When I first entered the 3D printing industry nearly a decade ago as a sales rep, most of my professional conversations centered on how 3D printers work and what they are good for. Today, things are vastly different.

Now, much of my time as a consultant is focused on helping engineers and manufacturers create a solid business case that will justify the cost of a 3D printer to management, leading to the approval to purchase. Conversations have shifted from; “How does the tech work and what can it do?” to “How do I convince management to buy it?”

In this article, I outline the exact seven-step approval roadmap that I’ve shared with hundreds of businesses of all types and sizes, helping them get the approval to purchase the 3D printer they wanted and needed. Here is a snapshot of the seven steps that apply to all additive manufacturing technologies and price points:

- Select Application – the parts you will print

- Establish Budget – including the peripherals

- Prioritize Needs – what can you live without

- Downselect Options – reduce options to a few

- Validate Capabilities – look beyond the marketing

- Estimate ROI – there’s a formula for calculating this

- Compile Business Case – summarized in one document

Now, let’s do a deep dive into this tried and proven process for getting to YES!

Step One: Select the Applications

The first step of your journey is clearly defining the problems that will be solved by owning a 3D printer. If that doesn’t quite fit your situation, you can also think of it as the benefits of owning a 3D printer, although this can be harder to articulate.

You must identify at least one, or better yet, two primary applications (what specifically you will print) and hopefully a few secondary ones. Primary applications are those that have a noticeable impact on the ROI and to your business’ bottom line, and will occupy a big chunk of the overall printer usage.

For example, your company’s primary application might be to 3D print tools, gigs, and fixtures for your manufacturing processes, which will be faster and cheaper than how you’re doing it, plus you’ll have a better, lighter-weight product.

Secondary applications are smaller print jobs that don’t necessarily affect profits but can reduce time, improve efficiency, or add convenience. A secondary application is a value add, and sometime only realized once the printer is in-house and fellow employees discover its usefulness. Another department may use the printer for prototyping while it would also be ideal for fabricating short run small replacement parts for your equipment as as well as for your customers’. Think of it as primaries being the cake and secondaries being the icing—and who doesn’t love icing?

If your considering a printers that cost less than $60k, you’ll likely have to come up with these application ideas all on your own, although companies usually have great ideas in their marketing materials. Printers at this price are often treated as transactional purchases by sales organizations, and they rarely involve site visits from their representatives. This is because the lower profit margins rarely support this level of activity. But as the price point of the printer you are considering increases, the sales process should shift to being more consultative in nature. and the sales reps can be called upon to help you uncover more primary and secondary applications that are unique to your business.

When I teach sales teams how to improve their performance when offering professional and production-grade systems costing $100k and up, I consistently remind them of their consultative responsibilities. As part of this consultant role, when selling at these higher price points, I suggest they offer qualified prospects a free “Application Audit.” This audit is conducted by an experienced Application Engineer (AE) representing the seller and is done at the buyer’s site to assess potential applications that can strengthen an ROI and business case. From the seller’s perspective, a qualified prospect is someone who has mutually shared information that is relevant to the deal at hand, such as their timeline for buying and budgetary range.

A few years ago, I was working with a major defense company that struggled to gain approval to purchase a production-grade printer from my company. Their corporate office had denied their purchase request for the same system for four consecutive years, and they knew they would be turned down again unless more value could be uncovered. As a result, they invited me and my AE to walk the shop floor of their Texas facility in search of additional use cases. Within two hours of being there, my AE identified a new application for 3D printing large tooling molds from polycarbonate. This single addition to their business case nearly doubled the ROI, eventually leading to the approval and purchase of the system they wanted. Sometimes, it’s just another set of eyes can do the trick.

If you’re considering an investment of $50k or less, asking for an onsite application audit may be met with resistance, but for investments of $100k and up, it’s a reasonable request that can add tremendous strength to your proposal to management, so don’t be shy and ask for the customized audit!

Step Two: Establish Budget

Once one or more applications have been identified, I strongly recommend that you attain some level of verbal support or buy-in before moving forward with the process, even if it’s only verbal. Don’t blindside upper management with tech terms in writing or spreadsheets of projections; soften them up first. Chat informally about the competition’s use of 3D printing or what it has achieved in other industries. Everyone likes to talk about 3D printed houses, race cars, and rocket thrusters; it’s relatable.

General budgetary parameters, which include a best-case and worst-case scenario for what your company could spend, will be enough to begin your buying journey. It’s best to know your limits in advance — before requesting formal quotes from 3D printer makers or benchmark parts because sales professionals will find it challenging to propose or quote suitable options without at least knowing a ballpark price range. This is for the $100k-plus solutions that are custom-configured for particular companies and applications. In the under $100k range, there are still valuable package deals and service arrangements that could be a great deal if you know your budget in advance.

Lastly, communicate with the sales rep. He or she wants you to have this 3D printer as much as you want it, but they need to know if you’re ready to buy or are in the state of building a package to management or at the beginning of the discovery process. This sets the proper expectations and may minimize any unnecessary sales pressure that unfortunately occurs occasionally. After all, the objective is to buy a 3D printer, not to be sold one.

Step Three: Prioritize Needs

You won’t get everything you want. Now that you have identified one or more applications and established preliminary budgetary parameters from management, it’s time to prioritize your needs. To accomplish this, rank the top five 3D printer attributes listed below in the order of most to least important — as they relate to your purchase.

- Price

- Quality

- Capability

- Service & Support

- Return on Investment

After completing this exercise, you might determine that capability is the most essential attribute and price is the least or that service and support rank at the top of your list. Regardless of your ranking, having these details worked out in advance will make the 3D selection portion of the buying process significantly easier.

Step Four: Downselect Options

Having prioritized your needs in their order of importance, it’s now time to downselect. If you’re not familiar with this term, it’s often used in the context of project management, procurement, and decision-making processes to refer to narrowing down or reducing the number of available options, candidates, or choices.

To help simplify the downselection process, prioritize the most important 3D printer capabilities similarly to how you ranked your needs in step three. Here is a list of 15 common capabilities to get you started, but you may want to add more:

- Available Material Options

- Dimensional Accuracy

- Maximum Part Size (x,y,z)

- Maximum Throughput

- Printer Ease of Use

- Open vs. Closed Material Ecosystem

- Maximum Part Resolution

- Minimum Feature Size

- Minimum Part Size

- Maximum Heat Deflection

- Open vs. Closed Source

- Part/Material Strength

- Post Processing Requirements

- Printer Software

- Warranty Coverage

When downselecting, experienced 3D printer sales professionals will typically direct your attention to key attributes and capabilities that offer them a competitive advantage, as they should. However, it is important to remember that it is only a competitive advantage if it helps you achieve your desired business outcomes. For example, a system that can print in 13 different materials should not be considered a differentiator if you only need to print in two materials. However, it could be weighted as a differentiator if you foresee the need for additional materials in the future.

Knowing in advance that “printer ease of use” and “post-processing requirements” are essential to your team can help eliminate countless technologies from the playing field — right out of the gate.

Although there are advantages to knowing what you need (or want) before reaching out to 3D printer sellers, it’s perfectly fine to throw up your hands and say, “I have no idea what I want or need!” After all, the best sales professionals are consultants and should be excited to join you on your journey of joint discovery.

When compiling your data and prioritizing your lists, try to make it a best practice to state “why” an attribute or “capability” is important to you. For example, “warranty coverage ranks at the top of my list because I know that money will not be available for unforeseen maintenance and repairs once the printer has been purchased.”

Step Five: Validate Capabilities

You’ve studied the tech data sheets and digested all of the marketing materials. You’ve kicked the tires, and now it’s time to really take it for a test drive.

In this critical step, you will validate that the 3D printer(s) you are considering are capable of meeting your stated needs and performing at a level equal to or greater than the manufacturer’s published specifications. Notice how I said, “equal or greater than the manufacturer’s published specifications” instead of “equal or greater than your expectations?”

The reason for this is simple: Many 3D printers are considered sophisticated technology, and it may be unreasonable to expect them to perform at a higher level of performance than what is touted by the manufacturer. For this reason, protect your time by only validating the capabilities of products that make the claim, upfront and in writing, that they can achieve the minimum (or most important) requirements you established during the downselect step.

Here is the four-step workflow I recommend for the validation phase of professional and production-grade 3D printers that represent a significant investment to your organization:

- Send an STL or CAD file representing one of your primary applications to the sales organizations that survived the downselect process.

- Request that the sales organizations provide you with a feasibility study to determine if they believe your primary application is suitable for their capabilities.

- Request a time and cost study, also known as a virtual benchmark, which shows how long it would take to print your part and how much it would cost if you owned the printer.

- If the data produced from the time and cost study is acceptable, request a physical benchmark part for testing and evaluation.

You should disclose how the benchmark part will be tested and evaluated to the sales professional or application engineer who will be printing your part in advance. Having this knowledge can help them determine the most optimal build parameters and orientation, increasing your chances of getting the best part possible—the first time.

Lastly, provide the exact part file to every sales organization still in the hunt. This will ensure you make a true “apples to apples” comparison of their capabilities.

If you want to validate a printer with a lower barrier to entry price point, requesting a customized benchmark will oftentimes be denied. However, it is reasonable to request an “off-the-shelf” sample part printed in a specific material. In some cases, depending on the sales professional, you may be able to get a virtual benchmark of your part file, which will provide you with print cost and speed data.

Step Six: Estimate ROI

The purpose of this article is not to teach you how to create a return on investment (ROI) document but to highlight its significance in the approval process and ensure it is included in your final business case.

There are countless online resources that provide step-by-step instructions for creating an ROI, but the gist is to determine the ratio between the net return and the cost of an investment, expressed as a percentage. My favorite ROI formula is pretty straightforward, as the calculation involves dividing the net return on the investment by the investment’s corresponding cost.

As an example, here are some data points you may want to include or take into account:

- How many parts do we anticipate printing monthly/quarterly/annually?

- How much will it cost to print these parts once we own the 3D printer?

- How are we currently making or acquiring these parts?

- How much money does making or acquiring these parts currently cost?

- How long does it take to make or acquire these parts?

- What competitive advantage do we gain by adding this new capability?

- What is the estimated financial impact of gaining this new capability?

Depending on the company, some managers will require a deep dive into the Total Cost of Operation (TCO), which means you will need to include cost estimations for electricity consumption, hazardous waste disposal fees, and asset depreciation, to name a few, so be prepared.

Step Seven: Compile Business Case

Now that the previous six steps are completed, the information should be compiled and organized into a fluid and easy-to-understand report. Before creating this document, I strongly suggest you ask your manager how much information they want to see. If your leadership only wants the highlights to be compiled into a simple summary, don’t send them a novel, and vice versa.

To this point several years ago, I was asked by a company vice president to create a budget for the upcoming fiscal year. After spending an entire week belaboring over this, I finally submitted a ten-page report via email, only to receive a response with the words: “Please reduce to one page.” Needless to say, lessons were learned as I was reminded of the axiom “know your audience” and that sometimes, less is more.

Here are four questions you should ensure are addressed and answered either at the opening or closing of your business case as a nice finishing touch:

- What problem can be solved or benefit gained by purchasing a 3D printer?

- Why does the problem need to be solved or the benefit gained?

- Why do I believe my proposed solution is our best option forward?

- What is the impact of solving the problem or gaining the benefit?

By following this seven-step process, you will increase your chances of getting the 3D printer you want, so get the data, do the work, and hit the mark!

ABOUT THE AUTHOR

Chris Harris serves as the Vice President of Defense for a global manufacturer specializing in point-of-need additive manufacturing technology for military readiness and warfighters, Spee3D. He is the author of Phase Selling for Additive Manufacturing and has provided his proprietary sales training and consulting services to more than 200 AM companies from over 60 countries. Connect with Chris Harris via LinkedIn.

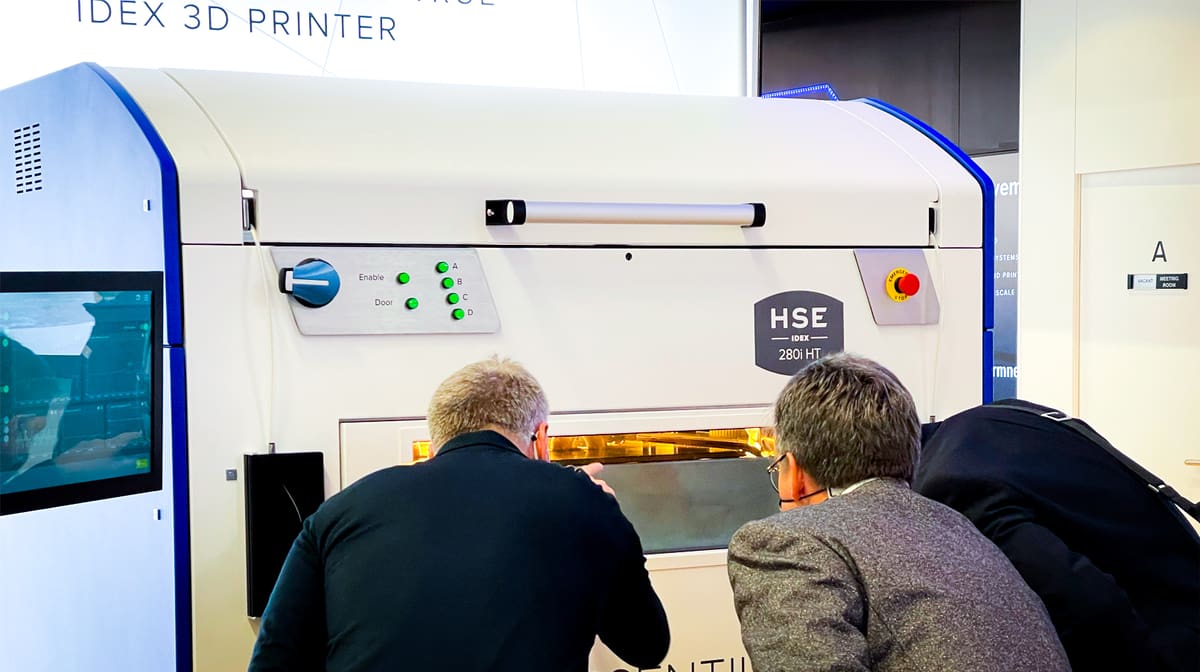

Lead image source: Photocentric

License: The text of "Purchasing a 3D Printer — How to Get Your Boss’ Approval" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.