For everything from carbon-fiber factory tools to stainless steel spare parts, there’s a 3D printing company (or additive manufacturer) to deliver high-quality parts cheaper and faster than traditional manufacturing. You don’t even have to know anything about additive manufacturing to use these services and get exactly the part or product you need. The companies below offer design, engineering, and manufacturing expertise to be your contract manufacturer for prototypes or final end-use parts.

The flourishing market of on-demand additive manufacturers across the globe serves as an introduction to the capabilities of various 3D printing technologies. If you’re curious about how your parts or products could be improved but you’re not ready to invest in your own 3D printing systems, get your feet wet first with some outsourced parts. Think of it as an easy way to jump-start your company’s transition to additive manufacturing as a replacement for – or a compliment to – injection molding or expensive traditional tooling.

The companies in this guide are different than the 3D printing services that All3DP features in several other guides, where you upload your design files online and, days later, receive your final part. Additive manufacturers offer engineering, design, and technical consulting, in addition to series production, post-processing and, in many cases, custom material development and non-destructive quality testing.

In many cases, you can simply bring them your idea for a part or product, and they’ll work with you to make it a reality.

Whether you want to have one component printed or establish a long-term production partnership with an additive manufacturer, our guide to the leading providers is the best place to start.

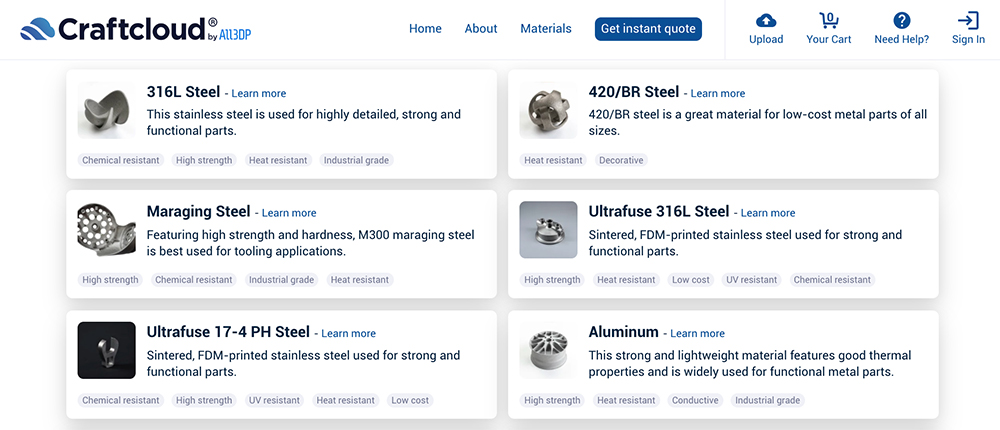

On the other hand, if you’re familiar enough with additive manufacturing to know exactly what you need, the companies that offer a fast upload-and-order system, such as Craftcloud, are also attractive options.

| Company | Service Area | Services | Other Technologies |

|---|---|---|---|

| Materialise | Global | Consulting, Design, Engineering, Post-Processing, Training, Series Production, White Label, Quality Control | Vacuum Casting |

| Burloak Technologies | North America | Application & Process Support, Post-Processing, Materials Testing, Quality Assurance, Rapid Prototyping | CNC Machining, Metrology |

| Oerlikon AM | Global | Consulting, Design & Application Engineering, Series Production, Rapid Prototyping, Post Production | Sand & Precision Casting, Die Casting, HSC/CNC Milling, Elastic Components |

| Fathom | US | Consulting, Engineering & Design Support, Series Production, Assembly & Finishing, Rapid Prototyping, Measurement, Inspection & Quality Documentation, Laser Etching | Injection Molding, CNC Machining, Urethane Casting, Metal Cutting & Forming |

| Sculpteo | Global | Consulting, Design for AM, Series Production, Rapid Prototyping, Training, Business Rewards Program | Laser Cutting & Engraving, Wax Casting |

| Quickparts | Global | Consulting, Engineering & Design Support, Series Production, Assembly & Finishing, Rapid Prototyping, | Injection Mold Tooling & Parts, CNC Machining, Investment Casting Patterns, Cast Urethane, Sheet Metal, Die Casting |

| Stratasys Direct Manufacturing | Global | Consulting, Design, Series Production, Rapid Prototyping, Measurement, Inspection & Quality Documentation, Painting & Custom Finishing, FDM Certification, 3D Fashion Troubleshooting | CNC Machining, Urethane Casting, Injection Molding |

| FIT AG | Global | Consulting, Design & Engineering, Technology Development, Series Production, Rapid Prototyping, Rapid Tooling, Spare Parts on Demand Service, Art Fabrication, Post Processing, Quality Control & Certification | Injection Molding, Elastomer Manufacturing, Vacuum Casting, RIM, CNC Milling, Polyamide Casting, Investment Casting, Laminating |

| BLT | Global | Consulting, Design, Series Production, Rapid Prototyping, Material Development, Measurement, Inspection & Quality Documentation | |

| Prototal Industries | Europe | Consulting, Model Design, Series Production, Rapid Prototyping | Vacuum Casting, Injection Molding, Aluminum Tooling |

| Sandvik BeamIT | Europe | Consulting, Design for AM, Series Production, Rapid Prototyping, Material Development, Non-destructive Testing, Quality Assurance | CNC Machining, Chemical Milling |

| 3D Metalforge | Global | Consulting, Diagnostic Analysis, Design Services, Series Production, Rapid Prototyping, Education & Training, Part Certification, Post-Processing Greening Operations, | 3D Scanning |

| GKN Additive (Forecast 3D) | US | Consulting, Design, Series Production, Rapid Prototyping | CNC Machining, Urethane Casting |

| GoProto | Global | Consulting, Design, Series Production, Rapid Prototyping, Painting & Custom Finishing | Urethane Casting, CNC Machining, Sheet Metal, Tooling & Molding |

| Replique | Global | Part Design, Simulation, Reverse Engineering, DfAM, Series Production, Spare Parts On-Demand, Digital Warehouse | |

| ProtoCAM | US | Consulting, Design, Engineering, Design for AM, Series Production, Rapid Prototyping, Post Processing & Finish Level | Urethane Casting, Wax Casting, Plastic & Metal CNC Machining, Rapid Injection Molding/Tooling |

| MakerVerse | Europe | Consulting, Design, Rapid Prototyping, Post-Processing | CNC Machining |

What to Look for in On-Demand Additive Manufacturing

As we mentioned, contract additive manufacturers are more than a printer for hire. In addition to their machines, you’re also hiring their expertise and experience, they’ll work with you on your idea and take it from concept to digital file to prototype to final product.

When selecting a company, look for the type of timely response and knowledgeable feedback you’d expect from any business, but specifically for additive manufacturing service providers, ask about their experience with your industry, your type of product, and why the technology they recommend is best.

Whichever contractor you choose, keep these questions in mind.

- Is my part printable? The manufacturer should be able to review your electronic file (if you have one) and determine its suitability for printing before the printing begins. You can also expect advice on how you can fix the design or they can fix it for you.

- What’s the cost and lead time? This information should be available once the manufacturer has reviewed your part file or sometimes even before.

- Will you make a prototype first? Often, manufacturers will print the first article, along with test samples for material testing and quality assurance. This may be identical to the final print or a prototype in another material.

- What post-processing services do you offer? Will the manufacturer polish, paint, or coat your final part to achieve the look you need? Can it precision CNC mill your part to meet ultra-tight tolerances? You don’t want to have to take your part to another company for post-processing.

- Can you certify my parts? Some manufacturers will work with you to gain part qualification and certification. If your parts must be certified for a regulated industry, look for a manufacturer offering this service. Many in medical or aerospace additive manufacturing can certify parts.

- How do you ensure quality? Your manufacturer should be able to detail the processes by which they ensure your part meets your specifications. Do they 3D scan the part and compare it to the CAD file? Do they CT scan the part to check for internal defects?

Manufacturer Marketplaces Do the Comparison for You

Contacting multiple 3D printing services for a quote and trying to determine if they offer the materials, technology, and services you need can be time-consuming, to say the least. A convenient alternative is Craftcloud, the 3D printing marketplace that works with many of the top service providers below to deliver a quick quote from a range of companies. Craftcloud automatically weeds out the services that can’t meet your needs.

Other companies in the comparative marketplace model, include Protiq, Xometry, Hubs, and Fictiv.

Services from 3D Printer Manufacturers

Several industrial 3D printer manufacturers also offer contract 3D printing services. Opting for one of these below is especially useful if you own some of their printers, but have reached capacity in-house and need to outsource on-demand or if you have verified the 3D printing process on a specific brand of machine and want to enable distributed manufacturing – making products closer to the point of need. Working with OEMs is also a great way to test-drive these printers’ capabilities for your business application before making a purchase.

Specialty On-Demand for Aerospace, Medical

There’s a growing number of contract additive manufacturers that specialize in particular regulated industries where 3D printed parts need to have specific certifications and materials. Often the processes by which the parts are made must also be certified so the manufacturer itself holds certain certifications – Nadcap and ISO / IEC 17025 accredited, AS9100/9110 certified, ISO 14001 certified, ITAR and OASIS registered, etc. – that specifically denote the quality systems for part manufacturing.

Aerospace is one industry requiring that certified materials be used in certified processes to produce parts that are then highly quality checked to achieve more certifications. Contract additive manufacturers in this industry, include:

In medical device and implant additive manufacturing, there are equally stringent certification processes, requiring experienced and certified manufacturers, such as:

Top 20 On-Demand Additive Manufacturers

Although our top picks are some of the largest global contract additive manufacturers, you may find outstanding local options right in your backyard. In fact, traditional contract manufacturers are some of the top buyers of industrial 3D printers and are quickly adopting the technology to offer their customers additive manufacturing alongside machining, milling, injection molding, and other fabrication technologies.

Read through our curated list below to find the best service for all of your needs.

Materialise

Materialise, the Belgian software, engineering, and 3D printing services company, uses its decades of experience in additive manufacturing to offer a range of services for small businesses and large industry.

The company separates its on-demand 3D printing into three offerings. i.Materialise is a 3D printing instant-quote service where you can upload your part model for printing, sell your 3D printed items or parts for white-label manufacturing. One level up, however, is Materialise OnSite for professional rapid prototyping, then the company’s most comprehensive offering is additive manufacturing for businesses and industry called “Materialise Manufacturing”. Here you’ll find expertise in additive manufacturing for mass customization, production tooling, rapid prototypes, and small series production.

The company boasts one of the largest fleets of 3D printers in Europe, encompassing eight technologies and more than 30 materials and 20 finishes. Its large staff of designers and engineers gives you the option to co-create new products and applications, from defining the scope and developing the prototypes, to engineering the part and determining final post-processing and assembly.

Especially useful if you’re new to additive manufacturing is the Materialise Academy Manufacturing training courses, where you can get the in-depth knowledge to make the most of 3D printing.

The company’s US office has a special focus is on additive manufacturing software solutions to help companies in aerospace, automotive, industrial goods, healthcare, and other industries grow their business and streamline their production. They also provide 3D printing production, clinical engineering services, and 3D printing software to medical device companies and hospitals across the continent.

Burloak Technologies

Focusing more on part development than most on our list, Burloak boasts a team of engineers that not only designs for additive manufacturing, but also has expertise in aerospace manufacturing, propulsion, thermal management, tooling, and molding. In fact, Burloak, a division of Samuel, Son & Co., works with Boeing to additively manufacture aluminum alloy components to the Boeing BAC 5673 specification.

The company’s approach is to deliver an engineering team that can work alongside yours, helping you understand the intricacies of AM as it may apply to your specific project and, in some cases, completely manage the product development.

From rapid prototyping in plastic to full-scale production in metal, Burloak Technologies also provides materials development, high precision CNC machining, post-processing, and metrology.

Oerlikon AM

Oerlikon AM is a division of the Swiss technology giant OC Oerlikon with production centers in Europe, the U.S., and China, plus a distribution center in Australia. From these three centers, Oerlikon is able to serve customers on all continents.

Oerlikon says it offers a sustainable, cost-effective additive manufacturing process that challenges traditional solutions. The company is also a leading AM research hub for academic and industrial partnerships in the EU and the US. Design and R&D teams can help turn your concepts into reality.

Although the menu of materials isn’t quite as varied as with some other services, having their own proprietary materials allows Oerlikon to make precise material recommendations for your specific needs. This is why they count among their customers several high-tech aerospace firms.

Fathom

Fathom is one of the largest 3D printing-focused contract manufacturers in the US with 12 manufacturing centers across the country. When it comes to additive manufacturing technology, Fathom features a full menu, including PolyJet, FDM, SLS, SLA, DMLS and MJF, plus practically all materials from polymers to metals.

The engineering and design team at Fathom is a group of experts with a wide range of digital manufacturing experience. You can contract these engineers to to support your in-house design team throughout the product development process from prototyping to production.

Fathom provides extensive know-how on designing for additive manufacturing with an affinity for applying additive in unique ways that address cost, time and geometry constraints of traditional processes, according to the company.

Sculpteo

Sculpteo (now a part of the BASF group) originated in France and has an additional manufacturing plant in San Francisco. They also have various offices in other European countries. Although they primarily focus on Europe and the U.S., Sculpteo does provide worldwide shipping.

Sculpteo also has extensive design and consulting services, along with a learning and education library. It provides useful, up-to-date information for both beginners and 3D printing experts.

Their services include an online 3D printing service, production additive manufacturing, laser engraving, and an in-house software platform called Fabpilot, which they offer on a subscription-based model. Sculpteo serves a wide range of industries, but they particularly cater to automotive, medical, and eyewear sectors.

Their material selection is quite large, and available technologies include all major methods. Each material is accompanied by plenty of information regarding the technical limitations, the appropriate uses, and design guidelines to help you optimize your parts.

Quickparts

Quickparts, as the name implies, is a global contract manufacturer with a focus on speed. The company’s new express service promises to have your parts same-day or next day. This speed only comes from 3D printing and the company’s 20-year experience in additive manufacturing.

Quickparts offers complete on-demand manufacturing services, from 3D printing to traditional manufacturing processes. They offer five 3D printing technologies on a wide range of printer brands to cover everything from prototypes to low-volume production. The service is a combination of in-house production and global manufacturing partners.

The staff of engineers at Quickparts can help you with selecting materials and even determining if additive or traditional methods are best for your project. The company is rapidly expanding, having acquired Xcentric Mold & Engineering (Xcentric), another on-demand digital manufacturer earlier this year.

Quickparts’ U.S. facilities are ISO 9001:2015 certified and ITAR registered.

Stratasys Direct Manufacturing

Stratasys is one of the largest 3D printer manufacturers in the world so it makes sense that they would also offer contract additive manufacturing, which they call Stratasys Direct Manufacturing. Their factory locations and international partners, however, don’t just offer parts and products printed on Stratasys machines. They offer various technologies, materials, post-processing, and quality control, alongside traditional manufacturing, such as CNC machining.

Their website offers mountains of resources on additive manufacturing (for free, no login), including case studies, design guidelines, and interactive material wizard to help you select the right plastics or metals for your application, and a “contact an engineer” button for more in-depth help.

Stratasys can print anything, but is especially known for its ability to make full-color anatomical models, investment casting patterns, and jigs and fixtures. The company has seven manufacturing locations throughout the US and one in China, in addition to a global manufacturing network with partners in Europe, Asia, South America, and the Middle East.

FIT is a German additive manufacturer that’s been delivering custom metal parts and components globally for more than 20 years. They have facilities in the US, Japan, Russia, and Europe.

When it comes to metals, FIT offers a wide range of materials and technologies and several conventional production technologies as well. Together with their development expertise for 3D printed components and their extensive post-processing possibilities, they offer metal additive manufacturing for everything from medical implants and aerospace parts to spare auto parts and sculpture.

FIT boasts that they make the entire value chain of 3D printing available to customers – from product design through to engineering, production, and post-processing. As a development and implementation partner, they’re more like a guide for additive manufacturing who can show you the best path to reach your project goal.

However, because they know additive manufacturing is not always the best solution in every case, they also have conventional technologies, such as CNC milling, injection molding, vacuum casting, or elastomer manufacturing.

Chinese manufacturer BLT (Bright Laser Technology) serves the metal additive manufacturing market primarily in Asia, but they deliver for international clients as well. BLM has established itself particularly in the aerospace industry, working with Airbus in 2021. All in all, the company has clients in Asia, Europe, and the U.S.

They’re not just about airplanes, though. BLT serves a wide variety of other industries, including automotive, medical, dental, and artistic segments.

With its proprietary printers, BLT is able to harness several technologies for various applications, including selective laser melting, laser solid forming, and wire arc additive manufacturing. They also have a perfectly adequate list of available materials and are the only company on this list printing with tungsten.

On top of metal 3D printing, BLT offers a slew of additional services, including design consultation, testing, and quality assurance. BLT is even able to provide their customers with customized process parameters and software solutions that are tailored to the customer’s specific needs.

For those active in Chinese or wider Asian markets, or the aerospace industry, BLT offers a comprehensive service package.

Prototal Industries

Prototal Industries, a leading company for polymer additive manufacturing in the Nordics, recently expanded into Austria, Switzerland, and Germany by purchasing rival 1zu1 and added Italy to its market with the purchase of Prosilas.

Capabilities range from resin, SLS, and multi-jet fusion, to polyjet and FDM.

The company says it not only has skillful model makers to guide you through part development and design, but it has the largest resin printer capacity in Northern Europe and can produce series involving several thousand parts at short notice.

Prototal also boasts an extensive menu of post-processing options from sanding, barrel polishing and dying, along with assembly, labeling and packaging.

Sandvik BeamIT

Swedish engineering group Sandvik has more than 150 years of metallurgy experience, so they know metal. They brought this expertise to additive manufacturing with the 2013 launch of Sandvik AM. So, if you’re looking for seasoned metal veterans to produce your parts for you, Sandvik’s the company to go for. In 2019, Sandvik acquired a significant stake in BeamIT, the Italian 3D printing company.

However, BeamIT still operates independently with nearly 60 dedicated additive manufacturing systems distributed across six facilities between Italy and UK. The facilities hold several relevant quality certifications, including AS/EN9100 and IATF Automotive, and NADCAP accreditation.

Both Sandvik and BeamIT offer design services in addition to extensive advanced post-processing and testing options. In 2020, BeamIT acquired a significant stake in Pres-X, a start-up in post-production processes for 3D printing. In the same year BEAMIT acquired AM service bureau ZARE and in 2021 acquired 3T Additive Manufacturing.

BeamIT engineers guide you through the AM process from design and material selection through production and post-processing.

3D Metalforge

3D Metalforge and their engineering teams are based in Singapore with a US office and manufacturing facility in Houston and another base in Australia. Specializing in selective laser melting through the Renishaw suite of metal printers, the company’s full range of additive manufacturing services includes a strong focus on consultancy. 3D Metalforge engineers will even visit your location to identify parts in your facility that could be made better with a material upgrade or re-design for additive manufacturing.

In addition to engineering services, the company offers computer-aided design, generative design work, simulation services, 3d scanning, and post-production services (eg. surface polishing and heat treatment). 3D Metalforge is an ISO 9001:2015 certified company.

3D Metalforge has a growing blue-chip client base that includes companies in oil & gas and defense.

GKN Additive (Forecast 3D)

Perhaps best known for their hassle-free ordering systems, GKN Additive, which purchased the on-demand manufacturer Forecast 3D in 2019, also offers a design service to walk you through product development and design for 3D printing, which saves time, money, and materials.

The company operates more than 45 industrial 3D printers in-house at three facilities, offering a diverse range of additive manufacturing technologies. Forecast 3D owns one of the largest fleets of HP multi-jet fusion 3D printers, and also offers resin and metal technology along with urethane casting and CNC machining services.

As a branch of GKN Powder Metallurgy the company has a specialty in metal additive manufacturing. The company’s aerospace branch, GKN Aerospace, plans to open a 10,000-square-foot facility for metal 3D printing in Texas in 2024.

GoProto

GoProto offers an end-to-end solution for product development and production needs: turning your ideas into reality. The US-based company specializes in quick-turnaround, on-demand, custom manufacturing of metal and plastic parts, using 3D printing and other manufacturing methods.

GoProto’s services include industrial design model making, rapid prototyping, cast urethane, CNC machining, rapid sheet metal, and rapid injection tooling. One of their strengths is helping you determine what process best meets your design, lead time, and budget goals.

Working within medical, aerospace, industrial, automotive, and many other industries, GoProto says it’s a rapid manufacturing company with customer service at its core.

GoProto is another large provider of HP multi-jet fusion 3D printing and, in 2020, GoProto acquired 3D Systems’ Australian on-demand manufacturing facility, the largest 3D digital manufacturer in that region.

Replique

Replique is a start-up and new to our list, but since its founding in 2020, the company is amassing an impressive client list and customer case stories that reflect its core focus, distributed manufacturing of spare parts.

Although many on our list have their own manufacturing facilities, Replique relies on a network of partners worldwide that it says are vetted for quality and consistency. This is the cornerstone to distributed manufacturing, which enables on-demand production anywhere, reducing costs in logistics, enabling higher flexibility, and eliminating spare part warehousing.

The Replique online platform boasts end-to-end encryption to secure your intellectual property, plus the digital warehouse software enables access to your spare part library from anywhere but parts can only be produced in the requested quantity.

If you’re not sure which of your spare parts can be 3D printed, Replique engineers can help you analyze your inventory. Because the company is an off-shoot of chemical giant BASF, they boast that their engineers have design knowledge as well as 3D printing technology and material expertise. Engineering services include 3D spare part design and simulation, reverse engineering, as well as design optimization for additive manufacturing.

The company new RSure technology is a quality tracking module that enables OEMs to track each of their 3D printed parts directly and ensure that final parts meet necessary quality requirements.

ProtoCAM

ProtoCAM provides what it calls “value-added” additive manufacturing because it lends its expertise in design and product engineering. Each project is assigned to a project engineer to help you choose a material, technology, process, and post-processing method.

The company offers engineer-assisted quoting as well as an instant quoting platform for customers who know exactly what they’re looking for.

More recently, ProtoCAM has expanded to rapid manufacturing services as consumers look for production alternatives to traditional manufacturing. Rapid manufacturing takes 3D printing beyond prototypes by producing the finished item that will be used by the end user. Typically, this process is used for a short production run from a single piece, to a few dozen pieces, to a few hundred items.

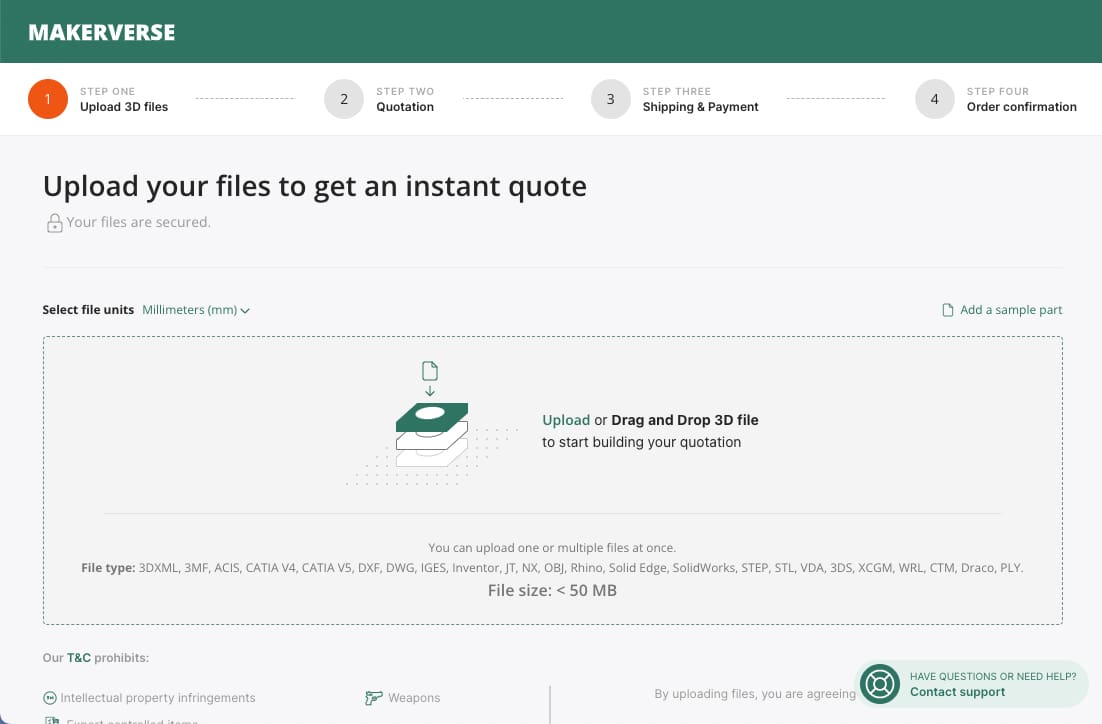

MakerVerse

Although it’s a start-up and new to our list, Berlin-based MakerVerse has an impressive pedigree as a joint venture of Siemens Energy and Zeiss. They aim to become the “leading platform for additive manufacturing services and accelerate the adoption of 3D printing by facilitating access to reliable, industrial grade, and custom manufacturing.”

Clearly, there’s a lot of competition (see above), but one ace up their sleeve may be the AI-based pricing algorithm, which they say provides quotes spanning a range of additive manufacturing technologies, materials, and post-processing methods. This can be handy when you’re unsure which material or technology to use.

They do not manufacture in-house but rather depend on a network of producers across Europe, now scaled to 700+ printers.

To make this list, you have to offer design services. At MakerVerse, after you upload your part file, it goes through a printability check and if it fails, an engineer will reach out to you on how to fix it. If you want more personalized service, the company says it works directly with some customers from the start to develop and supervise the entire manufacturing plan – including the design, but this is usually reserved for complex or sophisticated orders.

MakerVerse says its engineering services are not apparent from the website yet, but a rollout is scheduled for 2023.

Lead image source: Protiq, Your Marketplace For Industrial 3D Printing

License: The text of "Top On-Demand Additive Manufacturing Services" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.