Next time you’re eating at McDonald’s, strolling through a hotel lobby, or shopping at Home Depot, you’re likely to see 3D printed lampshades and lighting fixtures.

There’s been a quiet infiltration of 3D printing into the lighting industry. No one is making too much fuss that these fixtures are 3D printed. It’s more that they are stylish, easily customized, quick to manufacture, usually more economical, and more sustainable in a variety of ways.

When it comes to 3D printing lamps, what they deliver more than how they’re made, is leading to their mass adoption.

Signify, the world’s biggest maker of lighting fixtures, for example, says it 3D printed hundreds of thousands of lamps in 2023, its biggest year since starting to 3D print products in 2018. Start-up home accessory company Jonathan Y has a range of 3D printed lamps now sold in the US at Walmart, major home improvement stores, and through Amazon.

Add to these commercial successes the countless designers, small businesses, and Etsy shops selling 3D printed lamps online and in boutique shops worldwide, and it makes lighting fixtures one of the top 3D printed consumer products today by volume. It’s also a perfect example of how accessible manufacturing technology can spur entrepreneurship and disrupt an established industry.

Let’s take a look at who is 3D printing lamps, how they’re succeeding, and what to consider if you’d like to enter this market.

Commercial & Designer Lamps

Since well before Louis Comfort Tiffany helped popularize lighting fixtures as decorative art, lamps have been the perfect canvas for creative expression. This tradition continues with the application of 3D printing. The digital-first design, the accessibility of the means of production, and the variety of materials have sparked the art and craft of the 3D printed lamp.

Countless designers have added 3D printed limited-edition lamps to their portfolio, but a growing number of companies are focused solely (or largely) on 3D printing lighting fixtures.

There are dozens, if not hundreds of 3D printed lamp companies, but we selected a representative few to focus on below.

Signify

Hotels, restaurants, and retail shops want stylish, customizable, and functional lighting as much as consumers do, but what appeals to businesses about 3D printed fixtures has more to do with availability, consistency, and sustainability.

Signify, the world’s largest 3D printer of lighting fixtures, recently won a contract with the world champion of consistency, McDonald’s. Your dining experience, from the food to the staff to the decor, is engineered to be consistent worldwide. Signify designed a lamp for McDonald’s that’s part of its new design concept.

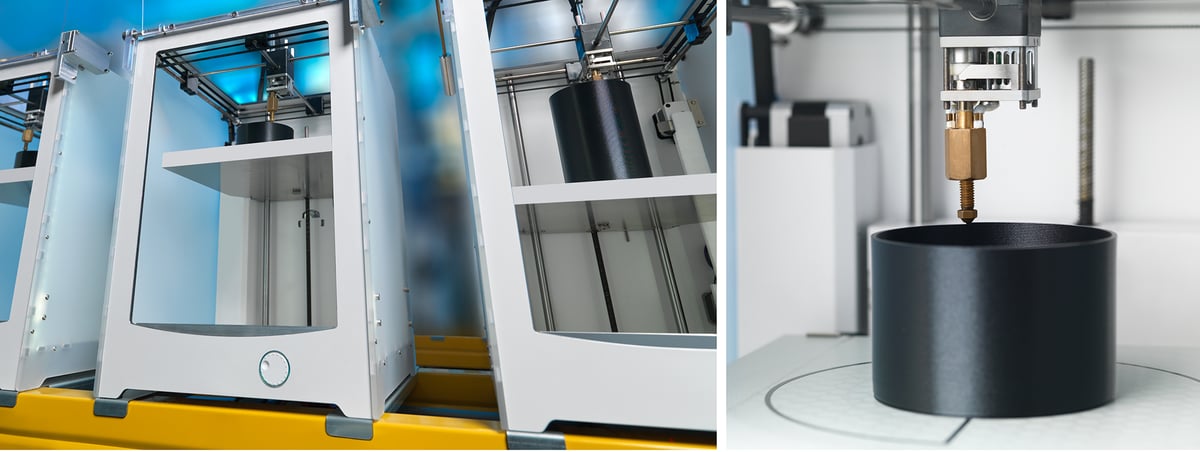

Signify is able to deliver consistent quality because it has its own factories of 3D printers, which it designed and built itself. Its factories, located in Belgium, Hungary, the US, Indonesia, and Australia, not only employ custom-designed hardware, but Signify developed the operating and design software, and, in many cases, the materials are all developed and made by Signify.

“Building a 3D printing platform on an industrial scale for mass production is not something available off the shelf,” says Kevin Raaijmakers, the commercial director of Signify.

There are hundreds of FDM 3D printers of various sizes in the Signify factory in Belgium. The hardware is customizable to grow with new product ideas. Raaijmakers says advances in FDM technology will enable it to make even more complex designs with even faster throughput in 2024.

“Previously, we were never able to print a full bowl, which sounds odd, but with FDM that’s really difficult,” says Raaijmakers. “Now, we’re closing those loops which opens up a whole new world of applications and possibilities. So, there’s a lot of new stuff coming.”

Recozy

European startup Recozy was founded in 2021 to “actively shape the change toward a more sustainable furniture industry,” according to the company’s managing director Rob Leenen. 3D printing provides Recozy with a way to produce products more efficiently and sustainably than traditional custom manufacturing and also respond faster to changes and trends in the marketplace. But, “3D printing should not be the main purchasing argument for our customers,” he says.

Recozy strives to incorporate the unique features that only additive manufacturing offers into its product design, but fundamentally, Leenen says, the products’ design and quality stand on their own.

The production of Recozy design objects, which include more than lamps, such as 3D printed furniture, takes place in the company’s German facility in Germany, which also houses its design studio. The company uses mostly recycled materials (90% of the plastics are recycled) and “resource-saving” 3D printers and automation, which use less electricity than injection molding machines.

Recozy offers about 50 lighting styles, ranging in price from about $114 to $191, delivers worldwide, and sells thousands of lamps a year, Leenen says.

Gantri

Gantri is a lighting design collective founded in 2016 that features the designs of several partner creatives. Each lamp is 3D printed on-demand at the company’s California facility.

Gantri uses 3D printing and plant-based materials in a digital manufacturing process, where “one-of-a-kind design doesn’t cost a fortune.” Gantri works with filament maker ColorFabb to source sugar cane as the base material for its proprietary Gantri Plant Polymers.

In all there are about 300 different table lights, wall lights, floor lights, and clamp lights available. The company has plans to expand its catalog into other lighting categories, and expand geographically into Europe and Asia. Gantri’s best seller is the colorful and toy-like Analog Task Light ($248) by designer Chris Granneberg.

“We don’t necessarily think of ourselves as a 3D printing business,” says Ian Yang, Gantri CEO. “We prefer to think of ourselves as a product company. Our strength is that we understand what our customers are looking for and how we can deliver better products in terms of design and cost by leveraging 3D printing.”

Jonathan Y

Jonathan Y is a New York City-based home decor company focusing mainly on lighting and offering a line of 3D printed lamps available at big box home improvement stores HomeDepot and Lowes. These retailers also carry Jonathan Y’s other, traditionally manufactured lighting fixtures, as well as its rugs and accessories.

“The opportunity to feature our lamps at HomeDepot and on Amazon was a result of our commitment to quality, and our dedication to environmentally friendly practices and unique approach to 3D printing technology caught their attention,” says company founder and president Jonathan Yaraghi. “To manage the volume, we employ a strategic blend of both on-demand and batch production processes.”

The spark to get into 3D printing came from caring about sustainability, Yaraghi says. “Our customers, much like myself as a consumer, value brands that strive for positive change.”

Jonathan Y has been 3D printing since late 2021 and uses mostly Creality Ender 3 S1 Plus and IdeaFormer IR3 V1 belt printers, according to Yaraghi. The company’s 3D printed lamps range in price from $100 to $144 and the company sells about 10,000 per year.

Honey & Ivy

Honey & Ivy started in a suburban Portland garage and now sells a wide range of 3D printed table lamps and accessories at its online shop and via Etsy. The company uses plant-based polymers and has planted over 2,500 trees in an effort to combat deforestation through a partnership with filament maker Polymaker.

From its website, the company appears to use Prusa 3D printers. Lamps retail for about $60 to $80.

Creme Atelier

Sweden-based couple Jacqueline Kessidis and Lucas Lind say they founded their lamp company called Creme Atelier after creating a single lamp for their home. The company offers one design resembling a soft-serve ice cream cone available in a variety of colors, retailing for between about $250 to $375 each, depending on size. The company 3D prints the lamp shade and base on-demand in recycled filament from material maker ReFlow.

In addition to its online shop, the company’s lamps are available through more than a dozen retail outlets in Europe, including German retail chain Globus and at the online lighting retailer Lightonline.fr.

Polyluma

Polyluma is a light design studio from Berlin, founded in 2019 by Johannes Schacht and Oliver Stark, with an online shop and a retail store.

Focusing on pendant lighting, the company offers a relatively wide range of fixtures to consumers as well as architects, light planners, and interior designers. Polyluma says its materials are a “specially developed biopolymer” with additives that create a somewhat rough surface that looks more like ceramic than plastic. The company prints on demand and will send out a box of sample materials for review (in the EU).

One pendant lamp retails for about $215 up to $415.

How To Enter the 3D Printed Lighting Market

Anyone who has 3D printed anything might look at a lampshade and think, well, that’s easy. Yet, 3D printing something and making a business out of it are two very different endeavors.

Apart from the business basics of launching a company or even an Etsy shop, the 3D printing lighting specialists we spoke to had specific advice for this particular market.

Protect Your Design

The simplicity of a pendant lampshade is a challenge to copyright so most lighting designers focus on other ways to establish their brand.

But it’s not just about the designs, notes Yang at Gantri. The overall concept of what you’re selling, which includes your mission, vision, product quality, and service, must all be convincing and appealing to consumers.

Although Gantri offers hundreds of designs, other designer shops, such as Creme Altier and Polylumina, focus on just one or two signature styles with slight variations, in order to establish their brand concept.

For entrepreneurs hesitant about selling products online due to concerns about design replication, Yaraghi at Johanthan Y says to “focus on continuous innovation, building a strong brand presence, and fostering a community where creativity can thrive.”

Signify, on the other hand, hold at least seven international patents on 3D printed lighting design and methods for 3D printing lighting fixtures.

Push Sustainable and Local

All of the lighting companies we found boast (some to the point of over-hype) about their dedication to sustainability and offering products made from natural materials, whether it’s recycled plastic from ocean waste or a bio-based plastic, such as PLA.

There’s a real and burgeoning sustainable movement, according to Yaraghi. “Our community in NYC perceives sustainability not just as a trend but as an exciting, new, and cutting-edge direction. We are motivated by the idea that sustainability is not just a choice but a transformative journey, and Jonathan Y is committed to being a part of that positive change.”

All the retailers we found marketed a sustainable aspect to their lighting solutions, which was either the eco-friendly plastic material, the idea of printed-on-demand leaving no overstock waste, or using a manufacturing method that generally uses less power and produces less waste than, for example, injection molding.

Leenan at Recozy, says his company’s environmental goals resonate with a growing consumer preference for locally produced, sustainable products. The company will even take back your lamps (and other Recozy items) at the end of their life and properly recycle and reuse the raw materials in keeping with the company’s circular economy philosophy.

At the end of their life, most of these products can be recycled, but not with household waste plastic, rather at an industrial recycling facility.

Local is another aspect of sustainability.

“We take pride in manufacturing our lamps in the USA, ensuring quality craftsmanship and supporting local communities,” says Yaraghi.

Oakland, Calif.-based design studio Model No. says that because it 3D prints lighting fixtures to order, holds no inventory, and ships most projects domestically or locally, its logistics eliminate the waste and emissions of traditional furniture operations that produce, store, and ship overseas.

Going a step further, the Model No. facility operates 100% on wind and solar energy, uses recycled material for packaging, and in the future, hopes to employ exclusively electric vehicles.

During the Pandemic when global supply chains were disrupted, Signify saw a spike in sales, says Raaijmakers, because the company prints on demand in its own facilities worldwide close to their customers. “So we were at sometimes the only ones who were able to deliver anything,” he says. “That’s one of the beauties of distributed 3D printing with a digital inventory; if some route gets blocked, then we don’t. Plus we, we print a lot of the components so we have very few suppliers.”

Understand Production Additive Manufacturing

3D printing one lampshade may be relatively easy, printing hundreds or thousands comes with unique challenges.

3D printing with fused deposition modeling (FDM) technology is the most widely employed method for lighting, using both filament in spools and polymer in pellet form. The machines range from economical consumer brands, such as Creality and Prusa, to custom-built.

“At first, we needed to develop the right setup of printers for serial production, focusing on ensuring processes run smoothly with a very high level of repeatability,” says Leenan at Recozy. “It’s also crucial to consider the interaction between different departments, as the products are not only manufactured but also assembled, packaged, and shipped.”

At Jonathan Y, which had already manufactured lighting using traditional technologies, the addition of 3D printing was uncharted territory. “Setting up our 3D printing business posed challenges at every turn. When venturing into new territories, there’s no handbook; it’s a journey of learning and overcoming obstacles on our own.”

Offer Customizations

Because 3D printing is a tool-less technology, easy customization is one of its strengths. For both consumers and businesses, uniqueness has value.

Recozy offers its in-house design team to sit down with customers and develop tailor-made solutions for their projects.

Currently, Jonathan Y is developing a “comprehensive customization plan” that will allow its customers to personalize their 3D printed products, tailoring them to their unique preferences. In addition to consumer customizations, the company has a successful history of working on custom projects and fulfilling volume orders for hospitality brands and other clients.

Signify offers auto-customizations online where you select your preferences, even adding a company logo to your lighting fixtures, as well as working with any designers on a client concept.

____________________________

Lead image: top left, Creme Atelier; bottom left, Honey & Ivy; center, Polyluma; top right, Signify; bottom right, Jonathan Y.

License: The text of "The Big Business of 3D Printed Lamps" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.