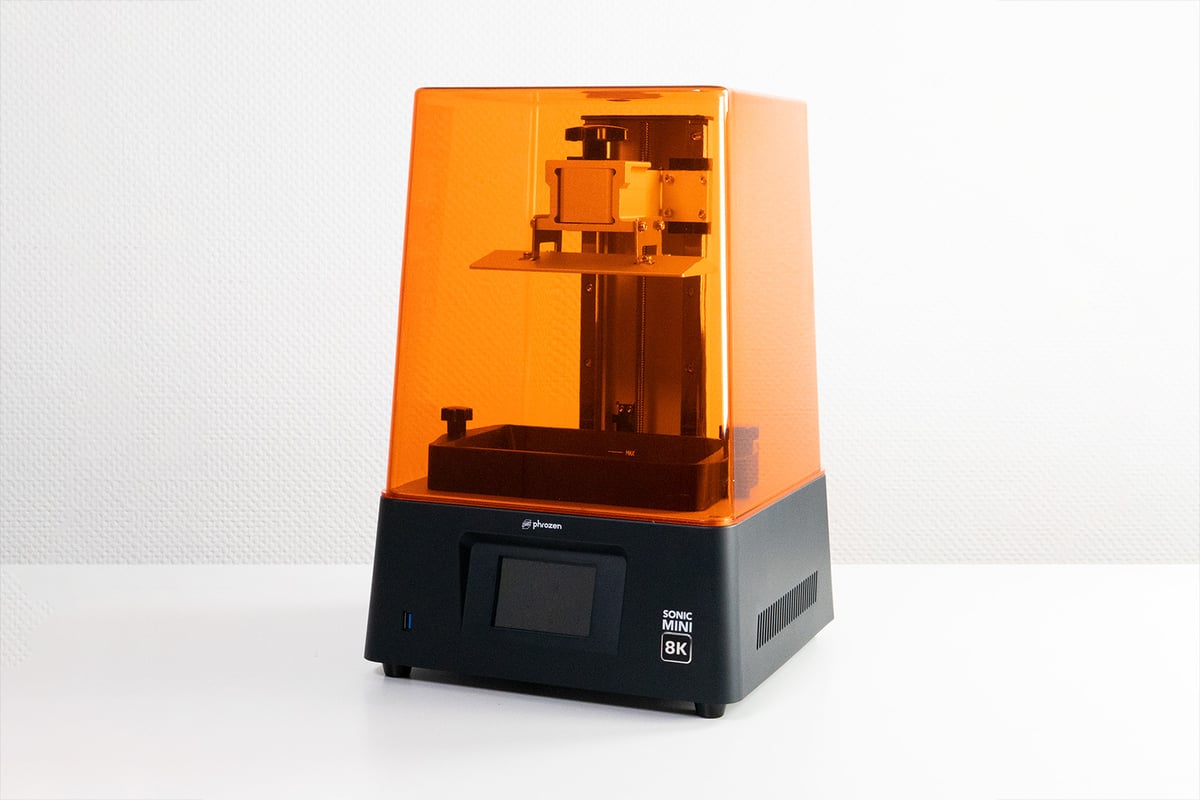

Achievement unlocked. Phrozen has once again taken a bold leap forward and beaten the rest to the punch in offering the next high-resolution standard for LCD-based budget resin printing with the release of its Sonic Mini 8K.

It was the first to bring mono screens and blink-of-an-eye layer curing times with the Sonic Mini; likewise a 4K LCD panel with its Sonic Mini 4K. Phrozen completes its trifecta with the latest in the Sonic Mini series of printers, the Sonic Mini 8K, which has a 7500 x 3240 pixel “8K” LCD. This, across the build area it offers, gives the Sonic Mini 8K an exceptionally tight pixel pitch of 22 microns. In short, the potential is there to produce the most intricate of models.

At $599, the Sonic Mini 8K promises to bring an unprecedented level of detail within the reach of tinkerers and hobbyists. But didn’t the last Sonic Mini offer unprecedented detail? What kind of results can you actually expect from such an apparent step up? We put one through the wringer to find out, and if the jump in pixels is worth the jump in price.

Verdict

Pros

- An outstanding level of print detail is possible

- Most user-friendly Sonic Mini yet

- Affordable price tag

Cons

- Prints adhere a little too well

- Bigger build volume, but less useful for large prints

- Phrozen 8K resin “needed” for ultra-fine prints

The Phrozen Sonic Mini 8K is a well-balanced machine that improves many things on past Sonic Mini printers, not just in terms of resolution. Being the first “budget” resin 3D printer to house an 8K LCD, its capability to 3D print at an astonishingly detailed resolution of 22 microns across its 165 x 72 x 180 mm build volume is, naturally, its biggest draw. This resolution bump is notable but probably unnecessary for many users, so it’s only in combination with the quality of life improvements that the Mini 8K is a resounding success.

Increased sturdiness from dual linear rails for the Z-axis and print plate cantilever, plus a better resin vat design and fixtures, and print plate provide many of the conveniences missing from past Phrozen Sonic machines.

The Sonic Mini 8K produces astonishingly crisp prints, especially when using Phrozen’s specially formulated 8K resin. A difference in surface quality to other, less precise printers is noticeable with the naked eye, although you will have to take a close look most of the time to do so. It’s not like the Mini 8K reveals formerly hidden details on every model you print, but you will be able to obtain more defined results, and intricate parts come out more pronounced.

At $599, however, Phrozen is asking quite the sack of pennies for it. You are essentially paying double the price of slightly less-detailed machines. Thankfully improvements elsewhere in the printer help the Phrozen Sonic Mini 8K get a big thumbs up from us. It’s *chef’s kiss*.

The Tech

Pixels, Pixels, Pixels

Current trends indicate that desktop resin 3D printing is locked in a resolution arms race. That is what qualifies as progression these days; moar pixels or die. Pushing its way to the front of the crowd is Phrozen, which seems to go to great efforts to tag large pixel counts and low micron pixel pitches to its machines. We liken it to that draw Uno cards meme. Release a budget resin 3D printer without a first in resolution or draw 25. By now, Phrozen is surely holding the whole deck.

But that’s neither here nor there. We’re here to explore the Sonic Mini 8K, not Phrozen’s jostling for position. Speaking of jostling, the pixel count on the 7.1″ screen and its 165 x 72 mm build area is pretty dense; 7500 x 3240 pixels dense. That equates to a PPI of 1152, with each pixel (and therefore curable voxel in a given layer) measuring out at 22 microns along its sides. As far as we’re aware, this is a first in the hobbyist-grade printers, approaching a level of detail that makes the Sonic Mini 8K attractive not only to tinkerers with gusto for crisp prints but also professionals with the need for tight tolerances.

Replacing the 8K LCD, which is necessary after around 2000 hours of use, will set you back $129.

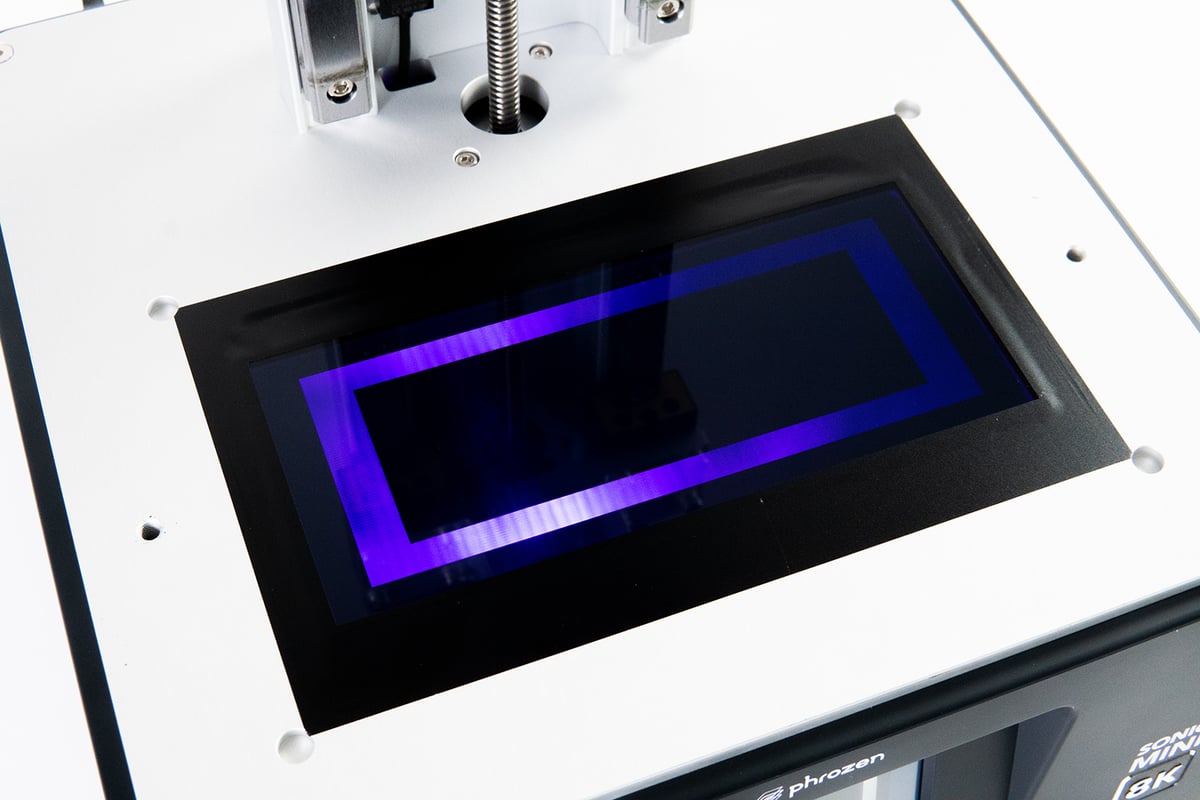

Letterbox LCD

Eagle-eyes readers may have noticed something odd about the pixel numbers Phrozen throws at us with the Sonic Mini 8K — more than double the amount on the X- than on the Y- axis, 7500 x 3240. This gives the LCD a close-to 21:9 aspect ratio — excellent if you want to watch Dune, but for 3D printing larger objects, quite restricting.

In fact, with a print volume of 165 x 72 x 185 mm, the Sonic Mini 8K as a supposed successor in the series is just weird. Compared to the Sonic Mini 4K, it gets a massive bump in the X- and Z- axes while shrinking its printable Y-axis. It offers a similar volume to the Elegoo Mars 3, both approximately 2.1 liters, but the extra space on the Mars’ Y-axis (143 x 90 x 165 mm) means it can print larger objects.

As detailed as the Sonic Mini 8K’s screen is, it’s not as useful as the Sonic Mini 4K for larger, full-plate objects.

New Lights

Printing at an extreme detail not only comes from the number of pixels. Another factor is the uniformity of the light hitting the LCD’s pixels. The more evenly a screen gets floodlit, perpendicularly, the more likely the prints at the edges of the build plate will match up to those in the center.

For the Sonic Mini 8K, Phrozen ditches the LED matrix found on its past printers for something it calls “Linear Projection.” The setup reminds us a little bit of what goes on in DLP-technology-based resin printers and – to our knowledge – is a novelty in printers pitched at hobbyists. Instead of an array of lenses matched off to LEDs directly beneath the LCD, the Mini 8K uses a condenser lens and mirror to direct the light towards the LCD screen. This setup requires a longer optical path from the light source to the LCD, Phrozen claims, to give a straighter projection, leading to even dispersal and more accurate results.

“Light uniformity” is the buzzword, typically accompanied by a percentage, used by manufacturers to describe the evenness of the light source illuminating the LCD. Poor light uniformity means light has to travel further or at oblique to the LCD; prints will cure unevenly across the build plate, leading to print failures or distortions. We printed multiple models covering the entire build plate throughout our review to see if any differences were detectable. Plastering the build plate with the intricate Ameralabs test models affirms Phrozen’s claim that the new light engine is doing a good job rendering sharp models even at the edges of the LCD.

The light engine needing more room for the light to travel also means the Sonic Mini isn’t so mini anymore.

Mighty 8K?!

The Sonic Mini 8K has packed on the pounds when held against the previous Sonic Mini series machines. To the point even where it might be more appropriate to call it the Mighty 8K. The Sonic Mini 8K has a larger footprint (290 x 290 x 420 mm) than the Phrozen Sonic Mighty 4K (280 x 280 x 440 mm). We suspect the only reason it’s not called the Sonic Mighty 8K is because the build volume didn’t grow all that much — it’s a distortion stemming from the larger light engine.

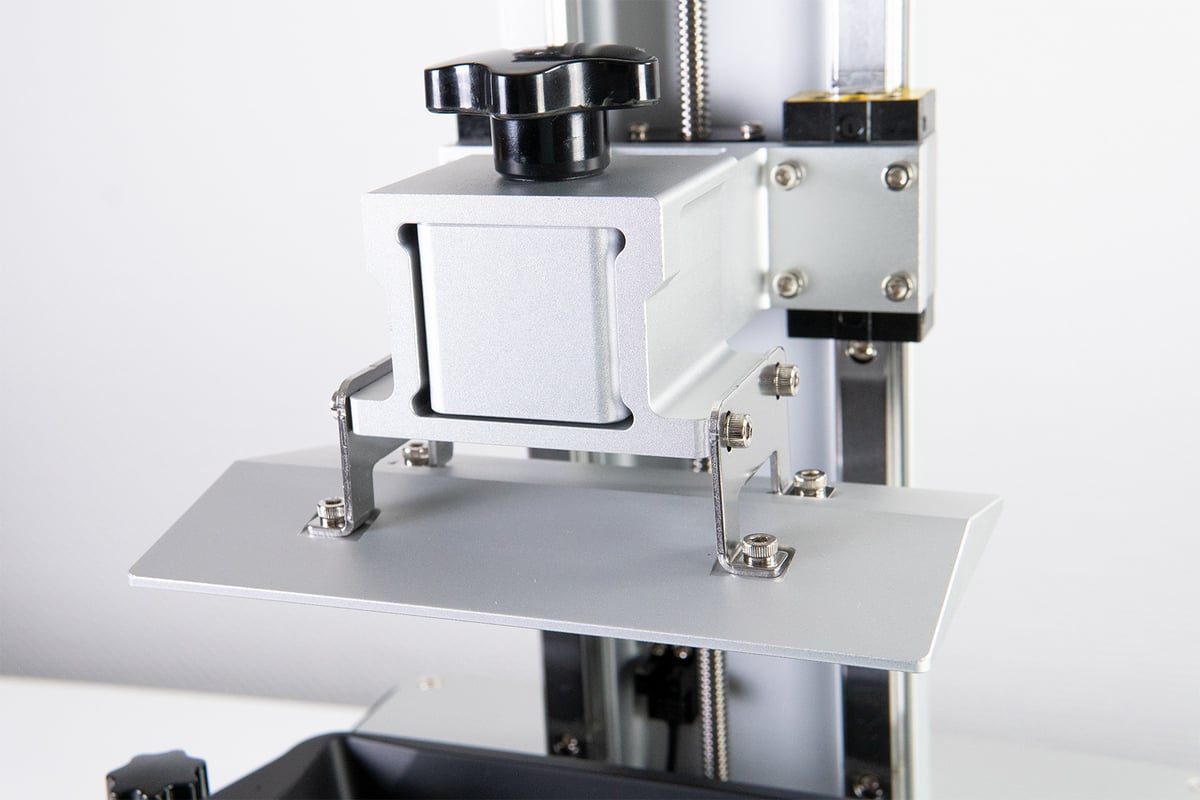

So with the Sonic Mini wearing the skin of a Sonic Mighty, what else has Phrozen done with all that extra space? Chiefly, dual linear rails flanking the printer’s lead screw, as found on the Sonic Mighty 4K. Some Sonic Mini 4K users reported wobble in that printer’s lead screw. We suspect this eliminates any chance of it happening again with the Sonic Mini 8K.

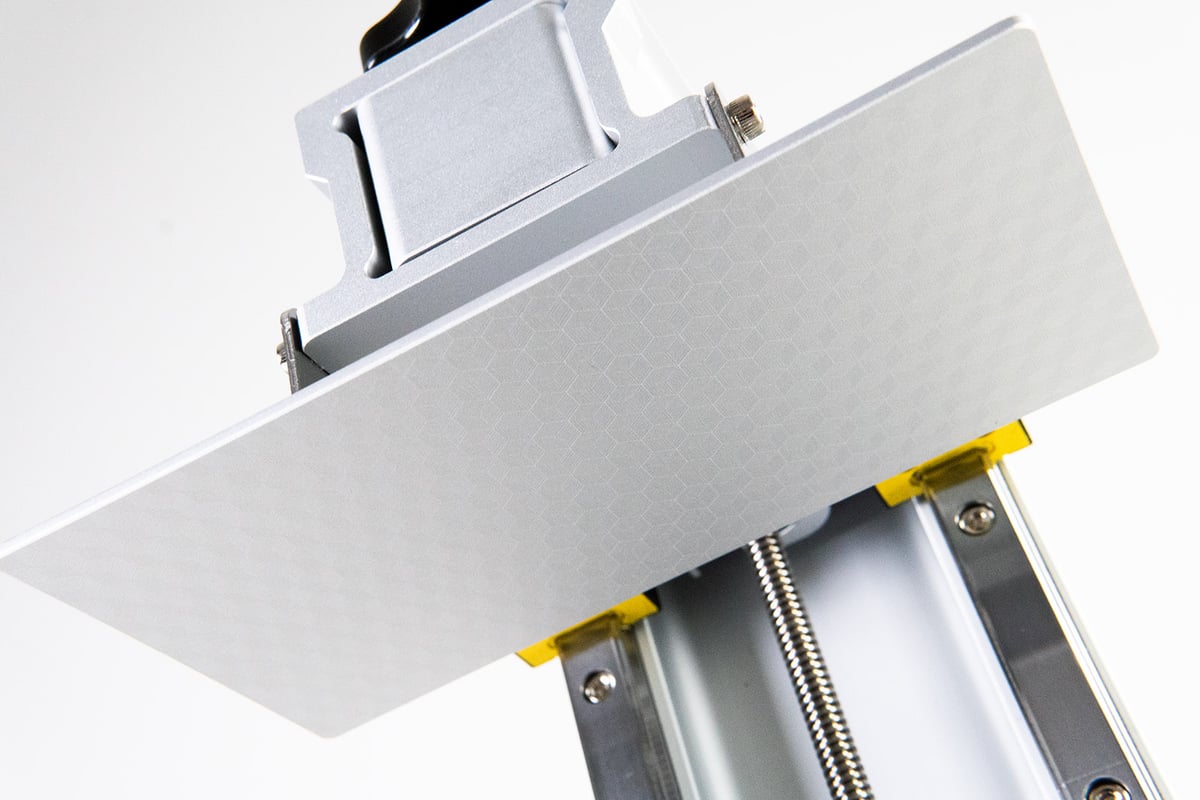

The Sonic Mini 8K also features a sturdy print plate mount, again borrowed from shape-mate Sonic Mighty 4K. Phrozen recently upgraded the Sonic Mini 4K with this part, too, so it’s a standard piece of Sonic Mini hardware.

New Bed

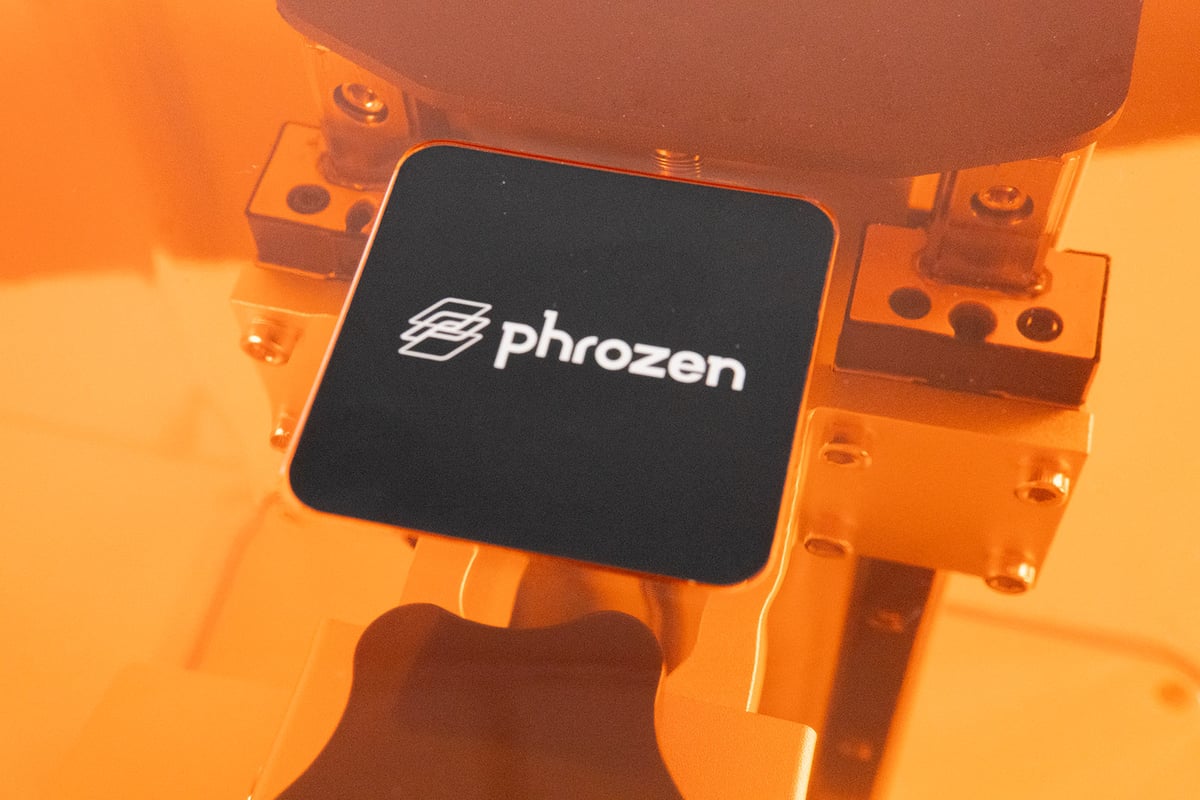

Sitting on the Z-axis cantilever is the print plate, which gets fixed in place using a large knob on top. Print plate leveling happens using four screws on the fixture that you must tighten yourself with a hex key. They’re easy to access and adjust. The print plate is made of aluminum and has an angled top surface for the pooled resin to flow off (except the four little indents where the screws are).

The most remarkable thing about this print plate is its surface’s fancy laser-etched geometric pattern.

Print plate surfaces come in many forms– usually coarse and sandblasted. The Sonic Mini 8K’s pulls off a laser-etched surface that looks great and inspires nothing but warm feelings for the printer.

Until you have to pull out a scraper and relentlessly hack at it, that is. Despite its slick looks, it seems that this print plate surface (in combination with the default slicer settings for the Sonic Mini 8K) sticks to prints a little too well. When printing, you will probably need to adjust your first layer settings if you don’t want them to break from the force required to get them off the plate.

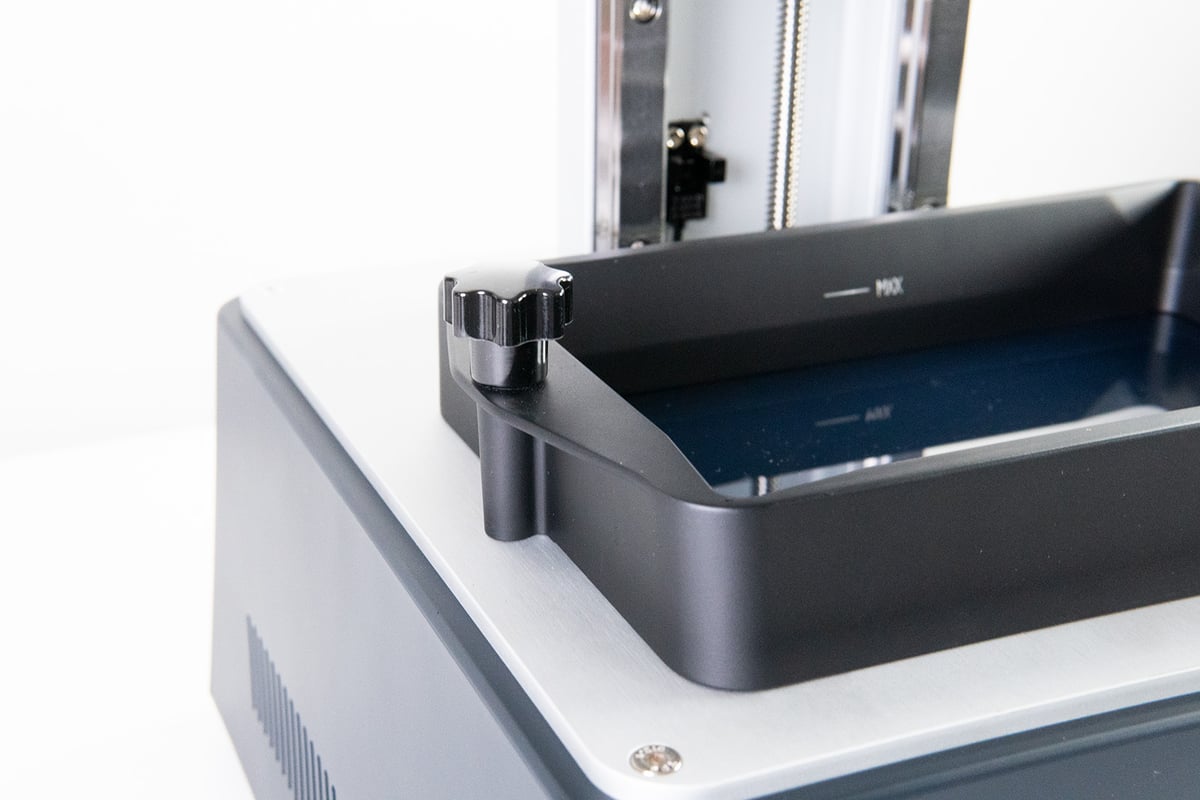

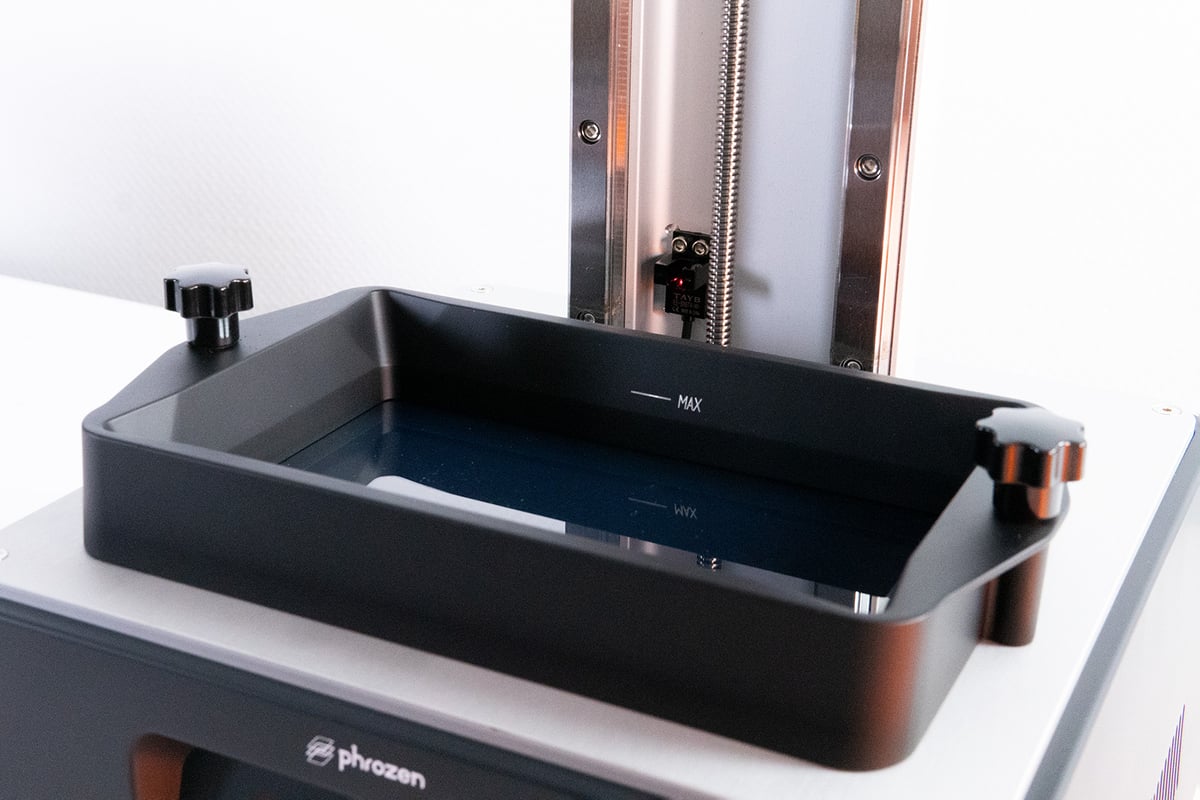

The rest of the printer’s interior is pretty straightforward. The vat is aluminum, with four pegs on the bottom to stand the vat up off surfaces when outside of the printer. The Sonic Mini 8K’s vat fixture is a welcome improvement on past Phrozen machines, using two top-down screws for quick mounting of the vat instead of the horrid system of spearing the vat onto exposed threads and fixing it with small, slippery nuts.

More Alikeness

The printer comes with a 3.5-inch color touchscreen, which is decent but having a slightly larger screen to jab at wouldn’t hurt. Phrozen UIs on its printers have always been a little on the small side. The USB slot is located conveniently at the front of the printer. It’s a minor gripe, but the power switch is on the side of the machine instead of conveniently accessible from the front.

In several areas, the Sonic Mini 8K improves on past Sonic Mini printers. The new USB location, new print vat fixture, vat stilts to place it safely on your workbench without damaging the vat’s film, and a maximum fill level indicator might not seem like much, but they go a long way in making a resin 3D printer easier to live with. Not to mention the upgraded Z-axis and T-plate. Putting the resolution aside, it is also comfortably the most well-rounded of Phrozen’s Sonic Mini printers.

Printing & Usability

Setting it up

Setting up the Sonic Mini 8K is a cinch. Relieve it of its foaming, plug it in, loosen the four leveling screws on the build plate cantilever, home the plate on a thick sheet of paper, tighten the screws, and you are good to print—same procedure as with any other desktop LCD-based resin printer. You can start your 8K journey with the provided test print, Phrozen’s rook. A lackluster print to kick things off with, to be honest — it has nowhere near has the detail or features to show off what this little wizard is supposed to be capable of, though.

Get the Settings Right

Before getting started, we advise looking at the slicing settings for your first print and paying attention to the bottom layer exposure time. Using the default settings resulted in our prints stucking too well to the bed.

Dialing the first layer cure time down to about 20 seconds each worked well for us — your mileage may vary. Working on our first few prints at stock settings, we learned the hard way that separating prints from the plate right next to the open printer results in a rain of shrapnel into the open vat. Cue a laborious time spent siphoning good resin from shards of failed Omni-Man. So, save yourself some post-print pain and dial in print plate adhesion before committing to any major projects.

Which slicer you eventually use to dial in your settings is up to you. The Sonic Mini 8K works with ChiTuBox and Lychee. Both slicers already have printer profiles for the Sonic Mini 8K and come with plenty of resin profiles for different brands and types to use. Bear in mind, ChiTuBox (Basic and Pro) provide manufacturer-specified profiles, while Lychee is an open platform for its users to submit their own (which can then be verified by the community.) For the most part, these are identical, though.

Regardless of the slicer you choose, the availability of specifically designed profiles for different resins shows that desktop resin 3D printing is getting sophisticated. It’s no longer a one-type-fits-all for adventurous users to experiment their way to print success. To achieve the best results, finding the right settings for your type of resin (and potentially even the color) is essential. Of course, you can also import or set up your own profiles, should your preferred resin not be featured on that list.

8K Resin

Speaking of more sophisticated resins: Phrozen has released a new 8K resin alongside the Sonic Mini 8K, promising an ultra-fine depiction of detail. Specific resins for specific use cases like jewelry or dental have been the going rate in professional resin printing but for hobbyists, resin choice typically came down to different colors of “ABS-like”. Of course, things are different now, and there’s plenty of choice and characteristics to be found in specialist consumer resins. For its new 8K resin, Phrozen states a tolerance of 0.05 mm compared to 0.1 mm for its 4K resin. We’ve tested the 4K version in the Sonic Mini 4K, and while it produced great prints, we struggled to see the difference. This was our expectation for the 8K resin, too.

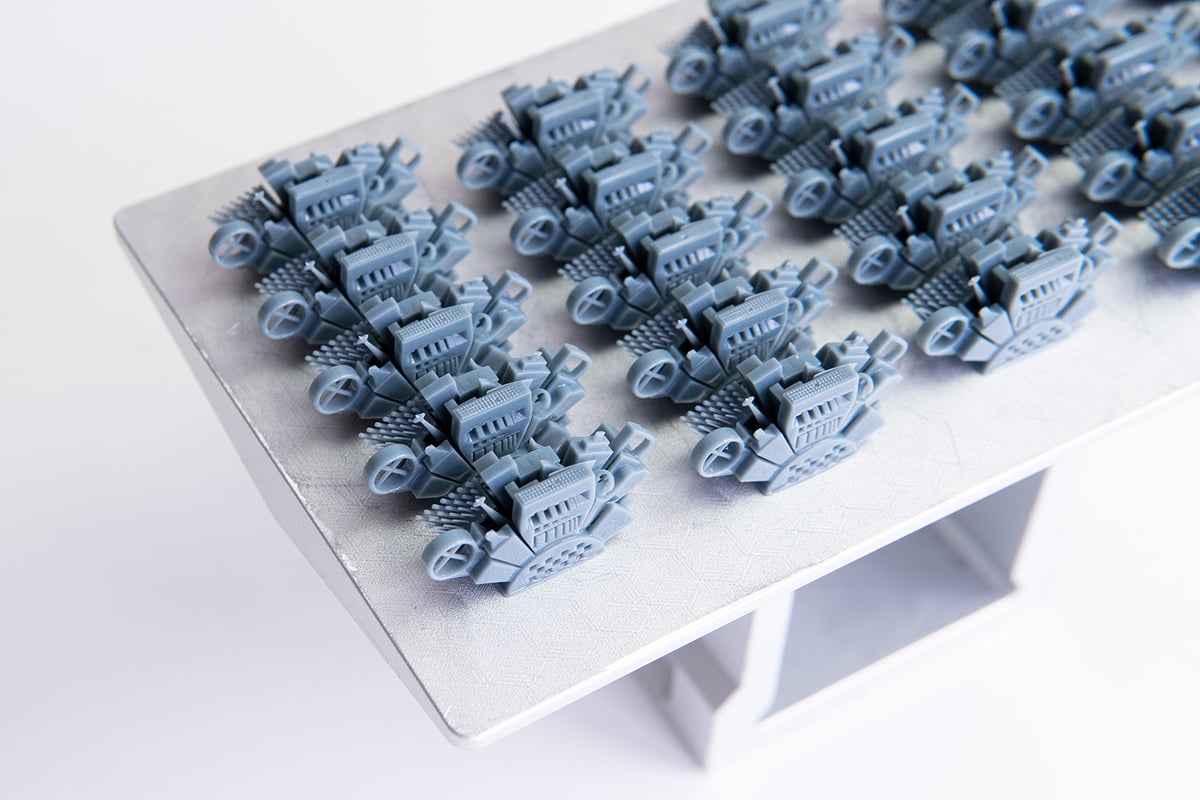

Perhaps the resolution being quite a leap from the current “standard” helps, but with the 8K resin and Sonic Mini 8K hardware, Phrozen might be on to something here. Details came out very clear, and thanks to its dark grey color, you can make out even the finest of subtleties. Typically we would stray away from recommending any specific resin in a review, but if you want to get the most out of your Mini 8K, Phrozen’s 8K resin does seem to make a difference and get the most out of the printer’s potential.

Naturally, the printer works with any resin, and once we used up our bottle, we switched over to other blends, which worked just as fine, although a difference in clarity was noticeable.

The Prints

So, is the step-up in resolution worth the price?

Going from a printer with 50-micron pixels (or even 35) to 22 sounds a lot, but what’s noticeable when comparing models? To answer that question, we’ve dusted off the Elegoo Mars 3 to compare against the Sonic Mini 8K.

The Mars has the same resolution as the Sonic Mini 4K, 35 microns, but because it has a considerably larger build volume than the 4K, it allowed us to print objects at full volume on the Mini 8K and compare it to same-sized objects. Essentially we are trying to figure out if there is a noticeable difference between 35 and 22 microns.

We printed different sized models ranging from 0.05 mm layer height, the default layer height for many desktop resin 3D printers, down to 0.015 mm per layer.

First off, prints of the Sonic Mini 8K with the 8K resin look stunning. Perhaps it’s the way light plays on the grey color, adding contrast, but even the tiniest details are defined and visible. Isn’t that the same for 35-micron prints, you ask? Not entirely, to be honest. While prints look to be the spitting image at first glance, scrutinize them closely and the sharpness is missing. In a wholly unscientific but telling test, we had colleagues guess between identical prints from both printers. The vast majority correctly identified the Sonic Mini 8K from the lineup, with the defining comment being that prints look more defined; sharper.

This sharpness mostly comes in the small details of a model; the distinctness of a figurine’s sideburns, a tiny ornament depicted on a skull, and other intricate details that appear just a bit hazier at 35-microns.

However, it is a long way off from just taking a glance at the prints and picking out which is which. Plus, not all models you are likely to print will depict a level of detail to make out the differences. This is also partially true in regards to the layer height. During testing, we found that printing most models with a finer layer height (0.02 mm or below) will only take longer without seeing a noticeable shift in detail vividness.

It’s worth noting that using Phrozen’s 8K resin in the Mars 3 had us see an increase in perceived detail in some of the prints we made back when we reviewed it. A trick of the light? Possibly. But we’ll also say that while the print resolution is important on a printer, getting the suitable resin and settings to go along with it is hugely important too.

Besides producing miniatures with an astonishing level of detail, we found the Sonic Mini 8K to be spot on in terms of tolerances of prints. If you plan to use it for printing miniatures or other artistic one-offs, tiny deviations from the desired size aren’t likely to ruin anything or even get noticed.

However, since the Sonic Mini 8K also styles itself as an alternative for jewelers, engineers, or other professional applications, tight tolerances of prints, reliability, and repeatability might be even more of a factor in a potential buying decision.

However, it’s not just the printer’s technical capabilities that come to play but also having the resin profile and printer settings fine-tuned, as over-or under-curing will affect the accuracy of the print. In our testing, we found the Sonic Mini 8K to reproduce uniform batches free of distortion – key in the professional production of parts.

Is It Worth It?

The Phrozen Sonic Mini 8K is the logical evolution of a technology that has gotten massive in the last few years. MSLA resin 3D printing went from 2K to 4K, and now, with the Sonic Mini 8K being, well, 8K, the even finer resolution of 22 microns has found its way into the hands of hobbyists and enthusiasts. But that’s not all the printer has to offer. Alongside its enhanced print qualities, the Mini 8K also sees a buff in usability over the series’ previous printers.

With a build volume of 165 x 72 x 180 mm, the Sonic Mini 8K offers reasonable space to put the resolution to work. Its letterbox-shaped screen and build area are a little restricting when trying to use the entire build volume for larger prints. Still, decent-sized models are possible with proper print preparation, and it’s a definite upgrade over the Sonic Mini 4K’s print volume. The draw of this printer is, obviously, ultra-high detail, not particularly large prints. While Phrozen pushes boundaries with many of the printers it releases, they’re usually a little rough around the edges. The Sonic Mini 8K, finally, tidies things up.

Printing with the Sonic Mini 8K can be a little challenging at first with the need to bring some slicer settings in line, specifically to counter the tough print plate adhesion, but with a few tweaks in the slicing settings, it’s easily fixed.

Its 7500 x 3240 pixel LCD and the new linear projected light engine beneath it produce sharp prints with detail and tight tolerances. You get little to no print imperfections even at the outmost fringes of the print plate, something we’re sure professional users will appreciate.

Using Phrozen’s 8K resin, we were able to print some of the most detailed and visually astonishing prints we’ve pulled out of an MSLA printer yet. Whether that’s it and no other resin comes close when used in the Sonic Mini 8K remains to be seen. We suspect not.

At $599, it is the priciest Phrozen Sonic Mini 3D printer — close to double the price of other “top” desktop resin 3D printers with similar build volumes. You could use the 8K resin in those printers, too. Technically, it doesn’t improve their resolutions, but the prints do look nice.

The Phrozen Sonic Mini 8K is a fantastic machine that delivers incredibly detailed prints right out of the box. Hobbyists should question whether they need 22-micron resolutions for their models (probably not, but it most certainly looks nice). Professionals will get a kick from the 8K’s abilities and price point.

Features

8K LCD Screen

Phrozen is well ahead of the budget market with a large-format 8K printer, the Sonic Mega 8K, already available, but cramming 7500 x 3240 pixels into the much smaller Sonic Mini 8K’s 7.1″ LCD screen is a much greater feat.

This resolution and screen size will achieve an absolutely mind-blowing accuracy of 22 microns across the 165 x 72 mm build area. To put that in perspective, the Sonic Mini 4K featured a resolution of 35 microns, albeit at a much smaller build area (135 x 75 mm). It even surpasses much more expensive professional systems like the Formlabs Form 3, which sports a now-dwarfed 25-micron accuracy (and likely a much slower print speed given the single-laser curing).

Linear Projection LED

And because Phrozen had to take things just one step further, the company has created a novel light system: Linear Projection. The new array uses a single LED bulb mirrored towards the LCD screen. In typical MSLA systems, light sources are below resin vats and shine directly through the LCD mask.

The reason behind this new array, according to Phrozen, is that longer optical pathing from the light source to the mask results in straighter projection — and so more accurate results. To achieve this in the small footprint of the Mini 8K, Phrozen opted for a mirror that reflects the light beams from the LED light source evenly onto the LCD mask. According to Phrozen, this new system “enhances light uniformity by over 90%” and will result in sharper prints.

Fun fact: the new linear projection system is also why the Phrozen Sonic Mini 8K is a bit larger and heavier than its predecessor, the Mini 4K.

Dual Linear Rails

The Sonic Mini 8K’s Z-axis accuracy is sure to be stellar given the dual linear rails on either side of the lead screw. The Sonic Mini 4K had a single linear rail and was already a seriously impressive system; dual rails further distributing forces can only improve the quality.

If Phrozen wants to make good on the 8K’s 22-micron accuracy, it has to be sure Z-accuracy is near perfect. At least, if it wants to make good on claims, the system will make pores distinguishable on models. To accomplish that level of detail, visible layering will need to be all but eliminated. Layering on resin systems has already become pretty impressive in recent years, but Phrozen is claiming the 8K will reduce layering further by 50%.

Laser-Etched Build Plate

Prints are cured to the Sonic Mini 8K’s 165 x 72 mm build platform that’s laser-etched into a rough, grippy surface and is slanted at the top to allow any splattering resin to drip off. Etched platforms have become a popular feature on resin printers for their reliable adhesion, and let’s face it – they’re pretty.

Further Features

Additional features on the new Sonic Mini 8K include the following:

- Metal resin vat: Users worldwide seem to trust metal more than plastic composites when it comes to holding resin at bay over long periods of time. As such, the Mini 8K is stated to feature a metal resin vat.

- Buffed-up T-plate: Not only did the linear railing get buffed, but the Mini 8K also features a thicker, sturdier print plate mount to withstand the pulling force exerted on the machine (and print) after each layer.

Tech Specs

General Specifications

- Technology: MSLA

- Type: Resin

- Year: 2021

- Assembly: Fully-assembled

- Manufacturer: Phrozen

3D Printing Specifications

- Build Volume: 165 x 72 x 180 mm

- Layer Height: 10+ microns

- XY Resolution: 22 microns (7500 x 3240 pixels)

- Z-axis Positioning Accuracy: N/A

- Printing Speed: 80 mm/hour

- Bed-Leveling: Manual

- Display: 3.5-inch touchscreen

- Third-Party Materials: Yes

- Materials: 405 nm resin

Software Requirements

- Recommended Slicer: Chitubox (Basic, Pro), Lychee

- Operating System: Windows / macOS X

- File Types: N/A

- Connectivity: USB

Dimensions and weight

- Frame Dimensions: 290 x 290 x 420 mm

- Weight: 13 kg

- Boxed Size: N/A

- Weight (packed): N/A

Similar Printers

Having spent time with the Phrozen Sonic Mini 8K, we can say it makes a strong proposition to make it into the ranks of our favorite budget resin 3D printers. You can check out which machines are on the list now over on our Best Budget Resin Printers Guide.

The following printers might also do it for you. We recommend checking them out.

Elegoo Mars 3

The Elegoo Mars 3 is a 4K resin printer that earned our recommendation as the best budget resin printer on the market just this past August. With what was a very impressive accuracy of 35 microns, it goes to show just how fast the 3D printing industry is still growing. If you don’t mind trading off a few microns with a slightly more usable build volume, the Mars 3 might be your pick.

Anycubic Photon Mono 4K

Anycubic’s Photon Mono 4K is another affordable 4K resin printer capable of a 35 microns resolution. With a build volume of 132 x 80 x 165 mm and a price tag of $289, it keeps things simple and affordable. If you don’t need uber detailed prints and don’t mind the smaller build volume, the Mono 4K is a strong pick to step into resin 3D printing.

Phrozen Mega 8K

Phrozen’s first 8K 3D printer doubled its resolution not with smaller pixels but with a larger build volume. If mini just doesn’t cut it for you, the recently released Phrozen Mega 8K boasts a 330 x 185 x 400 mm build volume with a respectable 43-micron accuracy. We were blown away with the results, but you’ll probably want it for slightly larger details.

License: The text of "Phrozen Sonic Mini 8K Review: Upgrade Pick" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.