Not only is the Original Prusa Mini+ not all that new, but it isn’t even all that new. Prusa’s updated Mini+ slipped its way into the final chapter of 2020, but, thanks to a combination of lockdowns and domestic relocations, it took a while for us to get around to spending some quality time with it.

Six months down the road and here we are, publishing our thoughts on a machine we widely expect to look, feel and print the same as its predecessor, all while using it to help us settle into a new home by printing those odd bits and pieces a new place always seems to need.

Now, before you say “Bro, haven’t you heard of online shopping?” Allow us this counter – “Bro, haven’t you heard of pretending stuff doesn’t exist for the sake of a vaguely entertaining editorial piece?” And this is how we learn if the Prusa Mini+ is worth your time, as well as if it’s a viable companion during our house move.

Verdict

PROS

- Great price for the user experience and finish

- Exceptional print quality

- A great UI without a touchscreen function

CONS

- Bowden problems (again)

- Lacks a carry handle

- Where’s the Wi-Fi upgrade?

If you don’t mind the below-average build volume, the Prusa Mini+ seems to be as good as desktop FDM gets. Unlike many 3D printers aiming at the budget-conscious, it’s a well-executed product that pays plenty of attention to the little details as well as coming with exceptional customer service to back it up. It forces us to wonder whether we are too used to below-average 3D printers. Surely all 3D printers could be as polished and attainably priced as this.

We’d like to see issues with the Bowden tube addressed in future updates and upgrades. It’s a cheap fix, but we’d rather not be fixing anything at all, and it took a while to diagnose. On the plus side, post-fix the prints are near-visually flawless, and the functional parts we printed are now being used back home doing what we hoped they would do – making our lives easier.

The Tech

Very little has changed between the previous Prusa Mini and the new Mini+.

You still get a 180 x 180 x 180 mm build volume, and the ability to print a wide variety of materials such as PLA, PETG, ASA, ABS, Flexibles and Polycarbonate. Plus, Prusa Research’s self-developed 32-bit “Buddy” mainboard, paired with TMC2209 stepper motor drivers. In short, the capable and versatile Original Prusa Mini lives on here, albeit with imperceptible enhancements.

The cool-looking LCD color UI is still here as well, a feature that makes the larger, more expensive Original Prusa i3 MK3S+ look like a bit of a dinosaur. The display and encoder on the Mini+ are far better to use. This particular writer appreciates the fact that it isn’t a touchscreen too. Not everything has to be.

When it was announced just prior to Christmas 2020, we suspected the lack of meaningful changes would translate to seeing little to no difference in practical use between this and the previous model. Spoiler alert: that’s turned out to be exactly the case, and we also don’t think anyone else will really see a difference either. The changes that have been made are all about reliability, and lessening the chances of problems occurring a fair old way down the road. Not something you can test in a review, really, so think of this as our Mini review redux.

The New

The SuperPINDA bed leveling probe is the only truly significant upgrade to be found on the Prusa Mini+. With the new probe, Mini+ users should see better repeatability and reliability long-term. Prusa has developed the SuperPINDA itself, and the change is an answer to issues with the MINDA probe found on the original Mini. We encountered zero issues with leveling during our time with the printer, we simply set it up the first time and forgot about it, which is great but leaves us little to write about. It works. Thumbs up. Issues with repeatability would probably show up later in the printer’s life, during our few weeks testing the Prusa we saw nothing to suggest they’d crop up though.

The other only changes of note concern some small tweaks beneath the Y-axis carriage, where new metal clips now fix the Y-axis bearings to the carriage itself. The reason for this tweak is supposedly to make it easier to assemble, which carries greater significance now that the Mini+ is available as a build-it-yourself kit.

Kitted Out

Now, our review sample is not the kit version of the printer. We received the partially-assembled version of the Mini+ from Prusa, so we can’t comment on how easy it is to assemble the full set. However, given that Prusa’s documentation and customer support are among the best in the biz, we can’t imagine that it would be too much of a stressful task. Of the few parts the “assembled” version of the printer requires you to build, it was relatively trivial.

There are solid instructions (and a stingily small bag of Haribo) provided in the box with the printer, and even if that isn’t quite doing it for you, then the resources on Prusa’s website are more than enough to help you pull through a build. Even then, even if you’re still struggling, the company’s live chat function, accessible through its website, is staffed by some very friendly and informed people; patient and likeable souls that we put to the test anonymously when we encountered an issue with the Mini+. More on that shortly.

It’s disappointing to note that there’s still no real Wi-Fi connectivity. Prusa has been teasing Wi-Fi for the Mini+ for a while now, but things have, for whatever reason, never come to fruition. The original announcement of the Mini back in October 2019 featured a spec table that said a Wi-Fi connection would be a “separate future upgrade”, something that’s echoed on the current Prusa Mini+ product page. Now, in summer 2021 it’s still not possible to natively control the printer remotely. Prusa support signposts us towards Octoprint instead.

Will it ever happen? Well, probably yes, but it’s hard to say when. Prusa has Prusa Connect in development still for the Mini+, a web interface than currently only lets you monitor the printer. But, for its SL1 resin printer you can already do a lot more, like uploading files directly from Prusa Slicer and change exposure times. That’s encouraging.

It’s worth noting here that the company does like to talk up the Mini+ as a potential print farm workhorse, and yeah, why not? It has a built-in Ethernet port as standard which is probably going to be the preferred connection method if you have a farm with a high number of machines. For a couple of machines, the convenience Wi-Fi could be a strong draw for the Mini+.

Printing and Usability

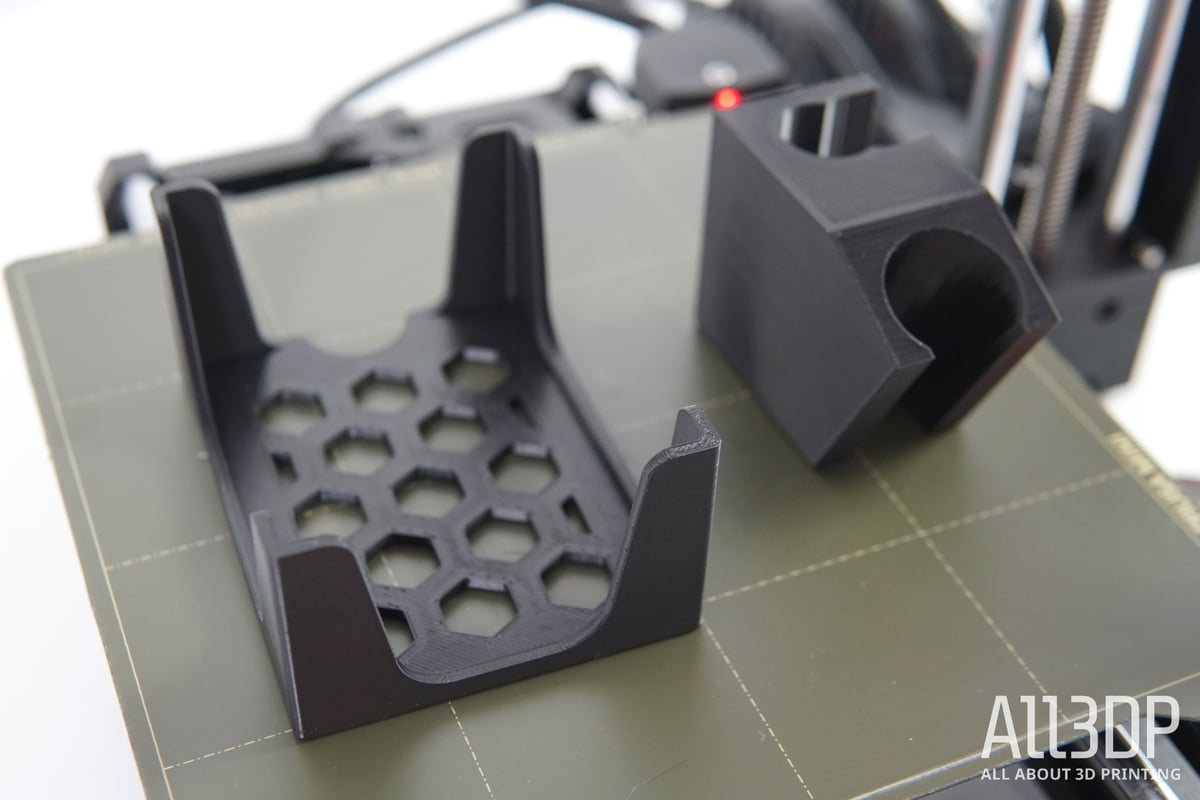

As mentioned previously, we had a real-world problem to fix with the Original Prusa Mini+: useful new-home things. Its task was to help this writer settle into a new home by printing off the bits and pieces you only really find you need after you get yourself in the front door. There’s always something. And we weren’t just thinking about temporary stop-gap prints – we wanted parts to be strong, good quality and look somewhat vaguely professional.

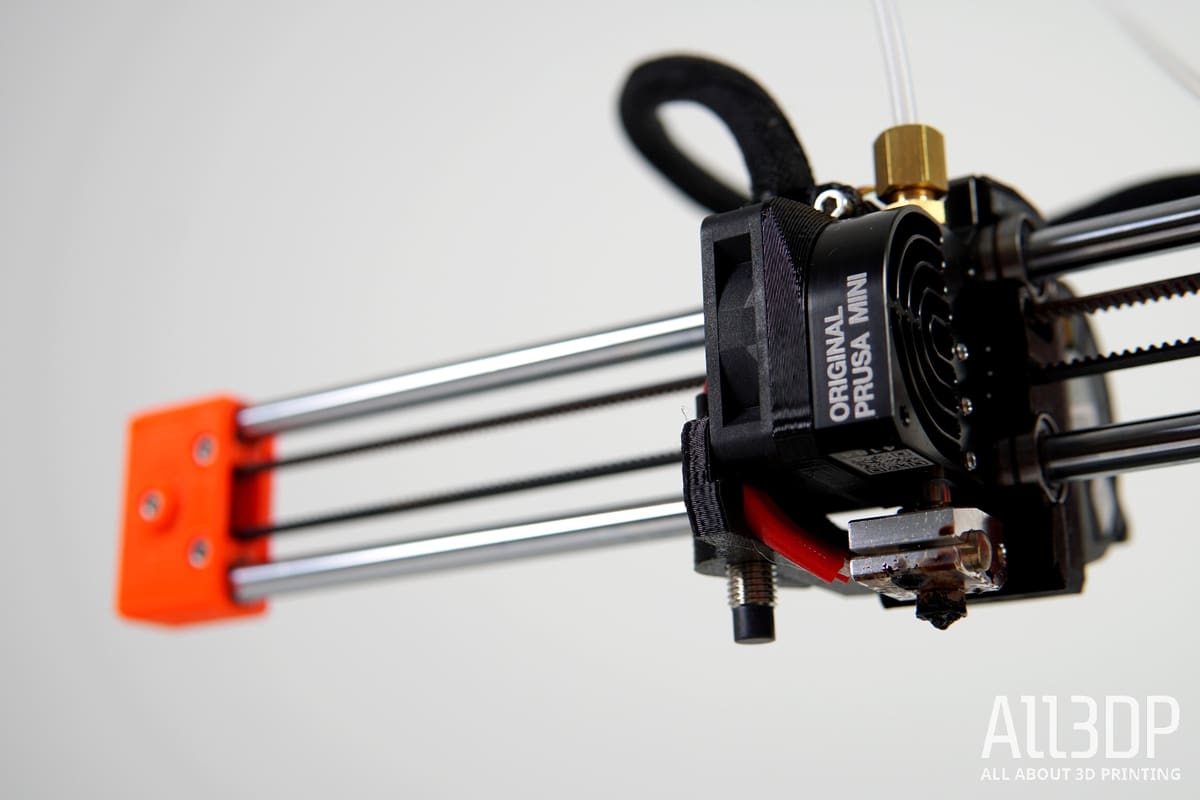

Given the continuation between the Mini and Mini+, we expected to have a similar, if not identical experience with the Mini+ as we did with the original Mini. As it turns out, that’s exactly what we got. Everything performed just as it did before, from the high-quality prints we find typical of Prusa Research’s FDM machines, down to issues with the Bowden tubing the filament feeds through. The keen-eyed reader with a long memory may recall that we encountered this exact issue with the original Mini, too.

Our printing with the Mini+ got off to a solid start, with test prints of a whistle and a bearing provided by Prusa successfully completed with zero fuss. Going off-piste with our own prints was less straightforward and quickly came to a halt with a blockage of sorts preventing the filament from reaching the hot end.

An immovable blockage somewhere between the extruder and hot end had developed. The Mini+ isn’t smart enough to know there’s a blockage – its filament sensor only registers the presence of filament, not movement – and would continue happily on its way, dancing into thin air. A techno-cool centerpiece in the room, but hardly useful. It wasn’t possible to remove the filament from the tube, which temporarily put the machine out of action.

Turning to the Prusa live chat function to see what could be done about this problem, after a few short rounds of troubleshooting the issue was diagnosed and a replacement tube on its way. The diagnosis that there was an internal diameter issue with the tubing was a frank assessment, and shows that despite the slickness of most of what it puts forward, Prusa Research is not infallible – problems do still occur. Fortunately, the company does a stellar job covering itself and its customers with helpful support channels.

After replacing the tube, we’ve encountered precisely zero print issues, with the Mini+ printing off a whole string of useful flat bits and bobs for us in PLA, ABS, and PETG.

Hooks, clips, a shower head holder, an Xbox controller stand, a key rack, and even more clips we’ve already put to use at home all printed off near-perfectly. Flaws only show under certain lighting and scrutiny – that we’ve managed to achieve this kind of quality with near enough no tweaking of the print settings across a variety of materials shows how foolproof the Mini+ is, Bowden tubing grief aside.

We love that the reversible magnetic print bed can be taken back to our desks so we can pop prints free as we gurn at a colleague with that “look what we made face.” Fingerprints will ruin your print bed adhesion though, but it’s easy to clean (use some alcohol – IPA, not your good stuff) between prints.

The ever-excellent Prusa Slicer is simple and easy to use. You can choose from a long list of default material profiles, fine-tune the temperature (Prusa-brand filament profiles are optimized already, needing no further adjustment), and if desired adjust further settings preferred for your print job; slice it, export the file to USB, plug it into the printer, and it will automatically queue up the new job for you to hit “Print”. From there, the printer does the rest, automatically leveling the bed with its new SuperPINDA and getting on with the task. At the time of putting the finishing touches on this review, it’s printing parts for our Mini+ upgrades, again with almost flawless precision.

Is It Worth It?

There are a number of key factors at play here that make this printer an easy recommendation. First, there’s the price. At $349 for the kit version or $399 for the semi-assembled version, it is a good deal for the quality of the product you’re getting.

With its well-finished parts and specification, clear and detailed documentation, and impressive customer support, you’re getting more than just the physical product here. Other manufacturers could do a lot worse than taking note of Prusa’s approach and it leaves us philosophically reflecting on whether we are simply just used to things being relatively poor quality in 3D printers. Prusa Research unquestionably sets the bar high.

Lastly, there’s the print quality. Where it all counts at the end of the day is here on the print bed after several hours of printing. The prints are generally fantastic. Minor grumbles with fine, wispy stringing could be ironed out easily enough with small adjustments in Prusa Slicer.

The Original Prusa Mini+ proved itself a more than worthy companion to settling into a new place, allowing us to just print virtually everything we wanted for the new apartment without having to resort to the pine-scented purgatory of Ikea or the internet. Using the printer is a great experience too – the UI is clear and easy to navigate, and the automatic bed leveling routine baked into every print job means you can just pop your USB stick in, press print, and walk away. Easy.

Is it worth it? Absolutely. This is about as easy as a recommendation can get, although we find it a little damning that of our sample size of two Original Prusa Mini printers, both suffered from similar issues with the Bowden tubing. Others have too. Keep an eye on that.

Features

Much like the new Original Prusa i3 MK3S+, the new Original Prusa Mini+ is a pretty mild update, bring reliability improvements and minor design tweaks, but generally leaving the performance and user experience of the printer untouched.

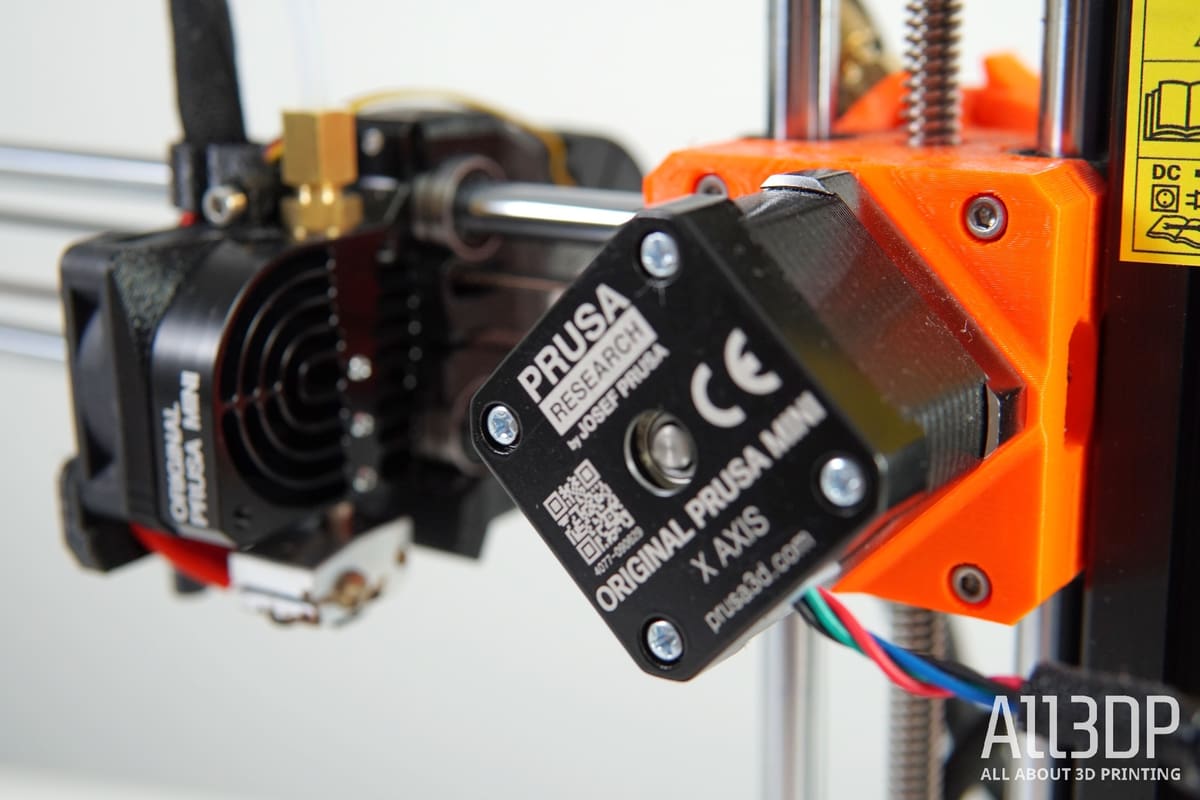

As such, the core features of the printer include, as with the original Mini, a cubic 180 mm build volume, with a cantilever-style open frame design. The print head is fed by a 3:1 geared Bowden extruder, which is mounted to the printer’s frame.

Control and operation of the Prusa Mini+ is, again, handled by the Prusa Research-designed 32-bit “Buddy” mainboard, paired with TMC2209 stepper motor drivers that, as with the larger MK3S+ printer, enable sensorless homing, 256-microstepping, and a very low operational noise. Not to mention the inherent farmability using its RJ45 port.

The printer is, performance and print quality-wise, the same as before.

SuperPINDA Bed Leveling Probe

The most notable improvement to be found on the Original Prusa Mini+ is the inclusion of the Prusa-developed SuperPINDA, an evolution of the PINDA 2 inductive bed leveling probe found on the MK3S. The new probe does away with the inbuilt thermistor (used previously as a measure to offset against the probe’s thermal drift), and increases repeatability and reliability, the company claims.

The SuperMINDA uses better components, and as such is generally thought to be a superior tool for measuring deviances in the print bed – something lacking from the original Mini with its smaller, less durable, and seemingly less accurate mini MINDA inductive probe.

The upgrade should put the Mini+ up to the standard of the MK3S+ for its set-and-forget mesh bed leveling.

Design Changes

A minor change on the Original Prusa Mini+ can be found beneath the Y-axis carriage, with new metal clips fixing the Y-axis bearings to the carriage itself. This change is said to make it a little easier to assemble, which wouldn’t seem all that important (since the Mini shipped in a three-part semi-assembled state), but matters now because the Mini+ is now also available as a full kit.

It’s a Kit!

That authentic kit-experience the Original Prusa i3 series is renowned for has come to the Mini+, with the company promising a similarly informative and easy time assembling the printer from scratch. It’s likely there will be Haribo gummy bears. Great documentation, customer support and a handy live chat function should make this a fun and easy to complete task.

Tech Specs

GENERAL SPECIFICATIONS

- Technology: Fused deposition modeling (FDM)

- Year: 2020

- Assembly: Assembled

- Mechanical arrangement: Cartesian XZ-head

- Manufacturer: Prusa Research

3D PRINTER PROPERTIES

- Build volume: 180 x 180 x 180 mm

- Feeder system: Bowden

- Nozzle size: 0.4 mm

- Max. hot end temperature: 280 °C

- Max. heated bed temperature: 100 ℃

- Print bed material: Removable magnetic PEI spring steel sheet

- Frame: N/A

- Bed leveling: Automatic

- Connectivity: Ethernet, USB

- Print recovery: No

- Filament sensor: Yes

- Camera: No

MATERIALS

- Filament diameter: 1.75 mm

- Third-party filament: Yes

- Filament materials: PLA, PETG, ASA, ABS, Flex

SOFTWARE

- Recommended slicers: PrusaSlicer

- Operating system: Windows, Mac, Linux

- File types: STL, OBJ, AMF, 3MF

DIMENSIONS AND WEIGHT

- Frame dimensions: 380 x 380 x 330 mm (without spool)

- Weight: 11 kg (boxed)

Similar Machines

The Prusa Mini+ is a mighty fine machine, but there are some alternatives to consider too. We’ve slid three in below for your perusal.

If you want to check out even more printers worth your consideration, then why not head on over to our Best Budget 3D Printers or our Best 3D Printers buyer’s guides?

Creality CR-6 SE

The Creality CR-6 SE impressed us during its stay in the All3DP print room. It is basically the luxury model of an Ender 3 V2, and gives you a superb automatic bed leveling system, live Z-offsetting, a quality touchscreen UI and dual Z-axis motors. It delivered in print quality too, and at roughly the same price as the Mini+ but with a bit more build volume, it could be worth a shout.

Biqu B1

For the price, the Biqu B1 is a difficult machine to top. It’s a machine that gives you some impressive features and the scope to expand with upgrades and modifications with plug-and-play ports pre-installed. It has more build volume than the Mini+ here, and a similar bed in that it’s a removable steel sheet, though not quite as good as the Prusa’s. Still, it’s not quite the price of the Prusa either.

Original Prusa MK3S+

If you’re going to have a Prusa, why not have the best Prusa? Or the best 3D printer, for that matter? For our money, that’s the MK3S+. It’s starting to feel a little bit dated now, particularly when you compare UI’s between this and the Mini+, but it’s an intelligent, feature packed 3D printer that’s easy to use and produces fantastic prints.

License: The text of "Original Prusa Mini+ Review: Best Small 3D Printer" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.