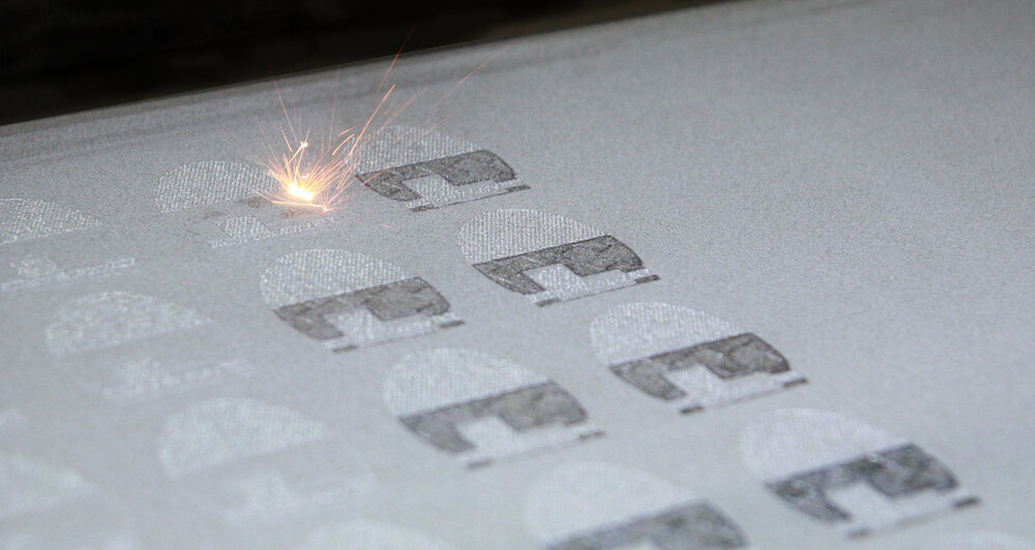

Most metal 3D printers use a technology that involves lasers melting a powdered metal, layer by layer into a final part. In fact, this method accounts for more than 80% of the metal 3D printer market and dozens of manufacturers worldwide offer machines in a wide range of sizes with varying features.

Officially called metal laser powder bed fusion (M-LPBF), the same technology is also called SLM (selective laser melting) by some printer brands and also direct metal laser sintering (DMLS). You may even hear the term “direct metal laser melting” (DMLM) and laser metal fusion (LMF). However, to get the definitive word on this technology, All3DP turned to one of the inventors of the process, Wilhelm Meiners.

What is Metal Laser Powder Bed Fusion?

Just over 20 years ago, Meiners and his colleagues Kurt Wissenbach and Andres Gasser developed and patented the technology while working at the Fraunhofer Institute, Germany’s largest applied science research organization.

According to Meiners, the technology’s official name is laser powder bed fusion or LPBF.

“The different names for the LPBF process are due to historical causes,” he says. “In the early years, every machine supplier created its own name for the same process and kept it until today.” All of these other terms are simply brand names for the standardized technology called laser powder bed fusion.

Indeed, German 3D printer manufacturer EOS coined the term “direct metal laser sintering” and still uses it today. It’s a bit of a misnomer since the metal powder is melted not sintered, but that could have been lost in translation. SLM, the more popular term, is actually a trademark held by the printer manufacturer SLM Solutions, which is now Nikon SLM Solutions. Concept Laser, on the other hand, called their process laser cusing, but once GE Additive acquired the company in 2016, they changed the name to direct metal laser melting (DMLM). Printer manufacturer Trumpf likes to use the term laser metal fusion while 3D Systems uses direct metal printing.

Although we used the most popular term, selective laser melting, in the title of this article, for the rest, we’re going to go with the official name used by Meiners and the standards organization ASTM: laser powder bed fusion, with the addition of an M for metal since there is also polymer laser powder bed fusion, although it’s more commonly known as selective laser sintering (SLS).

Despite the confusing terminology, metal LPBF is one of the most exciting 3D printing technologies available today. It’s used across industries for rapid prototyping, specialty high-performance parts, and mass production with a wide range of metals. Let’s take a look!

How Does LPBF Work?

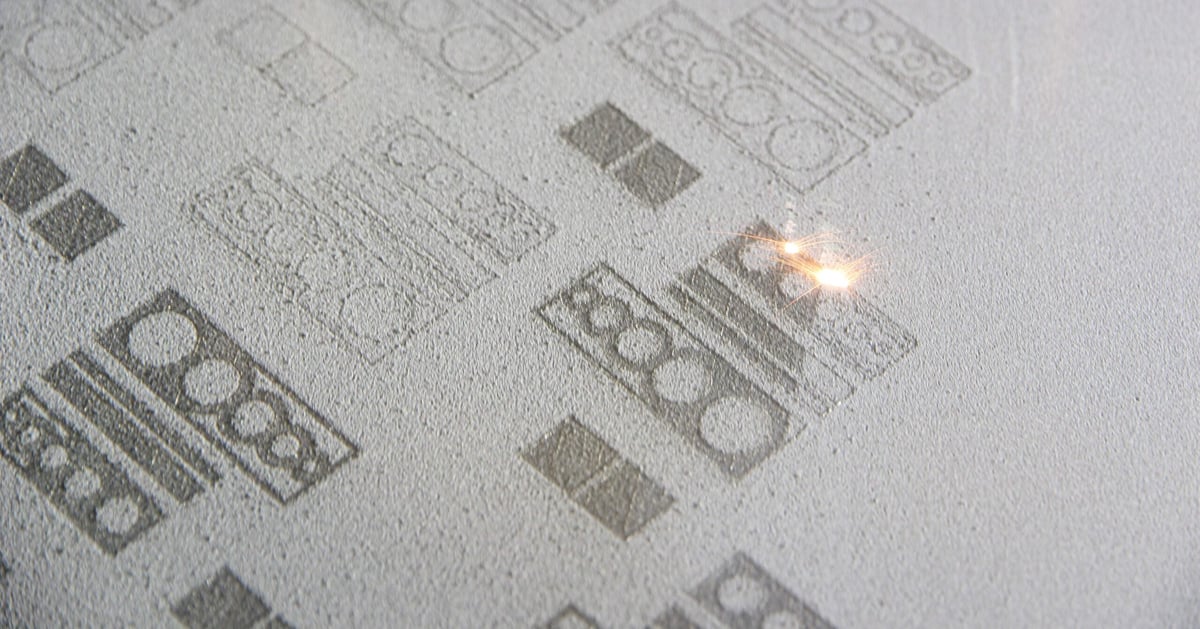

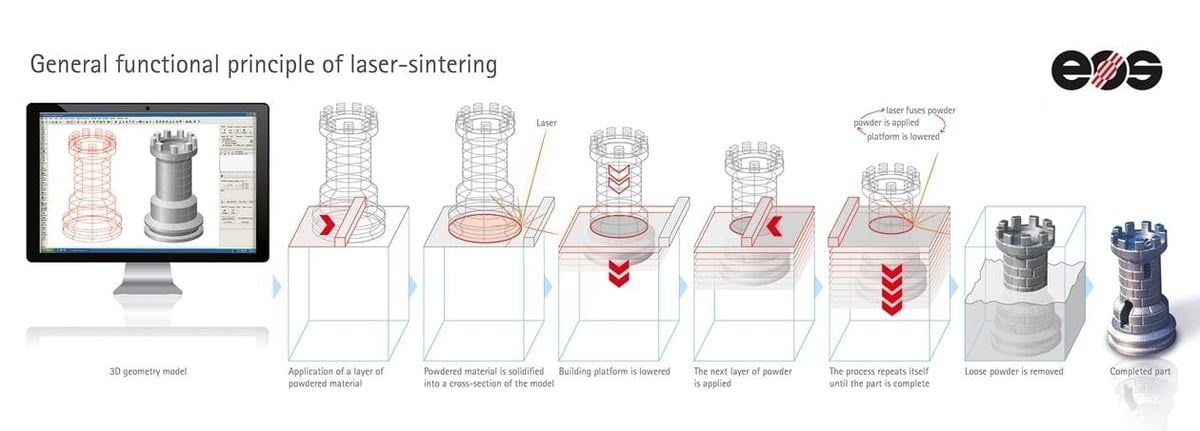

LPBF 3D printers use high-powered lasers to selectively melt a metal powder. The melted parts fuse together layer-by-layer on a molecular basis until the homogenous model is complete.

Printer operators can use “pure” metal materials, although alloys also see regular use. There are dozens of metals available for the LPBF process, but some of the most common materials include:

- Aluminum

- Cobalt Chrome

- Copper

- Nickel (Inconel)

- Stainless and Tool Steels

- Titanium

- Precious Metals

In theory, LPBF — like the related and similarly functioning selective laser sintering (SLS) for plastics — is a support-less AM technology. The packed powder on the printing bed provides support to the model during the printing process.

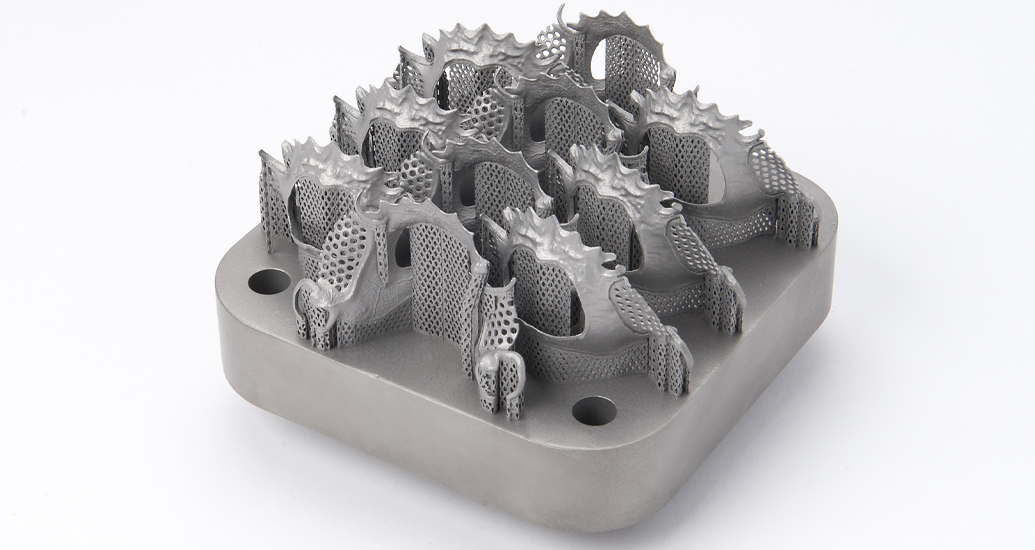

However, due to high thermal gradients between the molten part and surrounding powder, stresses can arise causing warpage and distortion. Support structures are therefore often needed in order to dissipate heat from critical areas and fix the part securely onto the build plate. A general rule of thumb is that overhangs or hollow structures angled between 0 and 45 degrees should be supported.

An LPBF 3D printer houses metal feedstock powder. The printer pushes powder into the chamber where a coater blade (like a windshield wiper) or roller spreads it into a thin layer across the substrate or build plate.

Next, a high-powered laser fuses a two-dimensional slice of the part by selectively melting the powdered material. The build plate then lowers by the height of one small layer, and the coater spreads another layer of fresh powder across the surface. The printer repeats these steps until you have the finished part.

Some printers have bidirectional coaters, which can push powder onto the bed moving both ways, speeding up the coating process by up to 40%. Another way LPBF printer manufacturers make printing faster is by employing more powerful or several lasers.

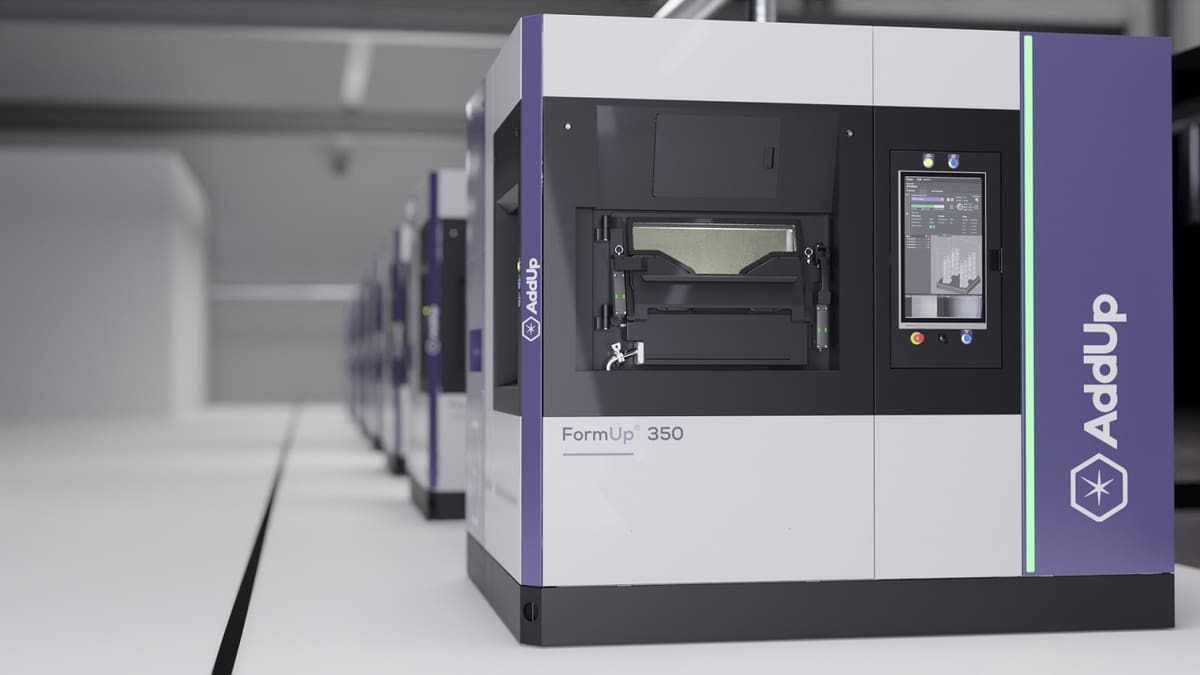

A small, compact LPBF printer might have a single 30-watt laser. As the machines grow larger, they can start incorporating stronger lasers or multiple lasers in one array. For example, the AddUp FormUp 350 features four 500-watt lasers, while the SLM Solutions NXG XII 600 employs a total of 12 lasers, each with 1000 watts of power.

Increasing the power or number of lasers means the printer can melt the metal powder more effectively. It directly results in faster build rates and increased throughput, and typically a higher price tag. As an example, SLM Solutions claims the NXG XII 600 can provide 20 times faster build rates than single-laser systems, up to 1,000 cm3/h.

Depending on your application, when considering in a LPBF 3D printer you’ll look at the level of laser power, the laser beam diameter, the scan speed, the possible layer thickness (from 20 to 120 μm), the scan strategy, the part cooling strategy, and other features that set different brands, and different models within brands, apart.

The LPBF printing process happens in a controlled atmosphere inside the machine, which means inert gas (nitrogen or argon) fills the build chamber.

Once the part is built, it can be removed from the machine after cooling. Large parts can take many hours to cool before handling is possible. Metal powder that is not fused is collected afterward and reused for further LPBF projects. Printed parts are initially attached to the build plate, from which they are usually separated by cutting or machining, or by wire erosion.

If the part needed supports, you must next remove them as well. As LPBF printers don’t use separate support materials, this can be a difficult and time-consuming process.

The surface finish of the final melted part is rough and, depending on your requirements, it may need post-processing to achieve a smooth and shiny result. It is also relatively common to further machine parts to achieve tighter tolerances and finish fine features, surfaces, and holes.

LPBF vs. Traditional Manufacturing

LPBF, like every manufacturing technology, has its strong and weak points. The pros and cons of producing a model via LPBF include:

Advantages

- Large range of available metals

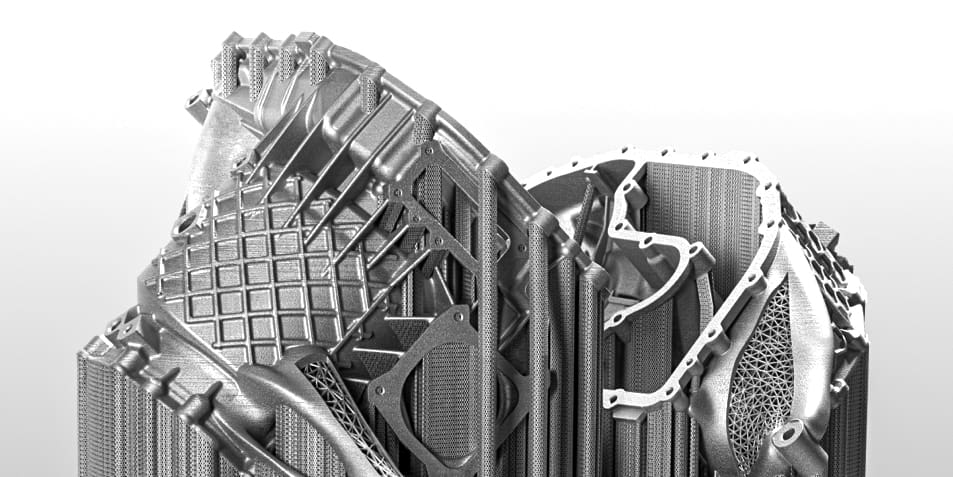

- Ability to realize complex shapes or internal structures, possibly without supports

- Reduced total lead times, due to no need for tooling

- Part consolidation, allowing operators to create previously multi-component parts as one print

- Reduced waste, due to additive manufacturing and powder reclamation

- Ability to reduce standing inventory due to fast on-demand production

- Potential for mass-customization of parts

Drawbacks

- No low-bar for entry. All LPBF 3D printers cost in the tens of thousands of dollars

- Cost per part can be a lot higher compared to traditional manufacturing methods

- Parts require post-processing, such as de-powdering, support removal, and surface grinding

- Size limited currently to one meter

- Lasers require a lot of energy

One of the most common questions when it comes to metal 3D printing is how part strength and durability of 3D printed parts using LPBF compare to traditional metal manufacturing methods.

Nick Estock, Deputy CEO at AddUp, the French metal 3D printer maker, explains to All3DP that it is possible for LPBF to produce parts with mechanical properties similar to traditional manufacturing. However, he adds, there are some caveats.

“Traditional manufacturing is subtractive and starts with a base material of known mechanical properties through very controlled and mature processes. In any additive manufacturing process, including LPBF, the material is being created simultaneously with the part. The process is fundamentally different and therefore not equivalent,” says Estock.

Metal LPBF processes create parts that have smaller microstructures than cast metal components. This gives them higher tensile properties, but cast parts are currently still stronger.

When we asked Meiners if the resulting prints from the LPBF process are equivalent to traditional manufacturing processes, he also said, it depends.

“The properties of LPBF parts can obtain or even exceed those of traditionally manufactured parts, but this depends on several conditions like the metal material (steel, aluminum, titanium, etc.) the post process (heat treatment, hot isostatic pressing, etc.), the traditional manufacturing process you compare it with (casting, forging, etc.), and the specific part property (strength at static load, high cycle fatigue, creep, etc.).”

Typically, LPBF technology is used today to replace cast components. In unique cases, printed components can replace forgings.

In the end, there’s no general answer, Meiners says. “In many cases, LPBF parts obtain the same properties [as cast metal], but not as a generic standard.”

For a look at some real-world examples of LPBF 3D printed parts in action, skip down to “Who’s Using LPBF Today.”

Top Entry-Level LPBF 3D Printers

Laser powder bed fusion 3D printers come in a range of sizes, with anywhere from 1 to 24 lasers, and a menu of options and features. Here we feature the “starter” solutions from the top manufacturers, but many companies also offer larger and more feature-rich machines tailored to address specific manufacturing challenges and industry segments.

In 2024, seven LPBF 3D printer manufacturers debuted new or upgraded machines:

- Farsoon’s FS191M

- Renishaw’s RenAM 500D

- Additive Industries’ MetalFab 300 Flex

- DMG Mori’s LaserTec 30 SLM

- Farsoon’s 12-Laser FS811M

- EOS’ M 290 1kW

- Farsoon’s new FS721M-8-CAMS

- Eplus3D’s EP-M400S

- BLT’s BLT-S450

When selecting an LPBF 3D printer, consider:

- Scalability. If you outgrow the entry-level machine, is there another level to upgrade to?

- Build Speed: How many cubic centimeters per hour can the machine produce?

- Laser Scan Speed: This is not the only indicator in part build speed, but it contributes.

- Layer Height & Resolution: How detailed can the final parts be?

- Gas & Power Consumption: Some machines consume more than others. How does this effect final costs?

- Material Consumption: Machines with good powder feeding and sieving technology can waste less powder.

- Open or Proprietary Materials: If you have to use the printer manufacturer’s materials, it could affect your manufacturing flexibility and costs.

One Click Metal MPrint+

One Click Metal is a spin-off from well-known printer maker Trumpf. The company says it produces an affordable, easy-to-use metal 3D printing system perfect for companies new to LPBF. One Click Metal MPrint+ works with cartridges eliminating the mess of metal powder, and it’s meant to be deployable with fewer requirements in terms of accessories and space. The base model is currently listed at around $130,000 for US buyers but European shoppers can get their hands on it for under six figures at €95,100.

It has a build volume of 150 x 150 x 150 and comes with the MPrep software.

The MPrint is part of the Boldseries which includes essential peripherals like the MPure, which is the company’s 3-in-1 unpacking station that depowders the component, screens the powder, and provides recycled powder for reuse. The cartridge system of both the printer and the depowdering station ensures easy and safe powder handling so that you have limited contact with the powder. With the side connection for a vacuum cleaner, you can efficiently remove excess powder from the unpacking chamber.

Xact Metal XM200G

Xact Metal wants to bring 3D printing to a wider audience with its flexible XM200G series available in a choice of single and dual fiber laser powers.

The XM200G is based on Xact Metal’s XM200C metal 3D printer. It integrates a high-performance galvanometer system to move the laser beam over the powder bed. This architecture allows for faster printing times, the company says, and the ability to support multiple lasers.

The XM200G tailors to customers who are starting their entry into metal 3D printing in various applications, including product development, tooling manufacturing, metal powder-bed research, and workforce development. It offers the option of using two lasers at one time with either a 100% overlapping work area using a 100-µm spot size or a 66% overlapping work area using a 50-µm spot size. This multi-laser system further increases build print speeds.

The new XM300G is bigger (300 x 300 x 350 mm) and features more powerful lasers 400W or 700W fiber lasers. Metal options include aluminums, coppers, steels, nickels, and titaniums. The laser scan speed is up to 34,600 mm/sec. The XM300G, offers several customization options. The build volume can be extended by another 100 mm in the z-direction for larger prints.

3D Systems DMP Flex 100

3D System’s entry-level DMP Flex 100 metal 3D printer offers a build volume of 100 x 100 x 90 mm and the ability to print parts with overhangs down to 20 degrees without supports. Surface features as fine as 5 microns should mean a minimal need for post-processing. 3D Systems calls its technology Direct Metal Printing, where each layer is melted onto the previous one creating a strong and dense part (up to 99.9%).

The system’s 100-watt fiber laser, while lower in power than those of the larger metal 3D printing solutions in 3D System’s lineup, is powerful enough to handle a broad selection of the company’s metal powder library, including a variety of titanium grades.

Tailored to niche uses that demand fine detail, the DMP Flex 100 makes use of dedicated gas lines to achieve the inert gas atmosphere necessary to print 3D System’s additive manufacturing-optimized powders. As such, it requires the necessary building infrastructure to facilitate this.

If you’re ready to move up from entry-level machines, 3D Systems offers five other, larger production units plus a networked factory solution called the DMP Factory 500 featuring three 500-W fiber lasers and a 500 x 500 x 500 mm build volume.

Trumpf TruPrint 1000

Germany-based Trumpf launched the TruPrint 1000 LPBF in 2019 for the production of small industrial parts and, without changing the name, has since made a range of upgrades to the machine.

The “next generation” TruPrint 1000 has a full-field multi-laser capacity and what the company calls a “completely redesigned homogeneity of the gas flow” and it now fits through a standard door frame. Trumpf says this printer is aimed primarily at the dental industry.

The printer’s two 200-watt fiber lasers scan the build area simultaneously, which the firm claims can increase productivity by up to 80% when compared to similar machines. A powder bed monitoring system analyzes each layer for maximum part quality. A tilting recoated makes the powder application process faster, which further increases production speed and cuts part costs.

There’s also a multiplate option for volume production. The build cylinder can optionally accommodate up to four substrate plates, meaning the substrate plate can be exchanged automatically without stopping the LMF process. The machine software provides fully automatic support once the first build job is complete and the next one is being started. Completed build jobs are collected in an overflow bin.

TruPrint 1000 can process amorphous metals. These materials make it possible to produce parts with high elasticity and corrosion resistance, while simultaneously cutting down on wall thicknesses. This reduces production times and final part weight.

Trumpf has seven other metal 3D printers in its portfolio of varying sizes and capacities. The TruPrint 1000 Green Edition features a green laser that enables it to 3D print highly reflective materials, such as copper and its alloys. Other machines in the company’s catalog scale power and production capacity up to higher-volume applications.

Trumpf‘s TruPrint 2000 3D printer now has more laser power — 500 watts instead of 300 watts — and a square build plate instead of a round one. There’s also a motorized beam expander that automatically adjusts the laser spot diameter (55 or 80 microns) according to the task at hand for more detail.

EOS M290

The smallest LPBF machine from EOS is now the M 290, which was introduced in 2014. The company discontinued the smaller M 100 in 2022, presumably ceding space in the entry-level, low-wattage category to the newer start-ups. And why not? EOS has a solid footing in production manufacturing and 3D printing service bureaus with its three larger machines, the M 300, M 400, and M 400-4. The larger machines focus on higher productivity with larger build volumes and more lasers.

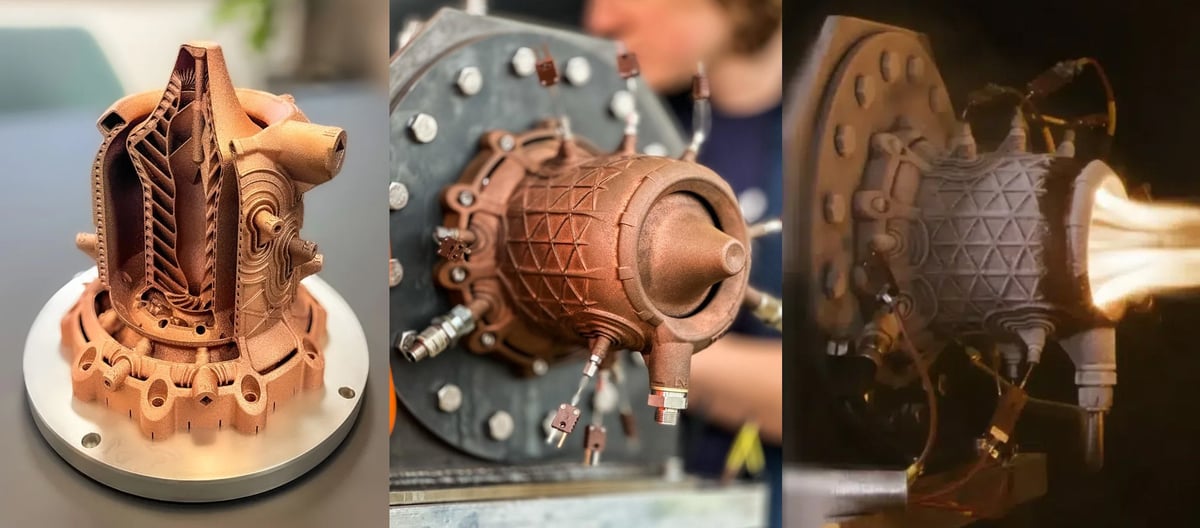

In 2024, EOS launched its new M 290 1kW initially focusing on copper (CuCp and CuCrZr). The boost in laser power to 1,000 Watts isn’t completely unexpected. The manufacturer has been custom-fitting its machines with this power at its AMCM customization wing and decided it was time to let this unit out into the wild particularly to cater to customers in space, energy, and mobility.

In fact, the AMCM machines are some of the most specialized metal 3D printers on the market making parts for the CERN particle collider and combustion chambers for Launcher’s E-2 rocket engine.

EOS offers an impressive range of materials for its six core metal 3D printers with more than 20 alloys and 70 validated “processes” or printer settings to get predictable outcomes. The metal portfolio includes aluminum, cobalt chrome, nickel alloys, refractory metal, stainless steels, tool steels, and titanium.

Nikon SLM Solutions SLM 125

SLM is one of the largest names in LPBF 3D printing, offering six printers and nearly two dozen metals. The company was acquired by Nikon, the camera and industrial precision equipment maker, in January 2023 and became Nikon SLM Solutions.

The SLM 125 is among its most popular machines. This 400-watt fiber laser 3D printer has more power than the lasers of other similarly sized machines, the manufacturer claims, which cuts powder consumption by up to 80%. Nikon SLM markets the printer toward research work and low-volume manufacturing.

The SLM 125 can process both reactive and non-reactive metal powders, and its reduced number of powder-transporting components makes swapping materials quick and easy. Laser Power Monitoring and Layer Control systems constantly check both laser output and layer consistency for high accuracy, which helps catch any irregularities. The 125 x 125 x 125 mm print envelope is sufficient for one-off parts and prototypes, especially with the wide variety of materials, including stainless steel, aluminum, and titanium. Research institutes and parts producers looking for power in a small package shouldn’t dismiss the SLM 125.

A nice feature in SLM Solutions’ technology is the ability to directly scale the production process with the company’s expansive catalog of other printers. The firm has a machine for pretty much every production level, with the latest model addition being the generously sized industry-level NXG XII 600 launched in late 2020. Its twelve 1,000-watt lasers and a 600 x 600 x 600 mm build volume provide not only size but speed – the company claims this is the fastest metal printer on the market. Nikon SLM recently began US production of the NXG XII 600.

In late 2024, Nikon SLM Solutions announced its newly redesigned SLM 280, SLM 280 Production Series, and SLM 500 machines promising to ensure a minimum of 85% uptime for customers, with a target of over 90% machine uptime.

E-Plus3D EP-M150

Eplus3D now offers 12 industrial metal powder bed fusion machines, which begs the question: How many options do manufacturers need? The company offers a dizzying menu of build volumes and laser counts. The latest addition launched in January 2024, the quad-laser EP-M400S, builds on the success of the EP-M400 launched in April 2023, the company says. This new model brings “significant enhancements” including a new top-feeding powder hopper and bi-directional powder re-coating, which reduces powder-spreading time by up to 30%.

The EP-M400S is also 10% smaller than the non-S version while reducing the build volume just a touch from 405 x 405 x 450 mm to 400 x 400 x 450 mm.

The smallest metal solution from Eplus3D is their EP-M150 LBPF machines designed for batch manufacturing of dental parts, medical implants, and material research, the company says. The company’s largest offering, with a build volume of 1,558 x 1,558 x 1,100 mm, is its EP-M1550.

The EP-M150 is a low-cost machine to operate, the company says, which is a feature after-thought for many purchasers but can drastically affect the bottom line. The machine has a powder feeding and sieving system that enables high material utilization, low gas consumption (0.8 l/min), and a tightly sealed chamber that minimizes gas leakage. The machine also features a clear UI and various security technologies for specialized industries.

Eplus3D also has a technical consulting team to help you select the right solution or to go with their contract additive manufacturing option. They can also help you figure out how to use advanced additive manufacturing to develop completely new business models, improve the efficiency of your existing productions, and create manufacturing innovations.

Colibrium Additive Mlab R

Industrial powerhouse GE spun off its additive manufacturing division in April 2024 as Colibrium Additive. It currently offers nearly a dozen metal 3D printers in various technologies, including electron beam melting, laser powder bed fusion, and is developing a metal binder jetting option.

Colibrium Additive’s LPBF machines (which it acquired from a company formerly known as Concept Laser) range from the smallest single laser Mlab R (90 x 90 x 80 mm) to the massive dual-laser X Line 2000R (800 x 400 x 500 mm). Mlab R can process an impressive list of reactive and non-reactive materials and produces fully dense parts with a surface finish that’s smoother than most. The small build volume is designed for research, prototypes, and precious metal parts. The modularity of the build chamber allows for quick and efficient material changes, and the semi-automatic sieving station enables powder reuse. The Mlab 200R version has a more powerful laser (200W) and the option of a larger build volume (100 x 100 x 100 mm).

Colibrium Additive is better known for its EBM machines, which are widely used in the medical industry for orthopedic implants and in aerospace for parts such as turbine blades. The EBM line boasts dimensionally accurate parts quickly and efficiently with a high-power electron beam for high melting capacity and productivity.

Renishaw RenAM 500

Placing emphasis on productivity, Renishaw’s RenAM 500 line is available in several configurations of one or four 500-watt lasers, each capable of hitting the entirety of the build volume. This enables the RenAM 500 to accomplish full-layer sinters quicker than single-laser systems, increasing output and, consequently, reducing cost per part.

In late 2024, the new RenAM 500D debuted. It has the same Tempus technology that allows the lasers to fire while the recoater is moving, improving overall efficiency. The machine has two 500-watt ytterbium fiber lasers, a beam focus diameter of 80 microns with dynamic focus, and a build volume of 250 x 250 x 350 mm.

There’s an automatic or flexible powder and waste handling in the 500 line. The flexible option enables you to change powders in-house while the automated system ensures operator safety and reduces the time required to operate and maintain the machine by recirculating. An “intelligent” gas flow system reduces both argon consumption and emissions.

The RenAM 500 features a typical build volume of 245 x 245 x 335 mm (substrate dependent) and can output some 150 cm3 per hour, depending on the geometries being printed and other material variables. The RenAM 500 series enables the production of components with >99.9% density, the company says.

AddUp FormUp 350

AddUp, the French 3D printer maker, debuted its powder bed fusion machine, called the FormUp 350 in 2021. It’s a modular, production-focused 3D printer featuring a material handling system that’s designed to store, move, recover and sieve powder within an inert atmosphere, preventing operators from being exposed to fumes and smelting residues.

The FormUp 350 is the only machine on the market with an interchangeable coating device. Choose the powder spreading system best suited to your production: a scraper system for maximum productivity, or a roller system for improved surface finishing. The recoaters can also bidirectionally recoat for 40% faster action. The company says that you can select from up to four 500-watt fiber lasers, each covering the entire platform surface, offering more freedom during build preparation. AddUp offers nearly a dozen metal powders.

Designed for mass production applications, the FormUp 350 machine limits the time between each production run to one hour or less, the company says. A cooling system for the machine’s Z-axis lowers the temperature of the platform at the end of production, allowing parts to be unloaded more quickly (2 hours to cool down from 200 to 65°C, compared to 12.5 hours without active cooling).

With a generous build volume (350 x 350 x 350 mm) and a range of features designed for production manufacturing, the FormUp350 boasts open parameters so you can tune to your needs.

Kurtz Ersa Alpha 140

Kurtz Ersa, the giant German machine maker and technology corporation, got into the 3D printing market in 2021 with the Alpha 140. The aim was to deliver an entry-level metal printer with simple operation at a low cost for small and medium-sized companies.

Featuring an open perimeter system, you can develop your own processes by adjusting the slicer according to individual requirements. The machine features a 200W fiber-coupled diode laser with a 110-micron focus diameter for fine details and thin wall thicknesses.

The Alpha has a small footprint so you can produce parts in stainless steels, tool steels, and nickel-based alloys on any size shop floor. Kurtz Ersa says the Alpha 140 can achieve metal part strengths comparable to larger LPBF machines and has a metal part density of up to 99.9%.

An optional laminar shielding gas flow creates more optimum conditions for the inert welding process while keeping the laser optics protected. There’s also a proprietary LMI SliceAM software that integrates with Autodesk Fusion 360 and Autodesk Netfabb CAD programs.

Kurtz Ersa has a larger, 8-laser, machine in the works, called Flying Ray, so stay tuned.

Farsoon FS121M

Farsoon, the large Chinese 3D printer manufacturer, aims to cover all the bases of metal printing with a wide range of printer sizes. Its smallest is the FS121M. This flexible and open system enables you to select between multiple laser spot sizes, different recoating blades, and powder choices. The company offers an 8 x 1,000 W-laser machine, the FS721, and in 2024 just launched the latest edition to the lineup; the FS721M-8-CAMS, whew, that’s a mouthful. We’ll just call it Cams, which stands for Continuous Additive Manufacturing Solution.

This metal LPBF machine features an internal conveyor system, which the company says opens up new potential for series production with increased automation. Integrating eight 500W or 1000W lasers, Cams automatically transfers a completed build unit to an “inert breakout station” and loads a second build unit to start another print job. Billed as “continuous production capability” this system ensures minimal machine downtime between build jobs.

In addition to the print automation, the powder handling is also automated. The closed-loop powder handling system integrates multiple powder processes, including powder recycling, storage, sieving, and new powder supply.

Print speed on the Cams can be up to 300 cm3 per hour.

Farsoon’s FS273M laser powder bed fusion 3D printer (275 × 275 × 355 mm) has dual fiber lasers (2 × 500W) or a single 500W fiber laser. Its recoater design enables faster speed and more stable powder delivery throughout the whole manufacturing process, a preheated base plate, removable overflow containers, and a backup powder supply sufficient for a full build.

Farsoon machines are open platform systems, which means that all machine parameters are unlocked for the user as well as an open material policy.

Velo3D Saphire

The Velo3D Sapphire “next-gen” metal 3D printer sets itself apart as a volume production system with the advantage of support-free 3D printing and a one-meter tall build volume. Using dual 1-kilowatt lasers in its 315 x 312 x 1,000 mm print space, the Sapphire can print in aluminum F357, Inconel IN718, Ti 6Al-4V Grade 5, and Hastelloy (a nickel-chromium-iron-molybdenum alloy) C22 and X, plus recently added the nickel-based superalloy powder Amperprint 0233 Haynes 282.

For Velo3D, support-free geometries mean the Sapphire can achieve prints with overhangs of zero degrees – flat surfaces on the horizontal plane, basically. In addition to saving time on post-processing prints, the printer is able to realize internal channels and volumes without consideration for support structures.

Velo3D also offers the new Sapphire XC printer, the name standing for “Extra Capacity.” True to its name, the Sapphire XC can increase production by five times compared to its sibling and reduce cost-per-part by 75%, the company claims. This XC has a build volume of 600 x 600 x 550 mm and eight lasers.

Velo3D announced in 2025 that its major financial restructuring will put Arrayed Additive with a 95% stake through its subsidiary Arrayed Notes Acquisition Corp. In late 2024, Velo3D entered into a licensing and support agreement with SpaceX, in a deal totaling $8 million.

DMG Mori LaserTec 12 SLM

DMG Mori started off in Germany as a tool-making company in 1948 and has grown with the times now offering a wide range of machines for turning, milling, grinding, and some acclaimed metal 3D printers. The company’s hybrid laser DED machines feature fast DED metal production with the fine-tuning of CNCing all in the same machine.

The Lasertec 12 SLM is a laser powder bed fusion 3D printer with a 200 W or optional 400 W laser featuring a 125 x 125 x 200 mm build volume.

Layer thickness can get down to just 20 microns and DMG Mori boasts an open platform enabling you to adjust parameters to your heart’s content and pair the machine with nearly any metal powder.

The machine’s automated rePlug powder handling tech integrates powder recycling for maximum efficiency and work safety due to the closed material cycle.

The company’s larger, Lasertec 30 Dual SLM features two 600-W lasers.

BLT S210

BLT (Bright Laser Technologies) is the metal 3D printer giant from China offering 12 metal 3D printers employing laser powder bed fusion technology, a massive metal print service, metal powders, and engineering expertise as a service. Supporting a long list of global manufacturers with hubs in China, BLT machines are widely used in automotive, aerospace, medical, and tooling applications.

The company’s smallest LPBF machine, the S210, features a 105 x 105 x 200 mm build volume, a 500-W laser, real-time monitoring, and a modular design. It runs on Materialise Magics software and BLT’s own BLT-BP and BLT-MCS. For materials, the S210 can handle titanium alloys, aluminum alloys, superalloy, cobalt-chromium alloy, stainless steels, tool steels, copper, tungsten, tantalum, and magnesium alloys.

Moving up in size and complexity and rest of BLT’s printers offer larger build volumes, higher wattage multiple lasers, bi-directional recoaters, and more production-ready features helping you track and monitor batch volume metal prints.

Considered the company’s flagship machine, the S310 features single or dual 500-W lasers and a 250 x 250 x 400 mm build volume.

In 2024, BLT debuted an upgraded BLT-S450 with a 450 x 450 x 500 mm build volume and four, six, or eight 500-watt lasers and an automated powder circulation system for powder recovery.

Who’s Using LPBF Today?

LPBF is used in nearly every industry today where traditional metal manufacturing is employed including aerospace, automotive, medical, energy, and machining.

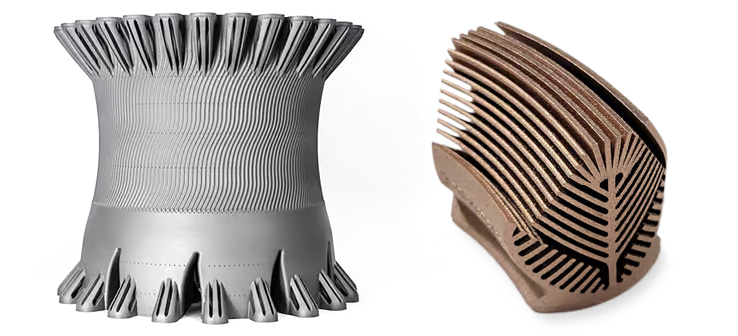

What connects all these industries is their need to produce more efficient and better-performing metal parts, faster, and at a lower cost. Although LPBF is also widely used for faster and cheaper production of spare and replacement parts, where the technology shines is in producing complex shapes and innovative product design enhancements that are not possible with any other metal manufacturing methods. With LPBF, multi-piece components can be 3D printed on one part, products can have internal lattice structures to make them weigh less, and parts like injection molds can have complex internal channels that would be impossible to machine.

Metal 3D printing, in general, can eliminate the need to maintain standing inventories and ship parts from long distances, since it can be done on-demand. Plus it’s more sustainable in that it uses and wastes less raw material.

Let’s take a look at some specific, real-world applications of LPBF in action.

Aerospace: Landing Gear & Rocket Engines

Safran Landing Systems and SLM Solutions worked together to improve a previously forged nose landing gear part for private jets.

At 455 x 295 x 805 mm, the landing gear component is the world’s first LPBF printed part of its size, says Nikon SLM Solutions. Since the component is a part of the system that transfers loads from the wheel to the plane’s structure, it was manufactured out of titanium. The choice of material gives the part strong mechanical properties while being corrosion-resistant without coatings.

It was printed using the quad-laser SLM 800 machine. Not only is the LPBF printed component 15% lighter than a traditionally forged component, but the technology also slashed the turnaround time.

“Additive manufacturing contributes to saving time in the qualification and certification phases by rapidly providing the parts for testing. We were able to produce the main fitting in a few days vs. a few months with the forging process,” says Gerhard Bierleutgeb, the chief operating officer at Nikon SLM Solutions.

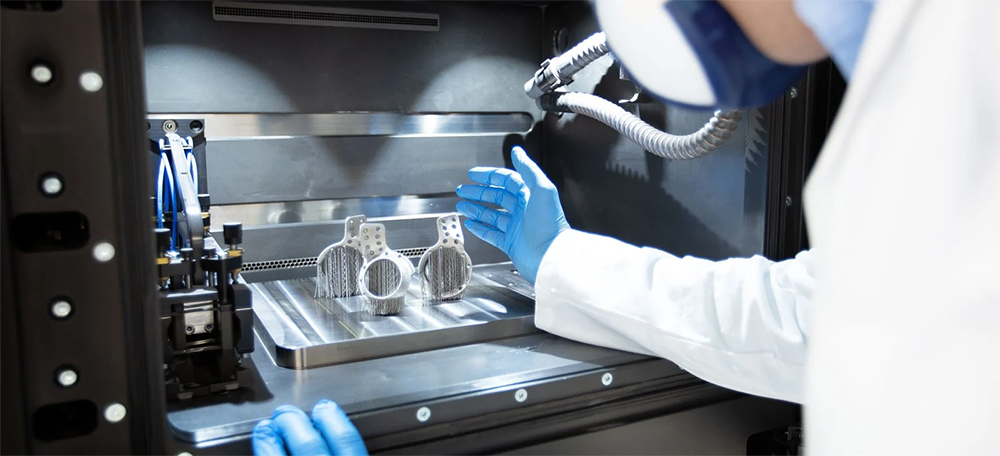

Automotive: Tools

LPBF can replace traditional manufacturing methods in many instances, but they can also work together. Traditional production methods are no longer used to create tool segments for hot-forming car parts, which is why Audi has replaced them entirely with 3D printed alternatives.

“Whenever conventional manufacturing methods reach their limit, we use additive manufacturing — which lets us meet quality standards and comply with production times,” said Audi Metal 3D Printing Center’s Project Manager, Matthias Herker.

Audi uses the EOS M 400 printer to manufacture hot-forming segments and high-pressure die-casting tool inserts. The individual segments can be up to 400 mm in length and weigh up to 120 kg.

LPBF 3D printing allows Audi to create topology-optimized, highly complex cooling channels, fine-tuned to the needs of specific components. As a result, the premium car manufacturer has been able to shorten cycle times and get more even cooling, which improves part quality.

Medical: Titanium Implants

Lumbar interbody fusion devices — or spinal cages — are widely used to treat patients suffering from back issues, such as degenerative disc disease.

GE Additive produces an additively manufactured option made from titanium powder using LPBF printing. These new spinal cages offer several benefits over machined versions, the company says.

Due to additive manufacturing’s greater design freedom, the spinal cages can be made lighter with larger windows and lattice structures. This not only reduces manufacturing costs, but makes the cages more effective as doctors can implant additional bone graft into the cage. It’s also possible to create customized porous structures that mimic human bone, which can further promote bone formation.

The new cages don’t require any coatings, which completely eliminates the risk of delamination. They’re also made of titanium, which is biocompatible and reduces cage migration and bone degradation.

Energy: Steam Distribution Block

Orano, a French multinational nuclear fuel cycle company, struggled with long lead times and high costs of obsolete spare parts. In early 2021, the company partnered with AddUp to evaluate LPBF’s technical and economic feasibility for their operation.

Using the FormUp 350 printer, Orano and AddUp created several copies of a 3D printed material transfer bridge and a steam distribution block, which has particularly long lead times when manufactured through traditional methods. The parts had identical design and mechanical characteristics to the originals.

Thanks to the use of fine stainless steel powder, the 3D printed parts had a high geometric accuracy and surface finish, particularly in their internal channels. Additionally, at the cost of three machined parts, Orano was able to print 16 additively manufactured components.

“The result is unexpected: the same design with complex geometries, the same mechanical characteristics, and above all, a 50% reduction in production costs compared to machining. Thanks to metal additive manufacturing, Orano now has an additional, agile, reliable, and economical supply chain for spare parts,” says Ana-Paula Serond, innovation manager at Orano.

Get Your Metal Parts Made: Contract Manufacturers

If you’re not ready to purchase your own LPBF machine, there are services to make your parts for you. Generally, there are two different kinds: 3D printing on-demand manufacturers and 3D printer manufacturers that offer a parts service on the side.

Top On-Demand Metal 3D Printing Services

Craftcloud

Craftcloud isn’t a metal 3D printing service per se. Instead, it’s a marketplace of 3D printing services that enables you to upload your part and compare prices and services from different service providers to find the right custom manufacturer at the right price.

With partners around the world, Craftcloud presents you with quotes generated in real time based on your uploaded models and location. You can choose from common metals like aluminum, titanium, and steel. Depending on the material you select, you can also request a particular finish. In the interest of full disclosure, Craftcloud operates independently under the All3DP business structure.

For more on the top on-demand 3D printing services for metal parts, check out this guide below:

Top Manufacturer Metal 3D Printing Services

Metal printer manufacturers, including 3D Systems, GE Additive, and EOS, offer metal part-on-demand services. These are ideal because working directly with a printer manufacturer also gives you a chance to demo their machines’ capabilities in case you want to buy one. If you’re considering a metal 3D printer purchase for your operation, it might be worth ordering some on-demand parts from a manufacturer to evaluate the machine – especially if you already have a specific printer in mind.

The printer’s manufacturer will know the ins and outs and limits of their technology down to the smallest details. This can make it easier for them to assist you with the choice of technology, materials, and parts design.

It could also be that you already own a printer from one of these companies, but your machine is just too busy to deal with a suddenly increased workflow or you want to 3D print a part using the same brand of printer at a location closer to where the part is needed. Ordering on-demand printing services from your trusted manufacturer is a good option for getting more parts done, and you’ll know exactly what kind of part quality you’ll get.

For all these reasons, consider these best on-demand metal printing services offered by 3D printer manufacturers.

GE Additive

GE Additive Print Services makes use of their EBM and DMLM metal 3D printing technologies, most of which have been obtained through mergers and acquisitions. They also provide their own materials, as well as their consultancy and training services. They focus on medical, automotive, military, dental, and aerospace industries. Although their services aren’t available online, they do offer US customers a full range of printing services via their Print Services Center in Pittsburg. The company also provides limited services in Europe through their Lean Manufacturing facilities.

EOS

Although Germany’s EOS doesn’t directly 3D print your metal parts, they do have a handy list of additive manufacturers with EOS machines who do contract manufacturing all over the world, including several in Africa, an underserved area.

AddUp

AddUp, metal 3D printer OEM and parts producer works with customers in the medical, automotive, energy, aerospace, tooling, and defense industries to print production parts. They offer part design and optimization for AM, consulting services and training, proof-of-concept production, serial part production and post-processing, plus ISO 9001 and ISO 14001 certified. With production workshops in Europe, US, and Asia, AddUp just opened a new 20,000-square-foot facility in Cincinnati, Ohio. The US-based facility is ITAR compliant.

Lead image source: LPBF 3D printing at Audi (Source: Audi)

License: The text of "The Complete Guide to SLM 3D Printing / Metal LPBF" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.