If you’re familiar with Prusa’s earlier iterations of the multi-material kit, which lets owners of Prusa i3 MK3 and MK2.5 print in up to five different materials simultaneously, the upgrades in the Multi Material 2S kit should come as a welcome relief.

The MMU 2.0 was a very finicky kit and was difficult to get to work properly. However, the MMU2S, priced at just under €300, promises to have fixed some of the issues, making it easier to print the rainbow or combine different materials in a single print.

This time around, Prusa boasts a”major revision” and a complete redesign, with a new body that includes a rotating pulley barrel and a single extruder motor. All these tweaks should make it more simple to use and more reliable.

But, does this latest upgrade kit improve upon the old kit enough? Is it worth your money? We haven’t had a chance to test it out yet, but we’ve pored over its specs to find out whether it’s worth your money. Read on for our review of the MMU2S’s specs.

Features

New Features

Filament buffer

This device is designed to prevent issue s with the filament tangling when it’s being loaded or unloaded. This handy tool saves room on your workspace and lets you position the five filament spools in a more convenient way for you.

Filament sensor

The MMU2S boasts a filament sensor upgrade — the same one that’s on the Original Prusa i3 MK3S. This nifty little fella can sense the filament is present and also that it reaches the Bondtech gears. It’s triggered by a simple mechanical lever, which means the optical properties of a filament can’t confuse it.

Old (But Still Nice) Features

F.I.N.D.A. filament sensor

The F.I.N.D.A. filament sensor is a repurposed P.I.N.D.A. probe you’re probably already familiar with from your Prusa 3D printer. As Prusa explains it in his blog, it works on a mechanical basis.

“When you insert a strong of filament, it lifts a small stainless steel ball. Then, the probe detects its proximity, which means the filament is loaded,” he writes.

Since this probe works mechanically, it can’t get confused by clear filaments or ones with strange textures — an important feature.

Direct drive

One of the complaints about the previous kit was its use of a Bowden system, which was less reliable. Prusa has done away with it for the new kit and boasts it now has a “direct-drive feed and a single PTFE tube to lead the selected filament to the extruder.” Though — as mentioned — we haven’t gotten our hands on the upgraded MMU2S yet, and aren’t able to compare the two, this should reduce filament jams, improve its ability to process flexible filaments, among other improvements.

Built-in blade to prevent filament jamming

This built-in blade automatically cuts off the tip of a filament line if it gets caught as it’s being unloaded. This solves a big problem of the previous system, which frequently jammed.

Filament conservation

Prusa’s slicing software Slic3r PE offers support for the MMU2S that helps you conserve filament while printing with tools like smart wipe tower, wipe into infill and wipe into object. This means you can do fancy tricks like use filament that would otherwise be wasted as infill, for example, where it’s out of sight, but still doing some heavy lifting.

Thoroughly tested

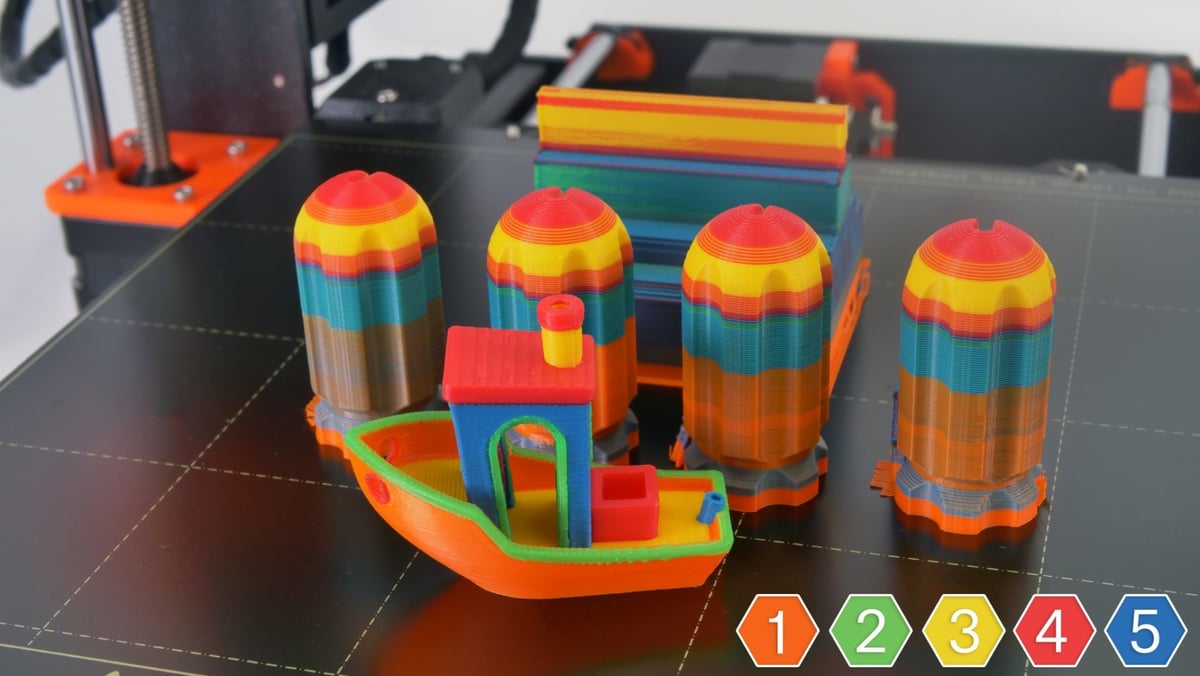

Perhaps to quell fears that this kit will be as difficult to work with as its predecessor, Prusa boasts the new kit as being ‘thoroughly tested,’ adding the process took two months to complete and was done using 20 printers, which created “478 test blocks designed to test frequent switching of all five filaments.” Prusa claims more than 93% of these prints were completed successfully.

Technical Specifications

Material compatibility: PLA, ABS, PETG, soluble materials (BVOH, PVA)

Printer compatibility: Original Prusa i3 MK3 and MK3S, Original Prusa i3 MK2.5 and MK2.5S

Power loss detection and recovery: Yes

Smart software features: Smart wipe tower, wipe to infill, wipe into object

Where to Buy

License: The text of "Prusa Multi Material 2S Upgrade (MMU2S) – Review the Specs" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.