Spanning SLS, FDM, SLA, LBPF, more printer technologies, All3DP follows all the new products so you won’t miss anything. This is your one-stop-shop for the newest machines from around the world. Check back every week!

To browse all the professional printers launched in 2021, see last year’s full guide below.

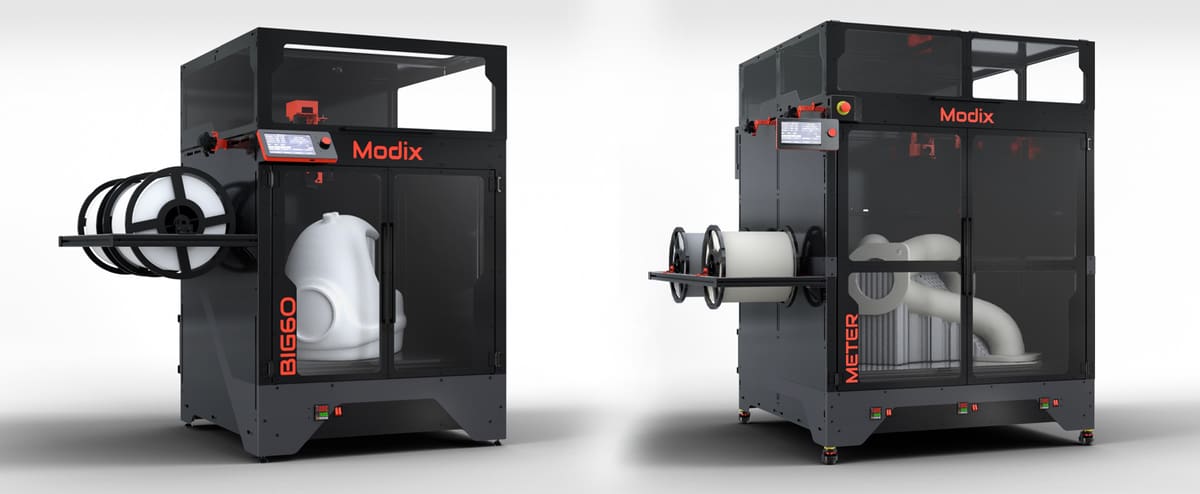

Modix Product Line Generation 4 Upgrade, IDEX

(Nov. 8, 2022) In a sweeping product-line upgrade, Modix, the maker of extremely large FDM 3D printers, has improved all five of its machines at once.

The Modix line (Big-60, Big-120X, Big-120Z, Big-Meter, and Big-180X) will all have Generation 4 in front of the product name to reflect the changes. The most significant of which is a move from dual extruders to independent dual extruders (IDEX). Even though the previous versions could also print soluble support structure material, the addition of IDEX makes the process faster.

The machine lines now boast a high-quality print speed of 100 mm/s and higher speeds in draft printing mode. The new speeds are attributable to a more powerful motor (a Nema-23 vs. the previous Nema-17). Also, since the IDEX configuration uses two Y-axis motors, one per extruder, the motor weight load on the Y-axis is reduced, and speed is increased.

Modix now offers a full set of automated calibrations, including automated bed tilt, bed leveling, gantry alignment, and Z offset calibration, on all models. Multiple other improvements include optical end-stops that improve job recovery accuracy, improved enclosure sealing and ergonomics, an emergency stop button as default and a fresh, new design.

- Modix BIG-60 – 600 x 600 x 660 mm – $4,900

- Modix BIG-120X – 1,200 x 600 x 640 mm – $7,500

- Modix BIG-120Z – 600 x 600 x 1200 mm – $7,500

- Modix BIG-Meter – 1,010 × 1,010 × 1,010 mm – $13,500

- Modix BIG-180X – 1,800 x 600 x 600 mm – $15,500

Boston Micro Fabrication microArch S350

(Nov. 8, 2022) Boston Micro Fabrication (BMF) just released its latest resin micro 3D printing machine, the microArch S350.

The microArch S350 is BMF’s highest throughput printer designed for end-part production, the company says, because it can not only print microscale parts with high-resolution (down to 25 μm) features but also an array of small parts requiring high accuracy or precision in volume. The machine is aimed at researchers and manufacturers for prototyping and production in the 1,000-30,000 part volume range.

The microArch S350 is based on BMF’s projection micro stereolithography (PµSL) technology, which is a type of masked stereolithography (MSLA) on the micro-scale using a flash of UV light.

Technical Specifications

- Technology: micro MSLA

- Build volume: 100 × 100 × 50 mm

- Layer thickness: 10 – 50 μm

- Materials: photosensitive resins, ceramic

Photocentric Liquid Crystal Titan

(Nov. 7, 2022) The Liquid Crystal Titan by resin 3D printer maker Photocentric is on a soft launch at the Formnext expo in Frankfurt this week. Even though the company is still calling it a “prototype” and its 2023 launch is uncertain, people are excited partly because Photocentric invented LCD 3D printing, which is today the backbone technology for dozens of printer brands.

The company still holds several patents around the technology, which generally involves the use of an array of LEDs as a light source, shining near parallel highly collimated light through the LCD panel and onto the resin layer. The Titan features an 8K 32-inch LCD screen to produce fine detail.

The Titan isn’t promising any groundbreaking technology advancements, but rather its size is what’s interesting. With a print volume of 700 x 395 x 1200 mm, Photocentric says this machine is built for large format printing of production parts, perhaps to rival the likes of Formlabs or even Carbon.

The size of this printer is supported by the speed of the machine, a zippy 16 mm per hour at 100 µm layers, which is the same as the company’s smaller LC Magna resin 3D printer.

Technical Specifications

- Technology: LCD resin

- Build volume: 700 x 395 x 1,200 mm

- Layer thickness: 25 – 100 μm

- Resolution: 8K screen. 7,660 x 4,320 px

- Print speed: 16 mm/h

- Price: est. $35,000 – $40,000

miniFactory’s New 3D Printer is Factory Ready with Print Quality Software

(Nov. 6, 2022) “Make it Right. Every Time.” It’s a goal most professional 3D printer makers are striving toward as they work to convince industrial manufacturers that this technology is dependable.

For miniFactory, the Finnish manufacturer of high-temperature FDM 3D printers for industry, this isn’t just their latest advertising slogan but rather the claim of their new quality control software inside the new Ultra 2 printer.

Called Aarni, this software is intended to give users a sense that the 3D printing processes going on in the build chamber are being monitored and recorded so that errors can be detected on the spot and successful prints are repeatable.

The just released Ultra 2 is an update to the company’s flagship Ultra but “two times faster”, the company says. How is it twice as fast, you may wonder. The company will only reveal that “improved technical solutions together with software optimizations” are behind the new 120 mm/s print speed for amorphous high-performance polymers.

On the outside, those familiar with the Ultra won’t notice much new with the Ultra 2. It has most of the same features, such as the same build size, servo motors, heated filament chamber, and integrated annealing setting. It’s still an open material system focusing on industrial thermoplastics, with print profiles for more than 50 high-performance materials, including PA, PEI, PPS, and PEEK.

E-Plus3D EP-M1250

(Nov. 1, 2022) E-Plus 3D now offers 10 industrial metal powder bed fusion machines, which begs the question: How many options do manufacturers need? E-Plus offers a dizzying menu of build volumes and laser counts, but the latest addition, the EP-M1250, is the largest yet, with a build volume of 1,258×1,258×1,350 mm or 2,000 liters.

The target application here is clearly large-size, high-precision parts for the aerospace, aviation, automotive, machinery, and oil & gas industry.

the EP-M1250 sports nine lasers and what the company calls “precise positioning” and “area splicing control technology” to ensure uniformity and stability throughout the printing phase.

Technical Specifications

- Technology: metal LPBF

- Build volume: 1258×1258×1350 mm

- Lasers: 9 (500 W, 700 W, or 1000 W) fiber lasers

- Spot size: 70-130µm

- Max scan Speed: 7 m/s

- Layer thickness: 20-120µm

- Build speed: 240 cm3 /h

- Materials: Titanium Alloy, Aluminium Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, etc.

- Gas Supply: Ar/N₂

- Software: EP-Hatch , EP Control

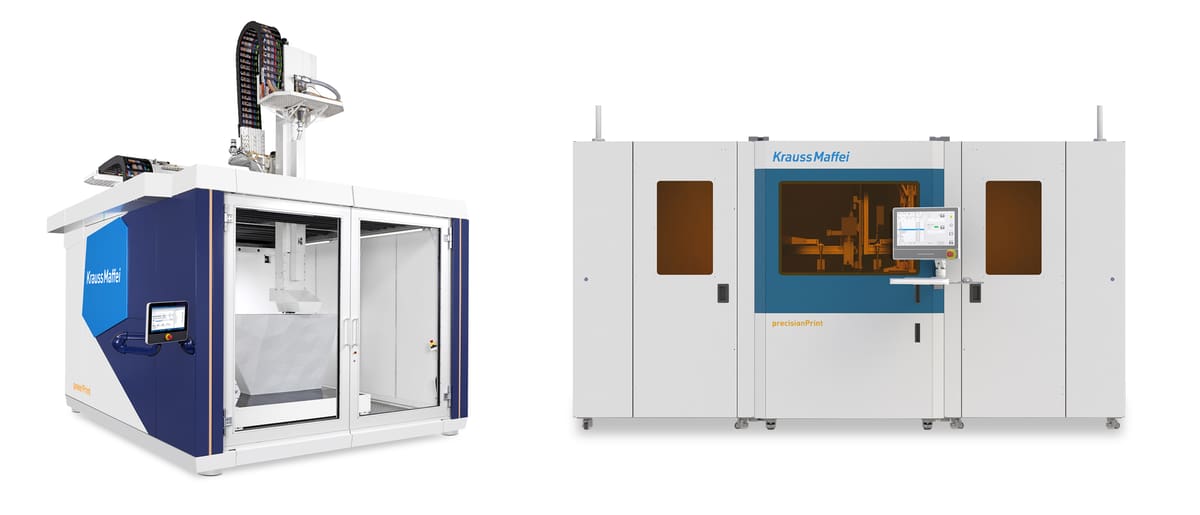

KraussMaffei powerPrint & precisionPrint

KraussMaffei is one of the world’s leading manufacturers of machines and systems for producing and processing plastics and rubber, mainly with injection molding. This expertise gave them a leg up when entering the additive manufacturing industry and launching two new 3D printers.

powerPrint is an extra large-scale (2,000 x 2,500 x 2,000 build volume) FDM 3D printer that prints with economical thermoplastic granules. It’s a high-temperature (400° C nozzle), robotic-arm machine that can extrude up to 30 kg per hour.

precisionPrint is an industrial-grade resin printer featuring stereolithography technology that the company says is aimed at the medical, sports, consumer products, and electronics industries. Aimed at production volumes, the precisionPrint features an automated build-plate changer, a dual tank system, and large build volume (250 x 250 x 400 mm).

With strong innovation capacity, we ensure sustainable added value for customers across their entire value chain, with standardised and individual product, process, digital and service solutions.

We deliver these services to customers in the automotive, packaging, medical and construction industries, and to electrical and electronic product and household appliance manufacturers, among others.

GE Additive Binder Jet Line

(Oct. 19, 2022) 3D printers that are still on the drawing board usually don’t make this list, but when it’s GE, it’s newsworthy. To be clear, the manufacturing giant’s anticipated version 3 of its metal binder jet 3D printer is still under wraps (the photo here is of their version 2, no photo yet of version 3), but a tentative “late 2023” date has been floated around.

Here’s what we know so far.

GE Additive has been beta testing and refining its binder jet solution with customers for about the last four years. As with almost everything binder jet-related, the focus of this machine is high-volume, serial production.

“Our system offers the ability to integrate into reconfigurable factory cells and is automation ready,” says GE Additive. “We are actively working to enable 20, 40, 100+ machine installations for true industrial production.”

Currently called simply the Binder Jet Line, GE Additive says it’s a complete, configurable ecosystem of production hardware and software “to bring an application from concept to full production while safely delivering quality parts, at cost, at scale.”

The pilot parts are stainless steel (only), up to 23kg, feature material properties better than casting, the company says, and also sport a wall thickness down to 0.4 mm. The Series 3 is UL and CE certified, has an inert and sealed environment, powder-free exposure (closed loop), is fully capable of (eventually) handling reactive and flammable binders and powders, and does not require hazard zoning.

Stay tuned to All3DP for details when it becomes available.

Zortrax Inkspire 2

(Sept. 20, 2022) Popular 3D printer maker Zortrax just launched a new larger, more powerful, and more expensive version of its resin-based Inkspire machine to target small manufacturers and attract those who may have thought tough, shop-floor parts only come from filament 3D printers.

Zortrax says its durable engineering resins from BASF Forward AM and Henkel/Loctite are functional equivalents of high-performance filaments. The result is the ability to print both prototypes and final parts using resin 3D printing only.

The Inkspire 2 features liquid-crystal display (LCD) technology that flashes complete layers of the part at the resin tank with UV light from an array of LEDs shining through the LCD screen, not a projector. The screen is a mask, revealing only the pixels necessary for the current layer and blacking out the rest. This technique is often referred to as “masked SLA” or MSLA.

Although LCD resin printing is a technology commonly found in consumer 3D printers (with some notable exceptions, such as Nexa3D), Zortrax says its light engine is powerful enough to work with high-grade engineering resins (those cured by light with 405 nm wavelength) that used to be supported only on industrial digital light processing (DLP) machines. Inkspire 2’s UV light engine is seven times more powerful than the previous Inkspire and is compatible with some DLP resins. (DLP technology uses a digital light projector and a digital micromirror device to selectively direct light.)

Developed entirely in-house by Zortrax, the proprietary light engine provides a consistent UV exposure across the entire build platform to achieve consistent print quality regardless of the position of the models, the company says. Compared to the original Inkspire, introduced in 2018, the new version boasts 40% more uniform light distribution.

The Inkspire 2 is also noticeably larger than its predecessor with four times the build volume (192 x 120 x 280 mm), while the layer height and resolution remain the same.

Tech Specs

- Technology: UV LCD resin

- Build volume: 192 x 120 x 280 mm

- Light source: LED panel at 405 nm wavelength

- Precision 50μm

- Min. layer height: 25μm

- Software: Z-Suite

- Price: $4,400

- Zortrax Cleaning Station: $3,800

- Zortrax Curing Station: $4,400

HP Metal Jet S100 System

(Sept. 12, 2022) American corporate giant HP – yes, the same HP that makes 2D printers, laptops, and ground-breaking polymer 3D printers – just unveiled a new and improved version of its metal 3D printer called Metal Jet S100 aimed at industrial-scale metal part production.

The company debuted the Metal Jet technology in 2018 and had some high-profile applications (Volkswagen, Cobra Golf) but did not release the machine commercially. Instead, it has worked closely with select companies in various industries on beta testing new features and processes before rolling out the new version, the S100, at the International Manufacturing Technology Show in Chicago last week.

The HP S100 metal 3D printer uses binder jet technology, which is a method of 3D printing that uses a liquid binding agent deposited in tiny drops on powdered materials in layers to create solid, complex shapes. As the build progresses, the print layers are bonded together, resulting in a powder box with the desired part geometry inside.

The process is similar (but not identical) to HP’s MJF but only uses metal powder, specifically stainless steel (316L and 17-4PH).

Binder jetting has several advantages over traditional metal injection molding and other forms of metal 3D printing, depending on your requirements. The technology especially shines regarding speed and resolution since printheads typically work faster than lasers or electron beams. There’s also a far lower material cost with binder jetting because it uses the same commonly available metal powder as injection molding.

Creality Sermoon D3

(Sept. 9, 2022) Creality, the China-based global 3D printing brand offering about two dozen machines mainly for hobbyists starting under $300, is expanding deeper into the higher-priced professional 3D printer category with the launch today of the Sermoon D3.

The company’s newest desktop 3D printer is aimed at industrial designers, Creality says, with target applications including product prototypes, jigs & fixtures, and even mass-production of small parts in carbon-fiber-filled materials including nylon and ABS.

Although not the company’s first “pro” machine — Creality launched the fully enclosed CR-5 Pro ($1,260) in 2020 — the Sermoon D3 sports features common on professional-level devices, such as an extruder temperature up to 300 ℃ and a heated bed to 110 ℃. These are not completely new features for Creality and appear on some of their other machines, but the company may be aiming for just the right combination of features along with an affordable price tag to appeal to industrial designers and engineers.

Creality hasn’t yet revealed the price but says it will launch on its online store this month. All3DP estimates, based on the company’s previous machines, that the Sermoon D3 will retail between $2,000 and $2,500.

Tech Specs

- Build Volume: 300 x 250 x 300 mm

- Print Speed: PLA ~150mm/s, ABS ~250mm/s

- Max. hot end temperature: 300 °C

- Max. heated bed temperature: 110 °C

- Slicing software: Creality Print, Creality Slicer, Cura, Simplify3D

- Filament materials: PLA, PLA-Wood, ABS, PETG, PET, PA66, ASA, PC, PC-ABS, TPU95A, TPC, PLA-CF, PA66-CF, PET-CF

Xact Metal XM300G

(Sept. 6, 2022) Xact Metal just launch the XM300G series of affordable ($200,000) mid-size metal 3D printers using laser bed fusion technology.

The XM300G family is a single-, dual-, or quad-laser system with 100% overlapping print zones. The printers feature a sizeable 300 x 300 x 350 mm build volume, which is upgradable to 300 x 300 x 450 mm, a selection of 400W or 700W fiber lasers, and an interchangeable build platform to reduce printing cycle time.

Shipments are scheduled to start 3Q 2023.

“The XM300G series is ideal for printing high quantities or large parts where print speed is critical,” said Juan Mario Gomez, CEO of Xact Metal. “Based on the XM200G multi-laser printer platform, the introduction of the XM300G is another example of how Xact Metal continues to combine the requirements of metal powder-bed fusion and advanced technology to establish a new level of price and performance for additive manufacturing.”

Xact makes two smaller metal LPBF printers, the XM200C and the XM200G.

Tech Specs

- Build Volume: 300 x 300 x 350 mm

- Laser: Choice of 1, 2, or 4; 400W or 700W

- Build Speed 11.5 cc/hr (with a 400W, Single laser)

- Adjustable Spot Size: 70-140 μm

- Materials: Aluminum Si10Mg, Bronze, Copper (C18150), Stainless Steel: 316L, 17-4 PH, 15-5. Super Alloys: 718, 625, Cobalt Chrome F75, Hastelloy X, Titanium Ti64, Tooling Steels: Maraging M300

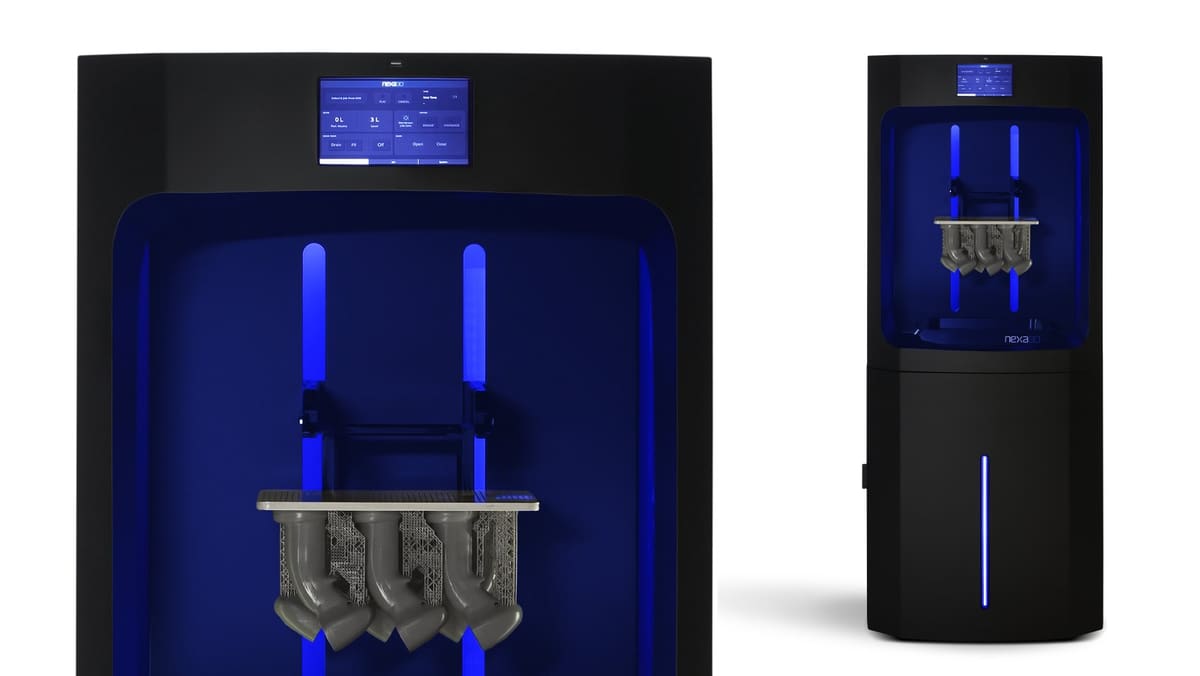

Nexa3D QLS 820

(Sept. 2, 2022) Nexa3D hosted a soft launch of its laser powder bed fusion (or selective laser sintering) 3D printer, the QLS 820, at the International Manufacturing Technology Show in Chicago, where the machine was featured at the company’s booth. Currently, the machine is available only to Early Customer Program participants and is expected to roll out commercially in 2023, but expect to hear more at Formnext in Frankfurt, Germany in November 2022. The QLS 820 appears to replace the QLS 350 announced in Nov. 2021.

With an eye toward mass production of parts, the QLS 820 is aimed at on-demand additive manufacturers and others needing to produce volumes of parts quickly. There’s a removable build unit that can roll to a depowdering station, but the technical details of accessory machines haven’t been released yet.

The quad-laser (100W) QLS 820 offers print speeds of up to 8 liters per hour, according to Nexa3D. The machine features a generous build volume of 350 x 350 x 400 mm and a 50-micron minimum layer height. With a removable build unit,

Materials include PA 12 at launch with PA 11, filled (aluminum, glass, and fiber) PA 12, and PBT available in Q4 2022, the company says, but unlike a lot of SLS machines, the QLS is an open-materials platform and technology-agnostic, meaning it is adaptable to integrations ranging from MES and ES systems to modular post-processing solutions.

The QLS Command Center is a large touchscreen control station, powered by NexaX software, enabling fleet management, print preparation, and real-time printer status and print performance all from a single centralized location.

Tech Specs

- Technology: Laser Powder Bed Fusion

- Laser Type: 4 x 100W CO2

- Min. Layer height: 50-200 microns

- Build Volume 350x350x400mm

- Print Speed: Up to 8 liters per hour

- Price: $528,000

Spectroplast SAM Silicone 3D Printer

(Aug. 16, 2022) Spectroplast, a Swiss start-up, just launched a 3D printer it says can make silicone parts and products with quality and precision on par with injection-molded silicone.

Spectroplast aptly calls its 3D printing technology Silicone Additive Manufacturing (SAM) and its printer is called SAM. It boasts a precision (or Z-axis layer height) of 0.1 mm and the complete freedom of design that comes with nearly all 3D printing processes. The company says products manufactured with SAM are 100% silicone and cannot be distinguished from injection-molded parts in appearance, feel, or performance.

Tech Specs

- Volume: 75 x 134 x 100 mm

- Printer Dimensions: 430 x 510 x 820 mm

- Layer Height: 100 μm

- Pixel Size: 70 μm

- Speed: 5 – 8 mm/hr

- Light Engine: UV-LED DLP

- Price: ~$100,000 (printer and all periphery equipment)

Formlabs’ New SLS Printer Delivers Parts Twice as Fast

(July 17, 2022) Formlabs, best known for its range of versatile and dependable resin printers, just launched a new version of its selective laser sintering (SLS) 3D printer that can make professional-grade parts from polymer powders twice as fast as its previous version. The Fuse 1+ 30W is a reengineered version of the Fuse 1 that Formlabs introduced in January 2021 to put SLS technology within reach of more small and mid-size businesses. The new upgrades don’t make every print situation twice as fast, but tripling the power of the laser, upgrading the material handling mechanisms, and boosting the ability to tightly pack parts into a single print job, will boost your overall productivity, Formlabs promises.

At a fraction of the cost of most SLS machines on the market, the Fuse 1 quickly became a favorite of small manufacturers, automakers, and shop floors of all varieties for its ability to produce lightweight rigid Nylon parts strong enough to withstand repeated impact, making it ideal for replacement and spare alternatives to metal parts, high-impact equipment, factory tools, and functional prototypes.

New Fuse 1+ 30W features include:

- A 30-watt laser (Fuse 1 had a 10-watt laser)

- Scan speeds up to 12.5 meters per second

- New Nylon 11CF (carbon fiber) powder option

- Optional nitrogen supply to boost print quality, powder recyclability

- Lower-waste printing due to high packing density, powder recyclability

- New powder hopper agitator for smooth material delivery

Tech Specs:

- Technology: Selective Laser Sintering

- Build Volume: 165 × 165 × 300 mm

- Price: $27,500

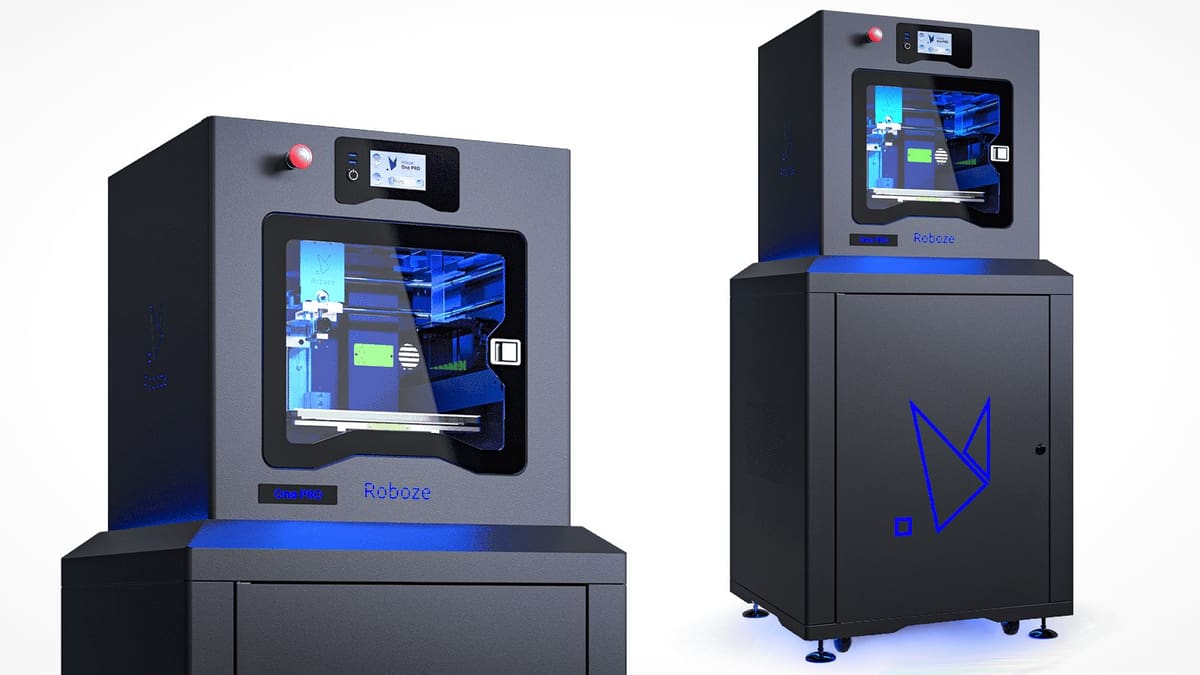

Roboze Aims to Accelerate Production of Industrial Tools With New 3D Printers

(July 7, 2022) Roboze, the Italian maker of industrial 3D printers with an office in Texas, wants you to ditch the cast aluminum and CNCed stainless steel you’ve been using to make your shop tools, molds, fixtures, and spare parts. 3D printing with engineering-grade polymers, such as carbon-fiber Nylon and PEKK, on the company’s two new single-extruder, high-temperature FDM 3D printers is faster, easier, and more versatile, they say.

The two new machines – the One Pro and Plus Pro – aim to shorten the prototyping and production phase of small components and high-performance tools with a host of new features.

Particularly interesting is the new integration of the Pro printers with the Roboze proprietary slicing software called Prometheus. New profile settings within Prometheus enable more click-and-print manufacturing and less manual settings. The UltraFast print profile within the slicer accelerates the printing speed when printing with Carbon PA and the Ultra-PLA, the company says.

Prometheus’ UltraQuality profile results in extremely detailed parts when printing with PEEK, Carbon PEEK, and Roboze’s new ToolingX CF.

3ntr Launches Giant Sequoia High-Temp FDM

(July 1, 2022) 3ntr, the Italian manufacturer of industrial-grade FDM 3D printing systems, launched the Sequoia “for the extrusion of any kind of polymer,” the company says.

Like its namesake tree, the new Sequoia is huge. It features more than 1 square meter (1200 x 1100 x 90 mm) of print volume easily capable of manufacturing large monolithic parts or numerous small elements.

Sequoia, the first machine in 3ntr’s anticipated V5 series, is much larger than the company’s other industrial FDM printer, the Spectral 30, but features a similar extruder capable of heating to 450º C and a heated chamber to 130º C to accommodate engineering grade filament polymers. There’s also automatic bed and extruder leveling, plus a massive 19.5-inch touchscreen display, and a built-in six-material filament drying and storage unit.

3ntr says the strength of this large printer lies in being able to maintain print quality and reliability even on large format prints.

Tech Specs

- Technology: FDM

- Build volume: 1200 x 1100 x 900 mm

- Max. Extruder Temp.: 450° C

- Max. Bed Temp: 200° C

- Max. Chamber Temp.: 130° C

Photocentric’s New Resin Printer Doubles Speed, Targets Production

(June 3, 2022) UK-based resin 3D printer maker Photocentric just launched what it says is a completely re-engineered desktop resin printer. The new LCD screen-based Liquid Crystal Magna v.2 is “significantly faster” than the previous version, Photocentric says, and features upgraded electronics, including a new control system and interchangeable platforms, all aimed at improving reliability and performance. On the outside, it looks the same as the previous version.

When it comes to speed, Photocentric says the Magna v.2 prints at 16mm per hour depending on the resolution. By way of example, the company says 36 custom dental trays (80-mm Z height) at 250-micron layers can be printed in 1 hour 13 minutes, compared with 2 hours 22 minutes on the previous version of the LC Magna. So, twice as fast as the previous version of the Magna.

Tech Specs

- Build volume: 510 x 280 x 350mm

- Print layer thickness: 25, 50 and 100µm.

- Resolution: 4K screen. 3840 x 2160 px

- Print Speed: 16mm per hour

- Cure Speed: 2 seconds per layer at 100um

- Light output wavelength: 460nm

- Price: ~ $22,000 – $26,000

- Software: Studio, Additive (optional)

Tractus3D Launches New Large-Format Printer that Hits the Spot

(May 20, 2022) If you need to print parts nearly a meter tall (920 mm) in your office space, check out the new T2300SE from Tractus3D. It’s not so much a new printer, but a new shape.

The latest printer to join the SE series was created to fit within any building, due to its height, but still have a massive 1,000 mm diameter. So it fits between the company’s T2000 and T3000SE, with all the benefits and features of the T3000SE and T3500SE.

The T2300 features a 15-inch touch screen, and accompanied with every printer, you receive a tablet. This tablet allows you to work mobile around the printer and operate it.

There’s also an onboard camera and a surprisingly hot extruder (500 °C) for a large-format 3D printer.

Starting July, the T2300SE will be sold for its regular price of $53,000 00 but in June, it’s on sale for $43,000.

Tech Specs

- Build volume: 1,000 x 1,000 x 920 mm

- Travel speed: up to 600 mm/s

- XY resolution: 20 microns

- Minimum layer resolution: 50 microns

- Heated build plate: up to 110 °C

- Nozzle: up to 500 °C

- Price: ~$53,000

Digital Metal Launches Higher Productivity Metal Binder Jet 3D Printer

(May 18, 2022) Digital Metal, the Swedish metal binder jet 3D printer maker, just launched a machine that doubles the maximum speed of its older binder jet technology.

The new DMP Pro has twice the maximum productivity (1,000 cm3 /h) compared to the company’s older DMP2500 metal binder jet printer in the same build volume (250 × 217 × 186) and the same maximum resolution (35 µm in z-direction).

Binder jetting is the fasted method of metal 3D printing and a favorite among manufacturers looking to produce significant volumes of small parts for industry, medical manufacturing, and consumer products. Because the method doesn’t require heat, there’s no lengthy cool down or heat up, no inert gas environment, and the time between batches can be as little as 15 minutes, Digital Metal says.

Read more:

Farsoon’s New Metal 3D Printer Doesn’t Skimp on Features

(May 13, 2022) Farsoon, the large Chinese 3D printer manufacturer, launched its new FS200M×2 platform for early adopters this week, expanding its portfolio of medium-sized metal laser powder bed fusion 3D printers. The FS200M×2 has a 425 x 230 x 300 mm build volume and a dual 500-watt laser configuration.

Farsoon says its advanced dual-laser scanning calibration algorithms sets it apart from other metal LPBF machines because the technology distributes each laser’s path for optimized build efficiency and speed, and features a “softened” laser overlap area for more uniform part properties. The FS200M×2 can also integrate multiple scanning strategies of different layer thicknesses in a single build according to the application’s needs.

The FS200M×2 is an open platform printer offering engineers a high degree of control to tailor the print parameters.

Other features that ensure uniform part properties throughout the build platform include the printers unique re-coater blade design, an integrated two-stage filter module, and an optimized gas flow layout.

As part of its quality control package, the FS200M×2 is equipped with in-chamber cameras which are used to monitor and record each layer. Besides logging the layer-to-layer data, the cameras also enable Farsoon’s real-time recoat monitoring feature, which records and analyzes each recoat layer in real-time. If a short feed or build error is detected, the software will automatically recoat or pause the build.

The FS200M×2 has a long list of ease-of-use features, no doubt developed from customer feedback, such as the top-feed powder system with sensors that alert you to refill once the powder level runs without disturbing the build process. There’s also the compact machine design consideration. The machine’s footprint is only 3.48 square meters with operational access from only front and right, and the build platform resides at a convenient hight for build plate install and removal.

Farsoon hasn’t released the price yet, but based on its other metal LPBF printers, this one, too, should be in the over-$500,000 range.

Stratasys Launches Benchtop 3D Printers for Tougher Materials

(May 12, 2022) The current F123 Series 3D printers from global giant Stratasys are already popular shop-floor FDM machines, churning out prototypes and fixtures worldwide, but something was missing. Two new extensions of the F123 series aim to fill that gap providing, what Stratasys says, is an easier-to-print experience for advanced engineering-grade materials.

With the introduction this week of the F190CR and F370CR 3D printers (CR stands for composite-ready), Stratasys debuts features it says will enable manufacturers and industrial machinists to move beyond product prototypes and 3D print end-use parts, such as jigs, fixtures, and work-holding tools. The older F123 series was already marketed as an end-use tool and fixture 3D printer, but apparently, customers were looking for more, namely, carbon-fiber-reinforced Nylon.

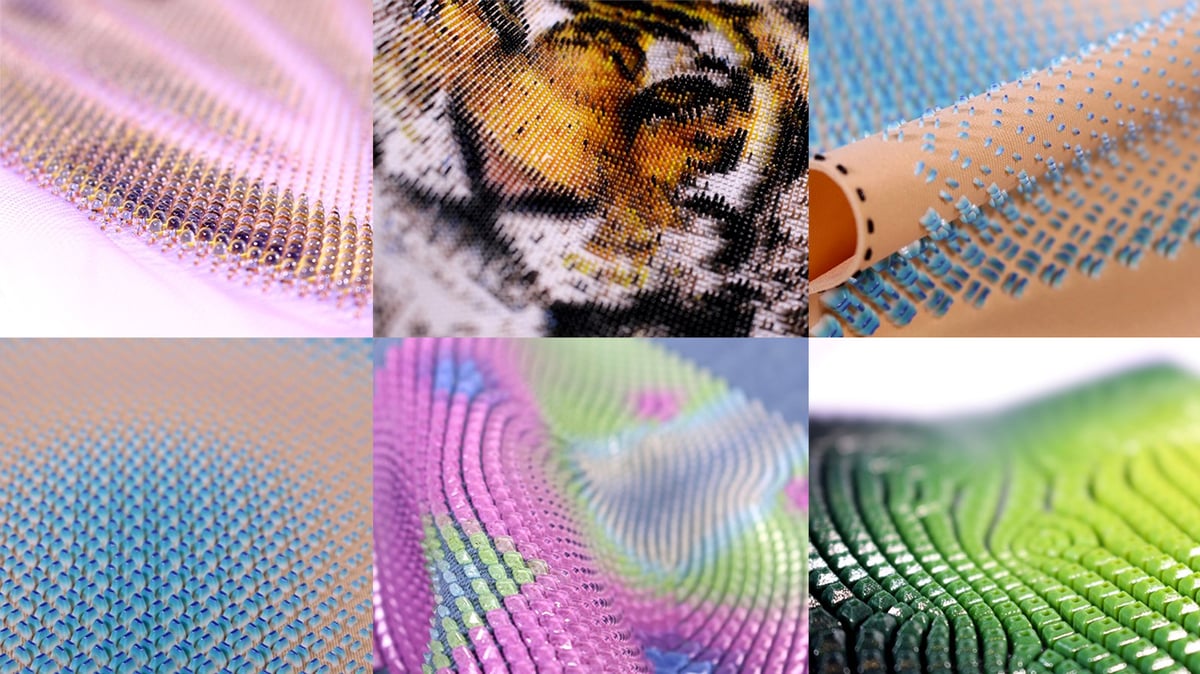

Stratasys Launches J850 TechStyle

(May 3, 2022) The new J850 TechStyle (a play on the word textile) from 3D printer maker giant Stratasys, uses the company’s established material jetting technology to deposit polymer resins, layer by layer, onto a piece of denim, cotton, polyester, linen, or leather at volumes ranging from single custom pieces to the tens of thousands.

Stratasys was able to 3D print directly on fabric before, debuting the method with its J750 PolyJet 3D printer in 2019, but the new TechStyle version of its J850 features parts and software focused specifically on fashion and making the entire process more accessible, the company says.

Stratasys’ 3DFashion printing technology couples computer-generated design for patterns that cannot be completed manually with colorful, clear, and translucent materials, to create illusions with color and light mimicking everything from butterfly wings to insect eyes.

Not limited to bead-like hard plastics, brands can print in soft and flexible materials and directly print features, such as buttons, cufflinks and clips directly onto the garment in heights up to 50 mm. A variety of materials are available for the J850 TechStyle 3D printer, which is able to print on textiles in over 600,000 unique colors. The Vero ContactFlex resin material, for example, produces a transparent coating on textiles that can be used to create a soft touch, silky feel. The TechStyle also prints with water-soluble support materials.

Stratasys hasn’t announced a price, but its similar multi-material, multi-color 3D printer, the J850 Pro, is roughly $200,000.

Tech Specs:

- Build Size Fabric Size Handling: min 560 x 460mm; max 2 x 2m

- Fabric Thickness: 0.1-3.0mm

- Effective Printing Area: 460 x 360 x 50 mm (18.1 x 14.2 x 1.9 in) on a stretch of fabric up to 2m2

- Layer Thickness: 27-micron to 55mm

- Software: GrabCAD Print

- Materials: 7 base resins.Vero & VeroUltra family of opaque materials + neutral shades and vibrant VeroVivid colors. Agilus30 Clear, Black, White, Cyan, Magenta, Yellow. Transparent VeroClear and VeroUltra Clear. Vero ContactFlex for soft touch model coating. Pantone Validated palettes. Translucent color tints. Flexible tactile materials in a variety of textures and colors. Support Materials.

Nexa3D’s New NXE 200 Targets Affordable Industrial Resin 3D Printing

(Apr. 27, 2022) Looking to bridge the gap between affordability and quality in professional resin 3D printing, California-based Nexa3D just launched the NXE 200, its fourth resin printer.

At $50k, the NXE 200 targets that elusive middle ground between prototyping and production capability. The goal is to give designers, engineers, and manufacturers who need fast and accurate prototypes, the ability to scale up to batch manufacturing on the same platform. If your shop uses one technology for iterations and then switches to another printer with its own workflow and set of perimeters for batch production, you know what a hassle that process is.

The NXE 200 is an industrial masked stereolithography (MSLA) 3D printer with all the features you’d expect, but at a price point to lure a new audience to volume additive manufacturing. Let’s take a closer look.

Tech Specs

- Build Volume: 10.8 x 6.1 x 7.8 inch (275x x 155 x 200 mm)

- Max Resolution: 4K (3840 x 2160)

- Pixel Pitch: 76.5 µm (0.0030 in)

- Wavelength: 405 nm

- Price: $49,999

- Build Materials: open material platform for UV curable plastics. xGPP-Translucent; XGPP-Grey; xPRO410; 3843-ABS-Black; xCE-Black; ABS-Black; xCE-White; xPP405-Black; xPP405-Clear; xPEEK147; x45-Natural; x45-Clear, x45-Black, xFlex

ExOne Launches S-Max Flex Sand Printing System

(Apr. 22, 2022) Made for foundries and pattern shops looking to modernize their metal casting, the ExOne S-Max Flex sand printing system pairs an industrial robot with an all-new printhead and recoater design.

Engineers from ExOne and parent company Desktop Metal created the S-Max Flex from the ground up off an existing concept, the S-Max Flex brings Desktop Metal’s high-speed patent pending Single Pass Jetting (SPJ) technology to the foundry.

This new turnkey sand 3D printer was developed to help smaller foundry businesses both survive and thrive into the future, the company says. The S-Max Flex boasts quick turnaround times on high-quality sand molds and cores regardless of complexity – eliminating the need for traditional core production and assembly, and all the labor, scrap, and complication that comes with it.

The S-Max Flex keeps foundries competitive by enabling same-day castings of the complex cores becoming increasingly common as manufacturers consolidate and lightweight metal parts for electric cars and a new future.

SLA 750 Dual, 3D Systems’ New High-Speed, Production-Ready Resin Printer

(Apr. 5, 2022) 3D Systems’ new resin printer launched this week, and it was worth the wait. The company hasn’t launched major advancements in its stereolithography technology for a while, apparently keeping all the bells and whistles for the new baby: SLA 750 Dual.

What 3D Systems claims to deliver with this release is the promised land of production resin 3D printing: A single platform combining size, speed, accuracy, and resolution for final parts with excellent finish and mechanical quality.

The SLA 550 Dual is 3D Systems’ fastest resin printer to date and features 15% more print volume than its ProX 800 while having a smaller overall footprint. The focus of the machine is to deliver large, production resin parts and batch-part production for industries from transportation and motorsports to aerospace and healthcare.

Let’s take a closer look.

The most exciting aspect of the SLA 750 is its dual synchronized 4-watt lasers that can trace out parts with high detail. Two lasers clearly double the speed of the company’s other SLA printer and, even if you opt for one laser on your SLA 750, 3D Systems says it will still be 30% faster than any of its other machines.

New tech behind this significantly improved printer speed and throughput is 3D Systems’ new and proprietary scanning algorithm called Hyper-Scan. The laser control feature optimizes laser focus, power, and vector motor kinematics.

The system also features a self-calibrating dual-rail recoater designed to improve print process reliability and final part mechanical properties, the company says.

3D Systems’ says the SAL 750 is “the fastest stereolithography solution available” without providing actual speed, so take claim that with a grain of salt.

FabWeaver Launches Type A530

(Mar. 25, 2022) FabWeaver, an off-shoot of the South Korean 3D printer maker Sindoh, announced that its new FDM printer called the Type A530 will start shipping this spring. FabWeaver debuted at the Formnext trade expo in November.

Dubbed a “prototyping workstation for industrial 3D printing”, the A530 features a modest build volume (310 x 310 x 310 mm), dual extruders, and a built-in multi-spool material chamber. Targeting the office environments of product designers, the open-material printer features print speeds up to 200 mm/s, the company says, and there’s a heated chamber (75 ºC).

The Type A530 is priced at just under $10,000.

Black Buffalo 3D Launches Modular Construction Printer

(Mar. 15, 2022) The number of construction 3D printers on the market is small but grew one bigger this week with US-based, South Korean-backed Black Buffalo 3D officially launching its Nexcon 1G.

Black Buffalo 3D sells, leases, and trains on its 3D construction technology to help increase adoption, it says. If you want one for yourself, the basic configuration will put you back about $800,000. But, according to Black Buffalo, the efficiencies gained and labor saved compared to traditional construction methods make it a savvy investment. The printer can complete a 1,000 square-foot structure in under 20 hours.

The Nexcon 1G is a modular 3D construction printer that can be extended on its X, Y and Z axis to scale up (or down) to fit the size of a project, up to three stories tall. A bit unique about the 1G is the ability for users to reposition the base tracks and move the printer to a new print area without having to dismantle the X or Z axis.

The multi-axis gantry system can generate prints for any 3D modeled design created using conventional CAD software. The printer uses Black Buffalo’s proprietary cement material – the company calls ink – that can be colored and customized to match temperature, humidity, and altitude-specific conditions. The company says it has worked for years in perfecting the materials science that goes into their “ink” to ensure it meets all of the International Coding Commissions Criteria for AC-509 3D Printed Walls.

Unlike construction printer makers Peri, Icon, or COBOD, Black Buffalo doesn’t have many 3D printed homes under its belt that people live in today, but after selling a printer to homebuilder Alquist 3D earlier this month, that soon may change.

The company is so confident in its new printer after several years of development, it recently purchased 106 acres in Pennsylvania to build a new construction 3D printer factory. Will they 3D print their 3D printer factory? We’ll see.

Fluicell's Compact Biopixlar Microfluidic Platform

(Mar. 1, 2022) Swedish company Fluicell launched the Biopixlar AER single-cell bioprinter this week. The technology maintains cells in their native environment within a compact microfluidic platform. The size of this bioprinter is one of the aspects setting it apart from others.

Biopixlar AER is the first high-resolution platform designed to fit inside a standard cell culture flow hood, making it easy to use together with other invitro and 3D cell culture technologies, the company says. This combination of compactness, ease-of-use, remote control, and portability makes it flexible enough for a wide range of applications, including aerospace and deep-sea exploration.

The exchangeable microfluidic printhead lets you deposit cells right where you want them with micrometer precision. This makes it possible to create everything from single-cell arrays to detailed tissues containing multiple different cell types. “Biopixlar AER’s microfluidic bioprinting technology requires very little sample volumes, making it the ideal choice for uses involving scarce and valuable materials, such as applications within personalized medicine using patient-derived material,” the company says.

The latest machine comes with the Biopixlar Wizard software to automate and follow the bioprinting process in real-time. The Wizard features a wide range of ways to control the built-in microscope, LED light source, and camera. With Biopixlar Wizard, you can follow the bioprinting process in real-time, using the imaging conditions that best fit your experimental setup.

The Biopixlar AER is the company’s second single-cell 3D-bioprinter to create detailed biological tissues.

New ChairSide Dental DLP 3D Printer from HeyGears

(Feb. 26, 2022) HeyGears, a Chinese 3D printer maker, launched a suite of new plug-n-play dental-focused resin 3D products this week: the UltraCraft ChairSide and ChairSide Pro DLP printers with separate AirWash and AirCure units.

Debuting at Lab Day, the dental industry conference and trade show in Chicago, these units focus on ease-of-use for dental pros promising they can go from scan to product within 30 minutes (depending on the application). HeyGears has at least four other dental resin printers on its menu, but the ChairSide versions are by far the company’s smallest.

Especially interesting is the ChairSide’s integrated resin tank, material, and feeding system called the CapsulePrint. CapsulePrint is made from recycled plastic and is disposable, eliminating the hassle of resin tank cleaning and used resin storage. This innovation “makes shifting between applications fast and easy”, the company says, without the need for calibration.

The UltraCraft AirWash completes the washing and drying process using the disposable platform as the base, preventing the need for contact with the liquid resin. AirWash can automatically detect the application in use and select the optimal washing solution for each output. The AirCure provides the final step in production, providing auto-calibrated fast curing by identifying the application and the proper curing strategy for each output.

ChairSide Specs:

- Build Volume: 125 × 70 × 70 mm

- XY Native Pixel resolution: 96 microns

- Accuracy: 37.5 microns ~ ± 48 microns

- XPR Pixel: 48 microns

- Light Source Wavelength: 385 nm

New Metal DED 3D Printer from Mitsubishi

(Feb. 24, 2022) Japan’s Mitsubishi Electric, the company that makes everything from industrial robots to semiconductors, launched its newest industrial 3D printer this week called the AZ600.

The two models of the new AZ600, a directed energy deposition (DED) technology 3D printer using metal wire as feedstock, are aimed at heavy industry use of DED for repairs and maintenance of parts and equipment in automobiles, marine, and aerospace.

The AZ600 has a 600 × 600 × 600 mm build volume and uses a wire-feedstock with a 2 kw or 4 kw laser.

Mitsubishi says demand is expected to grow for metal 3D printers that can significantly shorten conventional manufacturing processes, reduce waste materials in manufacturing, and improve design flexibility by making it easier to integrate multiple parts and reduce weight.

Linking it with a sustainability focus, Mitsubishi says “the growing need to reduce CO2 emissions in the metalworking manufacturing industry has stimulated an increase in demand for more efficient metalworking methods that reduce energy consumption and conserve finite natural resources.”

Desktop Health Launches Faster Dental 3D Printers

(Feb. 1, 2022) Desktop Health, the healthcare side of Desktop Metal, launched a new series of digital light processing resin printers designed for dental professionals. The company also came out with a dental resin it says is one of the strongest yet to receive FDA clearance for permanent use.

If the new series of printers from Desktop Health, which are called Einstein, look exactly like the Envision One DLP and Perfactory printers from EnvisionTec, there’s a good reason.

Desktop Metal bought EnvisionTec in 2021. But don’t think that these are simply renamed and repackaged. Desktop Health says there’s new tech under the hood and a closed-loop software upgrade that makes them faster and more accurate.

Sure, the core technology leverages EnvisionTec’s historical R&D and the 385-nanometer projector, but the Einstein series features new innovations, including something Desktop Health calls HyperPrint technology – although they haven’t released details yet on what exactly that is.

What they do say is that this new series offers 50% faster printing than the EnvisionTec versions.

Carbon Launches M3 Series 3D Printers for Easier, Faster Industrial Production

(Jan. 26, 2022) California-based 3D printer maker Carbon just launched a new version of its industrial resin printer that’s faster, larger, more reliable, and comes with new easy-of-use features.

Available in two models, the M3 and the M3 Max provide an “advanced end-to-end idea-to-production platform” when combined with the Carbon software called Design Engine and proprietary Carbon materials.

The M3 is the same size as Carbon’s M2 launched in 2019, but boasts a simpler print experience with the help of a new touchscreen that features more printer options. The company also says you can expect 2.5 times the throughput compared to the M2 and a more consistent surface finish. This is an impressive statement since Carbon printers are already among the fastest on the market and known for their high surface quality.

The greater throughput is thanks to better heat management, Carbon says, and you can expect about a 1.4 µm reduction in surface roughness.

More interesting though are the details about heightened reliability from what Carbon calls the next generation of its Digital Light Synthesis resin 3D printing technology. Without going into the weeds of the science, Carbon says the advancement creates lower forces on the part that reduces print failures. The new tech reduces the variation in parts across a single-build by up to 50%, which translates to higher general accuracy and more production repeatability in engineering resins.

Read More:

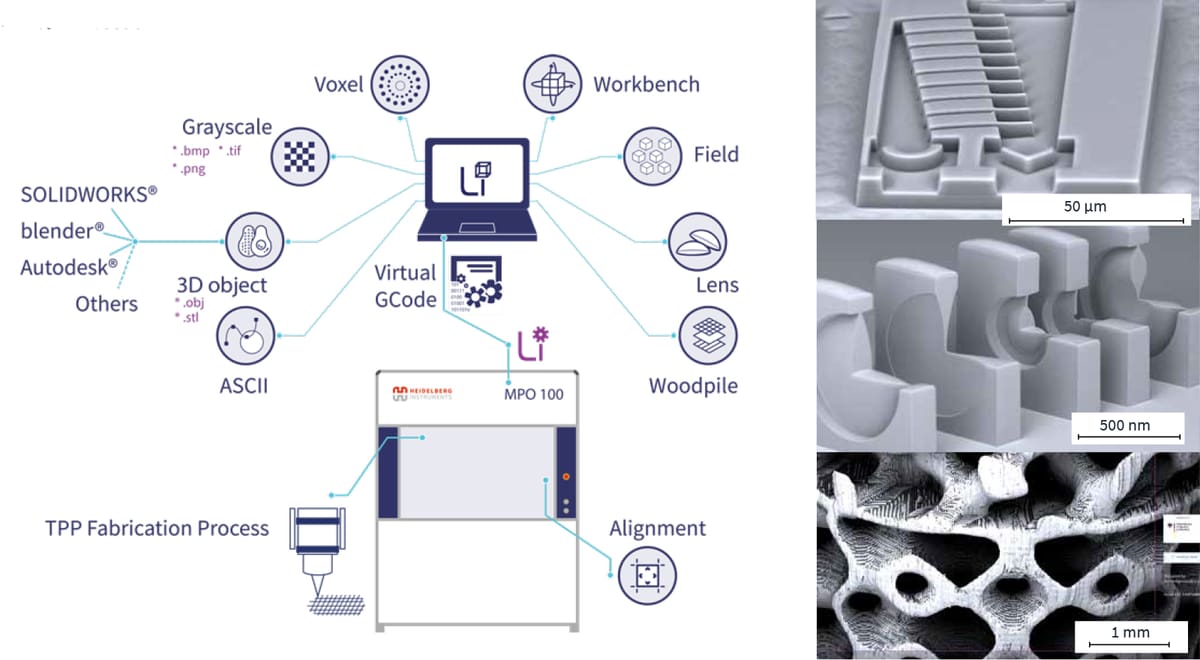

Heidelberg Instruments New TPP 3D Printer

(Jan. 20, 2022) German company Heidelberg Instruments is launching its two-photon polymerization (TPP) machine for micro 3D printing at the SPIE Photonics West Expo in San Francisco, Jan. 25 – 27. The new MPO 100 offers 3D lithography as well as high print volume for 3D microprinting and enables production of complex functional microstructures for applications in micro-optics, photonics, mechanics, and biomedical engineering.

The MPO 100’s femtosecond laser system operates at a wavelength of 522 nm. Compatible materials include a range of commercially available polymers including inorganic-organic hybrid polymers.

Application-specific modes enable fast switching between 3D lithography and 3D microprinting. A 100 x 100 mm print volume can produce a part size range from 1 cm down to 100 nanometers.

The MPO 100 includes the software package of LithoStream and LithoSoft3D as standard. LithoStream control software features printing time estimation, triangulation, process camera, alignment, print job creator, and application programming interface (API). Printing parameters can be saved into a data base and printing recipes can be loaded.

E-Plus 3D’s New, Large LPBF 3D Printer

(Jan. 19, 2022) If you’ve been looking for a way to 3D print metal parts that are about 1.1 meters tall (3.5 feet), Chinese manufacturer E-Plus 3D has just the thing.

The company’s new EP-M450H is a laser powder bed fusion 3D printer with a 455 x 455 x 1,100 mm build volume making it the tallest metal 3D printer on the market, the company says. Creating monolithic metal parts instead of assembling or welding multiple parts for a component, is attractive to manufacturers, especially aerospace, aviation, and defense, looking to optimize part performance while cutting costs and production time.

The EP-M450H also features single or dual 500W fiber lasers, a max build rate of 65 cubic cm per hour with dual lasers, a bi-directional powder recoater, and layer thickness of 20-120 µm.

By launching this new large scale metal AM machine, E-Plus 3D also is hoping to target production additive manufacturing. EP-M450H prints with titanium alloy, aluminium alloy, nickel alloy, maraging steel, stainless steel, cobalt chrome, and copper alloy.

E-Plus 3D offers nine other LPFB 3D printers ranging from the dental focused EP M150 to the industrial EP-M650, with a 655 x 655 x 800 mm build volume.

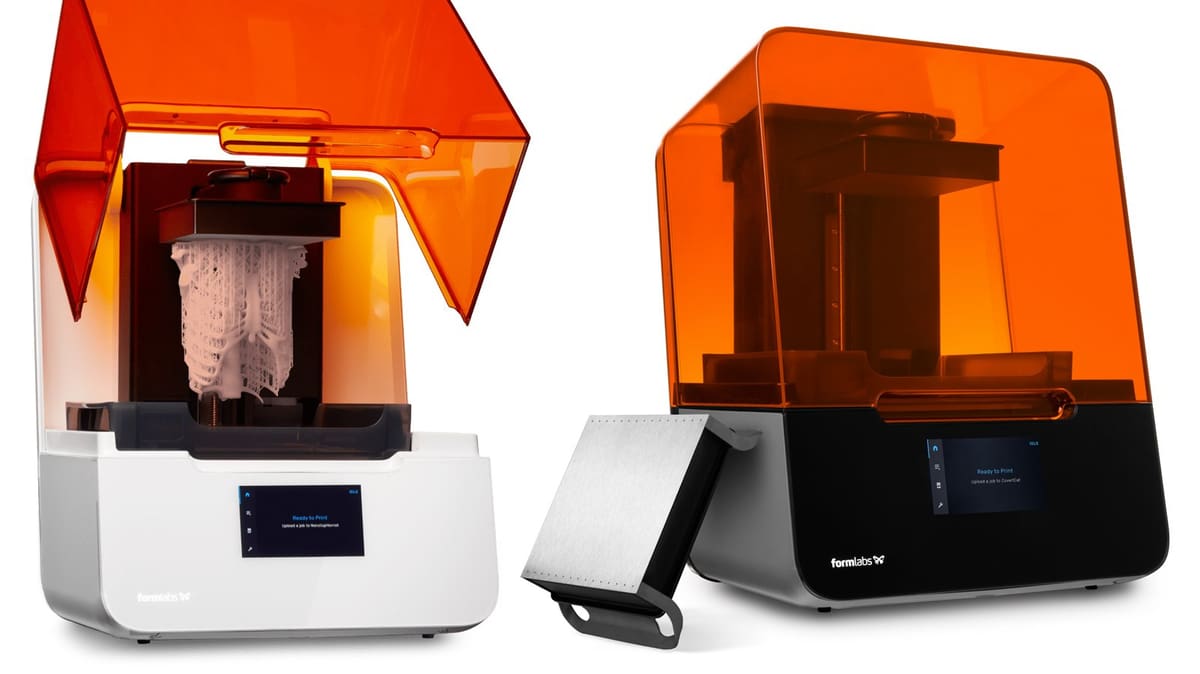

Formlabs Fastest Resin Printer – The New Form 3+

(Jan. 5, 2022) Just a few days into the new year – when many of us were still on vacation – Formlabs launched its newest SLA printer at the Consumer Electronics Show in Las Vegas.

It is not called the Form 4, which is what you’d expect from an upgrade that enables 40% faster printing. Instead, Formlabs put a + at the end of its existing model names and quietly replaced its Form 3 and Form 3B (designed for dental and healthcare applications) with the new Form 3+ and the Form 3B+.

Perhaps Formlabs is hesitant to completely rename the new version because the software changes that enable the faster printing are also retroactive to the older Form 3 and 3B versions already in use. Quite a bonus for existing Formlabs customers. By upgrading your version of PreForm and the firmware on your Form 3B, you will be able to experience many of the improvements of the Form 3B+.

Read More:

License: The text of "All the New Professional 3D Printers in 2022" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.