Creating an object from liquid plastic and light never fails to amaze. Resin 3D printing is a fascinating technology used by home hobbyists and industrial manufacturers alike. The machines and the materials come in a vast array, and the technology has different versions for various applications.

Here at All3DP, we have hundreds of articles on resin 3D printing because we use it ourselves; we evaluate the printers, we research the materials, and we talk to the people who make the machines, offer the services, and put it to use in their businesses. In this ultimate guide, we cover it all.

For the impatient, feel free to jump down to our buyers’ guides on today’s best resin printers for consumers and for professionals.

What Is Resin 3D Printing?

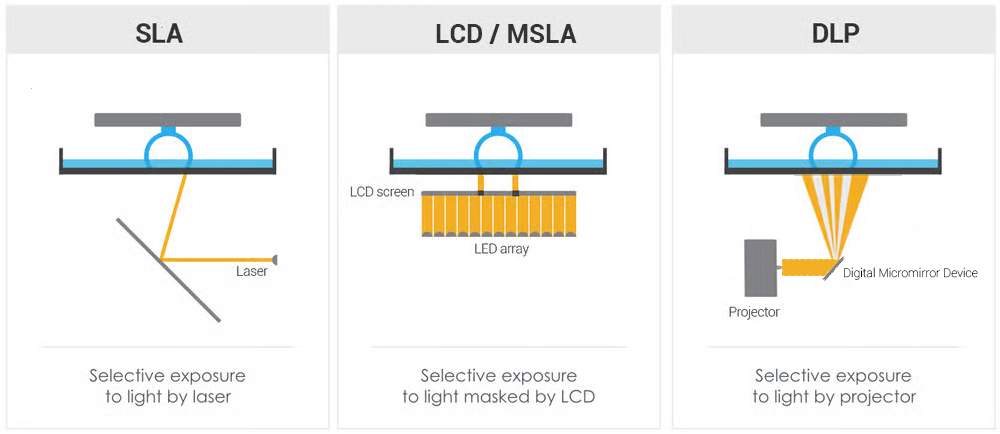

Resin 3D printing is a general term for several types of 3D printing that all use liquid resin. The most common use a vat of liquid resin leading to the technical term for resin 3D printing: vat polymerization. This comes in three main variations:

- Stereolithography (SLA)

- Liquid Crystal Display(LCD) also called Masked Stereolithography (MSLA)

- Digital Light Processing (DLP)

Resin is also used in some other industrial 3D printing technologies, including the material jetting methods called PolyJet and MultiJet Printing, but here, our main focus is on vat polymerization in all its forms.

Don’t worry, you don’t need to understand the technology to use a resin 3D printer, but knowing a little about how they work will help you pick the right machine for your needs.

Stereolithography (SLA)

Stereolithography is actually the first 3D printing technology developed. Invented by Charles W. Hull and patented in 1984 and unofficially marking the beginning of the additive manufacturing era.

Hull developed a process in which laser light solidifies layers of liquid resin, creating a three-dimensional object. Today, an SLA printer uses mirrors to rapidly aim a laser beam (or two) across a vat of liquid resin, selectively solidifying (or curing) a cross-section of the object you want. The build plate then moves up (or down, depending on the machine) one layer height and the next layer is solidified onto the previous one building up the object.

All 3D printing resin material is a “photopolymer” meaning it reacts to light, or solidifies upon contact with light. All three types of vat polymerization include some type of light.

Because of the laser and moving parts, SLA machines are usually not on our list of top budget resin printers but rather on our list of best professional resin printers, which start at around $3,500. SLA printers are highly accurate but slower than other resin technologies.

Liquid Crystal Display (LCD)

LCD 3D printing (also called masked stereolithography or MSLA), uses, you guessed it, an LCD screen. The LCD screen acts as a mask, displaying a single layer of the 3D model that is going to be printed. Below the resin tank, there’s a UV light source, usually an array of UV LEDs. When the LCD screen displays a layer of the 3D model, the UV light passes through the transparent regions of the LCD and selectively cures the corresponding areas of the liquid resin.

This build area is then moved one layer to stop additional curing of the polymer before flashing the next 2D layer that is cured to the first. Eventually, after many layers, the 3D object is formed.

Instead of a laser tracing each layer, like SLA, LCD uses a flash of light to cure an entire layer at once.

The LCD photomask is digitally displayed and composed of square pixels. The pixel size of the LCD photomask defines the granularity of a print. The print quality of an LCD printer depends on its LCD density and the size of the printer. The more pixels it has in a given area — 6K, 8K — the better the print quality, generally.

Digital Light Processing (DLP)

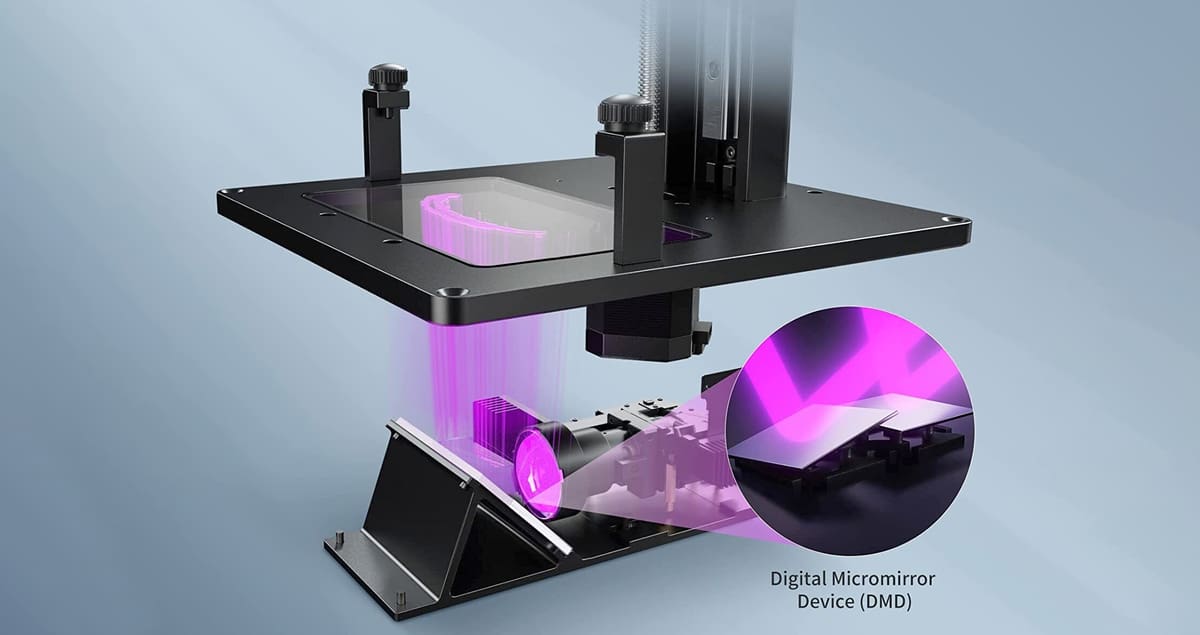

Our next method, DLP, is similar to LCD, but instead of a screen through which light passes or is blocked, DLP uses a high-resolution light projector (sometimes referred to as a “light engine”) to flash light onto a digital micromirror device (DMD) that then directs it – in the shape of a slice or cross-section of the 3D model to be printed – to a layer of resin.

You may be familiar with DLP projection technology as used in movie theaters or office projectors. These are powerful light projection devices and DLP machines can subtly manipulate the light for a more varied light intensity on the resin.

The tiny mirrors of the DMD either direct light to the resin or off to the side and out of the way. Each square-shaped mirror represents a pixel in the projected image. The light reflected by the mirrors on the DMD passes through projection optics, which help focus and shape the light into a beam. Because the mirrors direct light only where needed, DLP can produce crisper edges than LCD. With LCD, tiny bits of light can bleed around the edges of the masked pixels on the screen, plus the screen can never block 100% of the light.

Most desktop DLP 3D printers have a fixed XY resolution (between 35 to 100 microns), but some have additional sets of lenses that enable you to adjust the projection distance between the light engine and the resin layer. This distance, just like making shadow puppets on a wall with a flashlight, affects the level of detail that can be achieved.

If you’re trying to decide between buying a DLP or an LCD check out our in-depth technology comparison that’s sure to help you make up your mind.

Resin Technology Nuances & Outliers

As we just covered, the fundamental difference between these three main types of resin 3D printing technology is the light source or light engine they use to cure the resin. But within each technology category there can be substantial and subtle differences. Many of these differences separate the industrial versions from the consumer versions, but other features are proprietary innovations from particular manufacturers.

For example, one resin 3D printer manufacturer, Carbon, uses a vat polymerization technology it calls Digital Light Synthesis (DLS), which is a take on DLP. In DLS, the resin pool is exposed to both UV light and oxygen. Unlike traditional layer-by-layer approaches, DLS uses a continuous process where the object is pulled from the resin bath. The bottom of the resin pool has an oxygen-permeable window. Oxygen inhibits the curing process, and by controlling the oxygen levels through the window, the printer can precisely control the solidification of the resin. DLS requires special resins and the entire process is extremely fast.

Printer maker Stratasys offers another take on DLP in its Origin printer called Programmable Photopolymerization (P³). The outstanding feature of P³ is its ability to dynamically adjust the light patterns during the exposure process to create more sophisticated curing profiles, leading to, the company says, improved accuracy and the ability to optimize material properties.

Formlabs offers what it called Low Force Stereolithography (LFS), while 3D Systems launched a new resin printer in 2024 called PSLA 270. PSLA stands for for projection stereolithography, which is essentially DLP.

Why Pick Resin 3D Printing Over Filament?

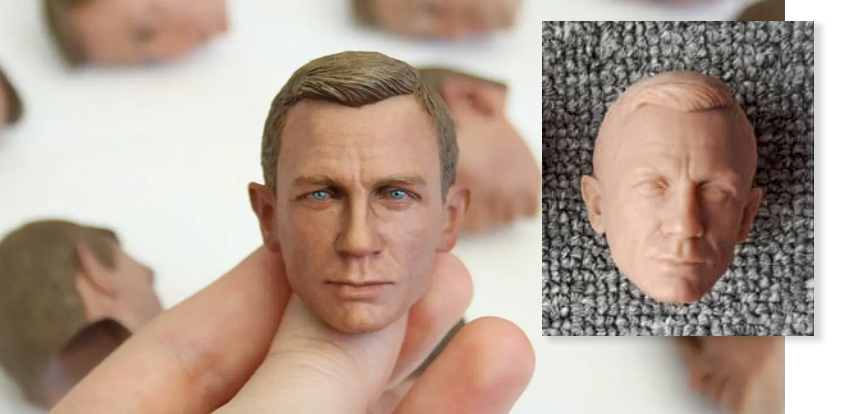

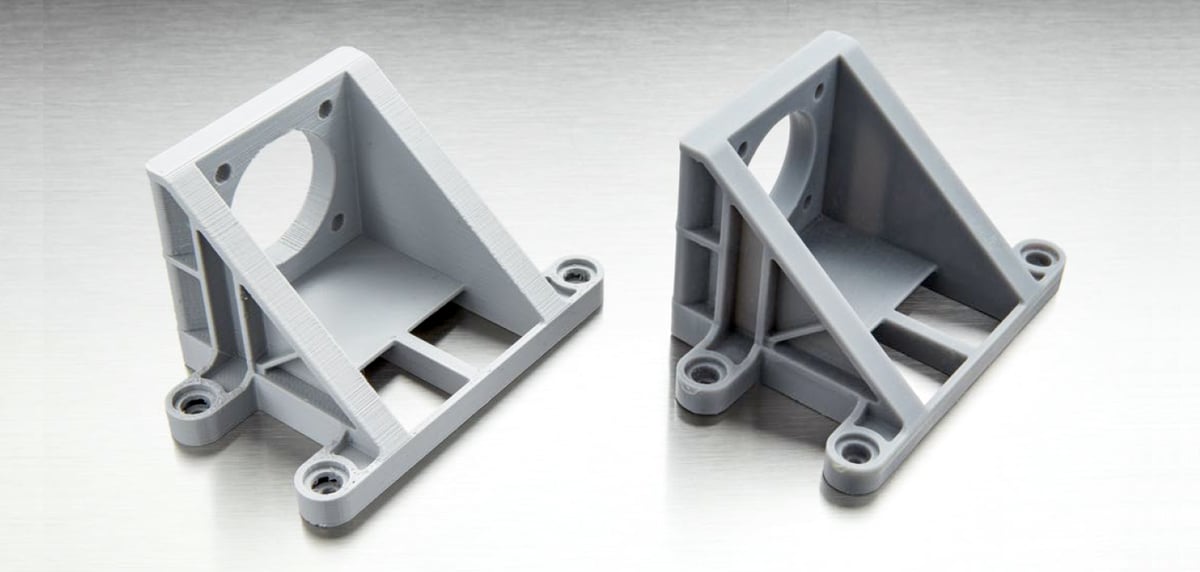

Compare it to 3D printing technology that uses rolls of plastic filament (called fused deposition modeling or FDM) and you’ll have less noticeable layer lines and more intricate detail. Is resin always better at fine details than FDM? No, it depends on the machine, but typically when comparing filament printers to resin printers in the same price category, the resin will win for high resolution. We cover accuracy and resolution in more detail below.

If you’re a hobbyist looking to print fine-detail figurines, toys, and even original sculptures, you may pick a resin printer like the Elegoo Saturn 4 Ultra 16K (one of All3DP’s picks for top resin printers in 2025) because it’s only $499 and has an impressive 16K LCD screen. No filament printer near that price can offer this level of detail.

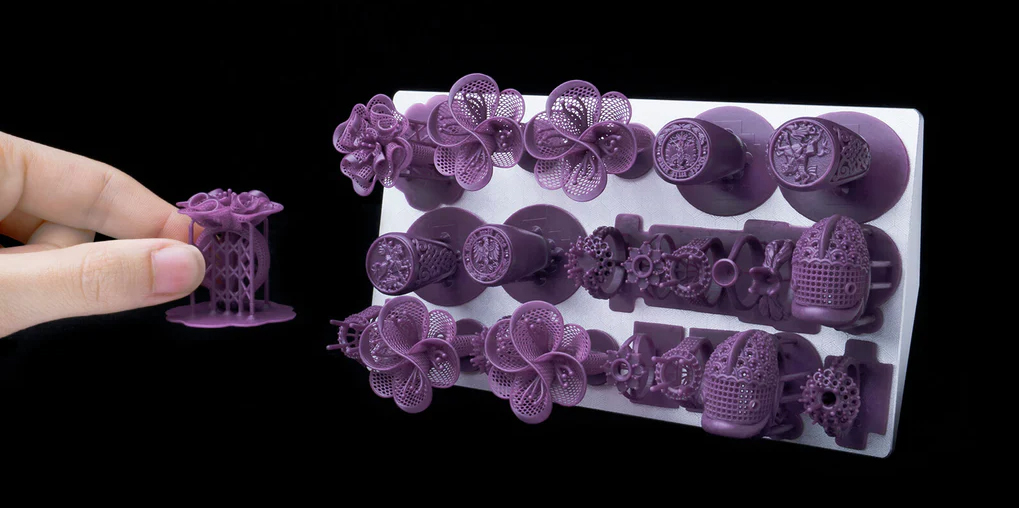

If you are a dentist who wants to print patient-specific dental models, you’d also look to a resin printer because of its level of fine detail, smooth surfaces, and available biocompatible materials. Perhaps the Asiga Pro 4K, which is one of the top machines in our guide to the best dental 3D printers.

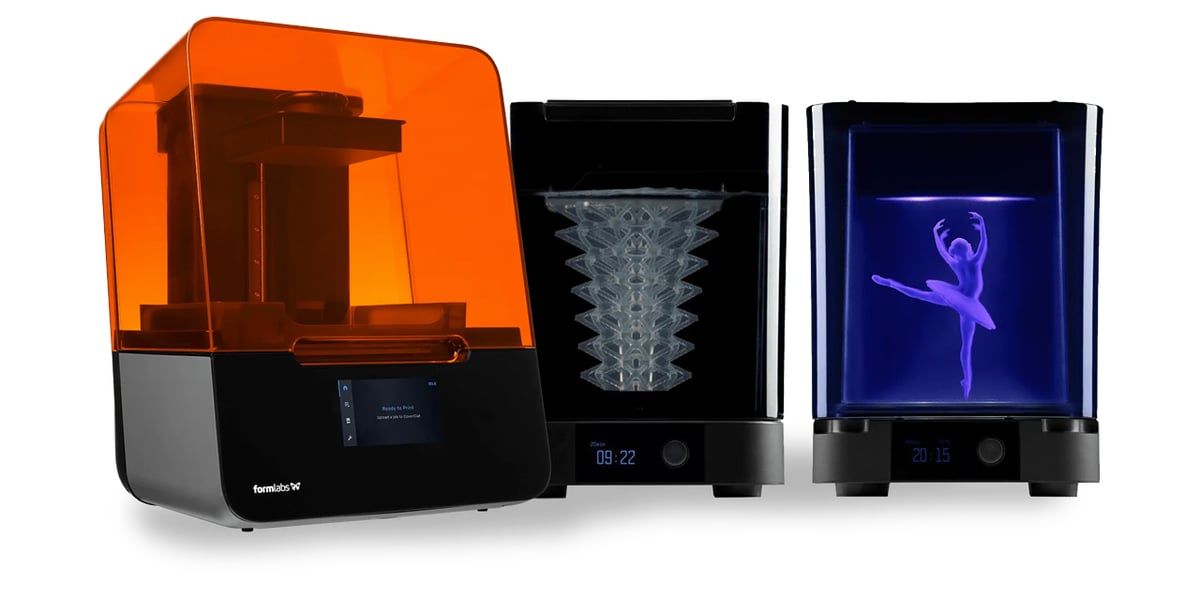

Resin 3D printers are also very popular with jewelry makers because they can print the very small features required for jewelry models that will be used to make molds. A good pick would be the new Formlabs Form 4 ($3,500) featured in our guide to the top 3D printers for jewelry making. The Form 4 is compatible with a variety of castable wax resin materials.

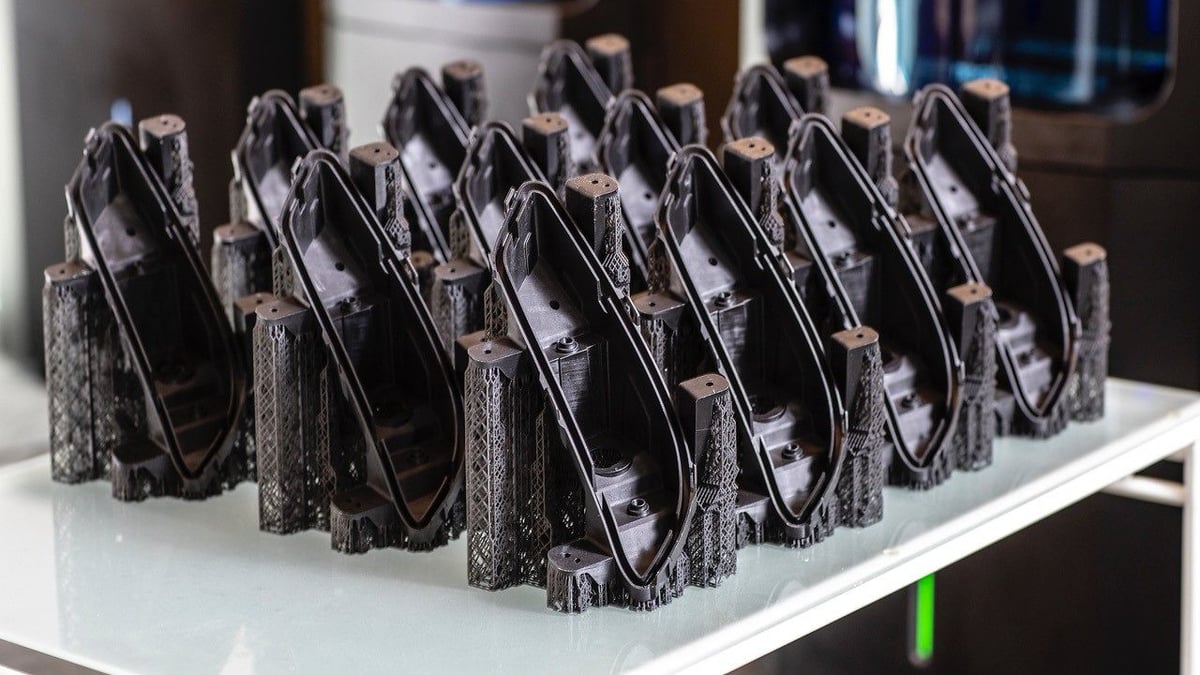

If you’re in manufacturing, you might pick an industrial resin printer like the Carbon M3 Max or the 3D Systems PSLA, both well over $200K. These can print large volumes with the speed, accuracy, and consistency required for applications like end-use auto parts.

Overall, resin 3D printing is prized for:

- Fine detail

- Smooth Surfaces

- Material Variety

- Fast Printing

- High Throughput

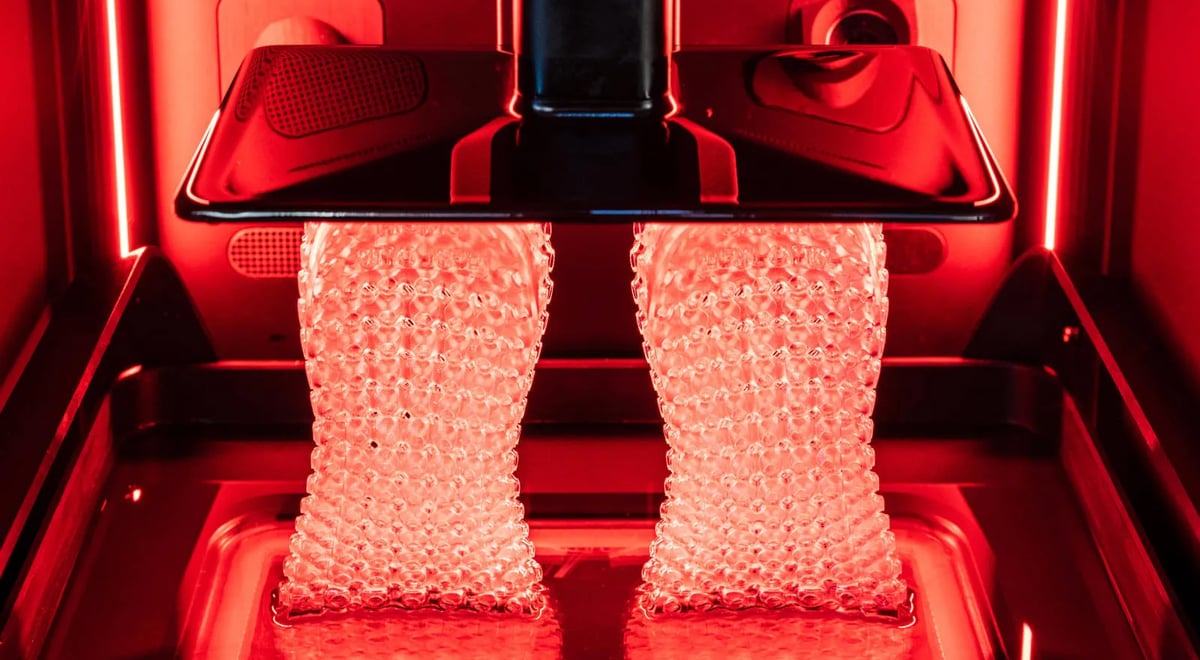

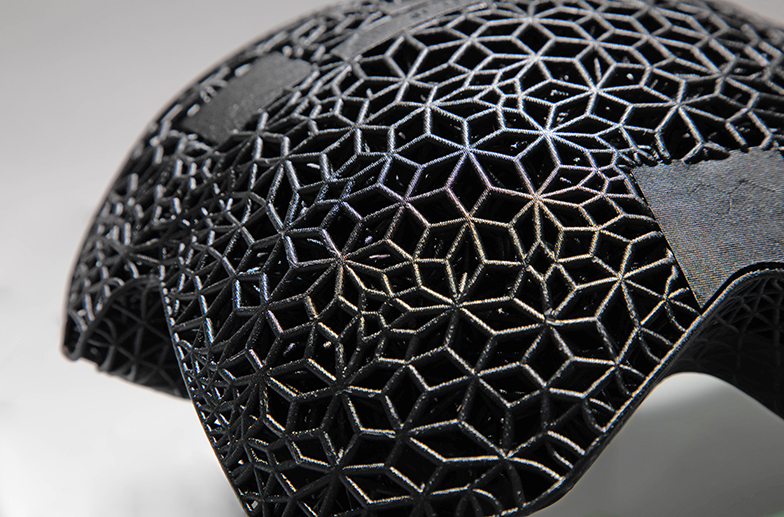

- Lattice Structures

What Are the Best Resin 3D Printers Today?

If you’ve skipped down to this section from the top, we respect your efficiency, but you may have missed the part where we explain how knowing the technology helps you pick the best machine. But if you’re in a hurry, here are All3DP’s top picks for desktop resin printers in 2025:

- Top Full Ecosystem: HeyGears Ultracraft Reflex RS Combo, $2,10

- Top Under $1,000: Anycubic Photon Mono M7 Max, $849

- Top Under $500: Elegoo Saturn 4 Ultra, 16K $499

- Top Under $300: Elegoo Saturn 3 Ultra, $299

- Top Under $200: Elegoo Mars 5, $179

- Top Small: Anycubic Photon Mono 4 Ultra Compact, $259

- Top Mid-Size: Elegoo Saturn 4 Ultra, $399

- Top Large: Anycubic Photon Mono M7 Max, $849

- Top Beginners: Elegoo Mars 5, $179

We’ve spent countless hours with these machines and many, many others. You can read our exhaustive accounts here: Best Resin 3D Printers in 2025: Our Picks in 9 Categories

Top Resin 3D Printers for Professionals

It’s impossible to say which resin 3D printer is the best for you without first considering your individual needs and circumstances. When choosing a resin printer, consider:

- Cost of 3D printer and materials

- Mechanical properties your final parts require

- Level of detail

- Print size and volume

- Print speed

- Material options (including biocompatibility)

- Specific market needs (dental, jewelry, etc.)

How to Narrow Down Your Options

When evaluating resin 3D printers to purchase, you’ll hear a lot of jargon and industry-specific terms, which we shed some light on below. And if looking at a printer’s technical specification sheet makes your head spin, know that you won’t find huge differences within comparable price ranges using the same technology. For example, the finest XY resolution for resin printers (apart from the industrial micro printers) is generally around 25 – 50 microns (μm). For reference, 50 μm is the width of a human hair.

Some manufacturers only talk about resolution, while others mention resolution and accuracy.

Resolution refers to the possible layer thickness, for example, 50 μm or 100 μm, which produces visible layer lines if you’re looking closely. Smaller resolutions, such as 25 μm (a quarter of a hair) is barely visible even up close. Remember, however that you can completely smooth the surface of resin prints with sanding or other finishing techniques.

The accuracy refers to the window of error for consistency print after print. For example, an accuracy of +/- 20 μm means your print resolution could be 20 μm over or under what you programmed.

In many industries, accuracy is critical. For most dental applications, professionals typically look for an accuracy of within 50 μm. For fine jewelry, some professionals require an accuracy of 25 μm, and for some medical applications and electronics, companies require an XY printing resolution of 5 μm with an even smaller accuracy, which you can find in a handful of ultra-high micro-precision 3D printers.

The general rule is that the higher the resolution, the longer your parts will take to print. But this is where professionals and industrial machines differ from consumer resin printers; printing high-resolution parts quickly.

For a deep dive into what resolution means and how to compare the resolutions of various machines, check out our guide: “High Resolution 3D Printers – The Ultimate Guide.”

How Fast is Resin 3D Printing?

There’s a long list of resin 3D printer makers that claim to have the fastest machine, but the comparisons are often apples to oranges considering all of the variables and technologies involved.

Speed in resin printers depends on the selected print resolution, materials, volume, plus the type and quality of the light source. This is why there are $250 resin printers and then there are $250,000 resin printers. That being said, there are some technologies that are faster than others. We already mentioned that SLA is generally slower than DLP, for example. The quality and intensity of the light source may cure the resin even faster. The ETEC Xtreme 8K DLP 3D printer from Desktop Metal for example has dual 4K projectors.

Next, consider the other equipment you need besides the 3D printer. Resin 3D printed parts are useless straight out of the print chamber. Washing off the residual resin and additional light curing is required. You can wash them by hand and leave them in sunlight, but dedicated washing and curing stations will significantly speed up the process.

Many printer manufacturers offer integrated or external cure and wash units. For the most streamlined workflow, try to get all three units from the same manufacturer.

At All3DP, we follow the resin 3D printing industry closely and produce multiple regularly updated guides to help you find the best printer whether you’re looking for your first or a fleet for your factory.

What Exactly Is Resin: Know Your Materials

You can generally think of resin as liquid plastic, and there are countless types. Your resin 3D printed parts can be stiff or bendy, rubbery or durable, flame resistant or industrial strength depending on the type of resin you use.

A unique aspect of resin is that it’s not really standardized like plastic filament or metal powders for 3D printing. For example, PLA is a specific type of plastic so all PLA filaments will have, as their base, the same polylactic acid (PLA) chemical formula that differentiates it from, say, another type of plastic such as acrylonitrile butadiene styrene (ABS). Likewise, metals for 3D printing follow the standard definitions of stainless steel, copper, and aluminum for the most part.

You won’t find standard chemical names with 3D printing resin. Manufacturers guard the precise components of their resins with great secrecy and simply call them “strong” or “flexible” or “tough” or “water washable” among others, which makes it harder to compare brands. Fortunately, most resins do come with technical data sheets that detail their major characteristics.

Of course, we here at All3DP have tested the major (and minor) brands and have our unbiased list of recommendations for the best resins for desktop resin 3D printers.

Once you move to the prosumer or professional resin 3D printers, however, you often are limited to the resins “compatible” with that brand of machine or with its specific technology, such as SLA, DLP, or LCD. Not every resin works optimally with each of these.

Some resin printers are designed specifically for the needs of certain industries. Dental resin 3D printers can use biocompatible, clear materials to produce mouthguards, surgical guides, and other dental appliances. Jewelry resin 3D printers often have very high detail accuracy and are compatible with printable wax resins that work directly with the lost-wax casting process.

Is Resin Harmful & Toxic?

Resin is a chemical, more specifically a photopolymer of monomers, oligomers, and various additives. Yes, 3D printing resins are toxic materials in the uncured liquid form. They’re carcinogenic, irritating to the skin and respiratory systems, and harmful to the environment. You must always use gloves when handling and cleaning resin-printed parts and print in a well-ventilated area to reduce fume buildup. You should also cure all unused resin and dispose of it at a hazardous materials collection point.

Although most 3D printers require you to pour the resin into the vat, more are adopting a resin cartridge approach to mitigate the mess and some of the hazards. Some professional machines offer a touchless conveyor system to bring parts from the printer to the washer and then to the curing station.

Our guide to keeping yourself and the planet safe while handling 3D printing resins will give you actionable advice. Plus, don’t miss our guide to properly disposing of resin and proper ventilation in your 3D printing workshop or office and building an enclosure for your resin 3D printer to capture some of those fumes.

How Much Does Resin Cost?

Naturally, it depends on the resin, but on the low end, a 1-kg bottle of standard 3D printing resin might start at $14. Think of standard resins as the starting point in the world of resins. They’re not tailored for a specific use case, instead, they’re just, well, standard-purpose 3D printing resin. Standard resins are mostly used for visual models because they lack specific features (mainly in strength) to be suitable for specific functional applications.

On the other end of the spectrum, some biocompatible dental resins can sell for upwards of $1,300 per kg.

Ceramic, Metal & Specialty Resin Materials

We did generally define resins as a type of plastic, but you can fill or infuse that plastic with large amounts of ceramic or metal particles to produce ceramic or metal parts.

Ceramic Resins

There are photopolymer resins reinforced with ceramic particles and then there are industrial or “technical ceramic” resins. The differences are in the ceramic-to-resin ratio of the material.

The most mature additive manufacturing technology for ceramics, being able to produce the densest structural parts, is vat photopolymerization using either the DLP or SLA approach. Ceramic materials have unique properties that are extremely valuable in the high-tech manufacturing of everything from semiconductors and bone implants to rocket engines and cutting tools. Add 3D printing technology, and you can create ceramic parts in shapes and with features not possible with any other manufacturing process.

Makers of ceramic resins (or slurries as they’re often called) are growing their compatibility partnerships with resin 3D printer makers. For example, the Tethon Porcelite, a UV-curable ceramic resin, is suitable for any SLA or DLP 3D printer with UV wavelengths between 350 and 405 nm.

Metal Resins

Metal infused resin or slurry is mostly used in the micro 3D printing industry but also for larger industrial parts. Metal lithography, also called lithography-based metal manufacturing (LMM), uses a mixture of photosensitive resins and metal power, as feedstock.

Austria-based Incus is an engineering start-up offering a lithography-based metal additive manufacturing printer called the Incus Hammer. It prints with a wide range of metal slurries. Admatec is another printer and materials maker specializing in photosensitive resins loaded with ceramic or metal powder. The AdmaPrint feedstocks can be used to print complex geometries, large and fine structures and a wide variety of functional products.

Regardless of the method, all technical ceramic and metal 3D prints require heat treatment or sintering in a high-temperature oven after printing. This process burns out the polymer and leaves behind only the ceramic or metal particles for a dense part.

Specialty Resins

We did mention that resin material is toxic but a special group of resins are biocompatible.

Medical and dental professionals require special resins that are approved for contact with patients, either for quick dental try-ons, for permanent implants or for products such as hearing aids or orthopedic braces. This is why the biocompatible resin market is huge and mostly filled with material makers that don’t make any other type of resin.

If you own a resin 3D printer that’s marketed specifically for dentists, like the Sprintray Pro S or the Rapid Shape D20+, it will come with a list of compatible dental-specific resins, but you can often use third-party resins. You don’t need a specific resin printer or use biocompatible materials, however.

Keep in mind that regulations on biocompatibility vary from the US to the EU to Asia and India. If you’re considering using 3D printing to manufacture and bring to market a medical device, such as an orthopedic brace or medical model, check out our guide to biocompatible materials linked below.

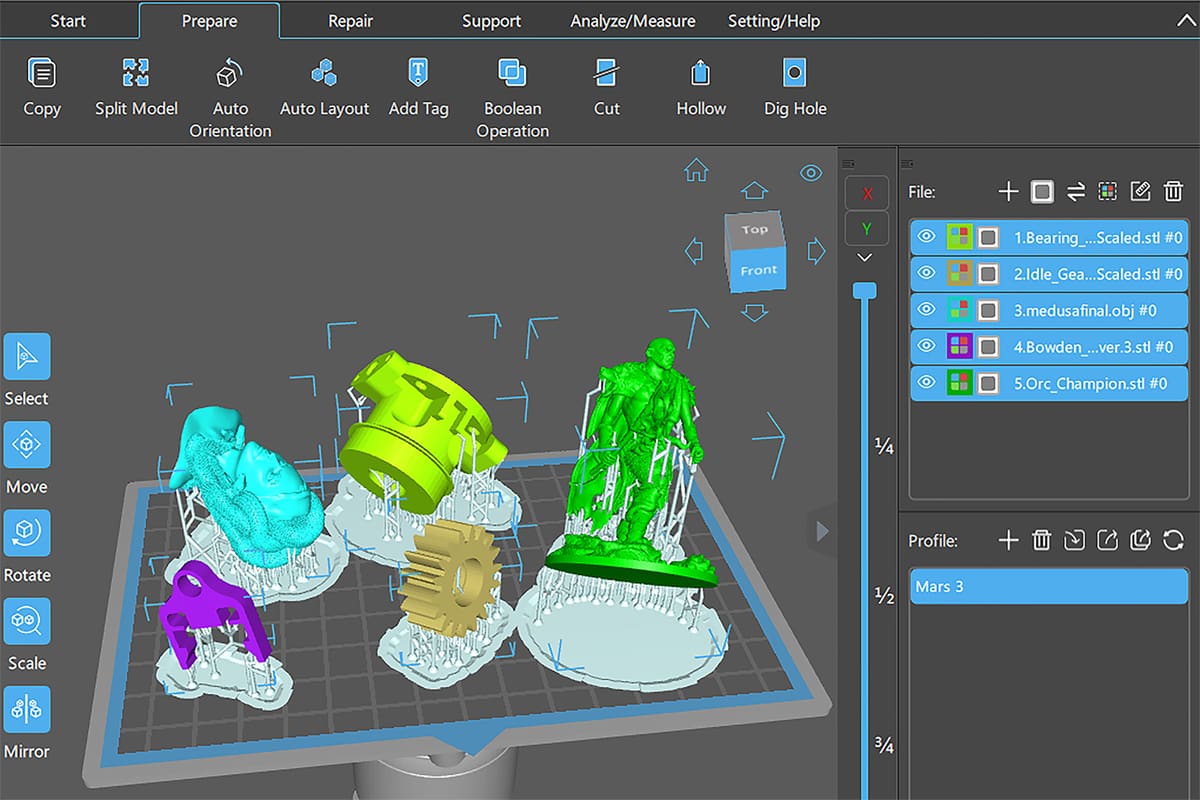

Software for Resin 3D Printers

All 3D printers require operating software to turn your digital model into instructions for the machine to follow. This software is called slicing software. If you’ve used filament 3D printers, you’d be familiar with the concept. But software for FDM machines won’t work with resin 3D printers.

In resin 3D printing, instead of generating G-code files, slicing software creates a series of images corresponding to each layer to be cured. The slicing software controls all the basic printing parameters plus the creation and placement of support structures.

In the past, it was quite common for users to stick to the default slicer that came with their machine or that was released by the same manufacturer. However, the market has moved on with the arrival of third-party slicers that support multiple resin machines, bringing more functionality to these users.

All3DP’s editors have taken these software products for a spin and come up with our eight best slicers for resin 3D printers, including official and universal software. Typical among the universal options, like ChiTuBox and Lychee, are printer-specific profile settings. For example, you can tell ChiTuBox exactly which resin 3D printer you have and which resin you’re printing with and it recommends settings already investigated to offer the best results.

As you may realize by now, professional resin 3D printers ramp up the complexity. ChiTuBox and Lychee are unlikely to be compatible with the pricier resin 3D printers, which come with their own proprietary software. Some, however, are compatible with the build preparation software inside computer-aided design (CAD) programs, such as Fusion 360.

Resin 3D printing in manufacturing is prized for another unique feature: lattice structures. For example, American football helmet maker Ridell uses resin 3D printing from Carbon to manufacture helmets (above) that are cushioned by 3D printed lattice structures, which are shown to absorb impact better than foam. These lattice structures can be created with lattice software or the lattice modules within CAD software.

Order Resin 3D Printed Parts

Resin 3D printers can range in price from a few hundred to hundreds of thousands of dollars. Fortunately, to get the resin parts you need, you don’t have to know all about the printers or materials. You don’t even need to own a printer.

3D printing service providers can print components for you at affordable prices. They also can offer advice to help you understand the technology better. They’re a good option when the low number of 3D prints you need doesn’t warrant purchasing your own printer. Printing services can also let you try out resin 3D printing before committing to a purchase.

There are many resin 3D printing services available, with their own strengths and specialties. Now that you understand the technology and the 3D printers a little bit better, you can order resin with more confidence. Check out our guide to the 10 best resin 3D printing services to pick the best partner for your project.

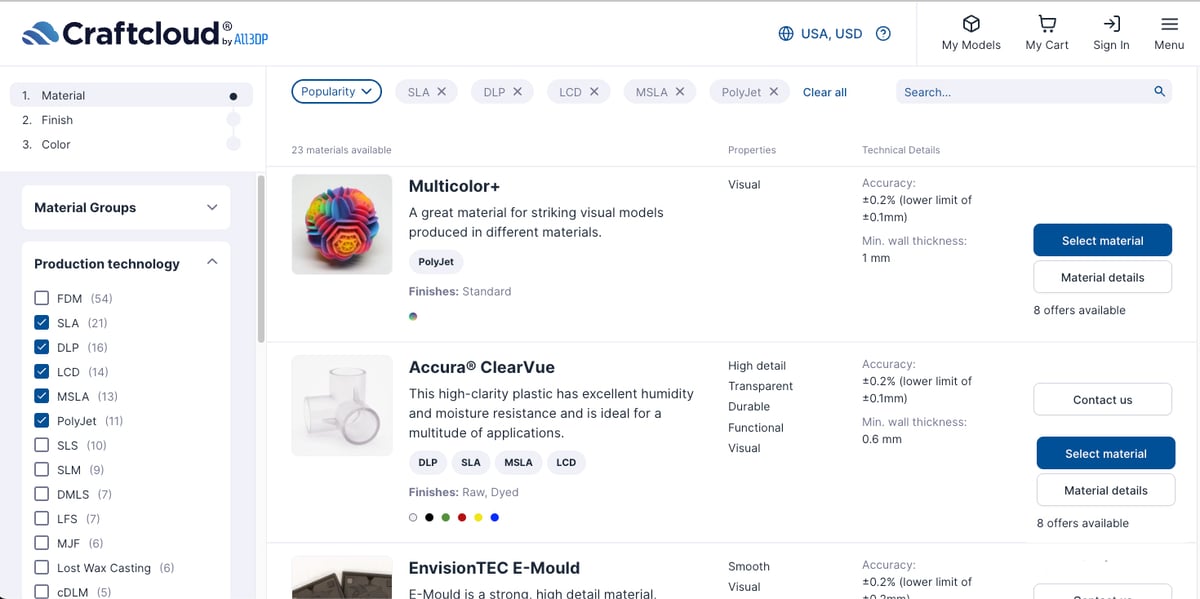

3D Printing Marketplace

Craftcloud isn’t just a 3D printing service. It’s a marketplace for 3D printing services. It helps you compare services and prices to find the resin 3D printing service that’s right for you.

Craftcloud partners with more than 100 printing service providers all across the globe. Comparing them is easy — all you need to do is upload your CAD model, pick the material and finish you need, and browse through the list to find a quote that works. Craftcloud generates quotes instantaneously in real-time and doesn’t include any hidden fees, so you will always get an accurate quote.

For resin parts, Craftcloud lists an extensive library of materials. The options include everything from standard, tough, and high-detail resins for display pieces and prototypes to transparent and elastic resins, castable resins for jewelry and metal casting, and even medical, surgical, and carbon resins.

The service works for both one-off prints, like gifts or prototype samples, and small batches of fully functional industrial-grade parts. Craftcloud also has an extensive library of material and support documentation to help you choose the right service provider.

License: The text of "Quick Start Guide to Resin 3D Printing for Beginners & Pros" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.