Considering today’s global supply chain disruptions and climbing manufacturing and shipping costs, businesses — from start-ups to large OEMs — are turning to this specific type of 3D printing as an alternative part production method that enables them to bring prototypes, spare parts, consumer products, and even production manufacturing in-house.

Setting itself apart from what the public often perceives as 3D printing — desktop machines that use plastic filament extruded into a shape for figurines and gadgets — selective laser sintering (SLS) is a professional manufacturing method. It’s on par with CNC machining and injection molding. In fact, it’s often used as a replacement for both of these technologies because it can be faster, cheaper, and produce parts in shapes not possible with “traditional” manufacturing methods.

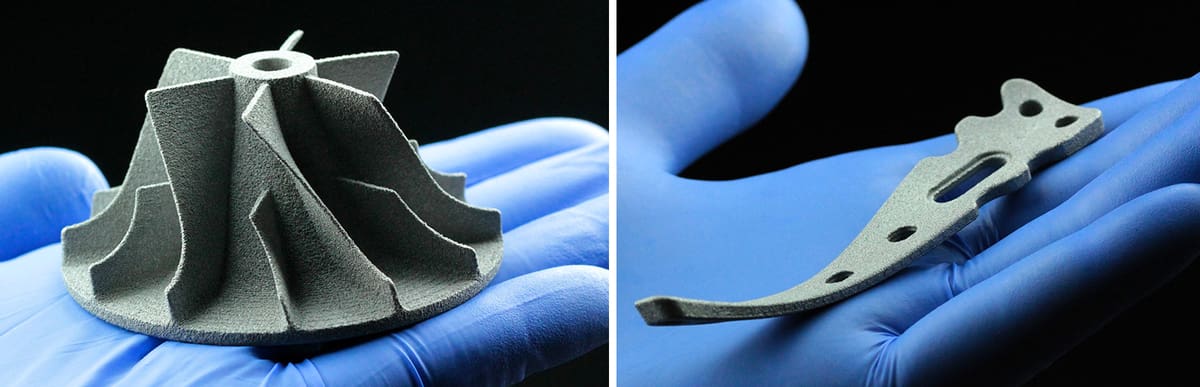

Prized for its ability to create engineering-grade parts with excellent mechanical properties and fine resolution fast, SLS 3D printing is what engineers and industrial designers turn to for functional rapid prototypes and larger volumes of end-use parts.

In this guide, we’ll cover everything you need to know to become grounded in the technology, to understand if it’s right for your business or application, and how to select the best machine or printing service for your needs.

If you’re already familiar with SLS and are looking to buy your first SLS 3D printer or upgrade to a more powerful version, check out our buyer’s guide to the top SLS printers on the market.

What is SLS 3D Printing?

If you’re not familiar with SLS 3D printing technology, in short, it uses lasers to fuse powdered plastic material together into 3D shapes, layer by layer. (Some machines can make metal parts, more on that later.)

The process begins by heating a powder bin full of powdered material, often nylon, to just below the polymer’s melting temperature. A recoating blade spreads a thin layer of powder across the build platform. Next, a laser (or lasers) is directed onto the layer of powder. Where they laser hits the powder, it sinters it into a shape that’s one small slice of the final part. Where the laser does not sinter any powder, the material remains loose and helps support the sections that are sintered.

Once a layer is complete, the build platform moves downward and the blade recoats the surface with a clean spread of powder. The laser not only sinters the next layer of the part horizontally but also vertically sintering it onto the layer below. This process is repeated until the part or parts are complete.

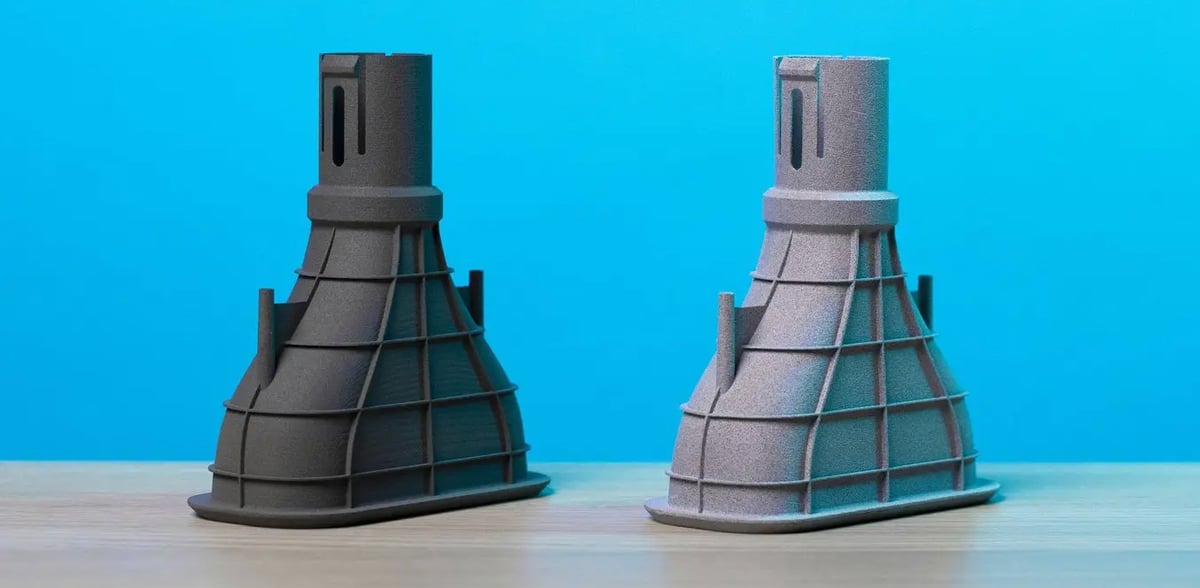

Once the printing process is finished, there’s a fair amount of post-processing that follows. Once the build chamber has cooled, which can take hours, your printed part is encased inside the unsintered loose powder bed. To excavate your parts, you’ll take the build chamber to a depowdering station. With a brush, compressed-air blower, or some other form of blasting technique, you remove the loose powder and collect it for use in the next print. Add-on and automated depowdering units cut down on the mess, but they will naturally bring up the total cost of your SLS investment.

The leftover powder can be reused for the next print job. Depending on the machine, you’ll need to add 10% to 70% of fresh powder for the next print.

Why Choose SLS Technology

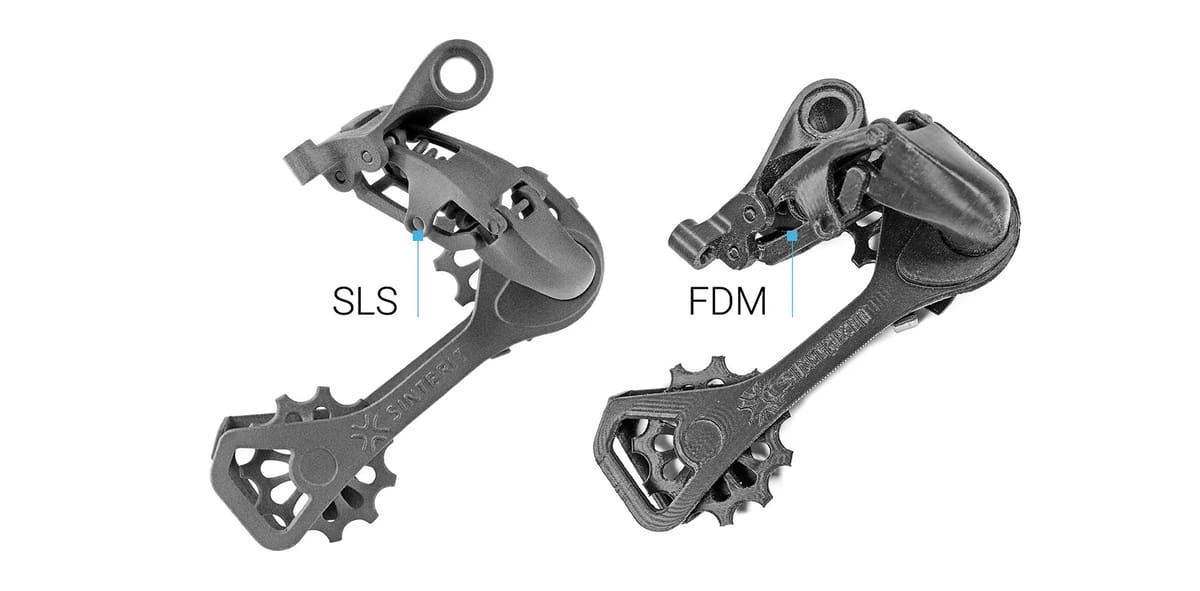

The primary reason for choosing SLS technology over 3D printers that use polymer filaments (called FDM printers) is to obtain prints with excellent and consistent mechanical performance and surface quality. Certainly, FDM is used for industrial parts and can produce incredibly strong parts especially when using engineering grade materials, such as PEEK and carbon-fiber filled nylon, but SLS is often chosen for its surface quality, which can be easily dyed and finished, its speed, and its ability to produce batches of parts in one print cycle.

Mechanical Properties

The lasers used in SLS fuse the polymer particles into a solid so that the layers are practically imperceptible. SLS 3D printing with industrial-grade materials, such as carbon fiber-infused nylon, produce parts strong enough for use in harsh conditions and factory applications. See some key examples below. But are they as strong as injection molded parts?

While anecdotal evidence shows SLS parts used in a wide range of applications successfully, scientifically, there’s scant research comparing the two technologies. One study in the Nov. 2022 edition of Engineering Fracture Mechanics looked at nylon (polyamide 12) parts made with SLS and injection molded and found characteristics of SLS that could lead to weaker mechanical properties, but tensile strength tests found little difference between the sample parts.

For example, the study found that injection molded nylon parts are very dense and exhibited only 0.2% porosity whereas SLS parts had 3.4% porosity. This relative high porosity, the study found, “is still an inherent weak point that can introduce uncertainties in the structural engineering design.”

Despite the porosity, tensile tests on the sample parts favored SLS. The SLS 3D printed nylon sample showed higher tensile strength than the injection molded part (47 MPa vs. 41 MPa), and could withstand more stress before deforming (Young’s modulus 1.64 GPa vs. 1.29 GPa). The main difference between SLS and IM specimens was in the elongation at break, or stresses equivalent to pulling apart. Values for the SLS part were half as strong as the IM part and 6 times weaker when the pulling was along the layer lines.

What engineers have found is that SLS parts are an excellent replacement for injection molded parts, just not for every application.

Design Opportunities

Another reason engineers are turning to SLS 3D printing over injection molding or machining is that it can produce parts with complex designs not possible or not practical with conventional manufacturing methods. Designers can consolidate complex assemblies that would normally require multiple parts. This helps alleviate weak joints and cuts down on assembly time. Parts can be created with internal lattice structures to reduce weight while retaining strength.

Fast & Productive

SLS printing is a generally fast additive manufacturing technology for functional, durable prototypes and end-use parts, but the speed depends on the printer. An industrial 12-laser SLS printer will print faster than a one-laser machine, for example. That being said, SLS is faster than layer deposition methods used in FDM.

You’re also not restricted to printing one part at a time. In fact, you can pack your build chamber to the brim with parts, which is particularly useful for printing multiple iterations at once.

Affordable

Especially for low-volume spare parts, prototypes, and custom tools, on a per-part basis, SLS 3D printing is less expensive than traditional manufacturing methods because there are no tools or molds needed.

SLS 3D printing usually comes out as the more affordable solution even after purchasing the machine and materials if your business needs small-run products, prototypes, and unique parts, such as jigs and fixtures. Guaranteed more affordable, however, is ordering your SLS parts from an additive manufacturing service bureau.

Examples of SLS Printing

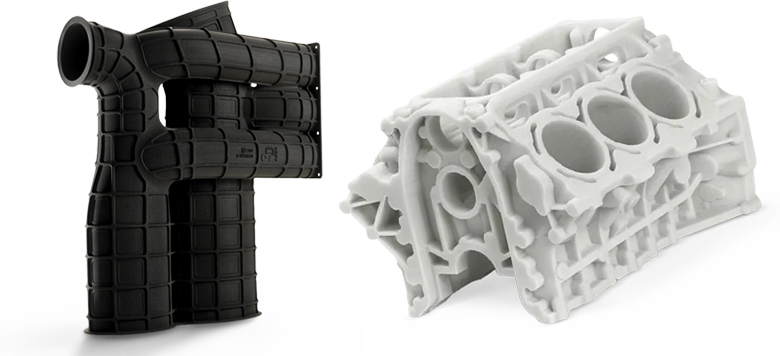

SLS 3D printing is widely used today because it rivals injection molding products in terms of strength, surface finish, and precision, but is much cheaper and faster to produce smaller quantities and customized parts. In addition, when compared to injection molding, 3D printing can create parts that injection molding can’t, such as things that have internal channels, lattice structures, and other geometrically complex features.

Industries that have taken a particular shine to SLS include:

- Automotive (jigs & fixtures, prototype car parts, race car parts)

- Aerospace (prototypes, tools, air ducts)

- Medical and healthcare (prosthetics, braces)

- Consumer electronics (housings, prototypes)

- Military (replacement parts, grips)

- Heavy Industry (sand casting patterns, tooling)

One SLS-printed part making headlines recently was the Wilson Sporting Goods’ 3D Airless Prototype Basketball that debuted at the 2023 NBA Slam Dunk contest. Showcasing the technology’s ability to print parts as one piece and in flexible materials, the prototype basketball may make its way onto sport shop shelves in the future.

SLS Materials

Can all SLS printers print with all SLS materials? Unfortunately not. Some SLS printers can print with just the two most common materials (nylons PA 12 and PA 11) while others can print with far more. Certain printers have lasers that aren’t powerful enough for certain materials, while many manufacturers offer materials that have been customized to perform best on their printers.

Always check with your printer manufacturer which materials are approved for use, because although some materials may generally work, your print may not display the promised strength or flexibility unless it’s printed on an approved machine.

An SLS printer with an open material system can produce quality parts from a wide range of materials supplied by an equally wide range of makers, so you have some choice when shopping around. A closed-system SLS machine is approved only for use by one manufacturer’s recommended materials (usually the printer maker’s). Typically, SLS prints have a matte, rough surface that can be smoothed with post-processing.

Below is an overview of the most popular SLS 3D printing materials used today (although there are others), but be sure to also check out our SLS Powder Buyer’s Guide to manufacturers, types, applications, and price.

Most Popular SLS Powder Materials:

- PA 12 (Nylon)

- PA 11 (Nylon)

- Elastomers (TPU, TPE, TPC)

- PA 12 CF (Carbon Fiber-Filled Nylon)

- PA 12 – GF (Glass-Filled Nylon)

- Alumide (Aluminum-Filled Nylon)

- Biomedical

- PEEK

- PEKK

- PP

Metal Parts from an SLS Printer

In late 2022, a material maker called Headmade Materials launched a special, patented material that enables SLS printers to make metal parts. It’s only been certified on a handful of existing SLS printers (Nexa3D, Sinterit, EOS), but the company says its technology, dubbed Cold Metal Fusion, could work with almost any SLS printer.

The key to this patented materials is the fact that it is made of tiny metal particles encased in polymer so it will sinter together into a shape and then it is post-processed in a sintering oven to melt away the polymer, similar to injection molding processes.

Of course, All3DP has a full guide on the technology that you can find on the link below.

Best SLS Printers on the Market

Advancements in technology have made SLS 3D printers more affordable and compact. Not long ago, all SLS machines were bulky and expensive, but now, there’s a few office-friendly benchtop-size SLS 3D printers on the market under $30K. Even industrial machines today have become less costly and easier to use compared to traditional fabrication methods, such as injection molding and CNC milling.

If you’re looking to buy your first SLS 3D printer or upgrade to a more powerful version, our continuously updated buyer’s guide takes a deep dive into the best printers currently on the market.

Our guide linked below covers more than a dozen of the best SLS machines ranging in price from $24,000 to $650,000.

SLS Printer Software & Workflow

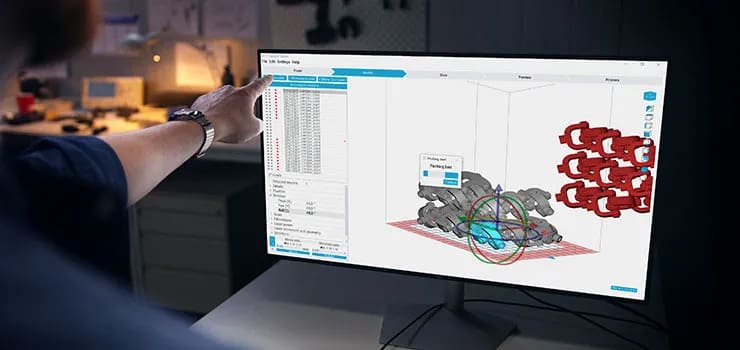

You can use any CAD software (Fusion, SolidWorks, Onshape, etc.) to design your part or product for SLS 3D printing. Once you have a design, you’ll export it to a 3D printable file format, such as STL, OBJ, or 3MF, and upload it to your SLS printer’s software.

Some CAD tools, like Autodesk’s Fusion, have integrations with SLS 3D printers so you can set up print jobs directly in Fusion and exporting a ready-to-print file to your machine, bypassing the machine’s software.

Each SLS printer is run by proprietary software to turn your digital part file into code that your printer can follow to produce your part.

Unlike the sea of free and universal software options for FDM machines, SLS 3D printers typically come with their own software, making it an important part of your printer purchasing consideration since some have unique features.

SLS printer software is where you specify a range of printing settings, orient and arrange parts within the build chamber, and slice the digital model into individual layers for printing. The more advanced SLS machines typically have more advanced software features that enable you to fine-tune settings to get just the right results. Many also feature pre-set printing profiles that automate the entire process.

Once setup is complete, the print preparation software sends the instructions to the printer via a wireless or cable connection. The software will give you estimated print times. If you’re using more than one SLS printer, some software solutions will provide information on all of your print jobs from one dashboard, from print preparation to job status and real-time printer performance.

If you have several 3D printers and want a overall dashboard to manage everything, there are some solutions, such as Materialise Magics and Siemens, that enable you, via an API, to manage your SLS print jobs over several machines as well as managing all of your other printing technology.

SLS Part Post-Processing & Coloring

SLS 3D printers can offer batches of parts to speed up your iterations and product development, but after printing, many companies run into the laborious and time-consuming task of post-processing. Extracting your parts from the powder bed, collecting the unused powder, and cleaning each individual part by hand or with standard water picks and air blasters can add hours to your part production. If your part count is high, these tasks can quickly become a burden without automated post-processing solutions. After basic cleaning there can be more steps to achieve the desired color and surface texture.

Many of the tools, machines, and products to clean and finish SLS 3D printed parts are not unique to additive manufacturing. In most cases, SLS 3D printed parts can be post-processed like any other type of plastic parts, according to the type of plastic. That said, there are companies specializing in 3D print post-processing that we mention within the techniques covered below.

Cleaning & Powder Recovery

Although removing the loose powder from the printed part can be done with any number of standard tools, recovering the unused powder for reuse is a process unique to additive manufacturing. Many SLS 3D printer makers also offer power handling stations that take the mess and potential hazard out of collecting loose powder. To end up with reusable powder with the least amount of dust and environmental contaminants, look for an enclosed depowdering or powder handling station.

One model shown below from Sinterit integrates several powder management processes into a single unit to simplify the step. The station has a suction hole to speed up depowdering and a detachable two-meter-long suction hose connected to a vacuum. Unsintered powder is automatically transported to a sieving module under the worktop where it’s ready to be mixed with fresh powder for the next job.

Media Blasting

Although air blasting is great for dislodging loose powder from your SLS parts, media blasting goes a step further. With this process, abrasive media, such as sand or glass beads, are blasted at the part under high pressure to create the desired surface polish. Again, this is a process used with other types of manufacturing, so your choices of equipment are wide.

Media Tumbling

Media tumbling is a smoothing process that goes beyond media blasting or can be used instead of manual blasting. During the tumbling process, parts are added to a tumbler bin that includes other media, such as plastic balls. The parts tumble together, resulting in a satin-like finish. This technique is not recommended for parts with sharp edges or fragile features. Tumblers are used with other manufacturing technologies and can start as low as a few hundred dollars.

Vapor Smoothing

During vapor smoothing, the top layer of the parts is dissolved by chemical solvents in a vapor chamber. The result is a smooth, glossy, and even surface that retains the part’s mechanical properties. The smoothing effect is not limited to the outside. Complex parts with internal channels or other intricate features can benefit from this technique.

Color Dying

The world of selective laser sintering is not black and white. In fact, your SLS parts can be dyed any color and receive a range of surface finishes that make them indistinguishable from injection molded parts. There are manual techniques for coloring and finishing, but automated solutions are ideal for speed and volume.

The leading name in coloring SLS parts is DyeMansion. The company offers the DM60 for deep dyeing parts in batches in virtually any color. If you’re not ready to invest in your own DM60, a wide range of service providers offer DyeMansion coloring.

Dyeing is unfortunately only available on one color per part, but SLS prints are paintable. After a clear coat to protect the paint, there’s no limit to the painting options.

Coatings

As with other types of plastic parts, various coating can be applied to SLS 3D printed parts, including metal electroplating to give parts a metallic appearance, ceramic coatings to give parts chemical resistance.

Order SLS Parts from a Service Provider

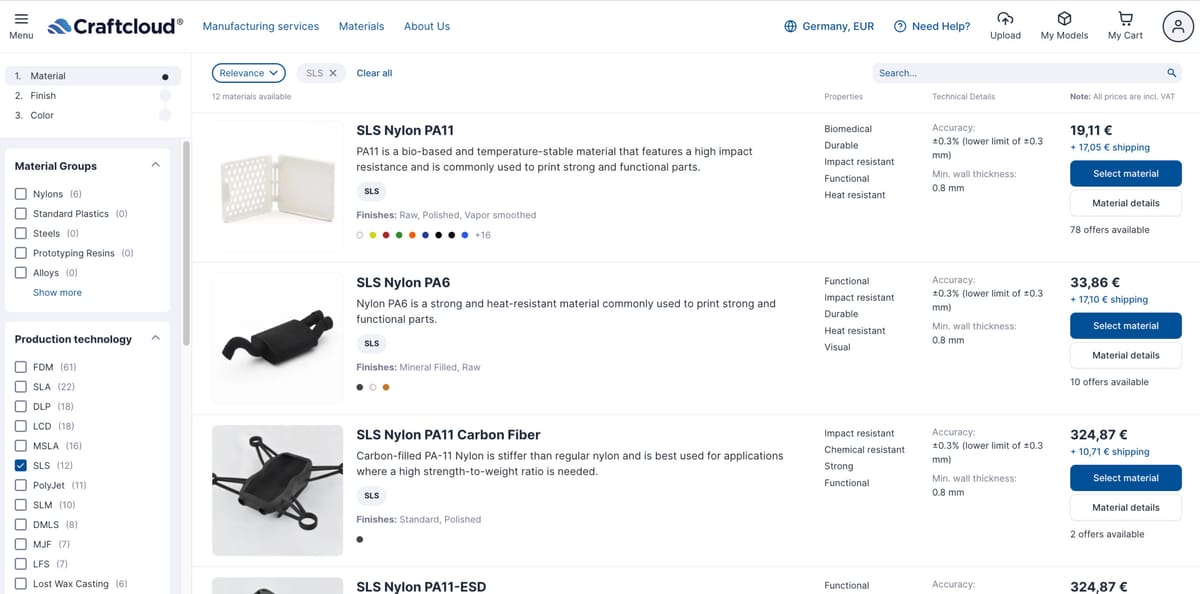

Even though SLS 3D printers are coming down in price, it makes sense to try before you buy. You can often order sample parts from a 3D printer maker you’re considering investing in, but you can’t always dictate what those parts are. With a service bureau, such as those we recommend in the guide linked below, you can upload to your digital design and select from a range of SLS materials and some company will tell you exactly which SLS printer they use.

Craftcloud is All3DP’s own solution for high-quality prints at the best price. Rather than competing directly with other service providers, Craftcloud is a search and comparison service. Upload your digital file and receive offers from many of the best 3D printing service providers available. The Craftcloud platform also shows you what capabilities each service partner has to offer, and the price quotes can be compared in real-time. Its comparison model is a great advantage for the consumer, who can see this aggregated information and make a smarter and more informed decision.

Never Miss Any News:

Read everything we’ve got on selected laser sintering:

Lead image source: SLS parts in Nylon printed on the Formlabs Fuse 1+ 30W.

License: The text of "The Complete Guide to SLS 3D Printing" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.