There are a lot of reasons companies and individuals turn to metal 3D printing: an important machinery part breaks and your overseas vendor can’t deliver a spare in time, or perhaps you need to check the fit and function of a metal part before going to full production on it, or you’ve found that injection molding a small quality of parts is cost-prohibitive.

You’ve heard about metal 3D printing, but how exactly does ordering metal 3D printed parts work and how much does it cost?

To give you a sense of the process, we ordered four metal 3D printed parts in various sizes and quantities at some of the top metal 3D printing services. What we found is that there is no standard way to order, no uniform description of materials or technologies, and a wide range of prices. This article, however, should take some of the confusion out of the process and enable you to order metal 3D printed parts with confidence.

Overview of Metal 3D Printed Part Order Process

Getting your 3D printed metal parts involves several steps, from initial design to final delivery. Here’s an overview of the process.

Designing Your Part

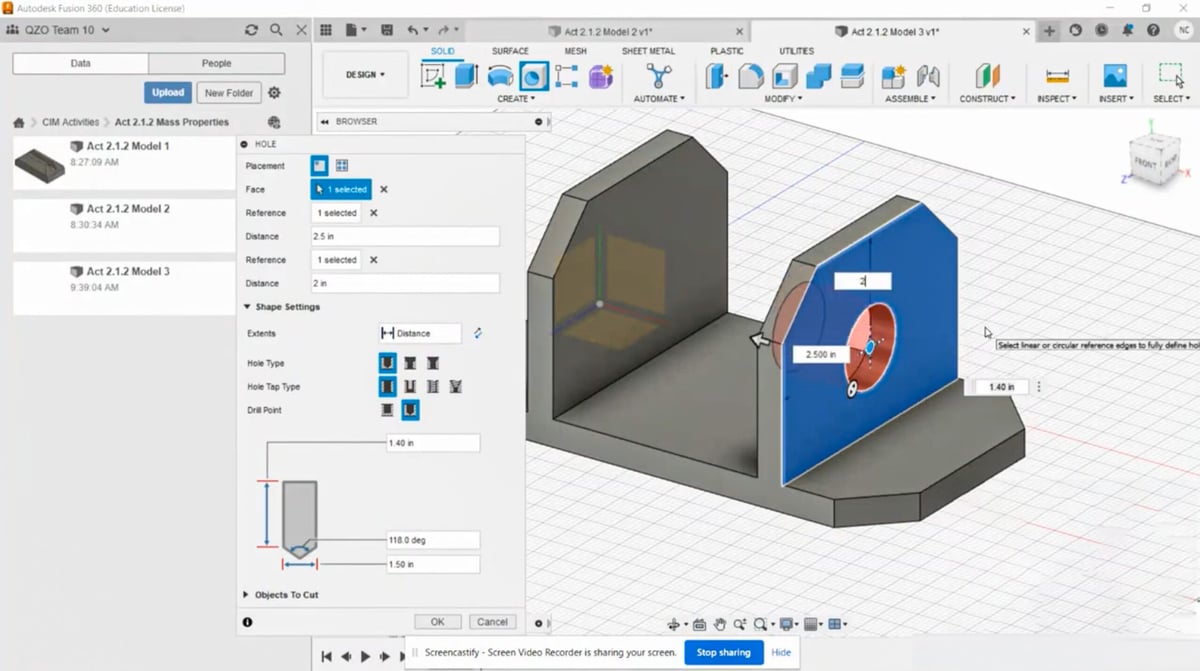

You must have a digital design of your part, also known as a 3D digital model. The same digital model that you use to injection mold your part or CNC it, is typically fine for the 3D printing process. Your model is created in computer-aided design software, such as SolidWorks, AutoCAD, or Autodesk Fusion, and includes all necessary features, tolerances, and specifications for your application.

If you don’t have a digital model, you can turn to a 3D modeling service to have one created. Often you can use a physical part and have it 3D scanned to created the digital model.

Your digital model has to be in a particular format to be uploaded to a 3D printing service. Some services only accept STL or 3MF files, but others will work with a wider range of digital formats.

Select a 3D Printing Service

Look for reputable 3D printing services that offers metal 3D printing. Examples include Craftcloud, Protolabs, and Xometry, and the others that we feature below.

Check if the service offers the metal materials you need (e.g. stainless steel, titanium, aluminum) and an industrial-level 3D printing technology. This is where it can get a little tricky.

Select the Metal 3D Printing Technology

There are ways to 3D print in metal that may not be suitable for your application. Not every part 3D printed in metal will have the same mechanical properties as a part traditionally manufactured in metal. For example, using a fused deposition modeling (FDM) 3D printer with metal filament can produce metal parts in stainless steel that are strong, but are not as strong as parts 3D printed using another technology called metal laser powder bed fusion (M-LPBF).

The FDM parts will be much cheaper, but in the examples below we designated M-LPBF for all of them. This technology is the most common among 3D printing services, but almost every service had a different name for the same M-LPBF technology.

So to be clear, metal laser powder bed fusion technology can also be called:

- SLM (selective laser melting)

- Metal Sintering

- DMLS (Direct Metal Laser Sintering)

… but they are exactly the same technology.

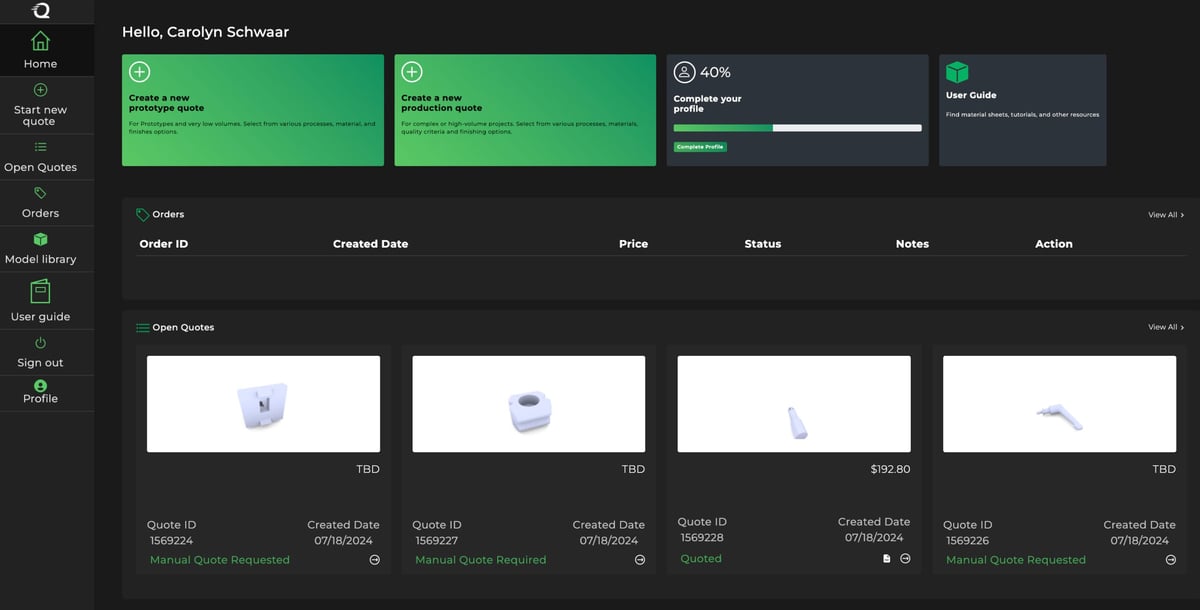

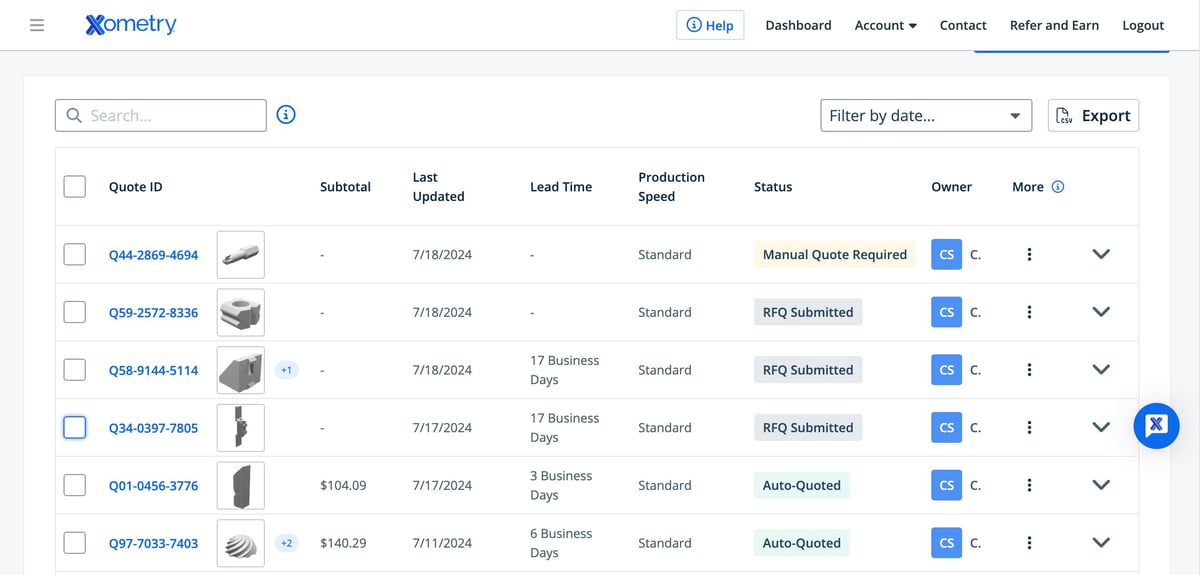

Request a Quote

Requesting a quote is not always a straightforward process. For most services, except Craftcloud, you first must register and create an account. Once we did that, we uploaded our model, which was scanned for its printability. If your digital file contains more than one part in the same file, we found it could be rejected for printing, depending on the provider.

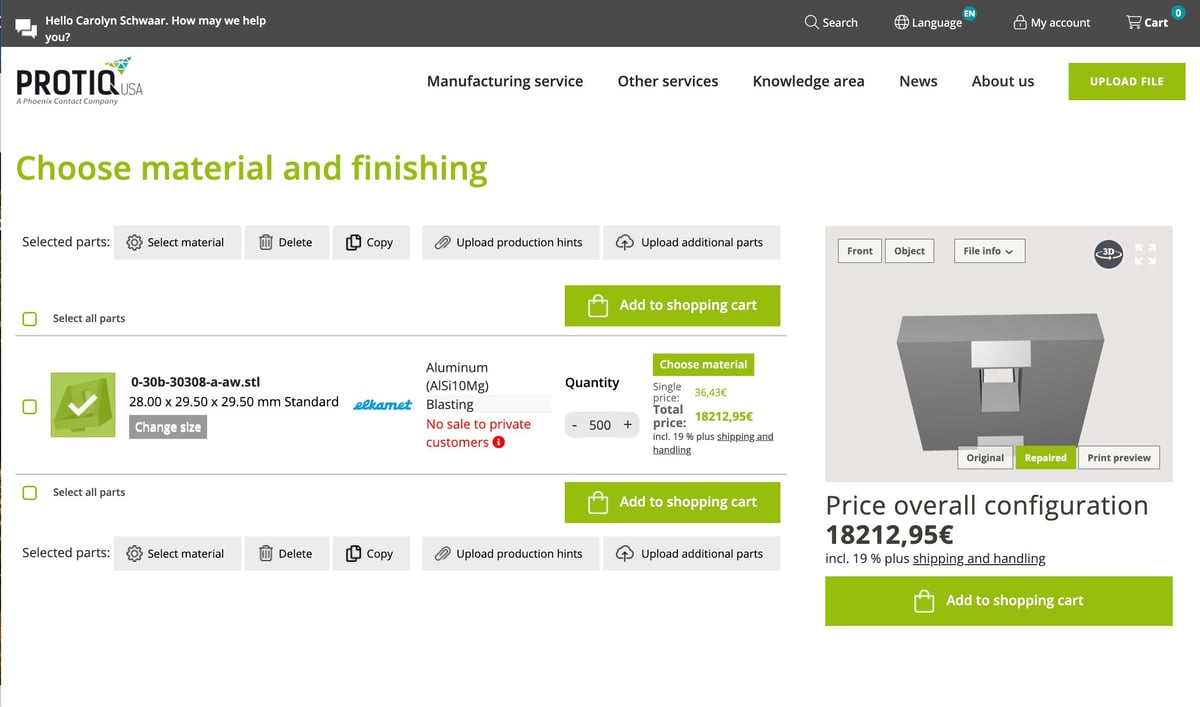

Once our digital files got the green light, we selected a material, then a technology, then how many we needed, but there’s more.

Note that online portals will ask if your digital model is in mm or cm. This is an oddity of digital models and no service provider can process your part without this essential piece of information. Another question you’ll be asked upfront is whether the part you need is subject to any US export restrictions or if it’s an order related to a government contract.

If your project requires manufacturing certifications, such as ITAR (International Traffic in Arms Regulations) or ISO 9001:2015 / AS9100D, 3D printing services will list these on their sites.

We were next given options for a finish (e.g. polished, raw, etc.) or other post-processing needs (e.g. machining, drilling), plus when we needed the parts. Often there’s a section where you can include any additional notes or documentation, such as required tolerances or structural integrity requirements.

Some providers enable you to simply upload your digital file without selecting any other options and they will get back to you with more questions about the part in a day or so, while others guide you through a more detailed process upfront and provide a quote right away, called an instant quote.

We encountered some services that would provide an instant quote for one item, but if the quantities were more, they would say an engineer would get back to us via email. Some quotes took 24 hours and some we’re actually still waiting for.

Along with your part production, some services offered various levels of quality assurances and inspections, which could also include part testing, at an additional fee. A standard inspection to ensure parts meet basic dimensional and structural requirements is typically included.

Place Your Order

Whether it’s an instant quote or one that you receive via email, you can always contact the service’s support staff to ask questions or confirm details before your order. Perhaps you have a question about post-processing options or maybe you want your order split and shipped to different locations.

Once satisfied with the quote, confirm your order by providing payment and any additional required information. The service will then start the production process, which will take as long as stated on your order confirmation. In our investigation, some companies could deliver parts in a few days and others took a few weeks.

If you receive your part or parts and are not satisfied with them, you can contact the service provider. There could have been an error in your digital model or the misprint could have been on the providers side. We found that many 3D service providers are reviewed on Trustpilot. There you can see customer experiences and ratings.

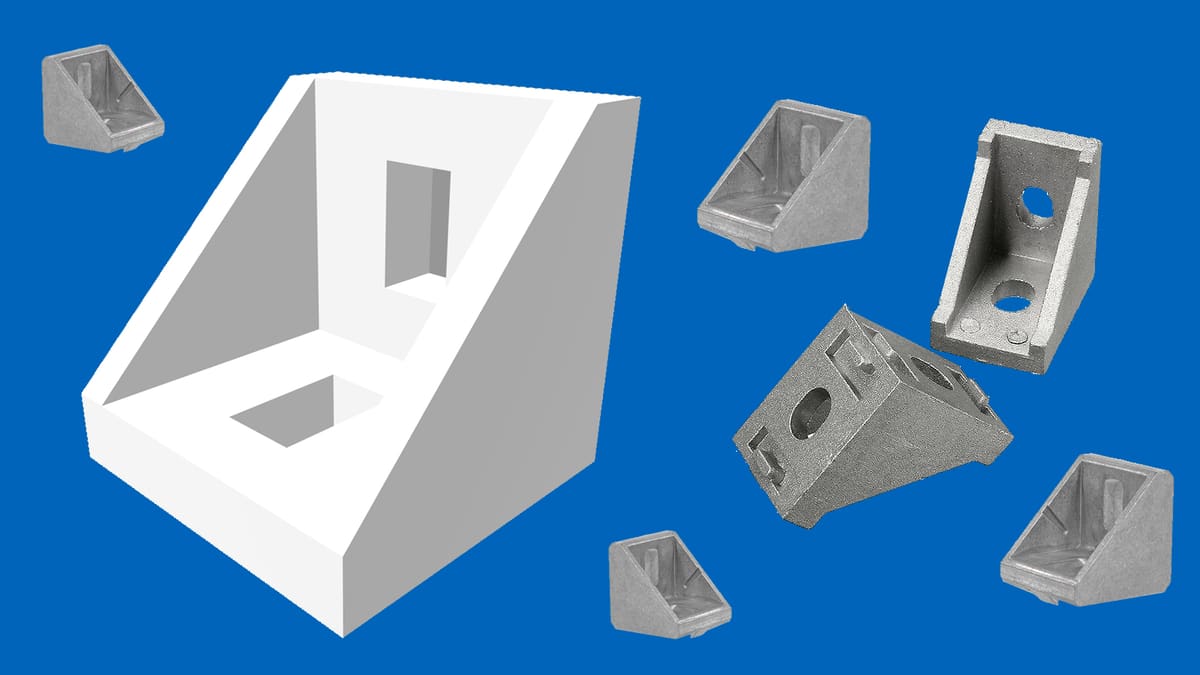

1. 3D Printing 500 Aluminum Brackets

This sample project represents a scenario any manufacturing company could find itself in when the normal part supply chain is disrupted.

Imagine a company that routinely receives thousands of these aluminum brackets a year, which are used as a component in its final product. Because of a factory fire, a spike in the price of aluminum or transport, or a change in global trade tariffs, the overseas supplier cannot deliver. 3D printing is used to bridge the gap until you expect your full order of injection molded or cast parts.

Note that this particular model file, as with all of our four project model files, are relatively standard and, in real life, could be sourced elsewhere. However, we’re using them as representative of more unique parts that our fictional company wasn’t able to source elsewhere.

*Quote requested July 18 was still pending as of publication date. We will update if quotes arrive.

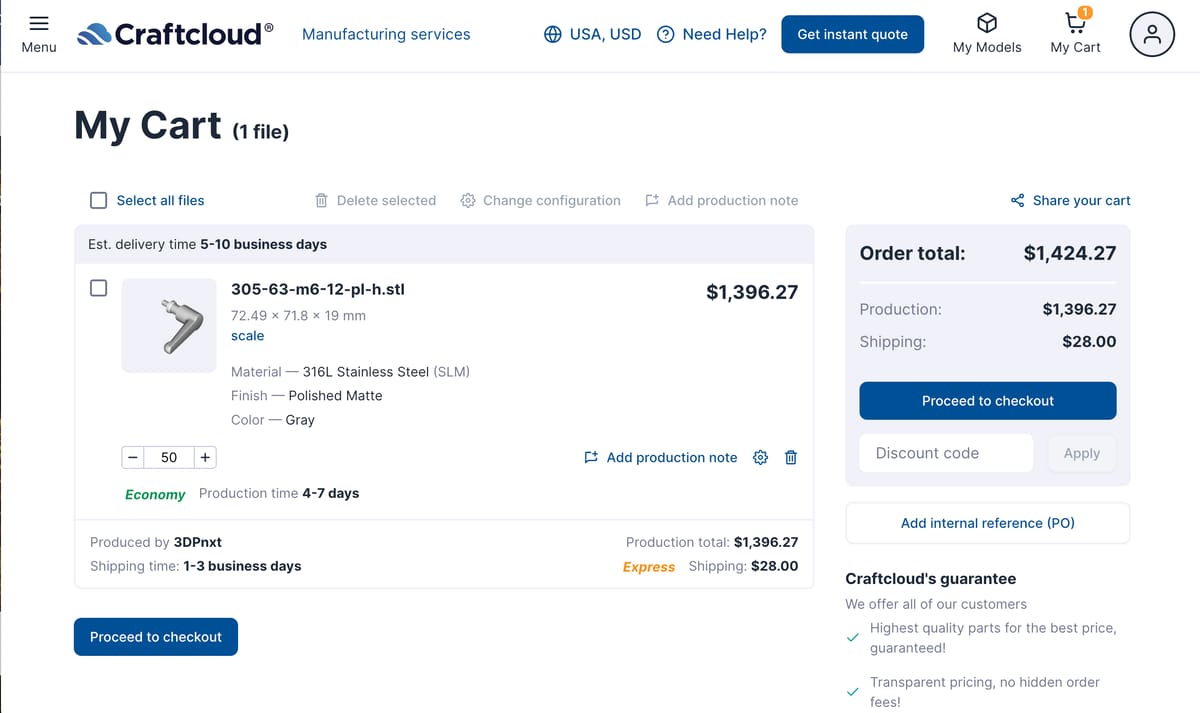

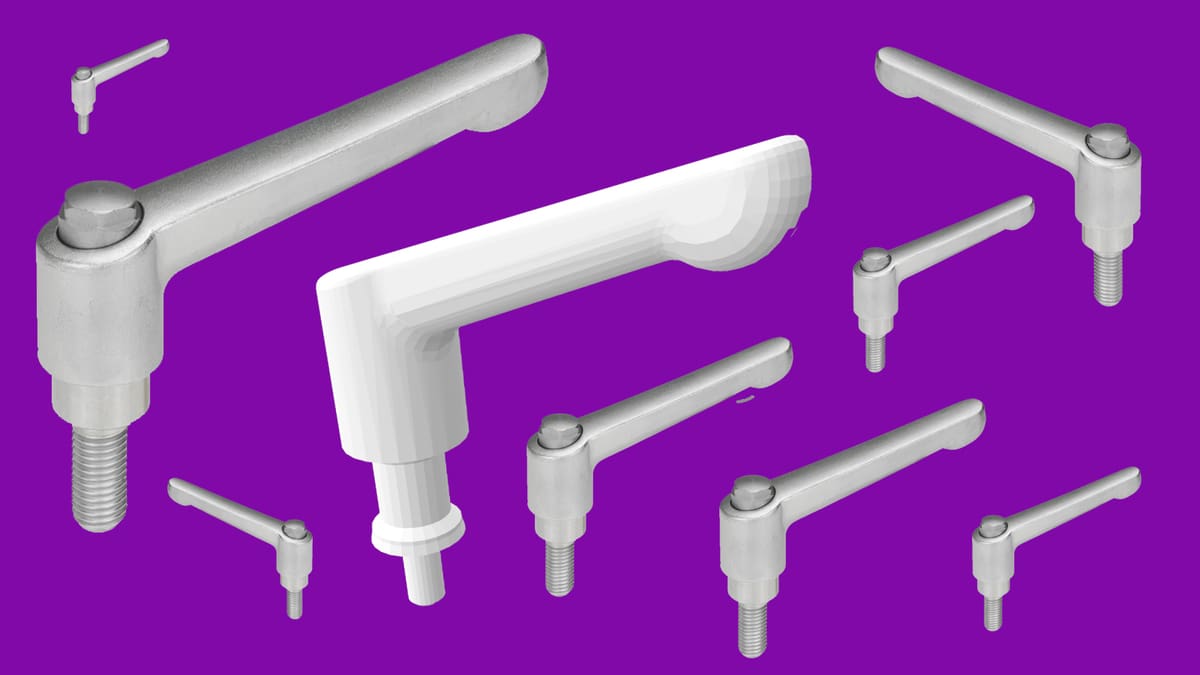

2. 3D Printing 50 Stainless Steel 316L Hand Levers

This project represents when a company needs a small volume of specific parts unique to their product, but machining or injection molding just 50 is cost prohibitive. The mold itself to injection mold these handles would likely be thousands of dollars and the cost of the steel to machine them would, likewise, be very high.

Typically, a company might change the design of their product to incorporate a “standard” or off-the-shelf part. This would reduce the uniqueness of the final product, reduce the innovation it delivers, and possibly affect its function and appeal in the marketplace.

Metal 3D printing enables companies to not sacrifice their design for what is more easily manufacturable.

*Quote requested July 18 was still pending as of publication date.

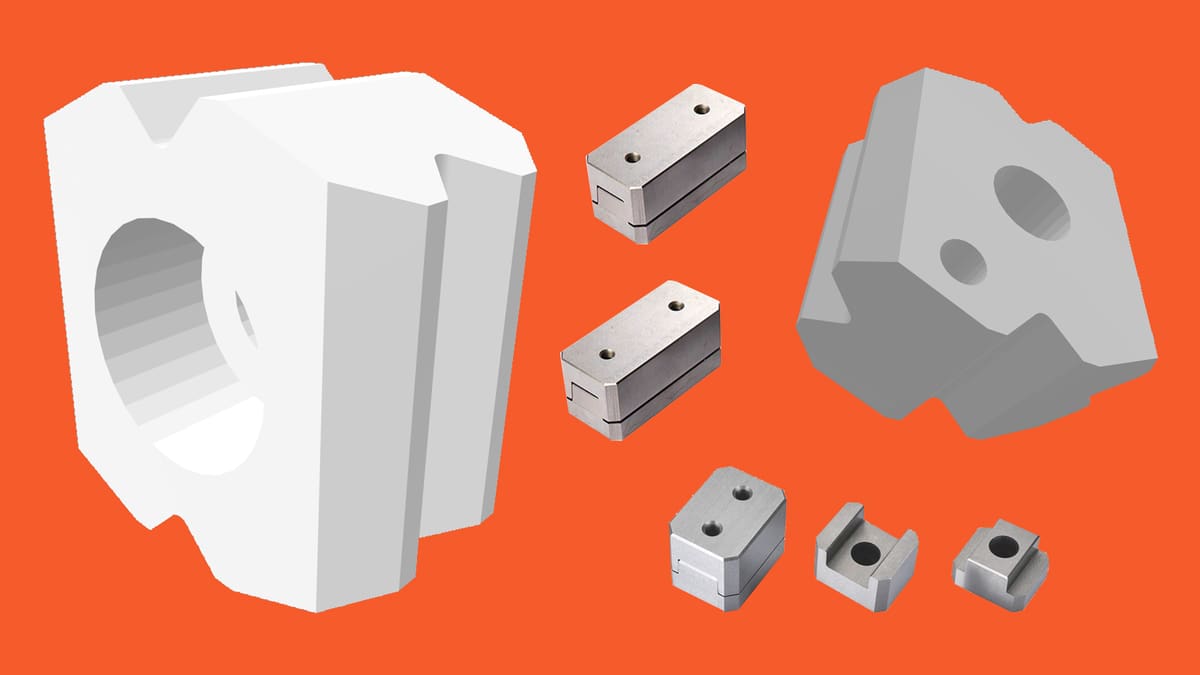

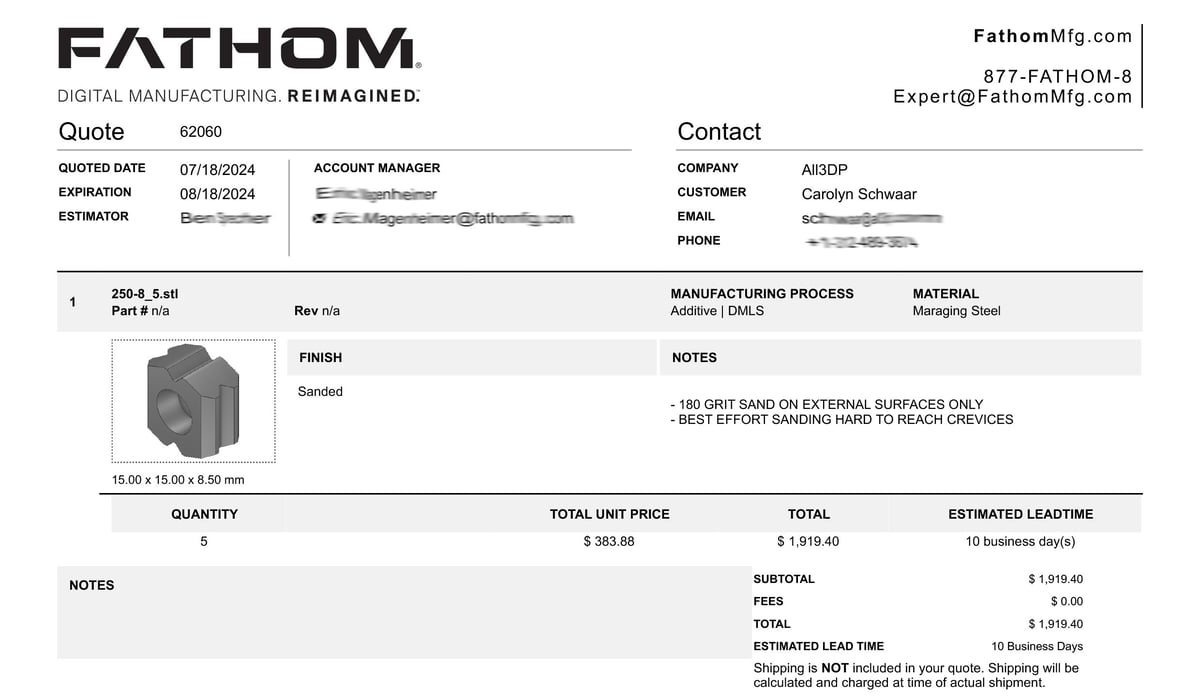

3. 3D Printing 5 Maraging Steel Positioning Blocks

In this example, we looked at speed of delivery in addition to cost. Here, in this scenario, we imagined an aerospace company that needs to replace an essential component on an ageing aircraft and there are no spares.

Maraging steel is often required for its combination of high strength, toughness, dimensional stability, and resistance to cracking, extreme forces, and high heat. Although it is not difficult to find at metal contract manufacturers, it is not common among metal 3D printing services. Not offering maraging steel as a option: Materialise, Forecast3D, Protolabs, ProtiqUSA, Quickparts, or Xometry.

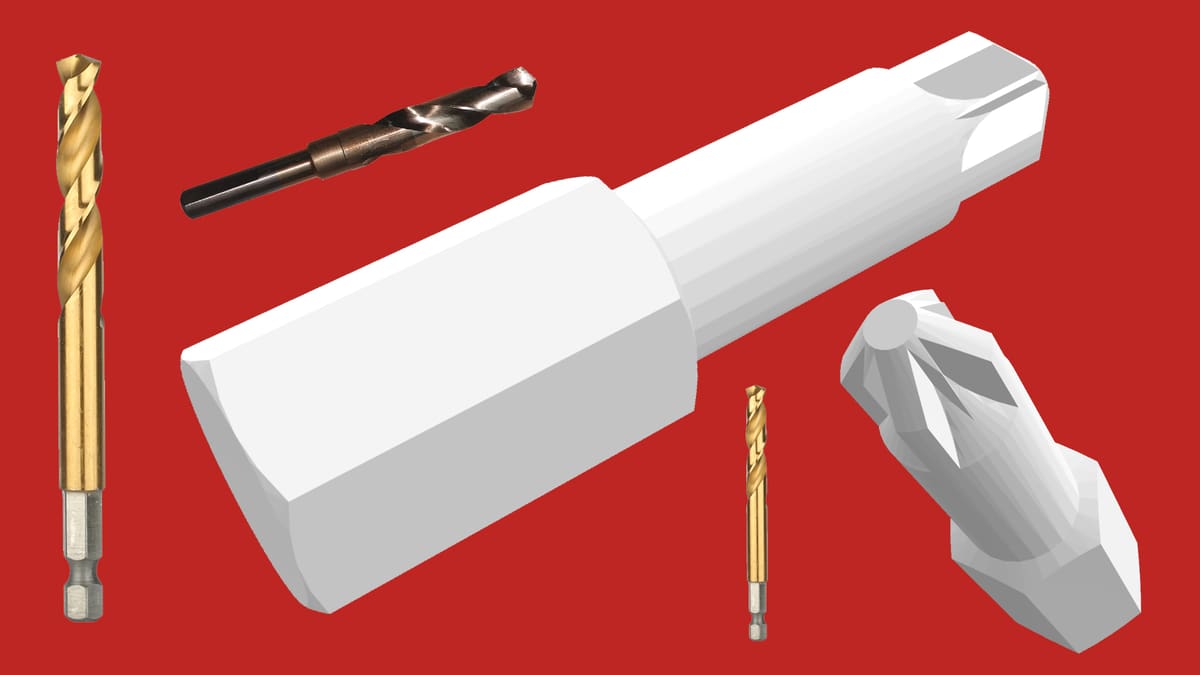

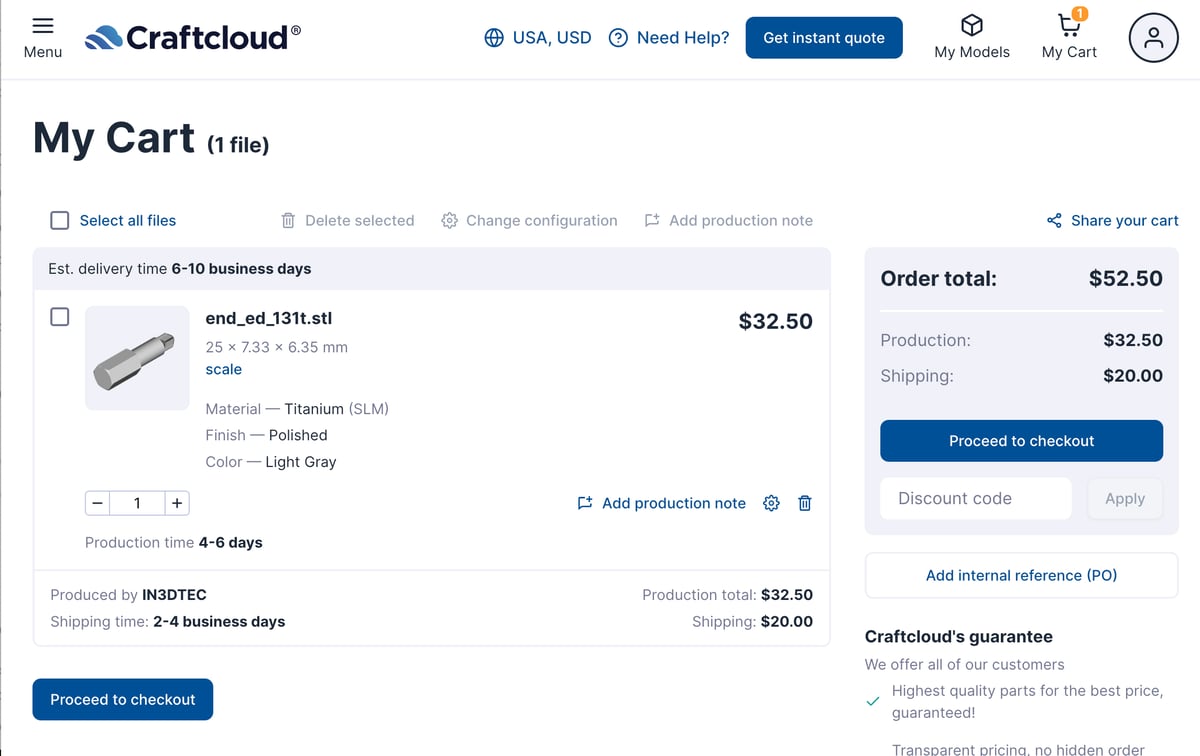

4. 3D Printing 1 Titanium Drill Bit

In this sample project, we wanted to test the availability and price of titanium. Titanium drill bits are extremely hard and maintain their cutting edge for a long time, making them more durable than standard steel bits. This metal also has excellent resistance to corrosion and is often used in marine or chemical processing applications, where exposure to corrosive substances could degrade other materials.

Although this standard drill bit design we used in this project is likely available from suppliers, we used it as a stand-in for a unique titanium part that a company may need only one of. Rather than a drill bit, you could imagine this project representing one unique aerospace part or one medical instrument in titanium.

*Quote requested July 18 was still pending as of publication date.

Disclosure: Yes, Craftcloud, which always had the lowest price, is a service by All3DP. However, in our experiment, we uploaded the same files to each service provider and received quotes as any customer would. There was no cooperation with Craftcloud. You can replicate these experiments yourself and confirm.

License: The text of "Metal 3D Printing Service Prices: 4 Projects Compared at 7 Services" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.