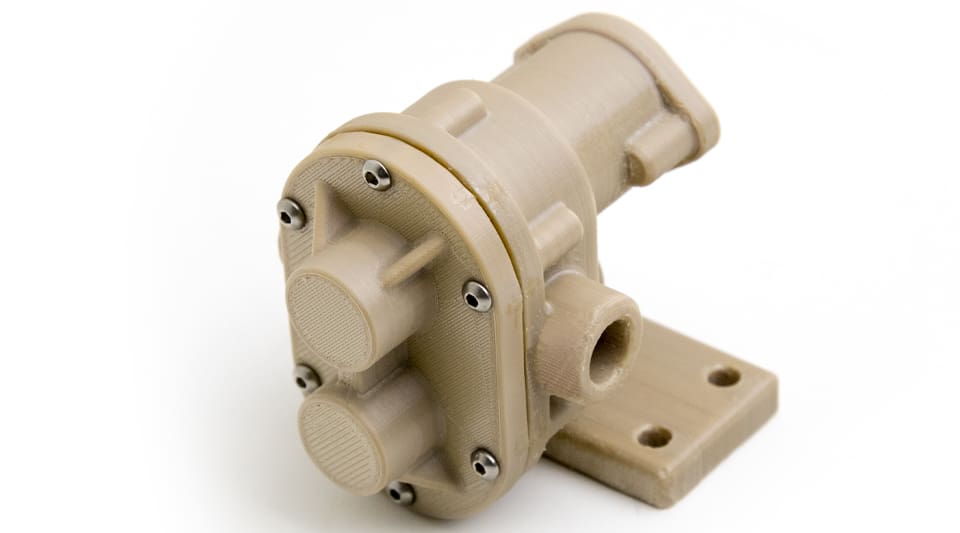

Prized as a polymer that can replace metal in many applications from aerospace to implants, PEEK (poly-ether-ether-ketone) is one of the most popular thermoplastics in manufacturing and for good reason. It can produce parts stronger and lighter than stainless steel and aluminum with extremely high thermal, chemical, and wear resistance, plus it’s biocompatible. Parts made from this engineering-grade material can be found in virtually every industry.

PEEK is also ideal for parts in electrical engineering due to its electrical insulation properties, and it’s widely used in applications requiring long-term resistance to pressure and wear, such as in the oil and gas industry.

It’s no wonder we’re seeing more 3D printed PEEK parts replacing metal in spacecraft, orthopedic implants, and even engine parts in high-performance auto racing.

Popular PEEK Applications

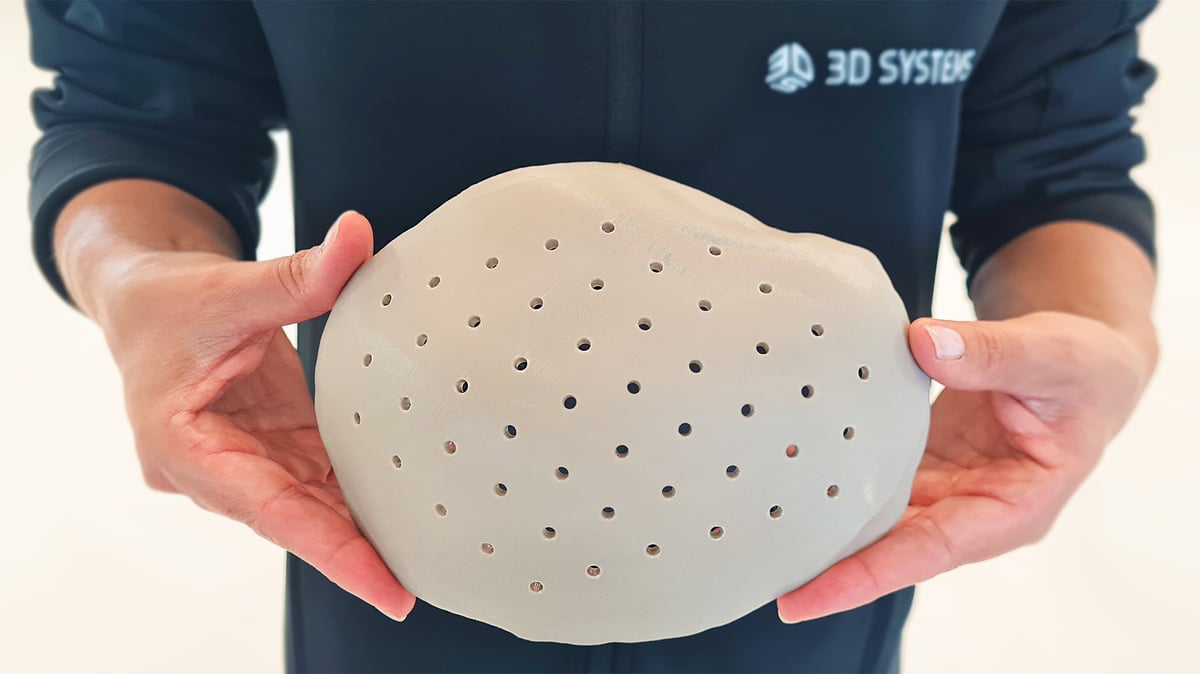

- First 3D Printed Spinal Implants in U.S.: Curiteva’s 3D printed implant, made with Evonik’s VestaKeep i4 3DF PEEK filament, was surgically implanted into a patient in April 2023 — the first of its kind in the U.S. The device, which received FDA 510(k) clearance, was the first 3D printed porous PEEK structure approved for commercial use.

- Nvision Biomedical Technologies’ 3D printed Spine Implant Cleared by FDA: In Sept. 2024, the first 3D printed spinal implant fabricated from Invibio Biomaterial Solutions’ PEEK-Optima polymer received FDA clearance.

- 3D-printed PEEK-based Cranial Implants Cleared by FDA: The VSP PEEK Cranial Implant system, which includes a complete FDA-cleared workflow comprising segmentation and 3D modeling software, a printer developed by 3D Systems, and PEEK resin from Evonik, wins FDA clearance in April 2024.

3D Printers Tuned For PEEK

At the same time, demand for 3D printers that can work with this material is growing, which has prompted manufacturers to produce increasingly affordable, larger, and easier-to-use PEEK printers for businesses looking to bring production and prototyping in-house.

Although PEEK is still among the costliest additive manufacturing polymers (yet cheaper than most metals), and it’s not the easiest to work with, it is far more accessible today than ever before. If you’re new to PEEK (and other polymers in the PEAK family), skip to the end to learn more about this sought-after and functional material.

Now, let’s look at how to pick the best PEEK 3D printer for you and our picks for the top machines in various sizes and price points, from office-friendly desktop versions to large-volume production machines.

| PEEK 3D Printer | Build Volume (mm) | Technology | Approx. Price | Max. Extruder Temp. | Max. Bed Temp. | Max. Chamber Temp. | Min. Layer Height |

|---|---|---|---|---|---|---|---|

| Intamsys Funmat HT | 260 x 260 x 260 | FDM | $7,500 | 450°C | 160°C | 90°C | 50 microns |

| CreatBot PEEK-300 | 300 x 300 x 400 | FDM (dual extruders) | $18,000 | 500°C | 200°C | 120°C | 40 microns |

| Orion AM A150 Series | 150 x 150 x 150 | FDM | $60,000 | 500°C | 300°C | 315°C | 20 microns |

| 3DGence Industry F421 | 380 x 380 x 420 | FDM (dual extruders) | $72,000 | 500°C | 180°C | 195°C | 50 microns |

| MiniFactory Ultra 2 | 330 x 180 x 180 | FDM (dual extruders) | $75,000 | 480°C | 250°C | 250°C | 100 microns |

| Aon3D Hylo | 450 x 450 x 640 | FDM (IDEX) | $120,000 | 500°C | 200°C | 135°C | 50 microns |

| 3ntr Spectral 30 | 300 x 300 x 300 | FDM (quad extruders) | $135,000 | 500°C | 300°C | 250°C | 100 microns |

| 3DXTech Gearbox HT2 | 457 x 457 x 810 | FDM (dual extruders) | $140,000 | 500ºC | - | 250ºC | 100 microns |

| Stratasys Fortus 450mc | 406 x 355 x 406 | FDM | $160,000 | 450°C | 250°C | 350°C | 130 microns |

| Roboze Argo 500 | 500 x 500 x 500 | FDM | $250,000 | 450°C | 150°C | 356°C | 10 microns |

| 3D Systems EXT 220 Med | 180 x 150 | FDM (3-Axis Delta) | - | 500°C | 300°C | 250°C | 200 microns |

| Orion AM M150 | 150 x 150 x 150 | FDM (3-Axis Delta) | - | 500ºC | 300ºC | 300ºC | 20 microns |

Not All Printers Can Print PEEK

A spool of PEEK filament may look like any other 3D printing plastic, but put it in a consumer machine and you’ll quickly realize that this material needs something more; specifically, more heat.

You not only need to extrude PEEK with a super-heated nozzle (300+ ºC), but you also need to keep it hot with a heated bed and chamber. A couple of 3D printers go beyond a heated bed and chamber, with technology that heats the PEEK part itself. Localized heating of the part, as well as a heated chamber to control the crystallization, improves the interlayer adhesion, according to Brian Alexander, polymer scientist and 3D printing PEEK expert at Solvay Specialty Polymers. The heat needs to be consistent and controllable since how quickly you let the final part cool down also makes a difference.

Recently, Alexander and his team put the Orion 3D printer to the test and found that its thermal radiation heating, which heats the material (not the air) to 320°C, produces PEEK prints with better than injection molded quality even on the Z axis.

Print speed and layer height are important factors in a successful PEEK print. Fortunately, the better PEEK printers will automate many of these settings for a more worry-free experience.

The material data sheet that comes with you PEEK filament usually provides an ideal print speed, which is typically about 15-45 mm/s depending on the brand. Many of the printers we feature in this guide make high-speed claims of 400-500 mm/s, but know that PEEK simply can’t be printed at that speed. Other engineering-grade materials can.

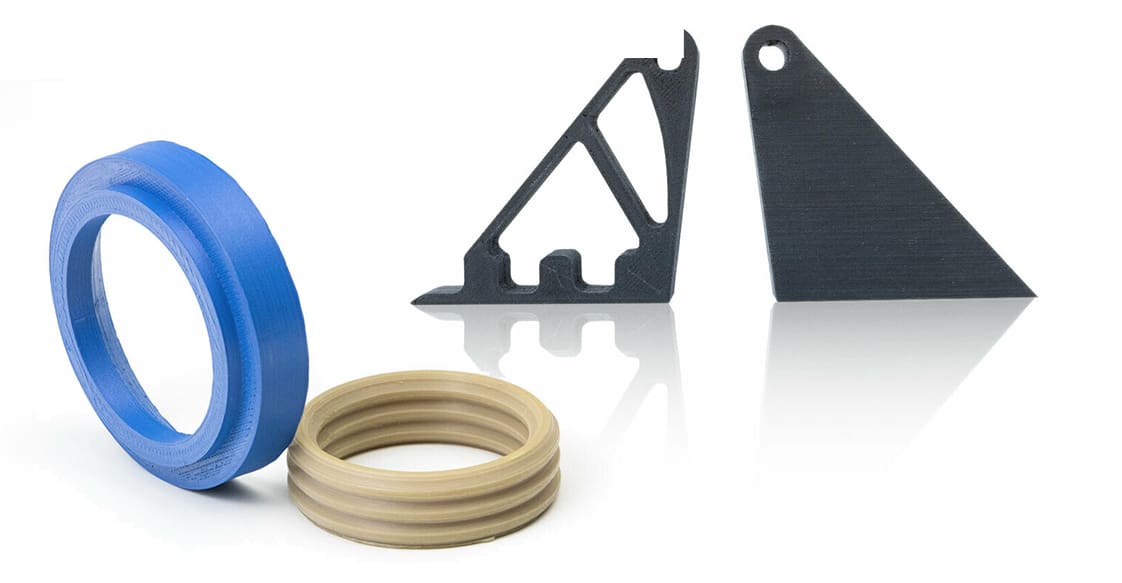

Although most PEEK is 3D printed using FDM printing with rolls of filament, more recently, PEEK is making headway in more economical pellet form and as a powder for selective laser sintering (SLS) 3D printers although SLS is not commonly used for PEEK.

PEEK Printers Can Print More Than PEEK

No 3D printer on our list is a one-trick pony; if they can print PEEK, they can handle other high-performance polymers with similar print perimeters and a need for high heat, such as PEAK, PEKK, PEI/Ultem, PPSU, and others. Of course, they can handle regular ABS and even PLA if you can turn the heat down low enough.

What To Look For in a PEEK Printer

Not all PEEK printers are the same, of course, and you’ll need to balance your budget with the features you need in a printer and the ones you might be able to live without. If you only need PEEK parts occasionally or aren’t sure you even need PEEK at all, try ordering your PEEK parts from a 3D printing on-demand service bureau, such as Craftcloud.

Below are some of the top features of the PEEK printers on our list.

- HEPA filter to trap harmful fumes and particles

- Insulated chamber so the heat doesn’t warm up your workshop or leak heat from the machine

- Rapid heating chamber so you’re not waiting an hour or more to start printing

- Dual extruders so you can print support material in something other than PEEK, such as a soluble material, for cost savings and easier removal

- Integrated filament dryer so your PEEK material is always ready to go

- Controlled cool down to prevent warping

- Camera embedded for continuous print monitoring

- Power outage protection that resumes the print from where you left off

- Sensors to detect whether you have enough filament to complete the job

- Sensors to detect a filament jam

Desktop / Benchtop 3D Printers

The following printers are small enough to fit on a desktop and can print small parts, batches of small parts, and prototypes. These versions may lack some of the bells and whistles of their larger cousins but can still produce metal-like parts with all of the characteristics you print with PEEK for. These machines could be considered more office-friendly in the sense that they’re small, but you’ll still want to follow proper safety and ventilation procedures.

Intamsys Funmat HT

The Funmat HT is Intamsys‘ starter machine (they have larger ones, too). As a desktop 3D printer, it offers a variety of features that are typically limited to more advanced, industrial-grade machines, which makes it a great intro to PEEK printing. It has an insulated chamber for constant temperatures up to 90°C, and a filament alarm, warning the user when the filament is about to run out. Funmat HT has a built-in camera, so users can monitor their print remotely. In addition to PEEK, it can print in PEI, nylon, PPSU, Ultem, and ABS.

Intamsys’ larger workshop offerings for PEEK printing include the new Funmat Pro 310, the existing Pro 410, and the larger Pro 610 HT. Intamsys’ 310, is also a desktop size but offers a new thermostatic print chamber (up to 100°C) and larger build volume (305 x 260 x 260 mm) than the HT.

The 410 is a larger version of the HT with a nozzle that can get a bit hotter. It features dual nozzles, a heated filament box, power failure recovery so you can pick up where you left off with a print, a liquid cooling system for more consistent temperature control, and something the company calls over-heat protection.

The Pro 610 HT machine offers everything on the 410 but a massive build volume (610 x 508 x 508 mm) and time-saving features like automatic bed leveling, auto-cleaning nozzles, filament monitoring, and WiFi connectivity.

All Intamsys printers are open-material machines so you can choose your filament brand and type.

Learn more

CreatBot PEEK-300

CreatBot offers the PEEK-300 3D printer that can produce parts in a wide variety of high-performance materials, from PLA and TPU to nylon, Ultem, PVA, and of course PEEK, plus about eight others. Its dual extruders come in handy for printing support materials.

CreatBot offers more than half a dozen printers but launched the PEEK-300 in 2019 to address the growing demand for printers with the features, such as a superheated hot end, print bed, and chamber, that can produce parts in this demanding material.

The PEEK-300 also offers a build platform with a carbon fiber sheet for easier part removal and a HEPA air filtration to absorb impurities and gases that are generated by printing polymers at high temperatures. The machine features what the company calls its Direct Annealing System which is a post-print heat treatment in the printer with no need for a secondary treatment in oven.

The company’s smaller CreatBot F430 also prints with PEEK, although it doesn’t get quite as hot.

Orion AM A150 Series

Orion AM’s passion for PEEK 3D printing led the company to develop technology that heats the print from all directions up to 300°C, in addition to maintaining a heated chamber and featuring a super-heated nozzle.

The company’s patent-pending Thermal Radiation Heating Technology penetrates through the material, allowing the layers to truly fuse together so parts are more uniform in strength and density, the company says. The radiation heating not only keeps the material at an elevated temperature preventing shrinkage and warping, but more importantly, allows semicrystalline materials like PEEK time to form the crystalline structures that give them their superior mechanical properties.

The results are in industrial-grade parts with injection molding strength, Orion AM says. In two recent studies, one conducted with material maker Solvay and the other with material maker Evonik, parts from Orion AM’s M150 tested better for strength than injected molded parts, even on the Z axis.

The single-extruder A150 prints with a range of high-performance polymers including ULTEM, PPSU, PA6, PA12, and others, in addition to PEEK. Some other features of the A150 include a modular removable printhead, a removable build plate, and a 7-inch touchscreen display.

Shop Floor 3D Printers

For PEEK printing in a more industrial capacity, these printers should do the trick. They require a little more expertise to get running (and sometimes a lot of space), but they’re designed to be efficient and come with a lot more features and build volume.

3DGence Industry F421

Industrial 3D printer manufacturer 3DGence offers three PEEK-enabled machines, the smaller Industry F340, and the newer Industry F421 and Industry F350.

A distinguishing feature of 3DGence machines are their swappable print-head modules that you can change depending on which engineering-grade material you want to use. This feature enables you to print with everything from PLA to reinforced materials to PEEK on a single machine without having to clean out your print heads. Very convenient.

The F421’s build chamber is actively heated via forced convection to maintain a toasty 180°C. At this temperature, it’s important to have adequate emissions control. F421 filtration system can eliminate macro dust, nano dust (VOC, UFP), solvent vapor, noxious gasses, and foreign particles.

The F421 is a high-speed PEEK printer boasting a print speed up to 400 mm/s and 1 meter per second of travel time. Like other industrial printers at this level, the F421 offers a heated filament dryer, automatic bed leveling, a heated ceramic build plate, and interconnectivity. There’s also a convenient material manager that automatically detects which filament is loaded and checks information, such as weight, type, color, and amount of remaining filament loaded.

If you need even larger PEEK parts, 3DGence is planning to launch the Industry F1000 (build volume (1,000 x 600 x 800 mm) soon , stay tuned.

MiniFactory Ultra 2

MiniFactory – not to be confused with the 3D model platform MyMiniFactory – is a 3D printer manufacturer focusing on industrial high-temperature 3D printers. Its Ultra 2 printer has an open material system that can handle a range of thermoplastics and features automatic calibration, automatic and integrated post-processing, plus quality assurance technology to detect errors on the spot. The Ultra 2 offers 120 mm/s print speeds, which the company claims is twice as fast as the original Ultra. The build volume remains the same at 300 x 180 x 180 mm.

The smart heated chamber can reach temperatures of up to 250 °C and there’s a remote-control system with a live feed of the extruder, chamber, and bed temperatures to help make the production ecosystem manageable for a single user. It’s possible to monitor which layer is currently being printed and when the process should complete.

The machine also features servo motors, ball screws, and linear guides to ensure large, dimensionally accurate, and reproducible prints. Additionally, there’s a pause and abort option controlled remotely.

The Ultra 2 can store validated printing parameters on a digital document, giving manufacturers a reliable part recipe that can be followed on any miniFactory Ultra 2, anywhere. With its predecessor, data transfer functioned with USB in the Basic model or a WiFi or LAN connection in the optional Security model.

MiniFactory says their technology is designed for daily industrial use and offers a warranty of up to five years.

Aon3D Hylo

Aon3D is another industrial FDM maker that believes software and “machine learning-assisted process optimization” along with in-process monitoring and inspection, is the future of industrial 3D printing.

The company’s flagship FDM, Hylo, is powered by software called Basis that enables you to slice, simulate, optimize, then print. Hylo has more than 25 integrated sensors for automated calibration, process control, and monitoring the print process to validate parts as they print. After printing, you can review the various data points of your as-printed part with its digital twin.

Basis also manages and monitors all of your Aon3D printers, projects, users, revisions, optimizations, and as-printed part data in one user interface.

Aon3D says its software replaces trial and error printing with AI-driven process simulation and digital file optimization. Basis can simulate the Hylo printing process, enabling you to identify and correct issues before ever hitting print.

For hardware, Hylo has dual independent extruders designed for a range of applications including tooling, jigs and fixtures, end-use parts, and rapid prototyping using high-performance thermoplastics. It features an open-material environment, so it’s compatible with a wide range of material brands, including Solvay, Sabic, DSM, Infinite Material Solutions, and others, and comes with validated print profiles for them.

In addition to open materials, there’s open parameters so you can fine tune various processes, temperatures, and motion settings.

3ntr Spectral 30

The Spectral 30 FDM 3D printer from 3ntr is an industrial high-temperature unit with four print nozzles. Why would you want four nozzles? The convenience enables you to print with PEEK and a soluble support material then switch to other materials, such as Ultem, without having to remove them from the four heated filament chambers and store them elsewhere.

The printer’s carbon printing plate with coating can be heated up to an impressive 300°C, and after the print is finished, the plate is simply removed with an easy magnetic locking mechanism. The Spectral 30 can process a wide variety of materials, including ABS, PC, PETG, Ultem, PEEK, and PPSU.

Other features include auto bed leveling, an integrated cooling unit, and a plugin that contains the profiles of materials qualified for the device by the manufacturer. All you have to do is select the desired material or the desired material combination, and the optimized settings for the 3ntr 3D printer are adopted. In addition, the Spectral has an automatic material recognition of all 3ntr materials.

The machine can reach a chamber temperatures for Ultem in less than 30 minutes while the nozzles can touch peak temperatures in less than 3 minutes.

The Spectral 30 takes filament drying and storage seriously, with the Vento filament drying module equipped with a 600W fan and space for 5-kg reels. The dryer has a monitor that detects the condensation point and, after the initial trying treatment, gradually reduces humidity and maintains it at 5%.

For larger prints, 3ntr offers the Sequoia with a build volume of 1,200 x 1,100 x 900 mm. There’s also the smaller and faster Veltra with a print area of 600 x 400 x 600 mm.

3DXTech Gearbox HT2

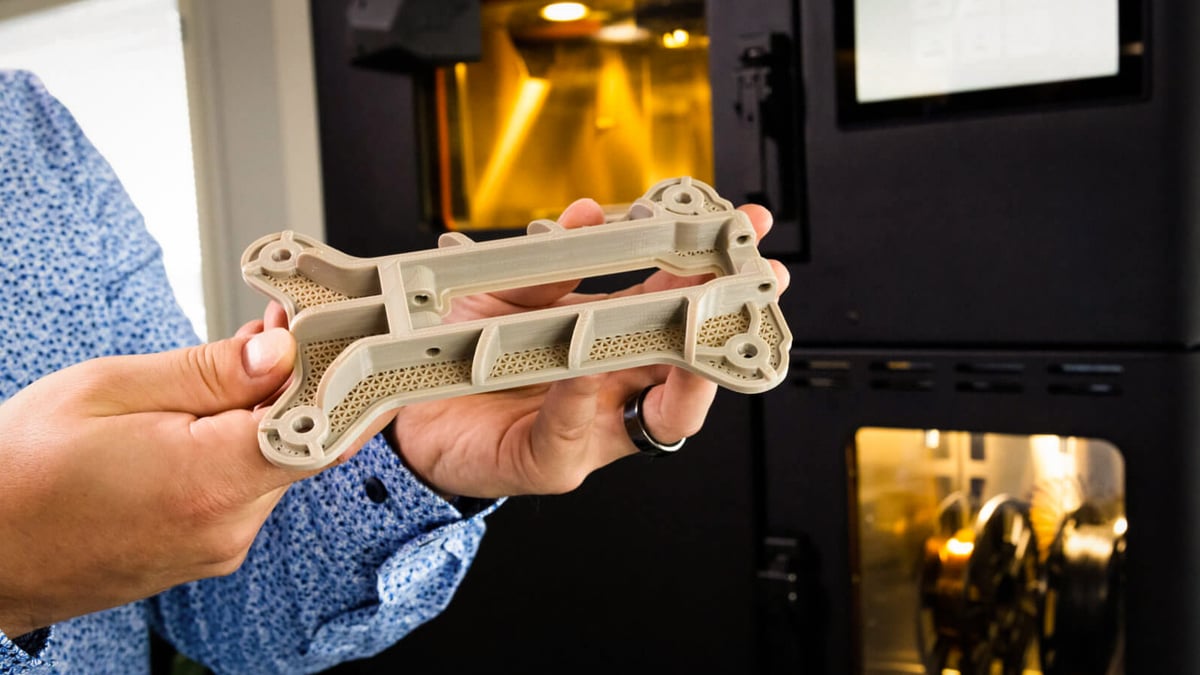

3DXTech is firstly a material manufacturer that offers its own PEEK materials but moved into FDM 3D printer design in 2018 to offer a machine it says is tuned specially for high-temperature materials like PEEK and Ultem, the Gearbox HT2.

The Gearbox HT2 is a large format dual-extrusion printer with a 7-inch touch control screen, four actively dried filament bays, and an on-board air compressor, so there’s no shop air needed to operate the printer.

In addition to hot, the HT2 is fast, and can print at up to 300 mm/s. There are servo motors and and open material systems. 3DXTech says the HT2’s bed is not actually heated but kept at temperature from the active chamber heating, similar to the Stratasys Fortus.

Stratasys Fortus 450mc

Stratasys industrial FDM 3D printers produce parts with their own PEKK material called Antero 800NA and Victrex AM 200, a PEEK-based material.

The Fortus 450mc and the F900 – the company’s two ultra high-temperature machines – are not open materials printers but that may not be the drawback it appears since Stratasys engineers have well-tested print perimeters for Antero on the Fortus 450mc and the larger F900 machine to ensure as close to error-free prints as possible. The F900 offers over 25 Stratasys Preferred and Validated Materials.

Fortus 450mc is one of Stratasys’ most popular printers widely used for printing Nylon and often in a production environment. It comes with integrated GrabCAD software that enables you to print directly from CAD formats and fine-tune part performance and material use for greater cost efficiency.

The F900 can be bolstered with an acceleration kit delivering faster print speeds.

Roboze Argo 500

Roboze is a 3D printer manufacturer that specializes in high-temperature machines with several PEEK-compatible options: the industrial Argo 500, Pro Plus (300 x 250 x 220 mm) and enormous Argo 1000 with a build volume of 1,000 x 1,000 x 1,000 mm.

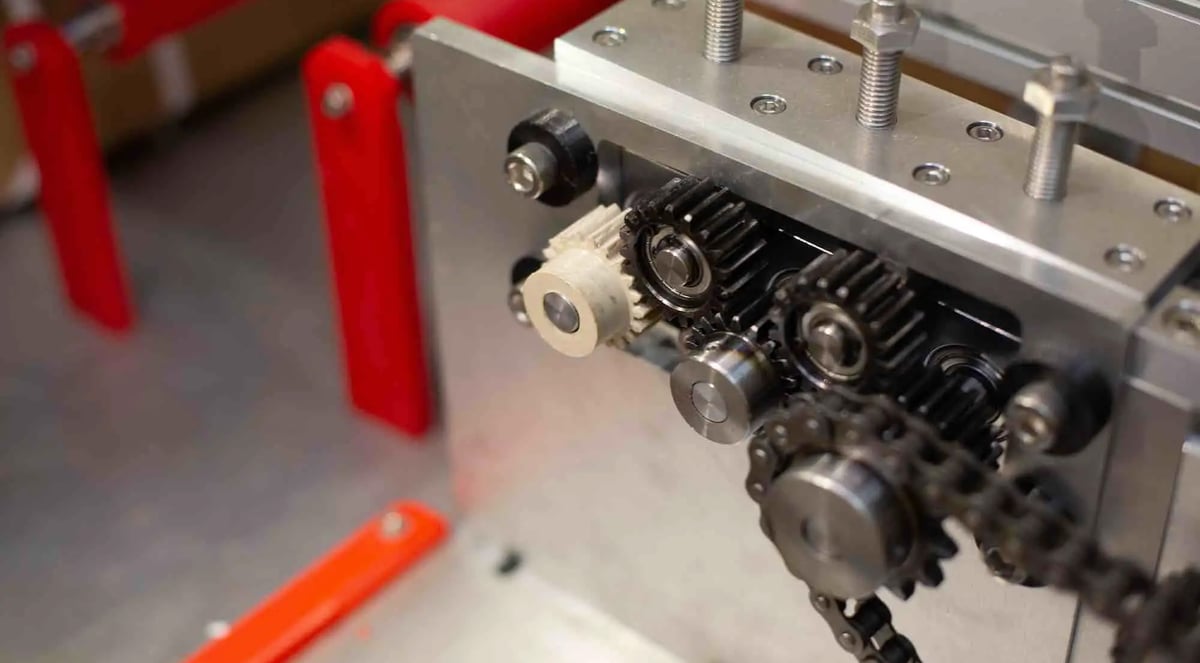

All Roboze machines feature what the company calls its Beltless System. By eliminating the rubber belts typically used in 3D printers and introducing a patented movement with gears, Roboze says its printers can deliver better accuracy (mechanical precision of 10 microns) and repeatability.

Argo 500 has been designed to produce high-performing PEEK, the company says, due to its monitoring the management of the material, from hygroscopic control to drying and preheating, up to the gradual cooling phase of the produced part.

The machine also has remote control to allow printing and status monitoring functions.

Speciality Medical PEEK 3D Printers

PEEK is a useful material for medical applications because it’s biocompatible, sterilizable, and lightweight relative to its strength. It can be used for prostheses, implants, and other products. Tens of thousands of people are walking around with PEEK implants. Although most of those haven’t been manufactured with 3D printing, it’s gaining ground among methods because it wastes less material and can be done in hospitals or at the point of care.

According to new market research by Consumer Patterns, the medical PEEK implant market size, which was valued at $1.5 billion in 2022, is projected to double to reach $3 billion by 2030.

A PEEK implant is very similar to the human bone in mechanical stiffness and elasticity and promotes osseointegration with bone. Since it’s also radiolucent, it is suitable for radiological diagnostics and therapeutic radiation technology. It has insulating properties and is less susceptible to temperature effects and doesn’t heat up like metal implants.

Medical-grade implantable and 3D printable PEEK is only available from specific polymer makers, including Evonik and Invibio.

Although most of the other printers in this guide can also be used to print PEEK items for medical or healthcare purposes, the following machines are specifically designed with this application in mind and carry the necessary medical certifications.

“Through AI-driven simulations and 3D modeling, engineers and healthcare providers can create precise, patient-specific implants that are more likely to fit perfectly, improving both patient comfort and surgical outcomes,” according to market research by Consumer Patterns.

3D Systems EXT 220 Med

3D Systems’ medical PEEK 3D printer (formerly known as the Kumovis R1) is designed for medical applications, such as implants. It has an adaptive local temperature management, so it can heat the current layer as well as maintain a consistent chamber temperature.

The 220 Med features a printing speed of 100 to 3,000 mm/s, auto bed-leveling, and an open-materials system. The printer uses Hyperganic’s Voxel-based slicing software and has Ethernet and USB connectivity.

It also has a patented temperature management system to homogeneously heat the build chamber and improve layer adhesion. You can turn the chamber into a clean room and get an optional HEPA filter upgrade to further ensure a clean environment. This will help prevent defects from particles that shouldn’t be in the chamber.

What’s more, the 3D printer is “clean room ready” for production in existing cleanroom environments and can be cleaned to medical standards. The printer is available through direct sales or as a subscription model. Build chamber fulfills ISO class 7 cleanroom requirements according to DIN EN ISO 14644.

Orion AM M150

Orion AM’s M150 system is designed with medical applications in mind. All internal components are made from medical grade, clean-room compliant materials to ensure that it meets medical industry standards and sterilization needs. The M150 works with medical-grade materials such as PEEK, PAEK, PEKK, PPSU, PC, and LCP.

Features like thermal radiation heating allow the print to heat evenly up to 300 °C. The heating chamber provides continuous thermal radiation throughout the printing process, improving fusing and bonding between layers, as well as the mechanical strength of parts.

Before introducing their 3D printing technology into the medical field, Orion’s team prepared for 18 months for the MedTech qualification.

PEEK Explained

What is PEEK?

The U.K.-based company Imperial Chemical Industries (today known as Victrex) introduced polyetheretherketone (PEEK) back in the 1980s. In its basic form, this material is a semi-crystalline, high-purity polymer comprising repeating monomers of two ether groups and a ketone group.

PEEK belongs to the polyaryletherketone (PAEK) family of polymers that also includes PEKK (Polyetherketoneketone) but outshines the others because it can operate at higher temperatures and retain its excellent mechanical properties at continuous-use temperatures up to 240°C (464°F), allowing it to replace metal in severe end-use environments.

PEEK is one of the few plastics compatible with ultra-high vacuum applications, which makes it suitable for aerospace, automotive, and chemical industries.

Not all commercial PEEK products deliver the same level of performance. You’ll find PEEK filament from a wide range of manufacturers, but be sure to check the technical specifications and data sheets to ensure you’re getting all of the PEEK qualities you require. Talk to your supplier about density and strength.

Specialty polymer makers, such as Solvay and Evonik, make PEEK especially for additive manufacturing and can advise you on the best ways to print their specific materials.

PEEK Powder for SLS 3D Printing

Selective laser sintering (SLS) is another 3D printing technology that can be used for PEEK. It promises a better surface finish, although adoption has been limited because there are very few vendors of PEEK powders and it’s difficult to print using SLS technology. SLS 3D printer maker EOS introduced a PEEK powder in 2010 but has since shifted focus to other polymers.

Top PEEK Filaments

When shopping for a PEEK filament, first consult your printer maker. Certain 3D printers have been tuned to perform with a specific brand. In other words, there’s a “print profile” for a specific brand of PEEK. Although some brands may promote one feature above others, nearly all PEEK products are biocompatible, flame retardant, and food safe to a degree, but some have certifications and others may not.

Some brands publish an ideal extruder temperature, while others say it depends on your machine. In any case, look for a material with a full data spec sheet and printing recommendations. Prices for 1kg of PEEK range from $350 to $675.

In 2023, Evonik launched the world’s first carbon-fiber reinforced PEEK, Vestakeep iC4620 and 612, for medical implants, and Invibio Biomaterial Solutions, a part of Victrex, launched PEEK-Optima AM Filament for medical implants.

Do You Even Need PEEK?

PEEK has many compelling features, especially when it comes to producing functional prototypes and parts for regulated industries, but it is expensive and difficult to work with, so you may ask yourself: Do I really need to print with PEEK?

Let’s look at the pros and cons:

PROS

- Highly resistant to extreme temperatures up to 260°C (480°F), as well as corrosive fluids, gases, and high pressure

- Insoluble in common solvents, preventing it from hydrolysis and allowing it to be used without any degradation from high-pressure water or steam

- Lightweight: PEEK has an inherently low specific gravity of 1.3 g/cm3, less than half that of aluminum and one-sixth that of steel

- High self-lubrication ability and low friction

- Outstanding creep resistance

- Very little attrition

- Good dimensional stability

- Low flammability and little smoke emission when combusting

- Exceptional insulation properties

- Excellent sterilization resistance at high temperature

- Fully bio-compatible

- Food-safe and resistant to oils and animal fats

CONS

- Has to be processed at very high and consistent temperatures

- More expensive than most other filaments

- Low resistance to chlorine/bromide, concentrated sulfur, and nitric acids as well as Keteons and Nitrobenzene. PEEK also gets attacked by halogen and sodium, limiting its use in certain industry fields

- Low resistance to UV light

- PEEK filament is highly hygroscopic and must be stored carefully and dried before use

- PEEK is prone to warping and dimensional shift during printing if heat is not precisely controlled

Some of the warping, shrinkage, and difficulty printing with PEEK can be alleviated by combining PEEK with composite materials, such as glass fiber, graphite, or carbon fiber reinforcements. Post-print annealing can also boost your part qualities. PEEK’s low UV resistance can be worked around by adding a layer of pigment that consists of special soot particles. Carbon-filled grades provide improved UV stability and can be used in certain applications that require greater UV resistance.

Alternatives

If your part doesn’t require all the qualities of PEEK, consider these alternatives that are easier to print with and lower cost.

PEKK is also part of the same polyaryletherketone family of semicrystalline polymers as PEEK but requires a lower processing temperature and has a wider processing window, which makes it easier to print. PEKK is a bit more elastic than PEEK with good shock absorbance.

Ultem offers similar properties to PEEK but at a much lower cost and is also easier to process at lower temperatures. Ultem has weaker friction and wear properties than PEEK. Ultem is the trade name for polyetherimide (PEI).

Carbon-fiber reinforced Nylon doesn’t offer nearly the strength or chemical resistance of PEEK, but it is still an exceptionally strong material commonly used for jigs, fixtures, tools, and a host of other industrial applications.

Tullomer is brand new polymer developed by Z-Polymers in 2024. It’s marketed it as a replacement for aluminum, steel, and advanced polymers, such as PEEK, PEKK, PAEK, and Ultem (no annealing is required).

Referred to as a “super-polymer” or a “3D-printable Kevlar,” what exactly Tullomer is made of is shrouded in a bit of secrecy and intellectual property protection. That said, Tullomer has extremely high stiffness and strength but the mechanical properties can vary with changes in extrusion temperature, extrusion speed, and layer height. This mean parts can be designed to have variable properties in different areas all using the same material (as long as your 3D printer can vary these properties while printing.)

Tullomer is reported to have better chemical resistance than PEEK, it’s half the weight of aluminum, and it’s inert, non-flammable, and radio-transparent. It’s also $500 for 1 kilo. Evonik Infinam PEEK 9359 is just over $500 per 1 kilo, while KetaSpire PEEK from Syensqo retails for over $800 per 1 kilo.

What is PEEK Annealing & Why You May Need It

Annealing is a heat-treatment and common post-processing method for PEEK that can improve a part’s material density. However, material scientists disagree about whether it’s essential for every part and whether it contributes at all to a part’s mechanical properties. It’s not a process unique to additive manufacturing as it’s used in injection-molded PEEK, too.

PEEK, as we mentioned, needs high heat to process, but it also needs the heat to change its very mechanical nature. How much heat and for how long your specific part needs isn’t also easy to calculate. Look to your printer manufacturer for print profiles and guidance, but certainly, you’re looking at a bit of experimentation in any case. Some printer makers say their machines achieve high enough temperatures during printing so as to change the chemical nature of the PEEK, so annealing as a post-processing step simply isn’t necessary.

Annealing also has its downside, according to Alexander at Solvay. “If you anneal you are shrinking the part as it crystallises so you are either going to get warpage or voids, which can lead to delamination. All polymers shrink during crystallisation but the difference between AM and injection moulding is that you apply a back pressure in injection moulding which removes the voids and you can design for the shrinkage.” Alexander notes that there are some tricks and tips to get around the warpage and voids in additive manufacturing as well, but he doesn’t recommend annealing.

Truly understanding PEEK requires knowing about material science concepts of crystallinity and folded polymer chains and more nuances than we’re going to dive into here. Just know that your printer may include an annealing setting or a list of annealing options you can follow, such as letting the component cool down at exactly 10 °C per hour up to 140 °C or leaving the component at 200 °C for one hour for every millimeter of wall thickness.

If you want to learn more about annealing, the folks at Aon3D have a great blog post: PEEK – Best 3D Printing Temperatures to Maximize Crystallinity.

3D Printing Tips for PEEK

Now that you have a thorough overview of PEEK, maybe you want to start printing with it yourself. Here are a couple of basic tips and tricks to keep in mind when 3D printing with PEEK:

Consistent temperature

PEEK does not react well under fluctuating or unstable temperatures. Therefore, a printer with a heated chamber is strongly recommended, if not essential. To get the best results while 3D printing PEEK, keep the 3D printer in an environment that undergoes minimal temperature changes, away from solar radiation and heavily trafficked areas.

Watch out for specks

Sometimes, you may notice black specks when printing with PEEK. Although this may have a number of different causes, the most common explanation is the impurity of the printing material used or that the 3D printer is having trouble processing the required temperatures.

Keep the nozzle clean

You should always clean the nozzle after the printing process is completed. All leftover material should be removed from the nozzle, or it may become blocked and eventually lead to specking (mentioned above).

Watch out for failed crystallization

Sometimes, when printing with PEEK materials, improper crystallization may occur. If parts of the print vary in color, such as a brownish discoloration as opposed to a default beige color, this could indicate improper crystallization. It can be caused by a fluctuating temperature during the print process.

Store filament in a dry place

When you’re not 3D printing with PEEK, you should keep the material stored in a cool, dry, and dark place until you use it again. By doing this, you will preserve the quality of the material and ensure that you will achieve optimal results.

PEEK Parts On-Demand

Not ready to take the plunge into buying your own 3D printer for PEEK parts? On-demand additive manufacturing is available for your PEEK and PEKK needs. If you’re new to this material or to additive manufacturing, experimenting with a few parts printed at a contract manufacturer may be the best way to prove your concept.

Many of the larger on-demand printing services offer PEEK printing and you may also find it’s an option alongside injection molding from manufacturers who specialize in high-temperature polymers.

Craftcloud, the 3D printing marketplace, provides instant quotes on your PEEK part from a range of manufacturers.

One start-up developed its own PEEK 3D printer, software, design approach, and patented technology to offer PEEK parts as a service. Bond3D specializes in helping companies design and create PEEK parts. It says that its pressure-controlled printing technology can produce completely solid, voidless parts that are stronger than other technology.

License: The text of "PEEK 3D Printer Guide & All You Need to Know" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.