soon (check back here).

Metal X System (Gen 2)

The Metal X System is one of the most accessible metal 3D printers on the market particularly appealing to small manufacturers. The systems can print in a wide range of materials from stainless steels to copper with pretty minimal training.

Especially compared to other more industrial metal 3D printing systems, the Metal X is affordable and, because it doesn’t use metal powder, like most other systems, it’s office-safe. The printer uses a bound powder filament and FDM technology, so producing metal parts requires several more steps than just the printing part. After printing, your metal parts need debinding to remove the polymer that holds the metal powder into a rod, then you sinter your parts in a furnace.

Fortunately, Markforged also makes a debinding machine, the Wash-1, with specialized fluid to remove the primary binding material, leaving the part semi-porous so the remaining binder can easily burn off during sintering. The Markforged furnace, the Sinter-2, features a 17-hour express run, for overnight sintering of part batches weighing less than 250 grams.

Unlike most other printer manufacturers, Markforged does not release specs like nozzle temperature, bed, or chamber temperature. These measurements seemingly don’t matter because you can’t use third-party materials.

In 2021, Markforged announced a software update that actually increased the speed of the Metal X. Called Next Day Metal, the update is the culmination of process improvements over the last three years. Now, it’s possible to go from design to part in as little as 28 hours.

The Gen 2 version of the Metal X, which was also introduced in 2021, features some small but significant upgrades. For example, the printer gains door position sensors that automatically pause active prints when the door is open and improved chamber insulation that shortens warm-up times and improves print consistency.

Eiger & Eiger Fleet Software

Eiger is Markforged’s integrated, connected platform designed to take you from CAD to functional part quickly. The browser-based workflow is fast and intuitive.

Eiger enables you to print composite parts reinforced with continuous fibers and metals. You can prep parts for printing with a single click, or drill deeply into part settings to optimize your final product.

A secure part library enables you to dynamically manage engineering projects of any size — complete with versioning. Eiger part files are securely stored and can be versioned, edited, and printed anywhere.

Eiger Fleet, launched in Sept. 2021, is a single place to manage your printer fleet in real-time, whether in one spot or worldwide. Benefit from automatic updates while getting analytics, usage data, and live telemetry in a single place. You can also give the right people access to the right devices and parts — when and where they need it — based on projects and team responsibilities.

Eiger Fleet also enables you to track and analyze part costs and lead time for insights into your additive manufacturing return on investment.

Blacksmith Software

Blacksmith is Markforged’s adaptive manufacturing platform that connects part design, production, and inspection with a powerful AI.

Blacksmith enables Markforged’s X7 to change how future parts are printed based on scans of previous prints. First, the onboard laser micrometer scans an OEM certified artifact to field calibrate the X7, enabling software augmented printer consistency and scan accuracy. Next, as you slice a part, Eiger’s patented “intelligent scanning algorithm” creates an integrated scan tool path. The X7 scans the part while printing and creates a point cloud of dimensional data. Then, Blacksmith compares the point cloud measured during printing to the design file, generating a detailed error field for the part and overlaying it on the initial STL. Eiger presents this error field in an easily parsable online report. Using these tools, you can set tolerance limits, compare different prints of the same part, and browse a centralized scan library of print quality data.

As Blacksmith leverages federated learning with Markforged’s large fleet of connected 3D printers. The company expects adaptive manufacturing technology to expand beyond the X7, enabling corrective actions from metal and composite printers.

Lead image source: The Markforged FX20

License: The text of "Markforged Carbon Fiber & Metal 3D Printers" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.