For the standard maker or small business, the integration of 3D printing usually comes in the form of FDM or SLA technology. These are the two processes that the average 3D printing enthusiast is most familiar with, as other techniques are oftentimes too expensive and require bulky industrial machinery.

But once upon a time, both FDM and SLA technology were restricted to industrial use, as no affordable desktop-sized option existed. Now, a similar renaissance of accessibility seems to be taking hold of selective laser sintering, a 3D printing technology that uses a high-powered laser to sinter powder material into solid 3D objects.

Last year, the Massachusetts 3D printer manufacturer Formlabs announced the Fuse 1, a $9,999 SLS 3D printer that has yet to surface on the market. However, tucked within the vicinity of the breathtaking pre-war architecture in Kraków, Poland, the 3D printing company Sinterit has been working for over three years to fit this industrial process into a compact and inexpensive machine named Lisa.

The Sinterit Lisa is a desktop SLS machine with a starting price of just $6,990 (€4,999), which is incredibly affordable for this type of technology. The full package, which includes a sandblasting station and powder sieve, costs an additional $2,000. Not only is the Lisa system low in price, it’s also essentially a plug-and-play printer.

What the Sinterit Lisa seems to symbolize is the disruption of industrial exclusivity, a 3D printer that makes SLS technology available to more makers and business than ever before.

All3DP paid a visit to the Sinterit team in Kraków, Poland. We had the opportunity to test and review the Sinterit Lisa on-site, giving us an up close and personal interaction with this SLS 3D printer.

Pros

- Incredibly cheap for SLS 3D printing technology

- Desktop-sized machine, industrial-grade performance

- High-resolution prints with movable parts and complex shapes

- Intuitive and easy to follow user interface

- User-friendly software

- Capable of producing functional prototypes and parts

Cons

- Lengthy setup/print time (but short compared to industrial-sized SLS machines and service providers)

- Relatively limited build area

- Requires a fair amount of preparation and cleaning

- Handling powder can get messy

Verdict

After spending two days with the Sinterit Lisa 3D printer, our first impression of this one-of-a-kind machine was mostly positive. It was our first time reviewing selective laser sintering technology, and seeing that the Lisa is the most accessible and affordable on the market, it made for the perfect starting point on this industrial adventure.

Thanks to the assistance and generosity of the entire Sinterit team, All3DP was granted a hands-on demonstration of the Sinterit Lisa 3D printer.

We tackled the entire process, from slicing the 3D model to sandblasting the finished product, granting us an in-depth look at how SLS 3D printing works, and also how accessible Sinterit has made this once unattainable technology.

It wasn’t long into our hands-on review that we noticed, this is still an industrial-grade machine. Despite the low cost and intuitive interface, the Sinterit Lisa still requires more work and production-savvy skills than your average FDM printer.

But the Sinterit Lisa isn’t a printer for the everyday 3D printing enthusiast. Instead, the Polish 3D printer manufacturer is targeting small-to-medium sized businesses looking to produce functional prototypes or end-use parts.

The 3D printer’s user interface walks you through every step to setting up and cleaning the machine. The clear and concise instructions made it easy to understand the 3D printing process on the first go.

After the print, we had to prepare for post-processing. This required removing the hot powder bed and unearthing the model (with gloves and tools, of course), which then had to be cleaned up in the Sinterit Sandblaster.

Although the Sinterit Lisa is compact and inexpensive for a SLS 3D printer, it’s still a professional-grade machine that should be taken seriously. You need a workshop that is fit for handling tasks like sieving fine powder and sandblasting. This 3D printer requires patience, awareness, and a little dirty work.

Features

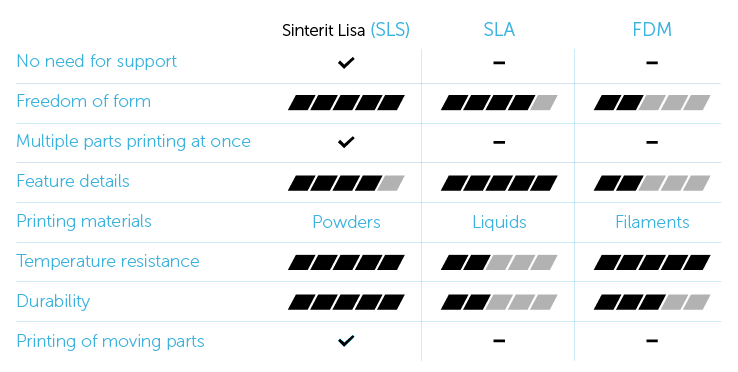

What makes the Sinterit Lisa so unique is the successful integration of SLS technology into a compact and easy to use machine. Generally speaking, there are a number of advantages that SLS technology offers over FDM and SLA, such as the ability to print without supports, nest multiple objects in a single printer, and produce parts that offer increased durability and temperature resistance.

The Sinterit Lisa manages to claim these same benefits at a major fraction of the cost. The printer is designed for small business, designers, or engineers that need functional prototypes and parts.

With SLS 3D printing technology, you are able to print without the need for support structures. Moreover, you can nest multiple parts in a single powder bed, making the technology more efficient than FDM and SLA 3D printing in many cases.

The Sinterit Lisa offers a minimum layer thickness of up to 0.075 mm, XY accuracy of .05 mm, and a 150 x 200 x 150 mm build volume.

The Sinterit Lisa also includes a 4-inch touchscreen to walk you through the entire printing process, from the initial set-up to cleaning the machine once the print is complete. There’s also Wi-Fi connectivity and an onboard camera, which means you can watch the print process through the screen.

Currently, Sinterit is offering two proprietary non-toxic powders, including PA12 and Flexa Black. After sandblasting the model, you’re left with a functional part straight from the printer. The Sinterit Lisa includes all of the tools you need to start printing, and the team also offers installation and training.

Specs

Here are the specs for the Sinterit Lisa 3D Printer:

- Manufacturer: Sinterit

- Powder Diameter: 20 – 100 microns

- Recommended min. wall thickness: 0.8 mm

- Build Volume: 150 x 200 x 150 mm

- Printing Temperature: 190°C Max.

- Printing Technology: SLS

- Weight: 35 kg // 77.16 lb

- Light Source: Class iv infrared laser, 5w, 808nm

- Material type: PA12 powder, TPU powder

- Special Features: Built in camera

- Layer Thickness: 75 – 175 microns

- Platform Leveling: Automatic powder spreading

- Dimensions: 650 x 550 x 400 mm

- Print Speed Guideline: 10 mm/hr in Z-direction, depending on model and material

- Connectivity: USB

- Slicing Software: Sinterit Studio

- File Format: STL

- Power Supply: 220-240 vAC, 50Hz, 7A // 100-130 vAC, 60Hz, 15A

- Software Compatibility: Windows

What's in the Box?

The Sinterit Lisa 3D printer is available à la carte or as a package deal that includes the Sinterit Powder Sieve, Sinterit Sandblaster, powder materials, and other assorted accessories.

When you unpack the Sinterit Lisa, you get a whole lot more than a SLS machine. The printer itself is equipped with a wide range of tools and protective gear.

Since SLS technology requires a high-powered laser and powder material, Sinterit includes gloves, protective glasses, and dust mask with the 3D printer. The Sinterit Lisa also comes with different sized brushes, metal detail purifiers, plastic spatulas, silicone grease, and more.

There are also some integral tools that help with post-processing, such as print cooling molds, plates for carrying the prints, and a powder trowel. You’ll also get spare recoater wires, heating lamps, laser protective glass, and so on.

Of course, if you opt for the full kit, you’ll also get the Sinterit Powder Sieve, Sinterit Sandblaster, as well as PA12 fresh powder and print ready powder.

Printing Process

Let’s get to good stuff, shall we? Before we could start the 3D printing process, we had to take a quick tour of the Sinterit Lisa slicing software (which we’ll get into a bit later).

Since this hands-on review of the Sinterit Lisa would only last a couple of days, it was important to find a 3D model that was both geometrically complex and functional. And so, the Sinterit team suggested we 3D print one of their most impressive sample pieces, a model of a functional car chassis.

After situating the model in the company’s slicing software, it was finally time to get the Sinterit Lisa up and running. Right off the bat, we found this SLS 3D printer to be incredibly intuitive. The user interface is incredibly helpful, essentially supporting the user through every single step.

Once the USB was inserted into the 3D printer USB port, we quickly loaded the model with the UI.

Before we get to inserting the the powder material, there was a few things to check and prepare. One thing the Sinterit Lisa does require is a fair amount of cleaning.

To ensure that everything will work properly, the user must clean the pyrometer meter and the glass protecting the laser, along with any other powdery areas that could impact your 3D print.

When you upload the 3D model into the Sinterit Lisa, the 3D printer is able to automatically detect how much powder is required in the divided print chamber. To help you measure the amount of material to pour in, the print beds lower to the exact point of measurement.

Now, you’ll pour the powder into the prepared print chamber. Sinterit recommends that you were the protective glasses, mask, and gloves that are provided with the 3D printer kit.

You’ll need to compress the freshly poured powder with the included spatula, leaving the powder surface even and compact. Next, the auto-level function comes into play, smoothing out and distributing the powder accordingly.

Before the Sinterit Lisa can begin the 3D printing process, you’ll have to use an ethyl saturated cloth to clean the parameter side glass, the laser protective glass, as well as the recoater guide. Next, you have to grease the bearing with silicone grease. If you notice any dust on the heating lamps or reflector, wipe those with a dry cloth.

Once this preparation is complete, it’s finally time to close the lid and start 3D printing the model. The Sinter Lisa’s UI will give you a start print option. You can even click on the camera view, which depicts the live 3D printing process on the small interactive screen.

Post-Processing

Once the Sinterit Lisa is finished with the model and cooling the chamber down, it’s time to remove the 3D print for post-processing. To protect the user, the 3D printer lid will not open until the inside is lower than 50℃.

When we were ready to clean the 3D print, we popped open the Sinterit Lisa and raised the powder bed with the UI. While letting the baked powder cake cool down, there were a few other crucial steps to undertake, such as emptying the overflow bin and preparing the post-processing tools.

There are two differently sized spatulas that are used to lift the powder cake out of the Sinterit Lisa, which is directly placed into a tray. We then started to chip away at the block of powder in search of our first-ever SLS 3D print. Cleaning the print feels similar to an archeological dig, sifting through unused material to find the treasured object.

Eventually, once the dust settles, we were left with a functional and high quality sample part. Scraping away the powder can get a bit messy, so it’s wise to work in an area that can easily be cleaned. Before even reaching the sandblaster, the Sinterit team explains that goal is to get as much powder off a possible. This means digging into every nooks and crannies of the 3D print.

The reason why this is so important is because a good portion of the powder can be reused. However, once it enters the sandblaster, it’s mixed with sand particles and can not be recycled for future 3D prints.

Now comes the fun part, sandblasting. This compact sandblasting station doesn’t take up much space, but there’s no doubt that a dedicated post-processing station is preferable.

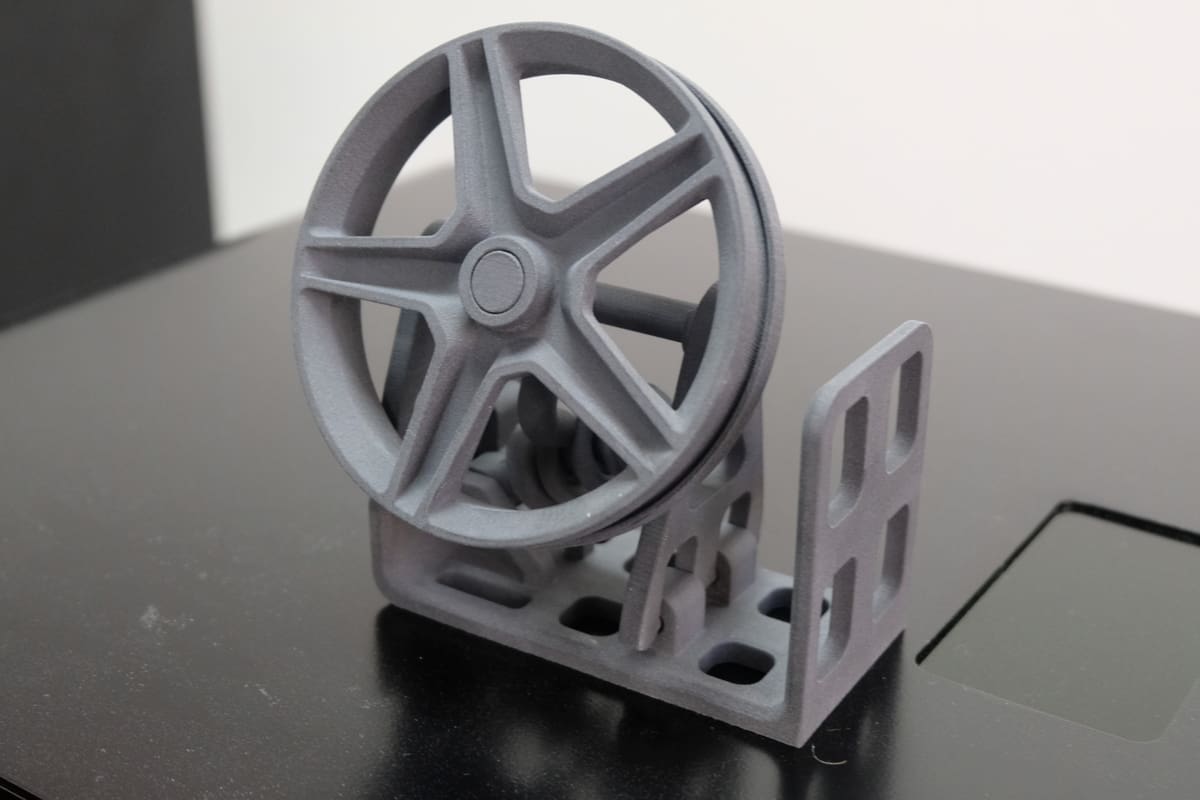

The final product was extremely impressive. This automotive chassis model was 3D printed with high resolution, and included a functional spring and spinning wheel. There were fine details like the Sinterit logo engraved on its side, and the print itself seemed almost layerless.

Aside from the PA12 used to 3D print the chassis, the Sinterit team also showed off the flexible material by 3D printing a tire for the rim. After all of the lasers and powder had cleared, we were left with a functional prototype that could never have been made with FDM 3D printing.

Last but not least, the Sinterit Lisa requires some light cleaning before things can be wrapped up. We had to gather the remainder of the powder from the print chamber and overflow bin and mix it with the rest of the unused powder cake.

In order to make the powder reusable, we had to mix it with 30 percent fresh powder. The Sinterit Powder Sieve is then used to sift the powder and prepare it for the next 3D print.

Software

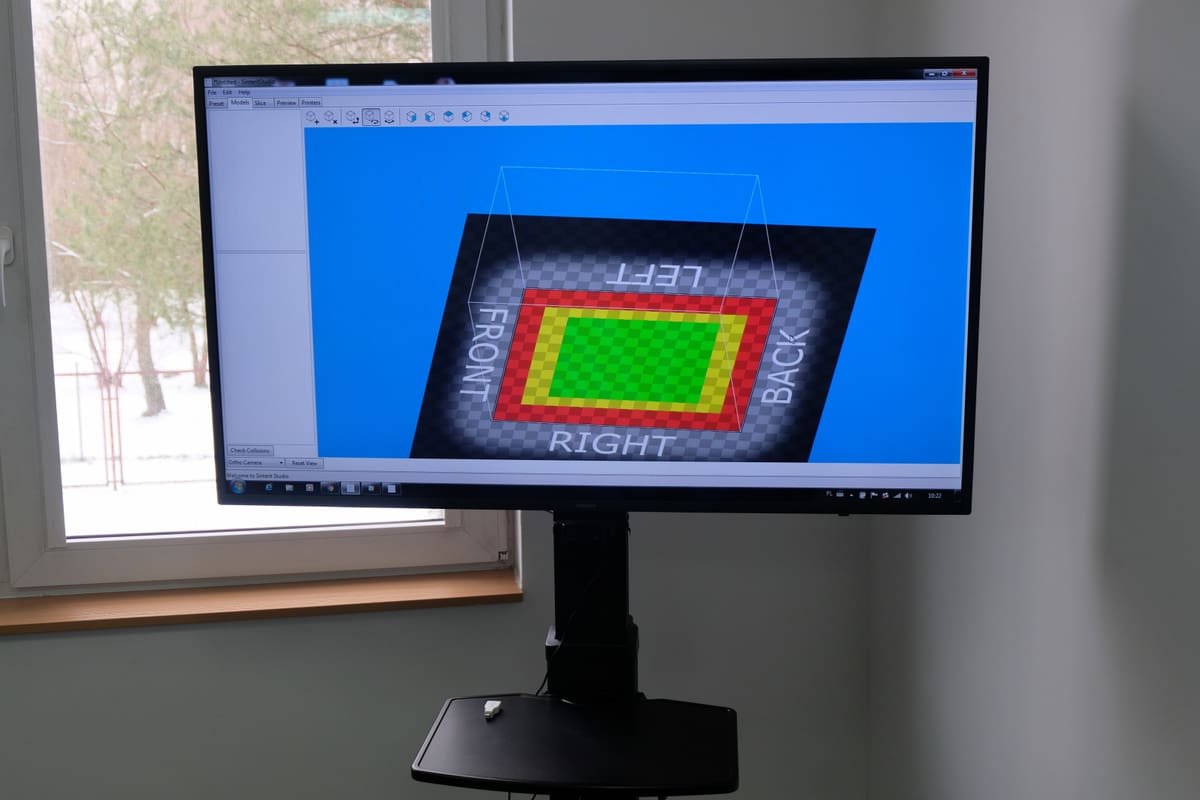

One are we wanted to touch upon was the software used for the Sinterit Lisa. The slicing program is quite intuitive and easy to use. It features a color-coordinated print bed that shows you where the print should be placed (green) and what areas you should try to avoid (yellow and red).

However, you still need to have a little knowledge on the best angle to position the model in. For instance, a 45 degree angle will usually produce the least amount of layers and offer the most strength.

All in all, the Sinterit Lisa software is still relatively new and underdeveloped, and more experimental versions are being worked on by the growing Poland-based team.

For a SLS 3D printer that prides itself on simplicity and intuitiveness, the software did seem a little lackluster as far as user friendliness goes. But it’s certainly not a deal breaker either, and is something you can expect to be improved upon as time goes on.

Wrapping Up

By the end of our hands-on demonstration with the Sinterit Lisa 3D printer, we were left with an impressive and functional sample print of a miniaturized automotive suspension system. This miniaturized object was produced in a single piece, and is equipped with a spinning tire, a flexible 3D printed spring, and other movable parts.

Equally impressive was the high resolution of the 3D print, which creates a layerless appearance. The Sinterit logo is proudly displayed on the surface of the 3D printed prototype. We even used the company’s flexible material to produce a tire to place around the rim.

As it was our first hands-on experience with SLS 3D printing technology, the Sinterit Lisa 3D printer was surprisingly intuitive and easy to use. Of course, having the Sinterit team there to provide a helping hand certainly helped, but there’s no downplaying the accessibility of this industrial-grade machine.

By making SLS technology more compact and affordable, Sinterit is making it easier for small-to-medium sized businesses to integrate 3D printing into its production workflow without breaking the bank or taking up too much space. Even larger companies can use the Sinterit Lisa as an introduction to this advanced manufacturing technology. The desktop SLS 3D printer is also ideal for use in research and education.

On top of that, the intuitive nature of the Sinterit Lisa 3D printer allows even the most inexperienced users to quickly learn how to utilize SLS technology to its full potential.

Still, the Sinterit Lisa is not the type of 3D printer for the average hobbyist or consumer. Nonetheless, this powerful Polish 3D printer is currently the most accessible SLS machine on the market, making it a intriguing option for pro-sumers, small-to-medium sized businesses, educational institutions, and anyone else looking to get more familiar with the magic of selective laser sintering.

License: The text of "Sinterit Lisa Review: Best Desktop SLS 3D Printer" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.