From a prototype specialist in New York City to an eco-friendly print shop in Sweden, these five entrepreneurs below each have a unique approach to printing for profit. Here they share their secrets to launching and growing a successful 3D printing business. Learn how to set yourself apart, how to get the word out, and how to keep customers happy.

Christina Perla, Co-Founder & CEO, Makelab, New York City, U.S.A.

- “We’re Makelab, a 3D printing company that helps creative firms with their physical prototyping needs. We work with any business, large or small, that develops hardware and physical products to speed up their product development cycles.”

Michael Lynn, Owner, 3D Print Everything, Fort Worth, Texas, U.S.A.

- “Whether you need a 3D-printed item shipped to you or want to come to our Fort Worth location and learn how to 3D print for yourself, 3D Print Everything is happy to work with you.”

Alexandra Bongartz, CEO, Beta2Shape, Munich, Germany

- “Beta2Shape is a company based in the heart of Munich, specializing in the professional production of 3D models, as well as expert advice and the sale of 3D printers, filaments, and accessories.”

Josh Stover, Co-Founder, 3D Printing Tech, Atlanta, U.S.A.

- “We combine our extensive experience in 3D-printing technologies with our business, personal, and problem solving skills to develop solutions for clients. We are a relationship-based company that understands the importance of effective communication.”

Lamin Kivelä, Owner, Xpanded Reality, Stockholm, Sweden

- “We believe in your ideas, in local design and local manufacturing. After many years of professional work with art photography, architecture, and design, we now love working as part of the Maker movement.”

Christina Perla, Co-Founder & CEO, Makelab

“We found there was a huge difference between having a love for the technology and monetizing it.”

Q. What’s your top advice for 3D printing hobbyists who want to turn pro?

My top advice is, find your niche, find your customer, and always keep trying to understand them and their needs. Yes, this is 3D printing, but at the end of the day, your marketing, customer insights, service, and targeting is what will get your business off the ground. Get yourself some research, market analytics, watch other companies and learn from their actions. You’ll soon attract a customer segment and then you can begin to strategize more ways to monetize it.

Q. What hurdles might entrepreneurs face when trying to set up a 3D printing business?

If you want to build a sustainable business, you need to understand what your 1-, 3-, 5-, and 10-year goals are. If you can define those, you have something to work towards and your job is to bridge the gap between present time and future goals. For example, we defined in year two that we wanted a scalable business that focuses on service. Because we knew this, we knew that offering a plethora of different types of machinery, materials, and having all the options in the world wasn’t the best choice for us. Instead we decided to focus on a handful of materials and only two types of printers. This way, we can create systems revolving around them.

We found there was a huge difference between having a love for the technology and monetizing it. My partner and I are industrial designers and our team is made up of industrial designers and engineers. For us, 3D printing wasn’t the most difficult thing to learn, but it was learning how to treat a customer well and learning how to get them to come back to us that took time. That’s what surprised us the most at the beginnings of Makelab. We definitely came into this a lot more naive than we are now.

Q. As more companies enter the 3D-printing services area, how are you staying ahead?

I don’t think there is one way to keep staying ahead. We have our goals and where we think our product-market fit is best, but our how-to-get-there may change along the way. The key for us is our team. I always talk about the importance of team and leadership. It’s a huge focus of mine as a leader and CEO. If I can get my team to move quickly and efficiently, while keeping everyone motivated and eyes on the end-goal, then we can handle anything. It is competitive out there. Anyone can see what we’re doing from the outside and try to copy us, but no one can copy how we move, how we communicate, how we talk, how we treat each other, and our balance of fun and work. That’s our secret sauce.

Q. There’s a growing number of online services, like CraftCloud and Treatstock, that match clients with printing services all over the world via online portals. Are these a threat to local entrepreneurs in 3D printing services?

We’re actually a manufacturing partner for Craftcloud, Treatstock, and 3D Hubs! We thought a lot about this very question. For us, it doesn’t hurt. Our branding and our website cater to a few different types of customers, but clients who find their way to other online service platforms may be very different. Servicing clients who come from different platforms is like practice for us. We get exposure to clients and parts that we may not have if we had just siloed ourselves and accepted orders only from our site. For Makelab, more experience is always welcome. Everything is a learning experience for us, so it fits right in.

Q. You offer more than just a print service. How important is it to also offer a design service as a complement to the printing?

Because we’re so focused on relationship building, word of mouth, and educating our clients, we find it extremely important to also offer design services. We don’t design and develop a part, but we will help to create a CAD file.

Not everyone has the technical skills to create an STL file, but they may have the creative direction to know what they want. For us, we love to bridge that gap between creativity and creation. Offering design services is one of the ways we do that.

Q. How time-consuming is it to help customers who submit a CAD file that won’t print?

To be honest, it can be quite time-consuming, but it is something we choose to invest in. We understand that many companies in the industry would rather not cater to the client that may not be the 3D printing expert and may submit a file that isn’t the most printable. However, we find that this is where we can invest in our relationships with customers. If we can take a little extra time to consult or educate a customer, they’re more likely to not only come back to us but refer us to friends. This helps us create a community. Plus, as creatives ourselves, it brings us joy to help others and be a part of their journeys.

For budding entrepreneurs, I’d say make the decision whether you want to offer design services and define exactly what that is. Just helping customers with design, without a clear service structure and pricing, will only confuse your customer and may lead to frustration on both ends.

Q. What has been your most successful marketing avenue?

Word-of-mouth really has been the biggest component of our growth. Again, it was really the decision to invest in our customers and their projects, give back, and just provide value, that propelled this forward. Customers wanted to come back to us for future projects. Customers will leave reviews, send us supportive emails in response to our newsletters and updates, and like our posts on social media and LinkedIn – and we do all of that back, it’s a two-way street. We root for our customers. If something is cool, inspires us, or we see progress in a customer’s career journey, we tell them. The world really needs more kindness and support, so we want to be that change.

Q. What are your growth plans for the future? How big would you like to see Makelab in five years?

We want to grow Makelab globally. We have big goals. I can’t say them all here, but I can say we aren’t slowing down. 2020 delayed our plans a bit, but we are looking to close a seed round this year. We are pretty excited and confident about it. So, I guess what I can say is – stay tuned!

Q. What advice do you have for other aspiring entrepreneurs who are either women or minorities or both, about entering the pro 3D industry?

Sometimes as a minority and a female in an industry where women make up only 10%, opportunities may not come by as easily. It can take a strong personality to break that mold. Depending on where you’re at in your career, you may not feel that courage and strength (I know I don’t all the time either). What helped really was Women in 3D Printing. Finding that community, finding friends that I spoke to outside of Wi3DP, and eventually being a leader in it, is what helped me find strength. For aspiring entrepreneurs, I’d say find a community of like-minded individuals that inspires you. Inspire each other, support each other, and really raise each other up. At the end of the day, community is what will kick you out of your bubble, expand your network, and attract new opportunities.

Michael Lynn, Owner, 3D Print Everything

“When people get started in 3D printing, some of the biggest mistakes are related to pricing and marketing.”

Q. What’s your top advice for hobbyists who want to turn pro?

I noticed a huge jump in interest to start a 3D printing business from people when the coronavirus hit, and anyone with a printer felt like they were really helping by printing PPE for everyone. People would tell me: “All I’ve done is give stuff away and now I want to try and get this to pay for itself.” I tell them, generally there are two paths of profit: 1. Be a service provider, or 2. Be a store for printed things.

As a service provider, you market and offer your business and accept orders from people. In this path you want to get a local Google listing, a nice place to put your printers (it can be in your home, just presented nicely), a website, pictures of your printers and products, and a Facebook page, to start. Local networking will help a little, too.

If you just want to be a store – or also a store – come up with what you want to print and sell, then market those items, and sell mostly online. The keys for success here will be finding out what is the best item to sell. The most successful sellers I’ve seen offer a unique fix to a problem. You can sell hundreds to thousands with a healthy markup. For example, the best stores I see focus on niches, like one company may just focus on Airsoft [a recreational air weapon]. So they are making mounts, grips, and other parts for Airsoft and have 50+ products related to that. When an Airsoft person runs across their site they find at least one or two things they will want to buy.

Q. What hurdles might entrepreneurs face when trying to set up a 3D printing business?

When people get started in 3D printing, some of the biggest mistakes are related to pricing and marketing. A lot of people start by just doubling the cost of filament and don’t realize that 1 or 2 failed prints will have you losing money very quickly. Then, when it comes to marketing, a Facebook or Instagram page is not enough. A Google business listing is very important for a service provider. Selling prints on platforms, including eBay, Etsy, and Amazon, is critical for being a store.

Q. As more companies enter the 3D printing services area, how are you staying ahead?

Lucky, I started a fews years ago, so a good section of business is from repeat customers. Even with more pop-up little shops, I still hold the largest shop locally. SEO is key, I made sure even my business name was engineered to pop up when people just search 3D printing, not even a 3D printing business. Reviews are key, as well. If you are highly reviewed, people will travel further and trust you more just because others recommend you. The key to getting reviews is just asking happy customers to review you after they pick up a part.

I also give away prints to people who really like or want them, but may not be able to pay at the moment, but would be happy to positively review the business if they can walk away with a Baby Yoda or a 12-inch-tall crystal print.

Q. There’s a growing number of online services, like CraftCloud and Treatstock, that match clients with printing services all over the world via online portals. Are these a threat to local entrepreneurs in 3D printing?

I think the online services are great! I wanted to get involved with 3D Hubs, but by the time I was ready they were filtering out small businesses. I don’t see them as a threat because, locally, I am getting a lot of business. Local businesses generally want to work with local businesses, so they will search Google for a 3D print store before they search for an online 3D printing service.

“Local businesses generally want to work with local businesses, so they will search Google for a 3D print store before they search for an online 3D printing service.”

A fair amount of projects I do are recreation jobs where I need to have an item in my hand, or I need to go to the clients location and do scanning or measuring. Local pickup is really good to get the personal relationship and repeat business. A handful of customers will buy two to five prints, then wind up buying a printer and coming to me for training and maintenance. Once you have a good relationship with a customer, they will come back many times.

Q. How important is it to also offer design, advice, and complementary services?

My business is a lot more than just a print farm. We offer full-circle engineering, 3D modeling, motherboard design, 3D scanning, programming, injection molding, CNC cutting, vacuum casting, and painting.

If someone just wants a single, full-color print from a 2D picture, we can do that, or if someone wants to develop a new product, get prototypes, make changes, then order thousands, we can offer mass production as well. We also are 99% finished with a new custom-designed 3D printer we will resell.

I would say 30% to 50% of customers wind up using two or three of my services for a single project. Many projects require us to do some 3D modeling, maybe 5% are painted jobs, and about 2% turn into mass production runs. Reselling 3D printers, filament, or equipment is less than 1% of my business currently, but this is something I want to scale up to 20% to 50% or more of my current income.

Q. How time consuming is it to help customers who submit a CAD file that won’t print?

Maybe 20% or less of files that get sent to me have issues of some kind. That can be scaling, missing parts, modeled in a software and exported so it has errors. Sometimes it’s scan data. I can generally fix about half of those files in less than 10 minutes in “mesh mixer” or Tinkercad or both. If I can not fix them, I might need to bring in my professional modeler.

Some files that wont print can take hours to fix or need to be completely remodeled, and that will cost the client money. My advice would be not to spend more than 10 to 20 minutes for free fixing a model. Make sure to charge for edits and fixes.

Q. Marketing is a major component of any small business. What has been your most successful marketing avenue?

The biggest most important marketing tool is Google! I have not paid for any advertising anywhere, just made sure that I had a listing on Google for my business, a website that ties there, and then good reviews.

Network marketing does help too. If you go out locally and meet enough of the movers and shakers, you will start meeting very important people, like mayors, people in the news, large firms, etc. They will take interest and send jobs your way. Over the last three years, I have done about four news interviews and quite a few other business magazine related interviews – like this one here! These help because occasionally, I’ll have a client say, “Hey, I found you from that channel 8 interview” or a magazine.

Q. How big would you like to see your company grow in five years?

What is my plan for the future? 3D printing homes within two years. The printer we have designed is a scalable printer, so to make a large printer, we will only need to get bigger parts, but the core motherboard and design will stay the same. This is a half-million dollar investment or more to get started, with a year of build and design time, so it will be quite the project. When it’s complete, we will have one of the first “3rd generation house printers.”

We also plan to produce our own filament and we’re currently talking with two scanner companies to become a reseller of their scanners.

Q. What would you say has been your biggest lesson learned in the 3D printing service industry?

The service process of completing orders had way more creativity than I first expected. I had no idea how much fun I would have when I started. Creativity will be a big key to success because when someone comes to you and asks: “What can I get 3d printed?” What do you say? Anything? everything? This doesn’t help them pick something.

I found that you have to lead customers with questions, such as “Do you have something that recently broke you want fixed?” or “Have any birthdays coming up or anything unorganized that you want a holder for?”

I had a client ask what she could buy from me for her husband’s birthday, and in conversation I found that he collects license plates. So we designed a custom plate that was his college colors, and had every state he lived in and “honey, dad, father” on the bottom. So it was super cool, custom, and he loved it.

Alexandra Bongartz, CEO, Beta2Shape

“Investing in good hardware and software in the beginning is something that will save you a lot of time, frustration, and money down the road.”

Q. What’s your top advice for hobbyists who want to turn pro?

Starting a business in 3D printing is not only about filaments, resins, and STL files; you need to have creativity, flexibility, and endurance. When transitioning from hobbyist to pro, you need to have good skills in computer aided design, as well as a deep knowledge and understanding of the different 3D printing technologies (e.g. FDM, SLA, SLS) and the materials used in each process. Sometimes, in order to meet the customers needs and expectations on difficult projects, you need to look beyond 3D printing to provide the best solution. Here, basic knowledge of other technologies (e.g. machining, laser cutting, etc.) is something that could distinguish you from your competitors.

Investing in good hardware and software in the beginning is something that will save you a lot of time, frustration, and money down the road. Also, ensure that you invest in your knowledge and keep up to date with the latest developments in the industry. Post processing of parts, to add that extra touch, is another service that will help distinguish you from the rest. For this, it is good to build up a network with the designers, artists, and even other 3D printing service providers in your area to exchange ideas and best practices.

“Only offering 3D printing without design and complementary services is something we see as unrealistic. Currently, more than 50% of customers also require design advice or assistance in some form.”

Q. What are your cautions for hobbyists who want to turn pro?

As with any other business, you need to draw up a good business plan before you start. Ensure that you have considered all your costs (e.g. rent, maintenance, materials, electricity, etc.) to get a good understanding of the revenues you need to achieve. At the end of the day, you should not only be able to cover your business expenses, but also need to be able to make a living from your new business.

In the beginning, it might also be challenging to build up a customer base and reputation for your business. To overcome these, it is important to always focus on your customers and deliver on their needs. Word-of-mouth marketing and returning customers are extremely valuable when starting off.

Q. As more companies enter the 3D printing services area, how are you staying ahead?

My career in 3D printing started more than 16 years ago with prototype development in Formula One. This experience is what enables us to not only provide 3D printing services, but also professional consulting and training as well CAD and 3D scanning services. Over the years we successfully completed thousands of projects for our customers who know that they can always rely on us to deliver outstanding quality on even the toughest projects.

Another advantage is our shop location in the heart of Munich. This enables us to easily service our local customers. Plus, 3D printers “dancing” in the window always attracts new customers.

Q. There’s a growing number of online services, like CraftCloud and Treatstock, that match clients with printing services all over the world via online portals. Are these a threat to local entrepreneurs in 3D printing?

Just like with escalators and stairs, we believe that in the 3D printing industry there will always be room for online services and local stores. For some customers uploading a file and getting their parts delivered is all that they need. Others, however, want to have that personal touch. They want to be able to feel and see the different materials and what is possible with the different technologies. We often brainstorm with our customers on the best way to approach challenging projects and also give them advice on how to optimize their designs and data for future jobs. This is something that you don’t have with most online platforms.

“We often brainstorm with our customers on the best way to approach challenging projects and also give them advice on how to optimize their designs and data for future jobs. This is something that you don’t have with most online platforms.”

Q. You offer more than just a print service. How important is it to also offer design, advice, and complementary services?

Only offering 3D printing without design and complementary services is something we see as unrealistic. Currently, more than 50% of customers also require design advice or assistance in some form. This could range from redesigning physical parts in preparation for printing to fixing existing data that might not be usable. Having a good knowledge of two to three different CAD systems is essential to help any customer with their design and data needs.

Selling 3D printers along with resins and filaments currently accounts for up to 40% of our revenue. We are proud of the fact that two of the biggest manufacturers of 3D printers, Formlabs and Ultimaker, count us among their preferred resellers in Germany.

Q. How time consuming is it to help customers who submit a CAD file that won’t print?

Depending on the complexity of the design, fixing CAD files can be a very time consuming task. When we receive data from a customer we first analyze the data to check the completeness and printability. We’ll mostly fix small mistakes ourselves, but when we find bigger problems we always discuss these with our customers. We’ll go through the data with them and explain exactly what the problem is and how it should be improved. The customer then has the option to either fix the data by themselves or contract us to do it for them.

Our advice for new entrepreneurs will be to include this step in your workflow and analyze the data carefully before agreeing to a price. A miscalculation here could easily cost you all the profits you would have made for that project. Also ensure that you are knowledgeable with the different 3D-data formats (e.g. STEP, IGES, STL, etc.) and how to work with these files in your CAD software.

Q. What has been your most successful marketing avenue?

When I started Beta2Shape, I was fortunate that many of my customers followed me from my previous company and we could further build on this existing customer base. Word-of-mouth referrals are very important for any new business and still accounts for around 20% of the new customers we receive.

Having a good website that is SEO optimized and a strong social media presence is an essential component of any marketing strategy nowadays. We are currently in the process of updating our website and incorporating a webshop, which will further benefit from online and social media marketing.

Q. What are your growth plans for the future?

Until now, I have built and run the company mostly by myself. Getting assistance from friends or freelancers where needed. We are now in a growth phase where we will be investing in additional 3D printers for our service contracts and expanding our sales offering via our webshop. We are also growing our team and adding more people with different expertise to better service our customer needs.

Our aim for the next five years is to become the hotspot for all things related to 3D printing, 3D scanning, and CAD in Munich and surrounding areas. Further helping our customers and startups to bring their ideas and products to life.

Q. What would you say has been your biggest lesson learned in the 3D printing service industry?

Looking back, there are two things that I would give to young entrepreneurs as lessons learned: First, always keep on investing in yourself and make sure that you stay up-to-date with the relevant developments in the industry. This includes being an expert in the 3D printers that you use and knowing how to troubleshoot, service, and repair them when necessary. This can save you loads of valuable time when things don’t go as expected. Second lesson is to always make sure that you vet your partners and have the right contracts in place. Unfortunately, we have paid business partners and suppliers over the years where we did not have the correct contracts in place or did not properly vet their performance beforehand.

Josh Stover, Co-Founder, 3D Printing Tech

“If you have experience printing PPE during COVID, then you have a taste of what it is like to 3D print with high demand and deadlines.”

Q. What’s your top advice for hobbyists who want to turn pro?

If you have experience printing PPE during COVID, then you have a taste of what it is like to 3D print with high demand and deadlines. You know what kind of failure rates you run and how often your machines need re-calibrating. Those are key factors in understanding how you should charge for your services, which is the key ingredient to successfully turning the switch from hobby to pro.

If you printed PPE during the pandemic, go back and think through that time about what worked, what did not work, how much you put into it to keep the machine(s) running. Then start to calculate what an hourly rate would have been to make that experience a worthwhile career. Then triple or quadruple that hourly rate because there will not always be as high of a demand for 3D printing as now during the PPE shortage, so you will need to cover some downtime. Use that hourly rate to then calculate what a price per part or piece would be, and you will have arrived at an understanding of what you would need to charge customers in order to turn your hobby into your profession.

Q. What are your cautions for hobbyists who want to turn pro?

There are plenty of people in the market already doing the same thing. In my opinion, the biggest hurdle for a new company at this stage of the industry is differentiation. If you are just another “me too” then you will not stand out and it will be hard to build momentum and traction.

Q. As more companies enter the 3D printing services area, how are you staying ahead? How do you differentiate your company?

Primarily, we differentiate by offering solutions, not just services. We contribute to our clients’ projects by offering ideas to make their projects even better, whether that is in the design, the production and printing method, or the overall concept. Our input and assistance is highly valuable, but it is not a line item that we charge for, it is just what we do. Customers are often unaware that they even need it, but when we start brainstorming with them to make their project even better, they certainly appreciate it.

Q. There’s a growing number of online services, like Treatstock and CraftCloud, that match clients with printing services all over the world via online portals. Are these a threat to local entrepreneurs in 3D printing services?

In ways, those online services are a threat, but we see them as opportunities. Their rise in popularity shows evidence that more people are designing for 3D printing, which means the industry is growing and in turn there will be more work for our local firm. Plus, as we list our services on those platforms it gives us ways to reach customers outside of our normal market. But to address their threat, online services are a long way away from beating the intangible benefits of personal relationships with clients. Design assistance, turnaround times, material selection, getting in touch with me over the weekend on my cell phone, the list is long.

Q. What percent of your business involves giving advice or guidance on 3D printing?

Complementary services are a critical offering for our business and how we leverage them is our differentiator. Our design plus print clients represent at least 50% of our print service work, but that is considering “design” as just 3D modeling or file repair. Our “professional input and print” clients represent 90% or more of our print service work. It is rare that a client will come to us with a working file and a knowledge of exactly how they want it printed.

“It is rare that a client will come to us with a working file and a knowledge of exactly how they want it printed.”

Q. How time consuming is it to help customers who submit a CAD file that won’t print?

This was a large challenge for us in the beginning. There have been numerous occasions where the price of a 3D print did not come close to covering our time spent repairing a file. Once we came to terms with the fact that it was going to happen quite often, we put processes in place to repair files efficiently and we determined a proper fee structure and a way to communicate that with clients. This is a critical “gotcha” right now for entrepreneurs in this space; if you do not have the 3D modeling and repair component figured out, your potential customer base just shrunk by an order of magnitude.

Q. What has been your most successful marketing avenue?

We’ve done it all, from SEO to paid search to word-of-mouth and having a physical retail presence, to email campaigns, cold calling, and social media. They all have varying levels of success depending on the vertical market, but the one common thread that has led to success in all channels is our reputation. We are known for understanding clients’ needs, being fair, and exceeding expectations. That has contributed to more marketing successes than any of our well thought out and executed campaigns.

Q. What would you say has been your biggest lesson learned in the 3D printing service industry?

Prints fail, and when they fail there are repercussions. I am much better at handling those repercussions, and devising ways to prevent failure than I ever was before 3D printing.

Q. What are your growth plans for the future?

We have lots of growth planned for our future! At our pace, and with our plans, in five years we – me and my business partner, and co-founder, Jason Daenzer – will be 10 to 20 times our current size. We will still operate our largest print farms in one location, but we will have satellite locations in additional cities. We will have not only expanded our print farms to include additional printing methods (currently we have FDM and SLA farms and are building out an SLS farm as we speak), but we will be bringing on additional “making tools” such as vacuum forming, CNC, and laser cutting.

We see the 3D printing industry starting to take significant bites out of traditional manufacturing, and we are evolving to meet that demand for production.

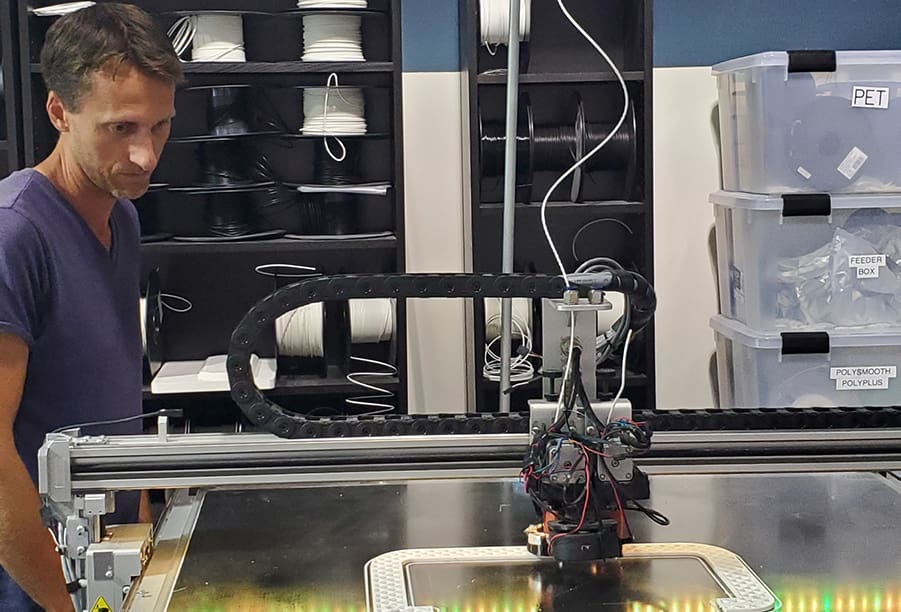

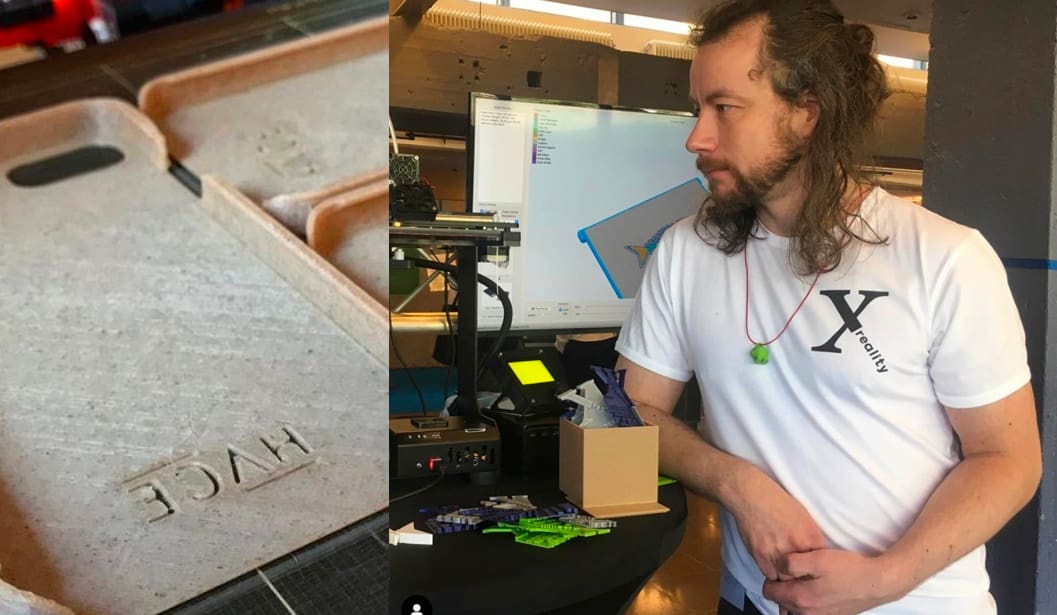

Lamin Kivelä, Owner, Xpanded Reality

“Put as much money as possible back into your business until you are where you want to be. You probably will have to work a lot of late nights and weekends the first few years.”

Q. What’s your top advice for hobbyists who want to turn pro?

Most customers you help with making stuff can buy a 3D printer themselves, but you know how much there is to learn about this tool. Show them that you can do it better because you know the craft.

Q. What are your cautions for hobbyists who want to turn pro?

Read up on creating a business, find a mentor that you trust, be frugal, and work with what you have. A basic FFF 3D printer often works as well as the most expensive, industrial FFF machines. The difference is often that the cheaper 3D printers need a lot more maintenance and adjustments, but that should not be a big problem with low volumes.

Put as much money as possible back into your business until you are where you want to be. I think that support from your family is crucial. You probably will have to work a lot of late nights and weekends the first few years. Our business would not have been possible without all the work my wonderful wife, Agneta Brundin, also has put into it from taking care of all of the economy, working on events, and coming up with great ideas and solutions all the time. She is also the entire finance department, so I can not do anything without her consent. That is a good thing!

Q. As more companies enter the 3D printing services area, how are you staying ahead?

We always make our customers’ projects a reality by getting ahead together, not just in 3D printing, but in solving their specific problem. We always keep to our principles. In short, the environment should not have to pay for what we or our customers do.

Q. There’s a growing number of online services, like CraftCloud and Treatstock, that match clients with printing services all over the world via online portals. Are these a threat to local entrepreneurs in 3D printing?

We want to work with people who we also would want to spend a Friday afternoon with. If we would get our customers from an online service, it would be like only having friends on Facebook. We believe online services could work for production transactions, but then it often is more about delivering an object. We want to work with a broader spectrum of problem solving.

Q. How important is it to also offer design, advice, and complementary services?

Our CNC and milling has never taken off and we’re thinking about refocusing that part on other stuff. But 3D printing as a tool for realizing ideas has never failed us. I would say that 80% of our business is design and production, mostly in architecture of different kinds. The other 20% is consulting.

Q. How time consuming is it to help customers who submit a CAD file that won’t print?

Handling 3D files from customers can be very time consuming, for sure! Sometimes you just have to accept that you need to redraw everything. Other times, you can just go through the model and fix too-thin walls or other problem areas that won’t print, but that is an important part of what we do, and it is actually a very stimulating part of 3D printing. To check 3D printability, we analyze the file with a slicer software. To fix things, convert between file formats, remodel or model from scratch, Rhino 3D is our favorite. It has a lot of modeling features that we like. For more organic modeling, we use ZBrush, and a file repair software or service is also a must, like Netfabb.

“Handling 3D files from customers can be very time consuming, for sure! Sometimes you just have to accept that you need to redraw everything.”

Q. What has been your most successful marketing avenue? Word of mouth?

For us, it has been only word of mouth.

Q. What are your growth plans for the future? How big would you like to see your company grow in five years?

We believe in keeping it small and close. That is all I can tell you for now!

Have you launched your own successful 3D printing business? Let us know in the comments below.

License: The text of "Start a 3D Printing Service: Advice from Entrepreneurs" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.