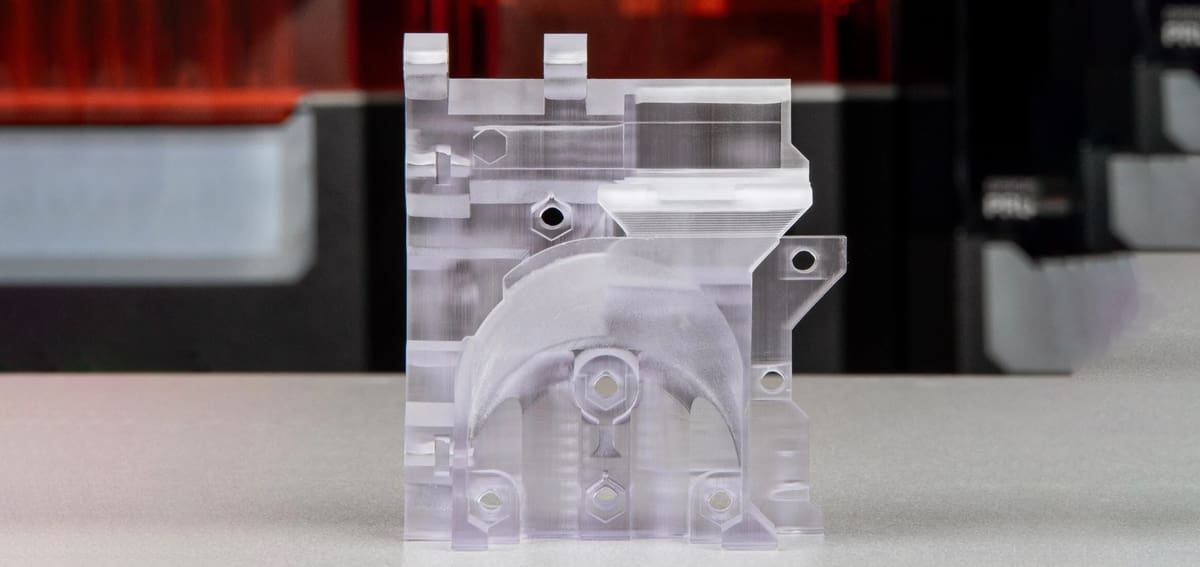

The availability of clear 3D printing is growing steadily as demand grows for parts and prototypes used in industries ranging from product design and medical modeling to automotive prototyping and scientific research (microfluidics). You can achieve visual insight into the inner workings of a prototype, diffuse light with clear lampshades, test the fit of eyeglasses, and create custom-built aquarium components that will blend in underwater, and this is just the start.

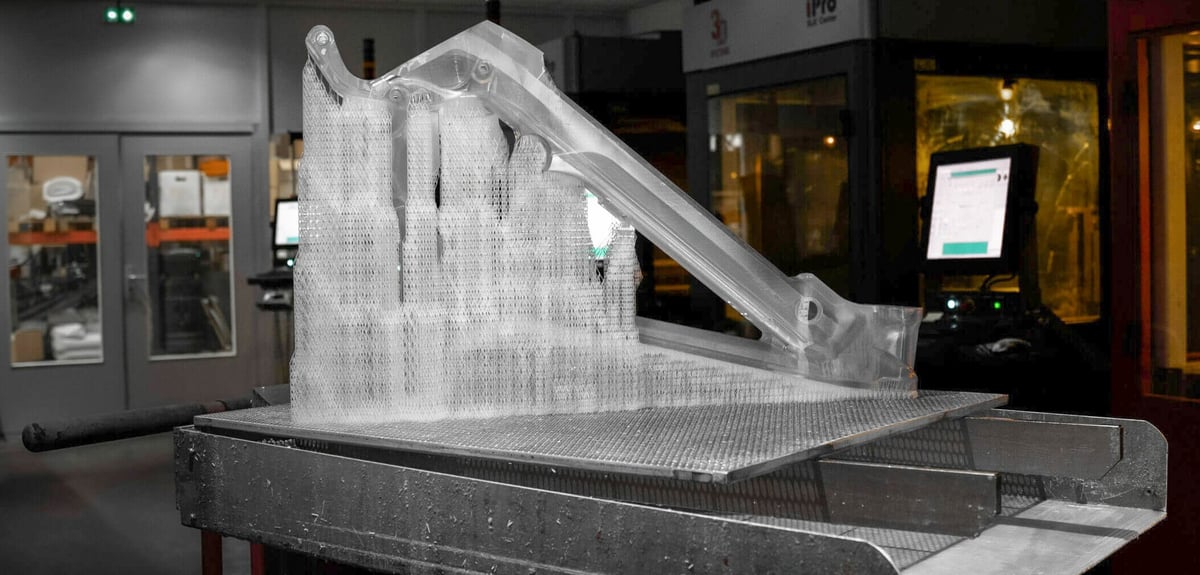

Crystal clear is tricky to achieve in 3D printing. Clear filament require sanding and clear coating while resins can yellow if over or under cured. This may be why more people are turning to 3D printing services, which, in turn, are expanding their offerings to meet increasing demand from industries like healthcare, automotive, and consumer products. New materials and technologies enable clearer parts than ever in larger sizes than before.

Because clear parts are 3D printed using a variety of materials and technologies, we present a primer below so you know which to order and what to expect from your final part. Some materials are meant for display, while others can be used as robust end-use parts; some may yellow over time, while others should remain clear indefinitely.

Note, too, that the design of your part plays a role in how clear it will be, so check out our design considerations below.

But fist, we uploaded a standard part to five 3D printing services to explore which materials and technologies they offer and at what price and delivery time.

Top Services for Clear 3D Printed Parts

We tested the clear resin options from five 3D printing services using a digital file of a common aquarium hose connector. Although widely available, three-way T-shape connectors like these were ideal parts to test out services because of their size and shape and the fact that they mostly come from China, which is a growing supply chain hurdle for consumers in the U.S.

We requested five parts from each provider in the clear material that they recommended or that we selected.

Craftcloud

Craftcloud occupies a unique space in the 3D printing community. It is not strictly a printing service, but an online marketplace that connects you with printing resources all over the world. I find that using Craftcloud takes the guesswork out of whether I am getting a good deal, and simplifies the ordering process; there are no long email chains to deal with, just a simple instant quoting platform where I can upload my STL and have an answer within seconds. It is ideal for hobbyists and designers who want a simple, streamlined ordering experience.

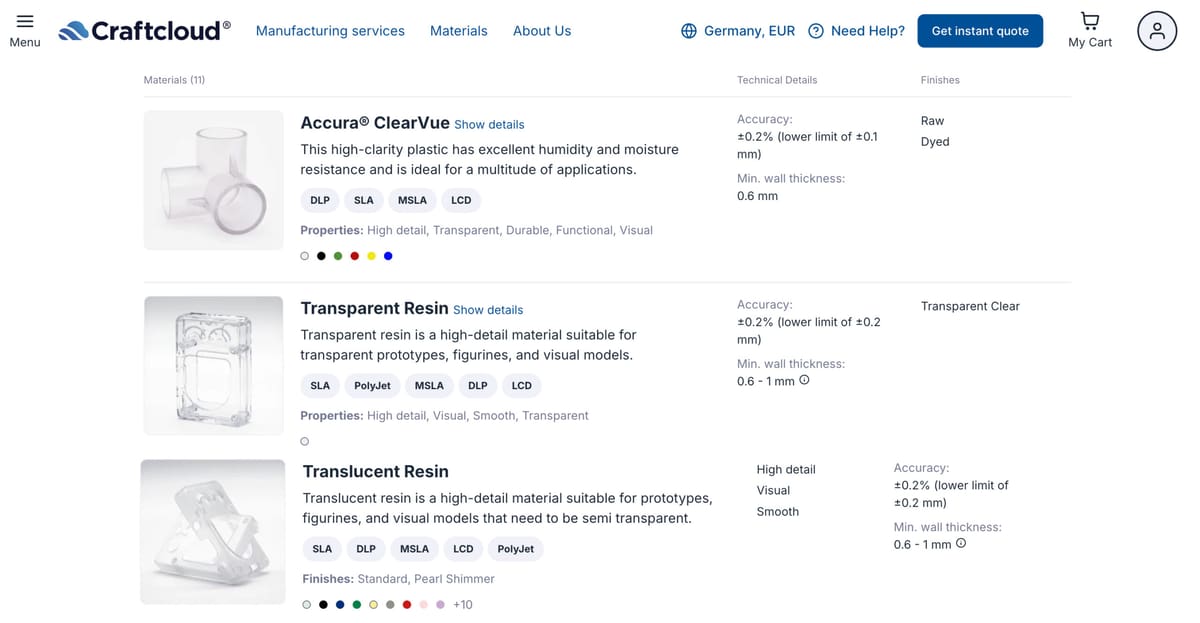

Finding a clear resin for this part was straightforward. Once I uploaded the STL file, I sorted the material groups by “functional resins.” This left me with a list of several options, including transparent and translucent resin, as well as high-resistance materials like Accura ClearVue. For this project, I opted for their transparent resin. It’s less expensive than ClearVue but more optically transparent than the translucent option.

Clear Material Options:

- Materials: Accura ClearVue, Standard Clear, Polymethyl Methacrylate (PMMA), PVB

- Technologies: FDM, SLA, DLP, LCD, Material Jetting, PolyJet

- Post-processing: Hand sanding and polishing, Clear coating for optical clarity

Transparent resin is ideal for objects that are going to be displayed, such as prototypes, models, and figurines. The material is capable of delivering fine details and a smooth surface with a see-through texture. Post-processing can vastly improve the final transparency of a part, but Craftcloud did not list any special sanding, polishing, or UV-resistant sprays as options.

Once the material and finish are selected, Craftcloud shows you three main options to choose from: the best possible price, the best combination of price and delivery time, and a local option from my region. If these don’t suit your needs, you can scroll down and explore more options at various prices and locations. We went with the budget option for this project, and it is the cheapest of all the services we explored.

Shapeways

Shapeways, founded in 2007 and headquartered in New York, enables individuals and businesses to upload digital 3D models and have them professionally printed in a wide range of materials, including plastics, metals, and resins.

Shapeways has a user-friendly platform but leans a bit more professional. It’s ideal for people designing consumer products, engineers testing prototypes, or artists who want higher-quality finishes.

Clear Material Options:

- Materials: Accura 60 (SLA clear resin, similar to acrylic), VeroClear (PolyJet), VisiJet (MJP)

- Technologies: SLA, PolyJet

- Post-processing: Hand sanding and polishing, Clear coating for optical clarity

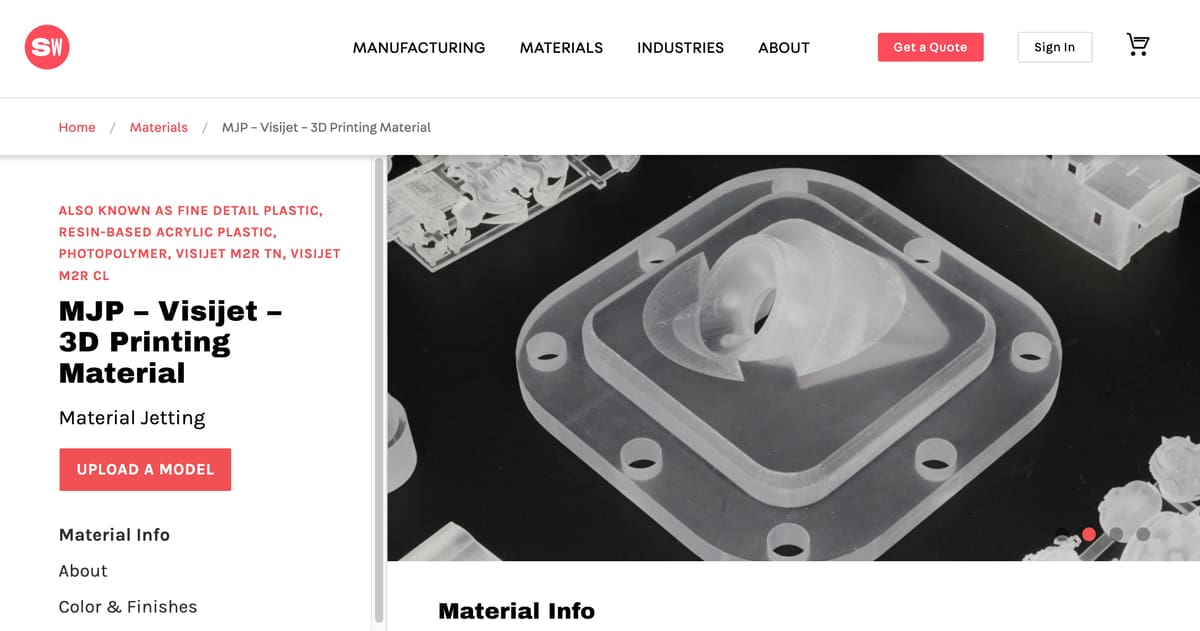

To receive a quote from Shapeways, after signing in, upload your model, select a material, and choose a finish, if desired. Upon first glance, I couldn’t find a clear resin in the list of materials. Instead of searching for information on each material one by one, I reached out to their sales team. Within one day, I had a list of suggestions for materials I could use to print in clear.

Ultimately, I went with VisiJet. VisiJet materials are acrylic-based resins used in MultiJet Printing (MJP). It is known for its high level of detail and precision, and tends to be popular among hobbyists for creating scale models, miniature sets, and decorative items due to its ability to capture intricate details with a smooth, paintable surface.

I chose the cheapest options for delivery — economy manufacturing speed (+$0.00) and expedited shipping (+$24.96).

Protolabs

Protolabs, founded in 1999, is a rapid manufacturing company offering quick-turn prototyping and low-volume production services. They operate globally and are known for extremely fast turnaround times while maintaining quality.

Protolabs is not really aimed at casual consumers, though they will print small numbers of parts — it just may be more expensive than other services. They’re serious about engineering-grade prototypes and functional parts; their strengths are precision, repeatability, and fast lead times. If someone needs a clear fluidic device, optical lens prototype, or transparent housing for mechanical testing, Protolabs is a top choice. They’re also great for tight tolerances and design validation before mass production.

Clear Material Options:

- Materials: Accura 60 (SLA clear resin), Somos Watershed XC 11122 (clear SLA resin)

- Technologies: SLA

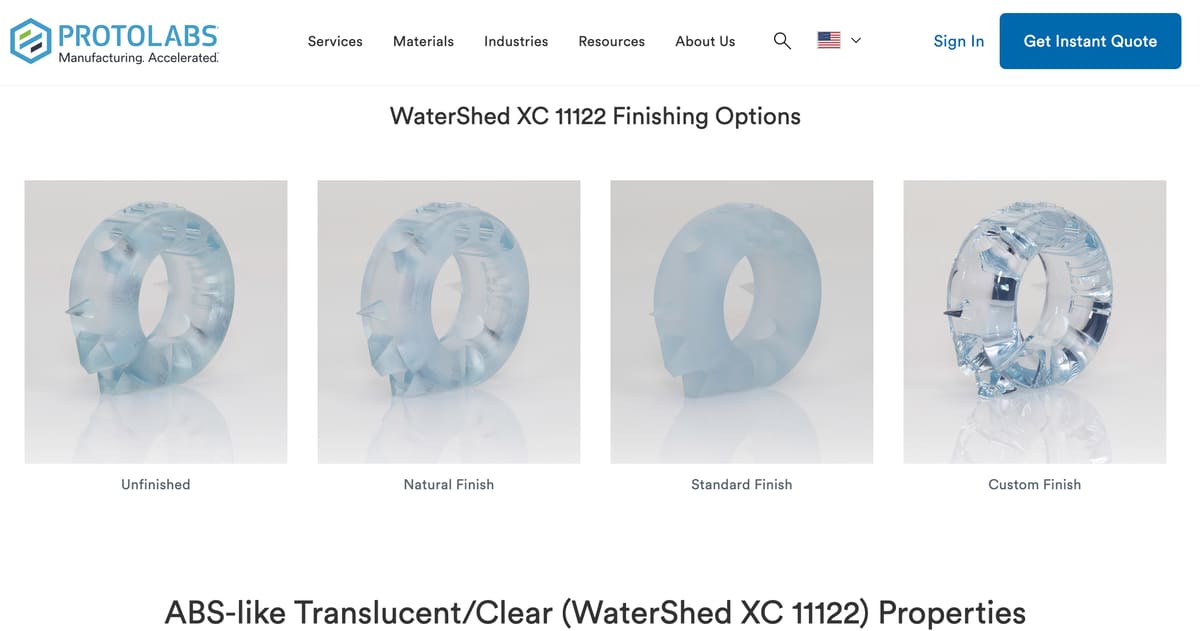

- Post-processing: Standard polishing, Vapor honing, Optional UV clear coating for better transparency and UV resistance

Once you upload your STL to Protolabs’ instant quote platform, hit “configure part” to adjust the quantity, technology, material, and finish from the drop-down menus. If you don’t see the material you need or want a specific finish that isn’t listed, add a note in the “special instructions” box at the bottom — someone from the Protolabs team will reach out to you directly to discuss the project further.

We went with WaterShedXC, which is perfect for our aquarium project; it has a near-colorless transparency right out of the printer, with low moisture absorption and water resistance. It looks very similar to plastic and will not stand out in our aquarium tank.

Addman

Addman Group is a newer entrant to the additive manufacturing industry, formed through the acquisition of several established 3D printing companies. They focus on high-performance applications across aerospace, defense, and medical industries.

Their clear parts are usually functional prototypes for military optics, surgical instruments, or light-transmitting aerospace components, not just decorative or aesthetic models. However, the team was more than willing to work with me on this small run of five parts.

Clear Material Options:

- Materials: Clear SLA resins (specific materials vary by project; often industrial-grade), Accura 60, Watershed XC

- Technologies: SLA, Potential for high-precision FDM for semi-transparent parts

- Post-processing: Custom polishing services, Optional surface treatments depending on application (e.g., clear coating, UV protection)

To receive a quote from Addman, fill out a “contact us” form with your information, a brief description of the project, and the related STL files. From there, a representative will contact you to discuss the best material and tech to suit the needs of your specific project.

Although a bit pricier than competitors like Craftcloud and Shapeways, the customer service and personalization from working with Addman made the experience easy and trustworthy. The team suggested using Somos WaterShed XC, which produces detailed parts with superior clarity and water resistance, well-suited to anything that has water running through it — perfect for our aquarium hose. The durable, clear parts look and feel similar to an engineered plastic with a smooth finish.

Materialise

Materialise, founded in 1990 in Belgium, is a global leader in 3D printing software and services. They specialize in medical applications but also serve industrial and consumer markets with advanced printing technologies and software solutions.

Materialise operates on an enterprise level. They’re best for very technical, critical applications — like surgical guides, aircraft components, automotive prototypes, or scientific research tools. While they do accept smaller projects, they’re more suited to high-value, complex projects that require certifications, ISO standards, or specialized post-processing. Our quote from Materialise was the highest of all five services we tested.

Clear Material Options:

- Materials: Stereolithography Clear Resin (Standard), Somos WaterShed XC 11122, Clear Medical-Grade Resin (FDA-compliant)

- Technologies: SLA, PolyJet

- Post-processing: Multi-stage manual polishing, Clear lacquer coating, Painting (for optical enhancements)

Hitting the “get a quote” button on the Materialise website will take you to Materialise OnSite, its instant quoting platform where you can log in and see all of your projects at once. To create a new quote, upload your STL from the right-hand menu and select your technology and materials from the drop—down menus.

This time, we went with TuskXC2700T. Specifically designed to simulate ABS, TuskXC is a strong, translucent material that offers high resolution and a smooth surface. It is ideal for water-resistant prototypes with ABS- and PBT-like specifications, such as parts for water flow analysis and wind tunnel testing. Once again, this is an ideal choice for our aquarium hose, as it will be submerged underwater for long periods of time.

Which 3D Printing Technologies Print the Clearest?

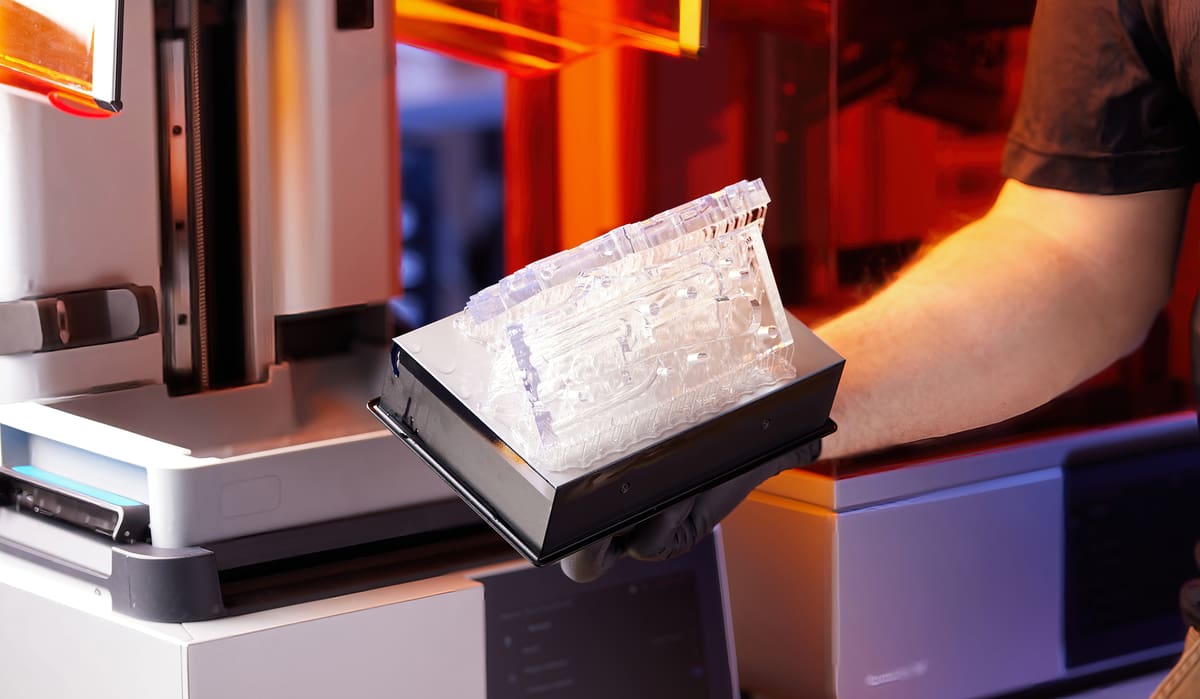

There are various methods of achieving a clear 3D printed part. Resin is the most popular choice due to its finer detail and better surface finish without the need for much post-processing, striking a balance between quality and cost.

Resin parts used to be brittle and sensitive to sunlight over time, but there are new industrial resin choices at 3D printing services that aren’t available to most home resin printers. We explore different types of clear resin offered by five 3D printing services later in this article.

FDM — printing with a clear filament — is perhaps the most accessible and budget-friendly method of achieving a transparent or translucent part. Using a clear filament like PETG or transparent PLA, FDM printing can provide you with translucent rather than crystal clear parts — perfect for early-stage prototyping.

Post-processing methods such as sanding and polishing can get you clearer results with fewer visible layer lines. Using FDM is perfect for basic functional parts like containers, DIY lampshades, or anything that requires long-term clarity that won’t degrade over time. The tradeoffs? Surface finish can be rougher and more uneven with FDM.

Stratasys PolyJet is another popular pick when it comes to clear prototypes. Jetting out liquid photopolymer in thin layers and then curing it with UV light gets you high-resolution surfaces that are both smooth and clear. PolyJet is ideal for professional settings where small details matter, such as medical models. In fact, you can order PolyJet printed parts directly from Stratasys Direct.

Similar to PolyJet, material jetting is also great for precise detailing and smooth finishing. It can achieve optically clear parts with less post-processing than FDM or resin, and is often used for functional prototypes and final models. This process can come at a higher cost compared to other methods, so it’s usually reserved for critical applications.

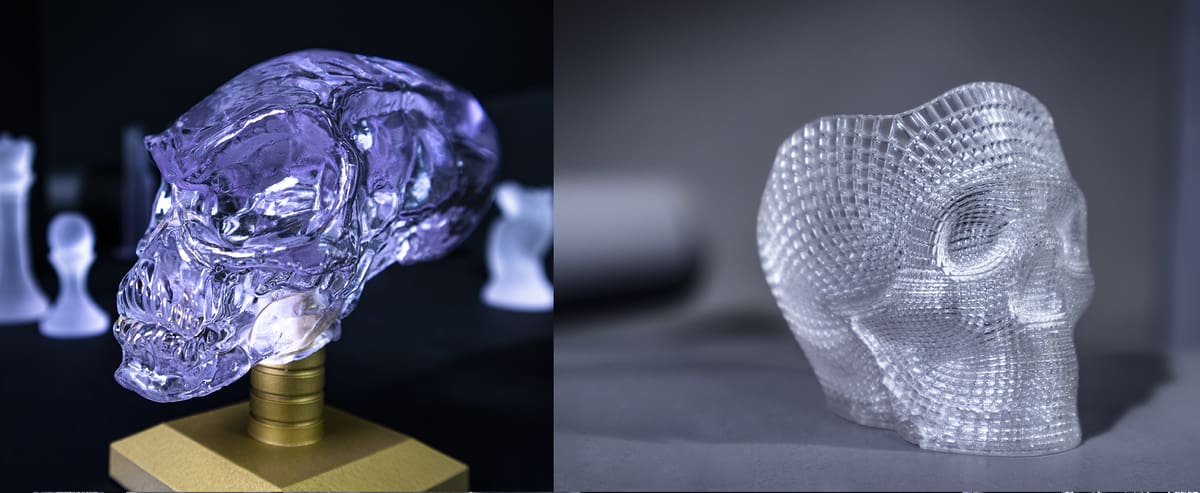

Which Materials Print the Clearest

“Clear” in 3D printing isn’t always glass-like transparency right out of the printer. Depending on the material, it can range from fully transparent to a hazy, frosted finish. There are two main categories of clear materials: Filaments (FDM) and clear resins (SLA, DLP, LCD).

Different materials will yield different results. For example, PETG is naturally clear but can scatter light; with its decent strength, it’s ideal for containers, clear mechanisms, and general-purpose goods.

Polycarbonate, in addition to being optically clear, is also far more heat-resistant, making it perfect for light fixtures, lab equipment, and any part that requires impact and light resistance. If you’re planning on using your part outdoors, look for a weather-resistant PMMA/Acrylic that won’t yellow over time. Unlike resins, this material is weather-resistant and thus is ideal for signage, displays, and other outdoor models.

While there are different types of clear resins available, many manufacturers will simply label them “Clear Resin.” SLA-printed resins can give you maximum optical clarity, but often require post-processing to make them shine. All 3D printed resins are photopolymers — meaning, they’re cured using UV light during printing. Unfortunately, continued exposure to sunlight or fluorescent lighting can lead to yellowing or clouding over time. Coating your part with a UV-resistant spray can help preserve your part’s clarity and improve its resistance to yellowing. Sanding and polishing will also help to reduce layer lines and haze that impact clarity.

Clear resins are ideal for detailed projects that require a high resolution and glossy appearance. This could be a highly detailed see-through medical model, an electronic sensor cover, or consumer prototypes that mimic the look of glass. Later in this article, we explore using different clear resins to print a custom aquarium pipe.

Steer clear of SLS and MJF printing if you’re aiming for clear parts. These methods use powdered materials such as nylon that fuse into solid parts that are always opaque.

Finishing and Post-Processing for Clear 3D Printed Parts

When a part comes off the printer, it’s usually not perfectly see-through; post-processing can get rid of any frosty or cloudy textures and give you a smooth result that is truly transparent.

Because rough edges can scatter light, sanding is the first line of defense for post-processing a clear part, especially for resin and FDM prints. The smoother the surface, the less light is scattered, and the clearer your part looks.

After sanding, a polish and/or clear coat spray will make your part appear glossy and fill in any tiny scratches. If you’re working with resin, UV curing is essential if you want to prevent yellowing and remove cloudiness.

When ordering 3D printed parts, after you select your desired material and technology, you’ll be prompted to select a finish or post-processing method. With most services, you can also send a message directly to the company’s engineering team to get advice and discuss the post-processing methods that are best for your project at hand.

Design Guidelines for Clear 3D Printed Parts

Getting true clarity in 3D printed parts involves more than just using a transparent material; even materials that begin optically clear can become cloudy or translucent during the printing process. The most important distinction to make is that you must design with the anticipation that you will print your parts in clear. Complex geometry, internal channels, or even holes in your prototype can both trap air and scatter light inside your prototype, making it appear cloudy and frosted. Simplifying your design and reducing the internal space within your part will improve the clarity of the final product and make post-processing easier.

The surface of your design will also affect its translucency. As your part is printed layer by layer, small ridges will naturally occur, but these too will scatter light. The smoother your design, the clearer it will be. Avoiding complex textures or tiny details will help retain a smooth surface, as well as using larger radius curves instead of sharp corners, if possible.

The wall thickness of your part can also affect its final translucency. Warping, cracking, or uneven curing can occur if your walls are too thin (less than 1.5mm). On the flip side, solid walls that are too thick (over 10mm) can sometimes trap heat and extra resin, making it appear cloudy. Try to aim for a thickness of about 2-5mm for best results.

You May Also Like:

License: The text of "Putting Transparency to the Test: We Review Five 3D Printing Services for Clear Parts" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.