There are a lot of acronyms in 3D printing and it’s easy to get SLS (selective laser sintering) and SLA (stereolithography) muddled. Even if you’re clear on the general differences, you may not know which one is prefered for various types of parts and projects.

If you thought SLS was for more durable parts and SLA was for finely detailed parts, you’re right … and wrong. A lot depends on the type of SLA and SLS 3D printer so the technology choice isn’t always black and white.

Here, we’ll not only look at the differences in the technologies, materials, and the parts they can produce, but also which is the best choice if you’re buying and printer and which is the right path when ordering parts from a service.

Let’s dive in.

SLA vs. SLS: The Tech

SLS technology is a method of 3D printing that uses a laser (or lasers) to “selectively” melt a powdered polymer material layer by layer until a solid part is produced. SLA is a method of 3D printing that uses a laser (or lasers) to “selectively” cure or harden a liquid resin layer by layer until a solid part is produced.

Not to muddy the waters, but if we want to get technical about it, SLS isn’t just for polymers; you can use it to make metal parts, too. Plus, SLA isn’t only with lasers, it just requires the use of a “light source” to cure resin and could include the other resin technologies of LCD and DLP. But for the simplicity of this overview, we’re going to stick to the most common use of SLS, which is for polymers, and the most commonly understood definition of SLA, which would include lasers (not LCD or DLP although many of the comparisons we make below would also apply).

What They Have in Common

The only thing they have in common at this point is lasers and layering. First, let’s look at the lasers. An SLS 3D printer needs lasers to melt the plastic powder so they are fiber or CO2 lasers of varying quantity and power. An SLA 3D printer only needs the laser for light, so they are UV lasers. As you might expect, SLA’s UV lasers require far less electricity than the fiber or CO2 lasers in SLS machines.

Most SLA 3D printers have a fixed laser, but some, like the 3D Systems dual-laser SLA 750 and the Stratasys Neo line, have variable laser focuses, such as 150 to 600 microns, which enables you to control where fine detail is placed on the part and where detail isn’t needed and therefore you can instead focus on speed.

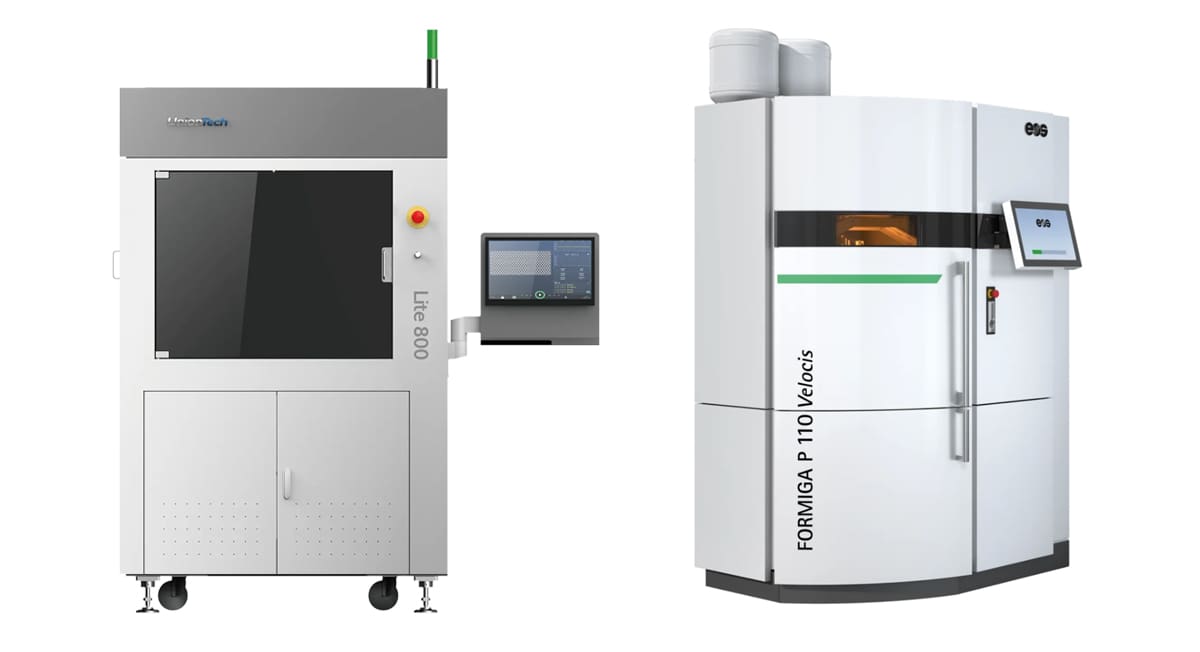

Likewise SLS machines have a fixed-spot-size laser that can vary, yet not all SLS machine makers disclose the spot size. The EOS Formiga P 110 Velocis has a 220 microns laser spot size while you can find a 650 micron laser in the in the Sinterit Nils 480.

Both technologies produce parts layer by layer, as all 3D printing technologies do.

SLS layers are made by rolling or spreading a very thin layer of powder over the build plate. SLA layers are created by the build platform, which is positioned just above the resin’s surface or slightly submerged in the resin. The distance between the platform and the resin determines the layer thickness, generally speaking. Note that there are some variations as to how SLA layers are created, but in general the layer thickness ranges from 25 to 100 microns. SLS layers can be as thin as 40 microns but vary with material and brand of machine.

How They Are Different

The most obvious difference between these two technologies is the materials: one is powder and the other is liquid resin.

There is a long menu of SLS powders that follow the common polymer naming convention, such as polypropylene, nylon, and TPU (thermoplastic polyurethane). The parts from these materials are generally comparable to injection molded parts made from the same materials.

Photopolymer resins used in SLA 3D printing are often proprietary and not as easily identifiable without taking a close look at the technical data sheet (TDS). Vendors sell “tough” resin and “flexible” resin, but to select the right one you need to look at the data a bit closer since there’s no direct parallel to the known polymers.

You may have heard that breathing in resin fumes is unhealthy, but breathing in polymer powder is likewise undesirable. Both technologies require the use of protective gear, such as a mask and rubber gloves. Some machines offer cartridges for the materials, which cuts down on hazardous material handling to some extent.

It’s after the printing is finished that you’ll most likely come in closer contact with the materials. SLA prints are not useable right from the printer, they have to be washed and cured, which usually requires two more pieces of equipment: a washer and a curing device. SLS parts are useable right from the printer but you do have to dig them out of the bed of loose powder like an archaeologist. Manual post-processing is not the only option, though. There are machines to shake or tumble the loose powder from your parts and then airblast them clean.

Removing part supports is another post processing step that should be taken into consideration when comparing these technologies. The same part printed with SLS will require far fewer supports because the powder does the supporting of the print. SLA parts typically have more printed supports and require an added manual support removal step. There are no machines that remove SLA part supports.

SLA vs. SLS: The Prints

Now to the direct comparison of SLA and SLS parts for different uses.

Resolution & Fine Details: SLA Wins

SLA printers generally produce parts that are very high in detail. In fact, other than micro 3D printing, resin 3D printing (which includes SLA and two other types called DLP and LCD) can produce the finest detail of any of the 3D printing technologies.

We already compared minimum layer height: SLA’s typical 25 microns, to SLS’s 40 microns. (The XPro Q/QHR SLA 3D printer from DWS claims a 10 micron layer height.) But in the XY or horizontal resolution, SLA also tops SLS “in general” but it depends on the machine. Resolution on both SLS and SLA machines is influenced by laser spot size, the precision of the laser’s movement and mirrors, and the material.

So, if ultra-fine detail is your primary part requirement, SLA is the clear winner, but that doesn’t mean you can’t get great detail in an SLS.

The tolerances (or how exactly your physical part will match the digital part) of SLA and SLS differ, again depending on the machine and materials. SLA generally has tighter tolerances, around ±0.05 mm, especially for small, intricate parts. SLS tolerances (typically ±0.1 mm) are broader.

The quality of your materials will also affect tolerances. Some resins can experience more shrinkage during curing and post-processing, which can slightly affect tolerances. SLS powder, which are heated during the printing process, experience thermal expansion, which can affect tolerances, plus the granular quality can introduce variations.

In both technologies, maintaining tight tolerances can be more challenging as the part size increases.

Generally, tolerances are affected by the quality of your materials and the quality of your printer. Some SLS 3D printer makers have put a lot of R&D into the best way to cool down a vat of powder after printing to avoid part warping. Similarly, better SLA machines have better thermal control heating the polymer vat and more precise controls of the laser. These are just some reasons you can spend $8,000 on a 3D printer or $80,000.

However, don’t confuse detail with part complexity. Because SLS prints with far fewer (or no) supports it can produce more complex parts, where SLA would be limited by the need for supports and support removal in tight spaces. An example would be print-in-place mechanisms, which are 3D printed components or assemblies that require no post-print assembly because they are designed to be printed fully functional in a single print job. These mechanisms ensure moving parts are free and functional right after printing as long as there are no (or not many) supports to remove. Parts, such as hinges, gears, and various types of joints and articulated parts, are best printed in a technology that requires the fewest supports. On the other hand, these parts do need to be designed so that there is no trapped, internal loose powder.

Surface Finish: SLS/SLA Tie

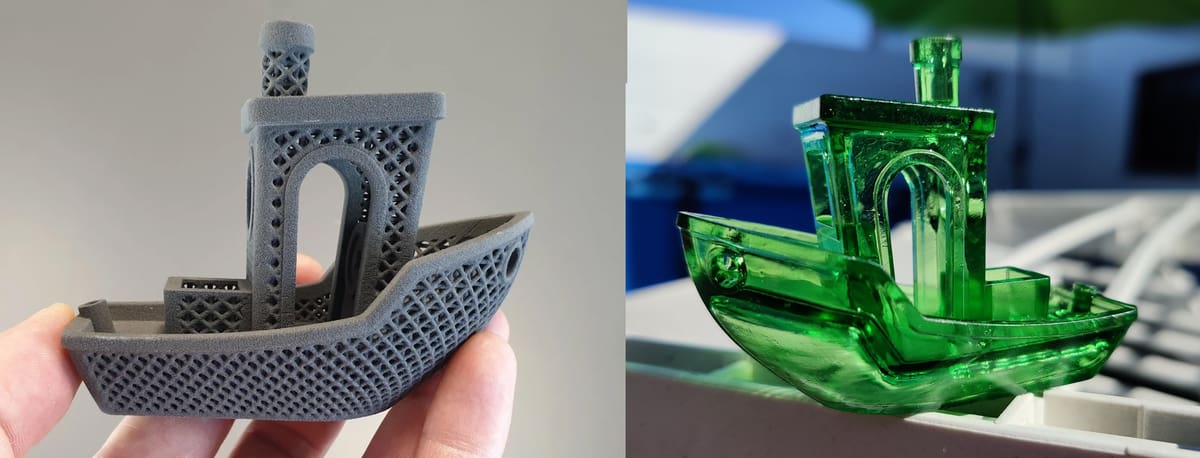

If you’re looking for a part that resembles something injection molded SLA will provide the smoothest surface finish without any post-processing. The parts can also be easily painted.

SLS parts on the other hand have a rougher surface finish right out of the printer but can be smoothed with vapor smoothing or other post-processing to also look just like injection molded plastic parts. SLS parts can also be dyed or painted.

If you’re looking for clear, transparent, or translucent parts, SLA is your choice. SLS does not print any clear or translucent parts.

Size & Capacity: SLS/SLA Tie

You may think of SLA 3D printers as smaller than SLS, but that’s only true for consumer SLA printers. Industrial SLA 3D printers, like the SoonSer Mars Pro 1600 can print parts more than 1.5 meters long. Polymer SLS 3D printers don’t get that large with, perhaps the largest being the EPlus3D EP-S600 at (420 x 380 x 600 mm).

You might want a very large resin part if you’re looking to make a mold or some type of special effect prop for a movie, while large SLS parts might be for full-scale auto part prototypes or functional end-use orthotics. Yet, more commonly, both large format SLA and SLS machines are focused on volume 3D printing, or making dozens of like or similar parts in one batch.

Print Speed & Production: SLS

Which is faster, SLS or SLA? Well, if by fast you mean the time from hitting print to having a final product in your hand, then it’s SLS. This is not only because SLA includes more required post-processing steps, but because it’s a faster printing method overall. For example, the Nexa3D QLS 820 SLS, with its four 100-watt CO2 lasers, can print at a rate of 8 liters per hour. SLS 3D printer manufacturers release print speed in terms of mm per hour or liters per hour.

SLS also includes post-processing steps that can be very time-consuming if done manually, but rather efficient if automated.

You may have heard that 3D printing with resin is fast but you’d be thinking of the two other resin technologies, DLP and LCD. These can cure an entire layer at once, whereas in SLA, the laser has to trace out the layer.

Although the faster resin technologies boast about their print speed, with SLA 3D printers, it’s not always released. Even the new 3D Systems SLA 750, which the company calls “the fastest stereolithography solution available,” doesn’t list an actual speed. For reference, DLP resin printers like the B9Creations Core 530 can reach 120 mm/hour and LCD printers like the Formlabs Form 4 can top out at 100 mm/hour.

Cost: SLA

You can spend half a million dollars on an SLA printer, but you don’t have to. You can also get a pro unit, like the Formlabs Form 3+ for just $3,000. The really low-cost resin 3D printers you may have heard of, like the perfectly capable Elegoo Mars 3 at $145, are not SLA technology but rather LCD — lasers are what makes SLA technology pricier than other resin technologies. Keep in mind that you’ll also need a washing unit and a curing unit.

You can’t touch an SLS machine for under $20,000. In 2024, a start-up company called Micronics debuted an SLS 3D printer on Kickstarter for just $4,000 to much excitement, but the company and its tech was swiftly acquired by SLS 3D printer manufacturer Formlabs, and hasn’t been heard from since. There’s also an interesting DIY SLS 3D printer kit called Inova from a new company in the Czech Republic called SLS4all. It’s selling for just about $6,500 and the first units are expected to be out to customers in 2025. As with SLA, SLS also requires some accessory equipment.

Mechanical Properties: SLS/SLA Tie

The strength, durability, and impact resistance of your part has more to do with the materials than the technology by which it is 3D printed. Both SLA and SLS offer tough, durable, and impact-resistant materials.

We already mentioned that polymer resins and polymer powders are apples and oranges, but there are some parallels we can draw.

Most standard photopolymer resins used in consumer resin 3D printers, mostly the LCD and DLP varieties, are rather brittle, which is where the reputation for resin parts being breakable comes from. But, although this may be true with most consumer resins, in the professional and industrial segment, you can find materials that are on par with SLS powders when it comes to mechanical properties, like strength, impact, and flexibility.

Application Comparison Chart

We’d love to be able to tell you definitively that one technology is better for, say, hinges than another, but, unfortunately, it depends on the material and the brand of printer (consumer or industrial).

The dental industry tends to use resin technology, although not exclusively SLA, because of the high resolution, smooth surface finish, and tight tolerances required to match a patient’s orthodonture. The auto industry tends to use SLS because it can create prototypes that can closely resemble the function and durable properties of a final auto part and can be made in the same material as the final part, such as nylon or polypropylene.

Let’s look at some primary part requirements and see which technology you can use.

Applications By Industry

In the last five years or so, 3D printer makers have started marketing their machines for specific uses and to specific industries where they believe their technology is best suited. For example, SLA 3D printer makers (and resin 3D printer makers in general) have targeted the dental and jewelry-making industries, along with wearable technology. SLS 3D printer makers have gone after the aerospace market, specifically drones, and in medical, prosthetics, and orthotics, and also manufacturing, such as jigs and end-of-arm robotic tools.

Keeping this in mind, below if a chart of major industries and the technology they tend to favor, currently.

Compare for Yourself: Order Parts at a Print Service

If you’re still not sure if your project requires SLS or SLA 3D printing, take both of them for a spin yourself. Ultimately, you want to see your part printed in SLS and SLS in a variety of materials to make an informed decision. This is where 3D printing services come in.

Fortunately, most 3D printing services will tell you exactly the make and model of the 3D printer they’re using to manufacture your part so you have a baseline for purchasing your own. Although there aren’t consumer-level SLS machines, watch out for companies that rely on more “budget” SLA (or other types of resin) machines when the order is for just one part. Typically a 3D printing service will combine your order with other customers’ orders and print them at the same time on an industrial machine, but, for a one-off, it could make more economical sense for them to use a smaller consumer machine. Always ask which printer brand and technology was used.

We’ve investigated a lot of 3D printing services and we offer our recommendations for the top SLS and SLA providers in the two guides below.

License: The text of "SLA vs SLS 3D Printing: Decision Maker’s Guide" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.