First, it was CoreXY. Then it was color. As far as trends in the budget 3D printing space go, Elegoo is behind the curve, which is why for the Centauri Carbon, Elegoo’s first CoreXY 3D printer, launching now in 2025, to have any impact it needed to be damn good right out of the gate.

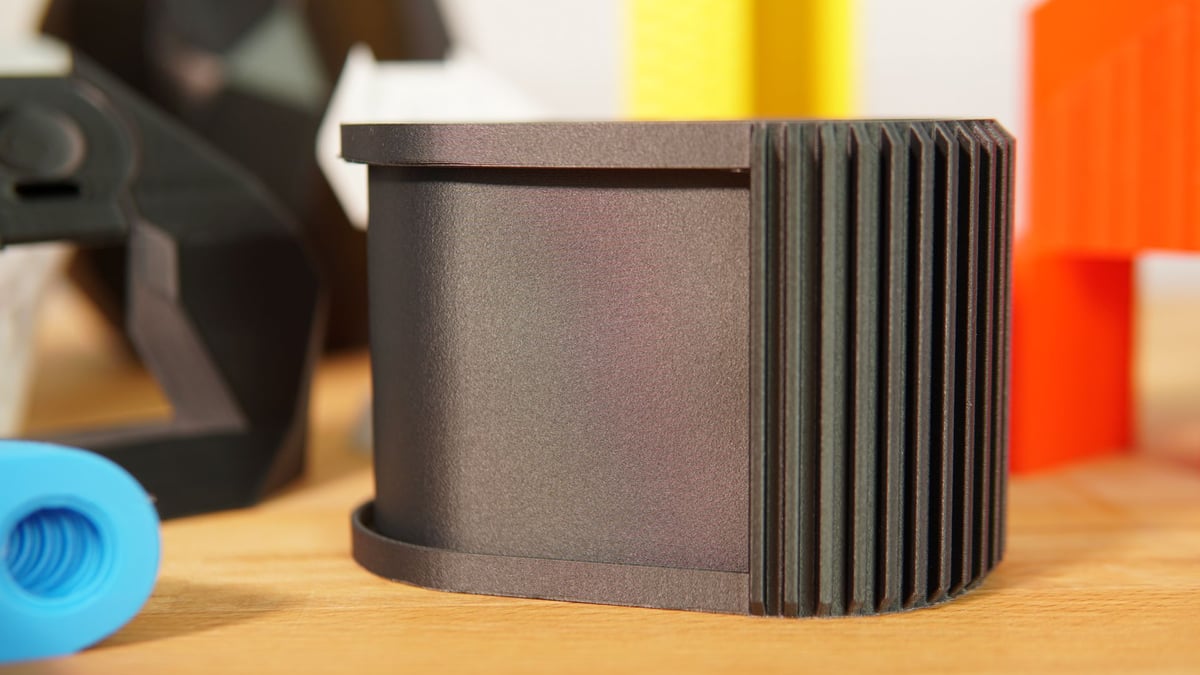

And, for the better part of the last two weeks spent printing with it, we’d largely say that it is. It hasn’t been perfect (no printer is) but while we doubt the Centauri Carbon will be remembered as a historically significant desktop 3D printer, we’re sure those who bought into its ~$300 price tag are too busy picking their jaw up off the floor at how quickly this thing heats up for a print to notice. It is a wicked little grey box that, on average, makes for a fine and versatile printing companion.

At a Glance

- Release: 2025

- Price: $299.99

- Build volume: 256 x 256 x 256 mm

- Temperatures: 320°C / 110°C

- Print bed: Double-sided (PLA-super grip | General PLA/PETG/TPU)

- Key features: Fully enclosed, fast-heating hot end, very fast-heating print bed, hardened steel nozzle as standard

The Tech

Elegoo has outfitted the Centauri Carbon with a fast-heating AC-powered print bed capable of up to 110 °C, and a 60W ceramic-heater hot end that can quickly reach 320 °C. A hardened steel-core nozzle comes as standard, meaning the printer can comfortably extrude high-temperature materials like PC and ASA and abrasives out of the box with some degree of confidence.

The bed heating is the most noticeable thing about the Centauri Carbon’s performance, brute-forcing its way up to printing temperature in an astonishing fashion. Unscientifically benchmarking it against a Bambu Lab X1E we happened to have lying around saw the Centauri Carbon win every cold-to-printing-temp shootout, without bed leveling or other preflights, which is where the Centauri Carbon loses its edge with slow, full-plate probing to create its mesh for the initial layers.

Localized leveling like that offered with Klipper Adaptive Meshing Purging (KAMP) would be advantageous here but, as we’ll detail later, that’s a no-go.

While you do get a chamber temperature readout and control over a print chamber regulation fan, it rarely seemed to be the case that the ambient heat from the bed ever got the chamber hot enough to hit a target temperature for the likes of Polycarbonate, resulting in odd fringe situations where we weren’t entirely confident of a print’s likelihood to succeed. We see no reason you couldn’t adjust your start G-code to include a heat-soaking phase with the bed at temp to preheat the chamber, but we haven’t tested this yet. We found it necessary to print on the hotter end of a material’s range to ensure layer bonding.

An auxiliary fan situated at the rear of the print chamber gives you the option to push print speeds with PLA. The profiles provided in Elegoo’s slicer, Elegoo Slicer, which is based on Orca Slicer, appear to top out at 21 mm³/s for PLA and high-speed PLA. A spec sheet provided by Elegoo lists the hot end’s max flow at 32 mm³/s, suggesting there’s headroom to experiment and push your own prints faster with the right material.

A silicon nozzle brush pad sits at the back of the chamber, next to the printer’s purge chute. the Centauri Carbon purges at filament change, with the resulting purge dropping out of the back of the printer. The printer’s default behavior did a decent job of keeping the nozzle clean.

The build of the Centauri Carbon is reassuringly solid, with a steel chassis and aluminum and glass body wrapping around it to provide one of the printer’s core qualities – it just feels nice to use. There’s a slight knockback on this “premium” feeling when the spool holder, which protrudes from the thin side wall of the printer, sags as you load a fresh, 1kg+ spool.

Unpacking the printer is a straightforward affair, with a few shipping screws holding the print bed secure for transit and foam packaging material supporting everything else.

A snappy touchscreen UI sits front and low on the Centauri Carbon’s body, attached via a delicate flat flex connector that you should pay careful attention to when installing. Next to this is a full size USB port, which you can use to slog print jobs from computer to machine. There is onboard storage – 8 GB of eMMC – meaning favorite or regular print jobs can be kept local to the machine for convenient recall.

The Printing

We’ll preface this section with complete honesty. The Centauri Carbon is not perfect. No printer is, not even for $1,000, let alone the $299 Elegoo is asking for this printer. We had print failures – some we’re sure were our fault, others less so.

Across the spread of materials we tested, PLA is, predictably, the most straightforward. We saw clean prints, particularly smooth curves and planes, suggesting decent layer uniformity. Across a spread of prints, we could reliably get tolerance pins as low as 0.2 mm free without issue, suggesting a relatively fine play between print accuracy and bed leveling (which the printer takes care of, remember).

Elsewhere, a variety of prints in PLA look great. Glossier filaments, particularly PETG from our printing, show some semblance of artifacts that look like Vertical Fine Artifacts (VFAs) which would suggest an adjustment to the print speeds for such shiny materials may be necessary.

The Centauri Carbon’s base printing specification puts it in league to tackle hotter engineering materials such as Polycarbonate, which we promptly ran through the system.

Printing at higher temperatures will warm the chamber enough to repeatedly trigger messages cautioning about the danger of soft filament clogging the nozzle. We expect this is mostly Elegoo hedging its bets against users accidentally leaving the lid on and door shut when printing with low temp materials like PLA and PETG.

Ignoring the printer’s pleading to open a door, it seems relatively capable of operating towards its temperature limits, with the chamber getting up to ~47°C from a 90°C bed over the span of a few hours (with the case fan off) and zero extrusion issues in the print.

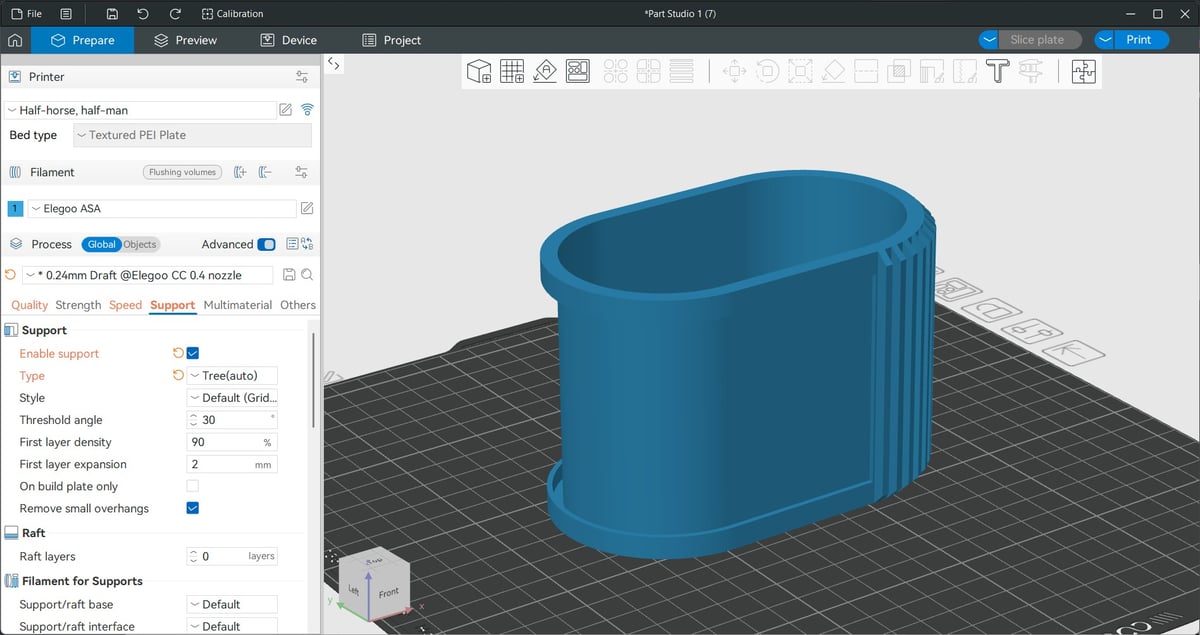

Print preparation comes in the form of Elegoo’s self-titled slicer, Elegoo Slicer, which is based on OrcaSlicer. The company credits this in the software’s “about” page.

Through Elegoo Slicer, you have Orca’s broad selection of printers at your disposal. Default material choice is limited to Elegoo brand and generic filaments. There’s a device tab, too, letting you connect to the printer via your local area network. Unlike Creality, Anycubic and Bambu Lab, Elegoo does not offer any kind of cloud functionality or app control of the printer. If your mobile device is on the same WiFi network as the printer, you can tap its IP address and view what is essentially the device tab from your mobile browser.

From the device tab you can view current stats, control the printer’s basic functions, and view the build plate remotely via the built-in camera. Calibration tests, an Orca staple, are present too, letting you refine your settings via prints from the comfort of the slicer.

You can also view and relaunch previous jobs, and load new tasks directly to the printer, circumventing the slicer’s job preparation workflow altogether. It all feels very much like the typical feature-limited Klipper experience offered in this level of machine. Except it’s not Klipper, and the Centauri Carbon doesn’t contain the hardware necessary to run Klipper without providing your own single-board computer.

This is the core distinction between the Elegoo Centauri Carbon and something like Creality’s K1C. Where the K1C uses a Crealityified version of Klipper that can be stripped away for the full, flexible, Klipper experience, the Centauri Carbon does not.

As we understand it, this makes the Centauri Carbon not so straightforward for tinkerers to bend to their will. We’re sure it’ll only be a matter of time before it’s documented and there are guides.

Casual users likely won’t care. But, still – good to know.

Is It Worth It?

The Elegoo Centauri Carbon is a step up on similarly priced machines, offering the advantages of an enclosure and some flexibility in your control of it to really put it to work on tougher print jobs. The overall design and feel punch above their price class, too.

In our communications with the company, Elegoo has heavily implied the Centauri Carbon should be considered against the Bambu Lab X1C, and certainly, in its main values like speed and printable materials, the Centauri Carbon can keep up. It lacks the full smarts of the X1C, though, with flow adjustments and the like left to the user rather than automagically calculated by the machine. The spread of print failures we encountered suggests those sorts of things matter more than is immediately obvious for anyone chasing a hands-off “it-just-works” time of their printing.

We’ll continue printing (larger objects, and more high-temp stuff) and update this review soon with our evolved thoughts. For now, we can say that the core printing experience, super-fast heating, and the premium look and feel of the printer do offer plenty for anyone tempted by its $299 price tag.

License: The text of "Elegoo Centauri Carbon Review: A Lot of 3D Printer for $300" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.