The 3D printing technology Multi Jet Fusion (MJF) is a favorite among manufacturers and prototypers looking for strong, durable parts, but it also produces rugged, flexible products. It is especially favored for creating volume batches of end-use plastic parts that are produced far faster than injection molding.

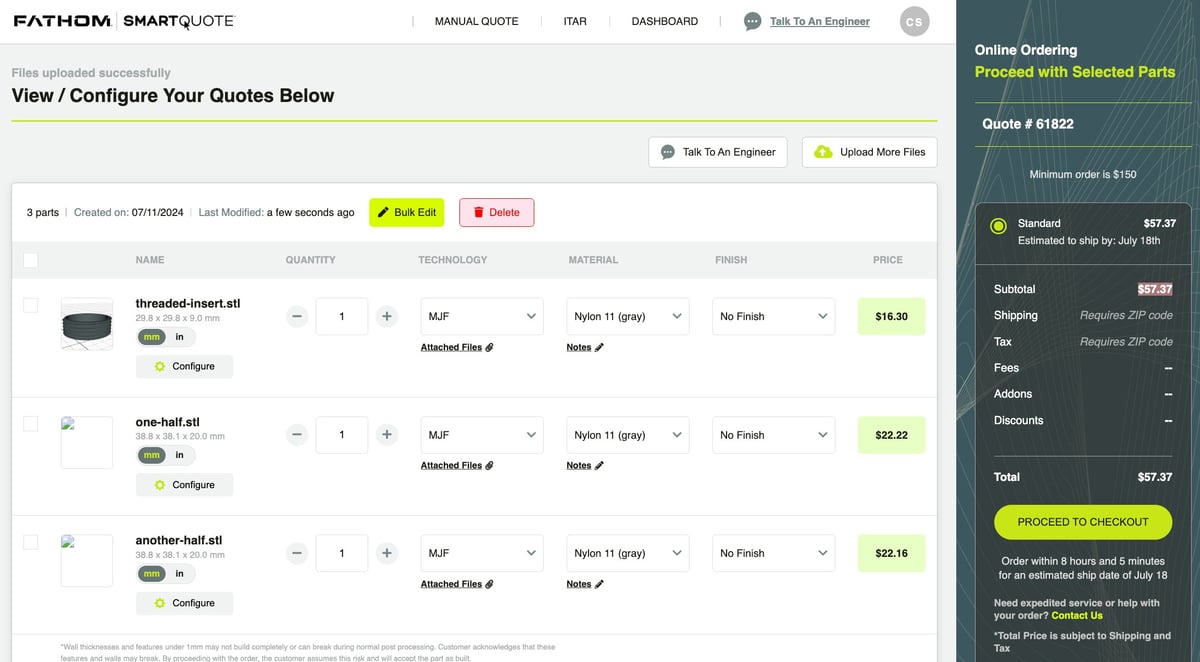

Here, we not only provide an overview of MJF, but we also talk price! You have a lot of choices for companies that can produce your MJF parts, so what should you consider, and what are your parts likely to cost?

Through five 3D printing order examples, we list the costs, extras, delivery and materials from a wide range of reliable MJF 3D print service providers.

If you’re unfamiliar with MJF 3D printing or unsure if it’s the right choice for you, check out the sections on the technology and its advantages at the end of this guide. Now, read on to discover the top 10 MJF 3D printing services and what they offer.

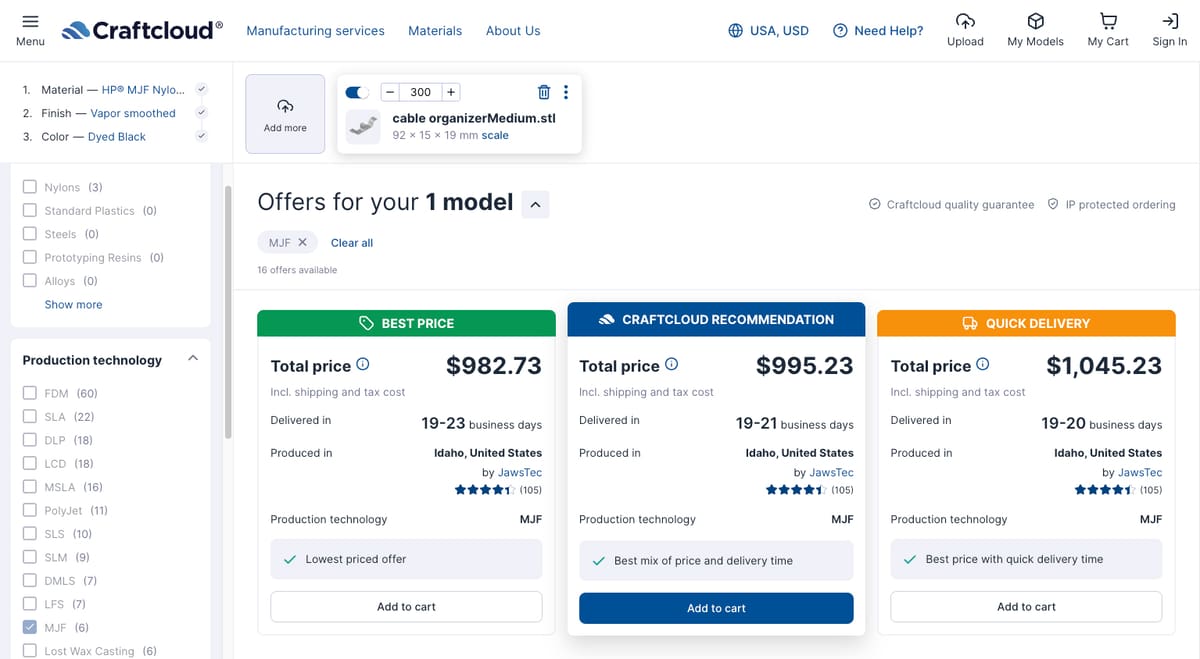

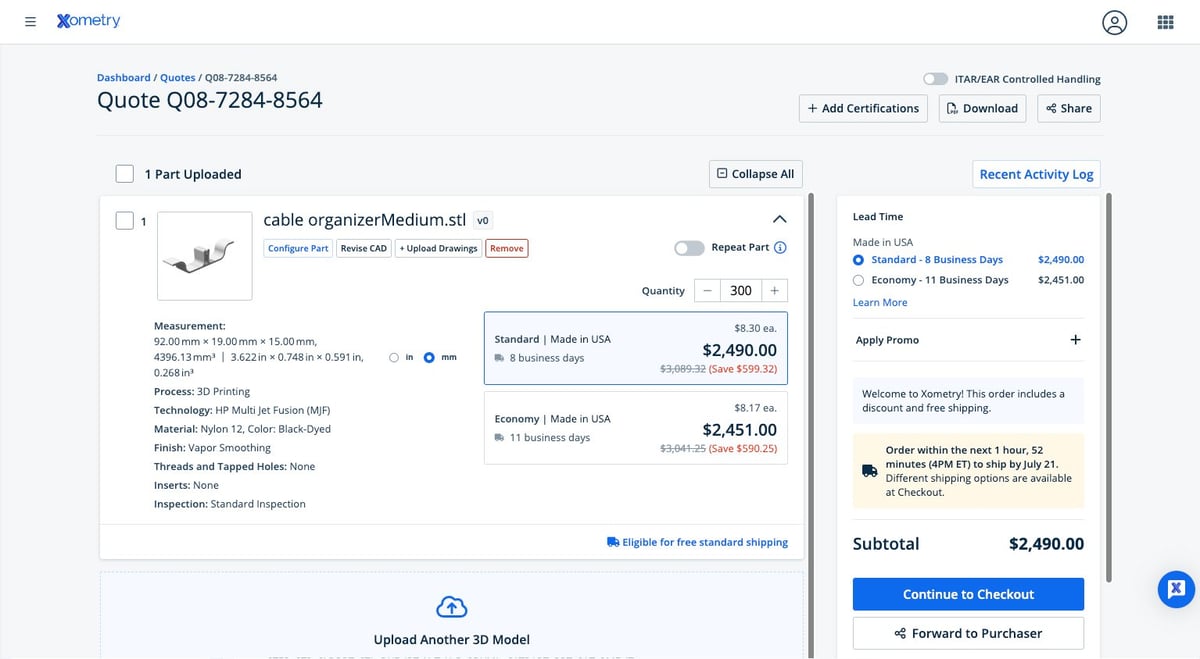

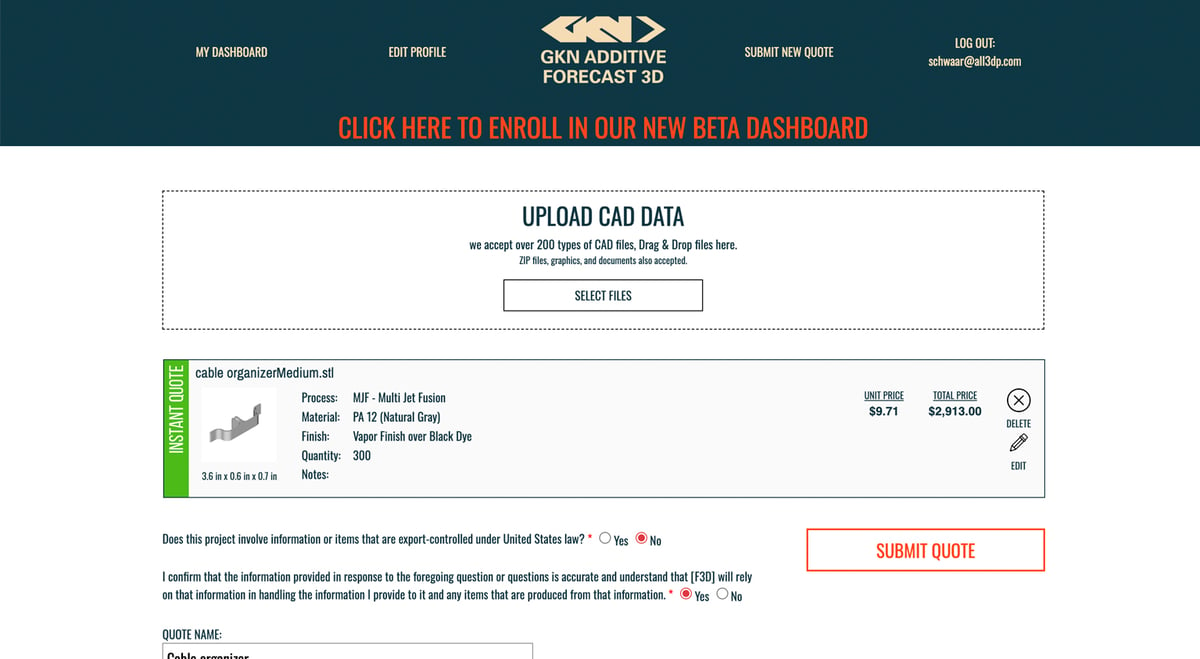

Volume Project: 300 Cable Organizers

There are countless reasons you’d want to order higher volumes of 3D printed parts. First, most production of parts under 1,000 are likely not affordable to injection mold since you’d first need to have the mold created, which can cost thousands of dollars. Perhaps your company needs a batch of products to bridge the gap between prototype and mass production in order to bring a product to market. Perhaps you’ve had a disruption in your usual supply chain and need parts fast.

It’s also common for small companies to entrepreneurs to only need a few hundred parts to bring their product to market.

For this project, we selected a small (92 x 15 x 19 mm) one-piece cable organizer (by a designer on Printables called Sponge) that needs to be durable and just slightly flexible. It required a smooth, injection-molding-like finish, so we opted to add the finishing process of vapor smoothing and dying black.

We were not in a hurry, so production time was the “standard”* provided, although there were options for express production for an extra fee. A few services we investigated offered MJF but not the option to vapor smooth or dye black, so they’re not listed here.

The project shipping location for all of the projects in this article is Chicago.

Artistic Project: Octopus Tablet Holder

MJF offers very fine resolution and high details, so we wanted to put it to the test on a functional part (requires the strength and durability of nylon with MJF) that is also visually appealing to see if 3D printing services could offer a result good enough for small shops to sell limited additions to consumers.

For this, we wanted to 3D print with MJF in HP’s newer material, Nylon PA 12 White, so that a crafting professional could easily paint the surface for sale, perhaps in a gift shop at low quantities. Unfortunately, HP’s White Nylon is hard to find. Materialise OnSite, Xometry, Sybridge, Sculpteo, and Protolabs (and Protolabs Networks) do not offer Nylon PA 12 White.

Endeavor 3D and Dinsmore, an Addman Group manufacturer, both list Nylon PA 12 White on their websites. Endeavor 3D does not have online quoting system, but, you can submit your project details via their websites. Dinsmore lists white MJF nylon, but it was not presented as an option in its instant quote, so you’d need to reach out directly.

This octopus-themed tablet holder is relatively large (210.53 × 132.78 × 69.5 mm), and our order of 5 units would likely to take up more than one build volume (380 x 284 x 380 mm) of an MJF 3D printer. When printing services can fit other part orders into the same build run, it can result in lower prices.

Note that our model here found on Printables by the designer listed as notcolin is available for commercial license, so it can be sold. Download this project’s STL here at Printables.

Protiq USA and Prototal also list Nylon PA 12 White as an available materials but were both unable to ship these parts to Chicago from Germany using the online quote system. Prototal’s quote systems didn’t not appear to work from the US. It is likely a shipping method could be found by reaching out to the companies directly.

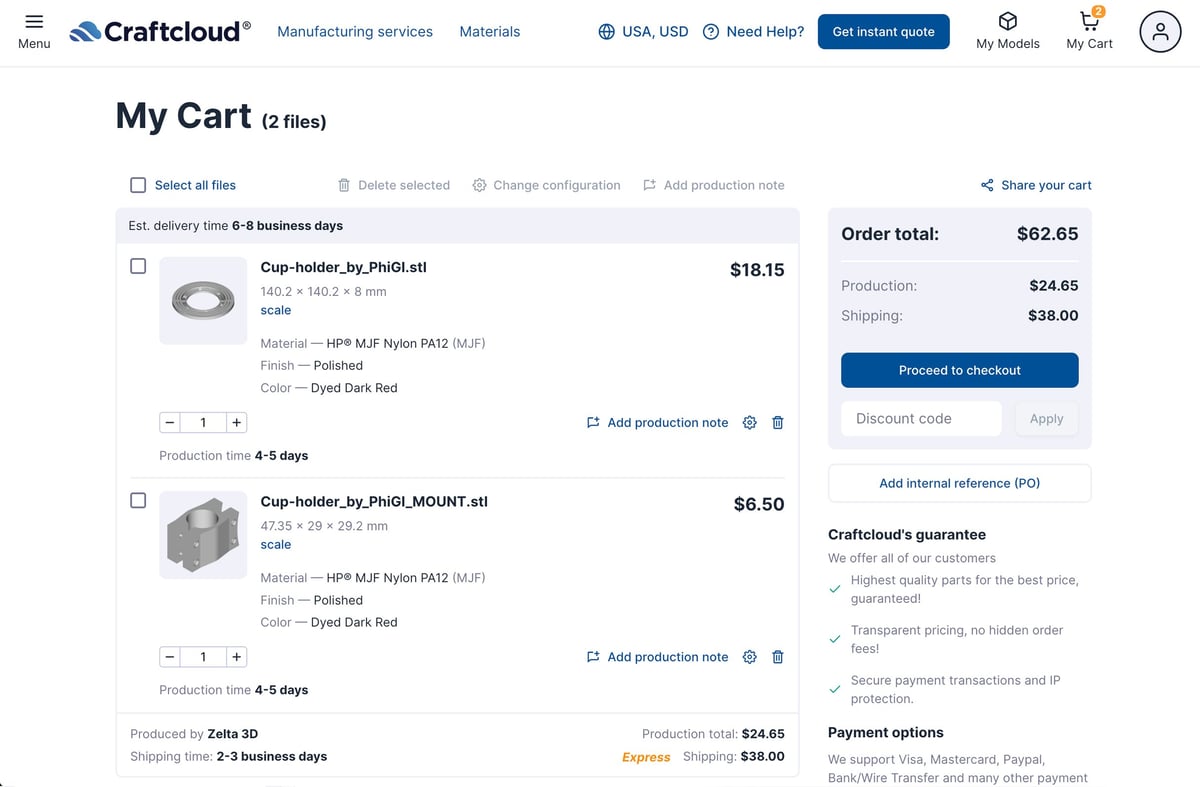

Multi-Part, Colored Project: Self-Leveling Cup Holder

Cup holders are so commonly 3D printed and require a tough material, so we couldn’t resist taking this great design from a Printables designer named phigl, and putting it out for a quote.

MJF 3D prints are easily dyed and available in a rainbow of colors from service providers that have the equipment to dye parts. We selected to have this cup holder dyed red, but color dying (other than black), was only available at Craftcloud.

What makes this project unique is that it includes multiple STL files for a part that is intended to be assembled. A feature of the digital files that proved to be tricky was that the cupholder mounting bracket has a top and a bottom side that you screw together, but both parts are together on the same STL file since they can easily be printed together. However, one platform, Sybridge, identified this STL file as containing two parts and required that they be uploaded separately, so were were not able to include that company in our chart.

*Despite the name Protiq USA, we found only German or French options when attempting to order our cup holder in MJF. We also attempted to select what the company says is “PA12 multicolor (MJF)” but the online platform never offered an option where we could actually select the color. The shopping cart then returned a quote in Euros, not dollars.

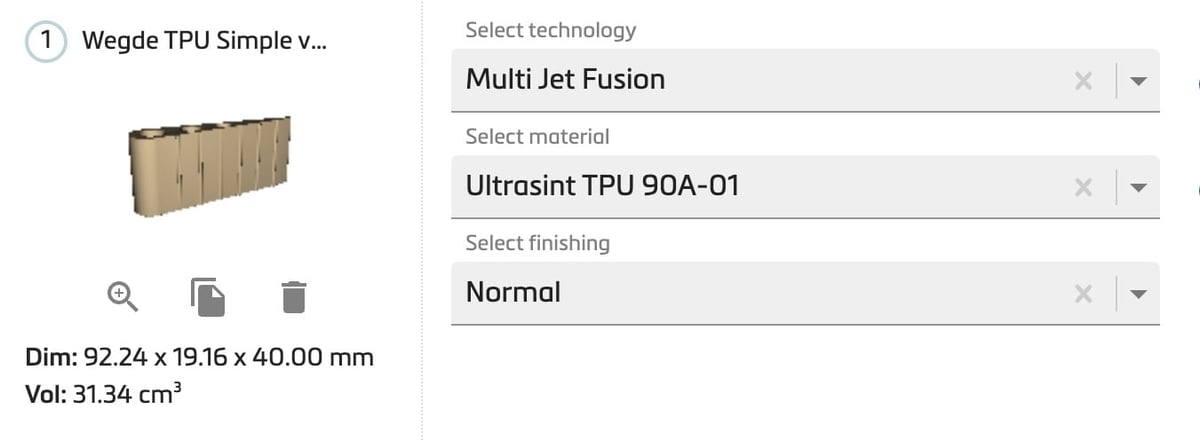

Complex Geometry Project: Spiral Sphere Container

For this MJF project, we wanted to investigate a 3D printing a part with a complex geometry that includes threaded parts that must align perfectly, so tight tolerances were essential.

The idea behind this spiral sphere container project (STL file available on Printables by IKA Meister) is to test MJF nylon 11 for a functional prototype. Our investigation is centered around the multi-prototyping and iteration process for products that are destined for mass production using another manufacturing technology, such as injection molding.

Here we found that one prototype was affordable enough to repeatedly order as your design develops.

We also wanted to explore nylon PA 11 because it is derived from renewable resources, specifically castor oil. It is more eco-friendly and sustainable than nylon 12, which is made from petroleum. Unfortunately, Protolabs and Skybridge do not offer PA 11 in MJF.

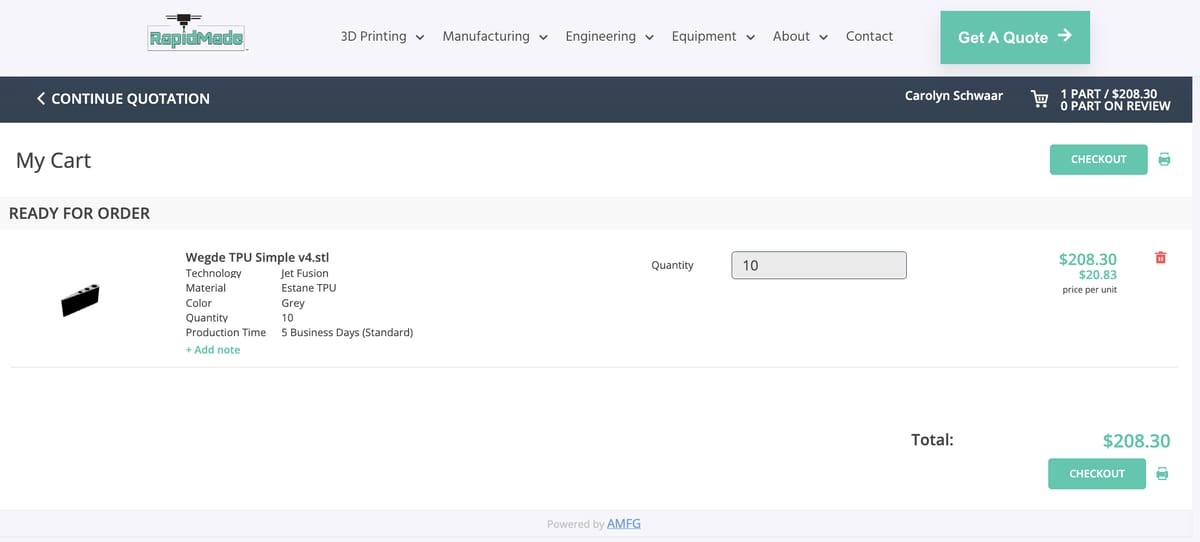

Flexible Low-Volume Project: Door Stopper

Here’s something we’ve printed many times around the All3DP office and can’t seem to have enough of: door stops. We also use them to keep our swinging windows open and the doors to our office patio secured. More than a few have made their way to our homes, too.

This project is a great way to uncover which MJF 3D printing services offer HP’s flexible TPU materials and what it will cost you.

We selected a wonderfully simple, yet easily scalable, door stopper design from a designer at Printables named MorgenKaffe. This file is not available for commercial use, however, so you can’t print and sell it, but you can print it for your own use.

The Basics of Multi Jet Fusion

In a nutshell, the technology involves using a type of liquid binding agent to fuse together powdered polymer material layer by layer. The technology gets its name from the multiple inkjet heads that carry out the process of distributing the liquid polymer (or binding agent).

We go more in-depth into the process below, but know that MJF is fast, detailed, and has proved itself to be reliable, which is why there’s hardly a 3D printing service around that doesn’t have at least one MJF machine among its equipment.

Don’t confuse HP’s Multi Jet Fusion with its Metal Jet printing process used in its metal printers, which is very similar but uses metal powder instead of plastic. Our focus here is the Multi Jet Fusion technology, which only uses plastics.

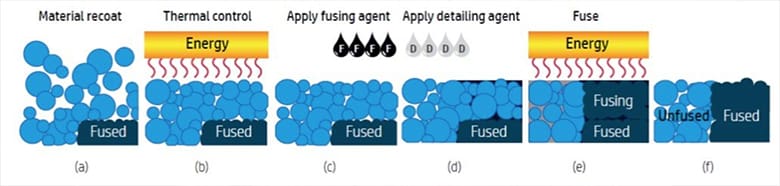

The Multi Jet Fusion Process

Although MJF doesn’t fit neatly into one of the seven 3D printing technology categories defined by the International Standards Organization (ISO), it is a type of binder jetting. All binder jetting 3D printing technologies use a liquid material jetted by an inkjet printhead onto a layer of a powder material. Traditionally, plastic or polymer binder jetting is a “cold” technology, but HP (and a few others we detail below) introduced heat, which substantially alters the process. This is why MJF is sometime in a category of its own.

In the Multi Jet Fusion printing process, the printer lays down a layer of material powder on the printing bed. Following this, an inkjet head runs across the powder and deposits both a fusing and a detailing agent onto it according to the digital model of the parts required.

An infrared heating unit also moves across the print. Wherever a fusing agent was added, the underlying layer “melts” together, while the areas exposed with the detailing agent doesn’t fuse completely, but acts as a layer to ensure surface quality. Areas with no agent apply remain a powder. The unfused powder supports the fused material, which generally eliminates the need for supports.

To finish the printing process, the entire powder bed – and the printed parts in it – are moved to a separate processing station. Here, most loose unfused powder is vacuumed up, allowing it to be reused instead of producing excess waste.

If you want to dive even deeper into Multi Jet Fusion and see some great case studies, check out our Complete Guide to Multi Jet Fusion (MJF 3D Printing).

License: The text of "MJF 3D Printing Service Costs: 5 Projects Compared" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.