Metal 3D printing is skyrocketing in popularity for applications across manufacturing, aerospace, automotive, marine, and construction using steel, aluminum, copper, and titanium alloys. Brass — an alloy of copper and zinc — however, is a trickier material.

The most popular metal 3D printing method, laser powder bed fusion (LPBF), struggles to overcome the volatility of zinc when melted with a laser (with the exception of one specialized machine from 3D4Mec).

Therefore, the most common method used in 3D printing brass isn’t actually 3D printing it, but rather 3D printing the model in wax and then using that model to create a mold into which molten brass is poured. This more traditional method is also commonly used with 3D printing of precious metals.

So it’s no surprise, then, that 3D printed brass is typically used for jewelry, figurines, and brass-plated 3D printed parts.

For industry, there are promising innovations on the horizon, including more LPBF and a large format foam 3D printer for lost foam casting brass.

For hobbyists and crafters, you can 3D print brass-like parts at home using brass-powder-filled filament that can polish up and tarnish like the real thing.

Below we cover why 3D print in brass, the methods used, and the services to turn to.

Why 3D Print in Brass?

Brass, a member of the copper family along with bronze, is prized for being less corrosive than copper but more affordable than bronze, so it’s both useful and affordable.

It’s a common metal to plate in gold as an alternative to solid gold jewelry. It’s also popular to brass-plate other 3D printed metals or even polymers for use in historical reproductions of common brass parts, such as plaques, door knockers, and architectural elements.

Metal 3D printing using brass has strong potential for applications in manufacturing, automotive, marine, and construction. It’s a versatile alloy prized for being corrosion and high-temperature resistant, a good conductor of heat and electricity, and easy to machine, so there’s a lot of potential for its industrial use. It’s long been used for heat exchangers, musical instruments, pipe fittings, locks, and even as ammunition casings.

Parts and products traditionally made in brass can be improved and delivered faster and cheaper with 3D printing.

Italian 3D printer maker, 3D4MEC, launched its unique laser powder bed fusion (LPBF) 3D printer for brass and copper-based alloys a few years ago and recently installed one at WeAreAM—the Center of Competence in Additive Technologies and Powder Metallurgy for Industry in Lombardy, Italy. The 3D4Brass 3D printer is the world’s first specialised LPBF 3D printing system for brass powders, the company says. The process is currently qualified for CuZn42 (CW510) brass powder 3D printing.

Get Brass 3D Printed at a Print Service

As we mentioned above, the main method for achieving brass parts from a 3D printing service is called lost wax casting. This method involved 3D printing your part in a wax material, coating the model in a type of plaster, melting out the wax from the plaster to create a hollow mold into which brass is poured. Finally,

break the plaster when the brass sets and then polish.

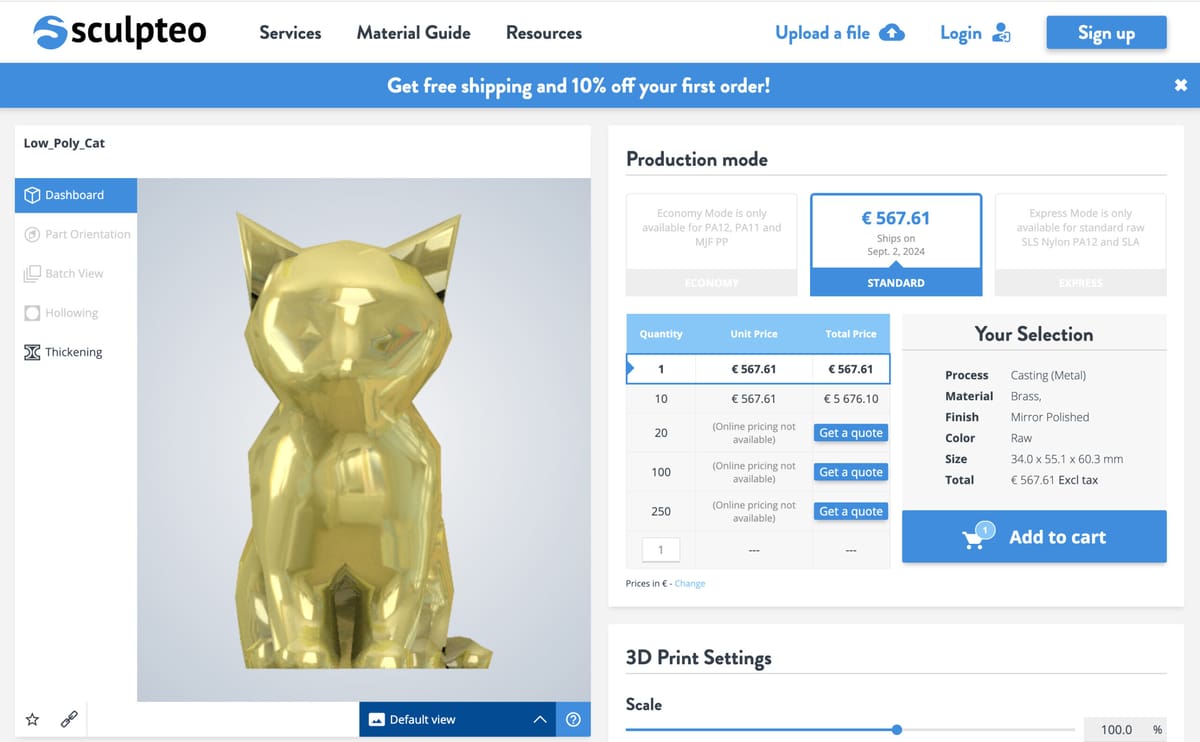

These 3D printing services below offer brass 3D printing using lost wax casting. You can quickly upload your digital model and receive a quote. We took to for a spin with a figurine cat (34 x 55 x 60 mm) from Printables designer Matthias L.

Brass-Filled Filament

It’s not difficult to find brass-colored plastic 3D printing filament with a metallic shine, like eSun’s Antique Brass filament, but a step up from 100% polymer, is plastic filament embedded with real brass powder (as high as 70%) that produces polishable parts.

Filament maker ProtoPasta offers Brass-Filled Metal Composite PLA filament for 3D prints that finish just like real metal, the company says. Once printed, you can polish parts to a bright mirror finish or opt for a naturally rustic finish.

Filament maker formFutura at one time offered bronzed metal powder filled filament — you may still be able to find it at some filament resellers — but now only offers copper-filled PLA, which delivers a similar effect as far as polishing and tarnishing.

Another option for bronze-filled filament comes from the Virtual Foundry. This filament maker offers several composite filaments with metal powders, including Bronze Filamet also available in pellet form. This material requires post0-processing steps to remove the PLA base and condense the part into 100% bronze, the company says.

You may also like:

Lead image sources:

- top left brass necklace by Michael Mueller’s called Rose Window 3D printed via i.materialise.com

- top right pipe 3D printed on a 3D4Brass LPBF machine by 3D4Mec

- center brass benchy fabricated from a 3D printed benchy model using lost wax casting by Reddit user shizzilbiscut

- bottom right bronze filament from ProtoPasta

- bottom left bronze-plated historical signage

License: The text of "Quick Start Guide to Brass 3D Printing" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.