Compared to CNC machining and metal injection molding, you can save up to 90% on the cost of creating metal tools and components by 3D printing them in metal. This is the alluring claim of desktop 3D printer makers that have launched metal capabilities on their fused deposition modeling (FDM) machines in the past few years.

But how strong are these metal parts printed layer-by-layer, and what are they used for?

There’s no doubt that metal 3D printing is more accessible than ever now, thanks to a growing number of affordable FDM 3D printers compatible with metal filaments. These machines, priced from $4,000, produce real metal parts (after post-processing) and are rapidly disrupting metal 3D printing.

Not long ago, metal-powder-and-laser-based technologies were the only way to 3D print metal. These laser powder bed fusion machines start at around $100,000. Today, however, 3D printing with economical metal filament is an affordable entry point into metal 3D printing for a growing segment of businesses and the ideal solution for a wide range of applications.

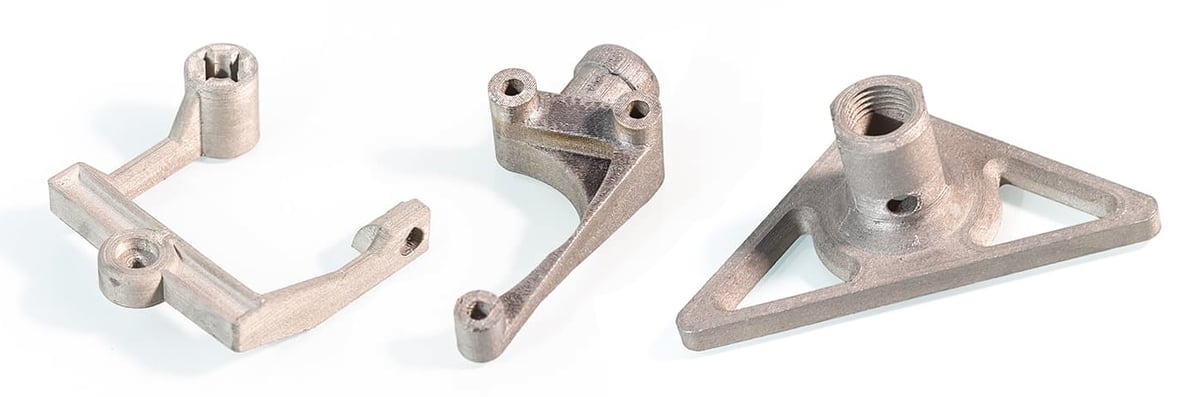

It’s certainly not a solution for every metal application and is completely unsuitable for some parts. But for small stainless steel replacement parts, tools, and prototypes that need to be durable, temperature resistant, chemical resistant, wear resistant, and dimensionally stable, 3D printing with metal filament is proving to be significantly cheaper and faster than traditional manufacturing methods.

Below, we look at the strength and durability of parts made with metal filament, several real-world applications, and the machines that are making it more affordable than ever.

| Metal 3D Printer | Technology | Build Volume (mm) | Printer Price | Required Accessories | Post-Processing |

|---|---|---|---|---|---|

| Zortrax M300 Dual | FDM | 265 x 265 x 300 | $4,300 | Full Metal Package ($635) | Shipped to Third-Party |

| UltiMaker S5 | FDM | 330 x 240 x 300 | $7,000 | Metal Expansion Kit (~$1,500) | Shipped to Third-Party |

| BCN3D Epsilon W27 | FDM | 420 x 300 x 220 | $7,500 | Metal Pack ($1,400) | Shipped to Third-Party |

| Raise3D Forge1 | FDM | 300 x 300 x 300 | $10,000 | None | Shipped to Third-Party or Purchase Raise3D Accessory Equipment |

How Strong Are Metal Filament Parts?

There are only a few metal filaments on the market and the most relied upon by far is Ultrafuse from Forward AM, a division under BASF, one of the world’s largest chemical companies. Its metal-infused filament, which comes in 316L stainless steel and 17-4 PH stainless steel, contain 88% metal powder in a proprietary polymer-based binder. It can produce nearly solid metal parts (98%+) when used properly, the company says.

Although, theoretically printable on a wide range of desktop FDM 3D printers, only BCN3D, UltiMaker, Raise3D, and Zortrax so far offer a full solution of hardware, software, verified print settings, and accessories designed to ensure successful metal printing of metal parts. Prusa Research has print settings for Ultrafuse in its Prusa Slicer software, but there’s a lot more to 3D printing with metal filament.

At almost $200 a spool, failed prints are expensive. This explains why only a handful of desktop 3D printers are promoting their compatibility with the material. From our experience at All3DP with BCN3D, UltiMaker, Raise3D, and Zortrax in our own testing lab, these are the top in reliability among professional desktop machines.

In addition to a quality machine, software that enables you to accurately account for the 15% to 20% shrinkage is critical, a nozzle that can take the wear of the metal, and training on what parts you can and can’t print is key.

“The complete and seamless integration of the printer platforms in terms of hardware and software enables entry-level to professional users to produce metal parts with unique geometries that are only possible with 3D printing,” says Tobias Rödlmeier, product and application technology manager at BASF Forward AM.

The four printers we feature are also dual-extruders. This comes in handy printing with the Ultrafuse Support Layer, which is currently only available in Europe. Support Layer is an aluminum oxide material used for “layer isolation”. In other words, it enables breakaway supports as a separation layer between the support and the prints after sintering. Outside of Europe, your metal part shape may be somewhat limited is you need to avoid supports, although they can be machined off just like removing the gate or flash from metal injection molded parts.

Parts are not solid metal directly off of the 3D printer bed. In fact, they are rather delicate so called “green parts.” Like metal injection molding, these parts require a two-part post processing with industrial equipment to remove the polymer binder and bake (sinter) the part into solid metal. If you don’t have your own debinding and sintering equipment, you can outsource your parts to a local manufacturer that does (BASF has a list and a dedicated debinding and sintering portal). This is an added time and expense to be calculated into your processes.

For a deep dive into the process of 3D printing metal parts from metal filament, see the guide linked below.

As Strong as Injection Molded Metal?

When it comes to mechanical properties of parts printed with Ultrafuse we look first at information from BASF. In fact, the mechanical properties you’ll find listed by printer makers, such as UltiMaker and Raise3D, are the same as BASF below.

Mechanical Properties

*Catamold 316L and 17-4 PH are types of metal injection molding (MIM) feedstock material.

BASF’s lab testing of sample parts made with Ultrafuse stainless steel filament are compared to metal injection molding (MIM) since the materials are similar. MIM also uses powdered metal mixed with a binder material to create a feedstock, which is then injected into a mold of the desired shape. The molded part is then heated to remove the binder and sintered to create a solid metal component, like 3D printing with filament.

The results show that parts made with Ultrafuse 316L stainless steel have virtually the same tensile strength as injection molded parts made with Catamold, slightly higher yield strength and hardness, yet half the elongation at break in the ZX plane.

The Ultrafuse 17-4 PH stainless steel shows better tensile strength than Catamold in some orientations (flat Y, upright X) and weaker in others (flat X, upright Z). There’s better yield strength in the Ultrafuse, similar hardness, and comparable elongation at break.

As you may notice, the print orientation of your part is important to get the most strength where you need it. Putting your digital files through simulation software, such as the simulation module in Autodesk Fusion or Ansys Discovery Simulation, can highlight where the forces will be on your parts and contribute to your understanding of how to orientate them on the print bed.

For independent research on the mechanical properties of Ultrafuse stainless steel, check out “Correlation between Metal Fused Filament Fabrication parameters and material properties of sintered 17-4 PH” by Federico Fazzini et al., (2023) and “Experimental study and characterization of 316L stainless steel parts fabricated with metal fused filament fabrication” by Abbas Raza et al. (2024).

Additional recent research published in Materials Today Communications by Chanun Suwanpreecha et al. found that there is “no discernible difference in microstructure, preferential orientation and grain size between MEX [material extrusion] and MIM parts … . MEX parts have slightly higher tensile properties than MIM parts due to the higher relative sintered density. However, the endurance limit of MEX parts is lower than MIM.”

Machining Metal Filament Parts

Parts made with Ultrafuse are up to 98% dense and can be welded, polished, or machined just like standard stainless steel.

What Are Metal Filament Parts Used For?

Metal filament 3D printing is attractive as a time and cost saving option for a wide range of applications.

For companies that outsource metal part fabrication frequently, metal filament 3D printing at less than $10,000 for a printer, can bring that production in-house. The ROI could be less than a year depending on the volume of parts you print.

For manufacturers that have CNC machining or injection molding capabilities, metal filament 3D printing offers a faster and cheaper prototype solution. Parts can be printed, tested, and redesigned, before moving to more costly machining or molding processes that require tools, like molds.

Small companies already in metal fabrication, including machine shops, are ideally positioned to adopt metal filament 3D printing, especially if they already own their own debinding and sintering equipment.

Of coruse, companies not interested in making their own metal parts at all, can turn to 3D printing services, like Craftcloud, which also offer Ultrafuse as their most economical metal option. This makes experimenting wether or not the parts you need are suitable for this method and material as easy as uploading your digital file and ordering.

Common metal filament 3D printing applications include:

- Prototypes

- Small replacement parts

- Heat sinks

- Polymer injection molds

Companies Turning to Metal Filament 3D Printing

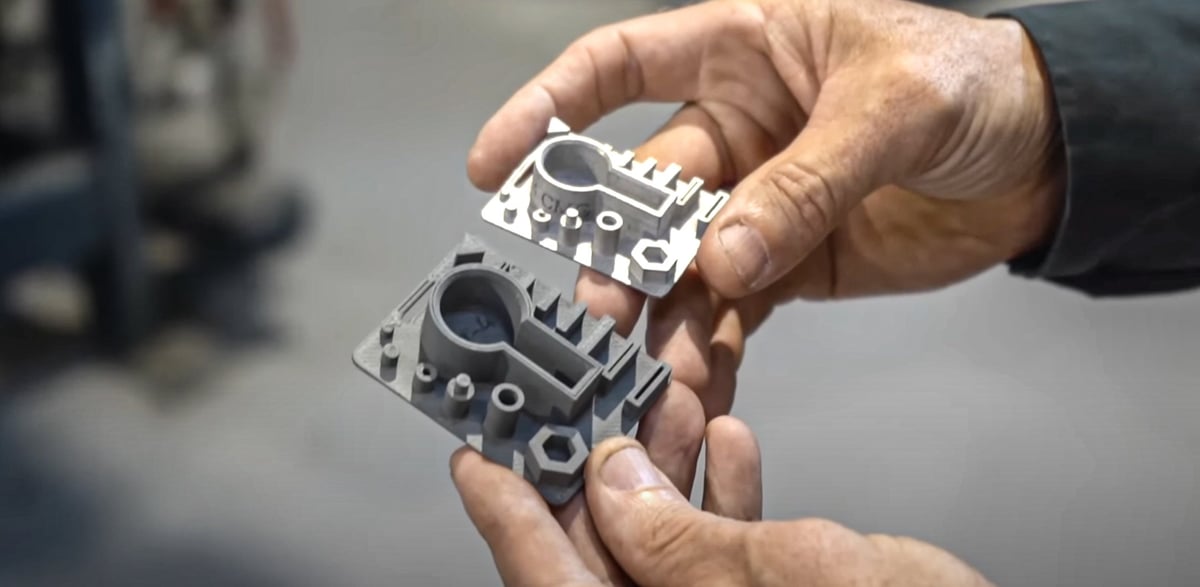

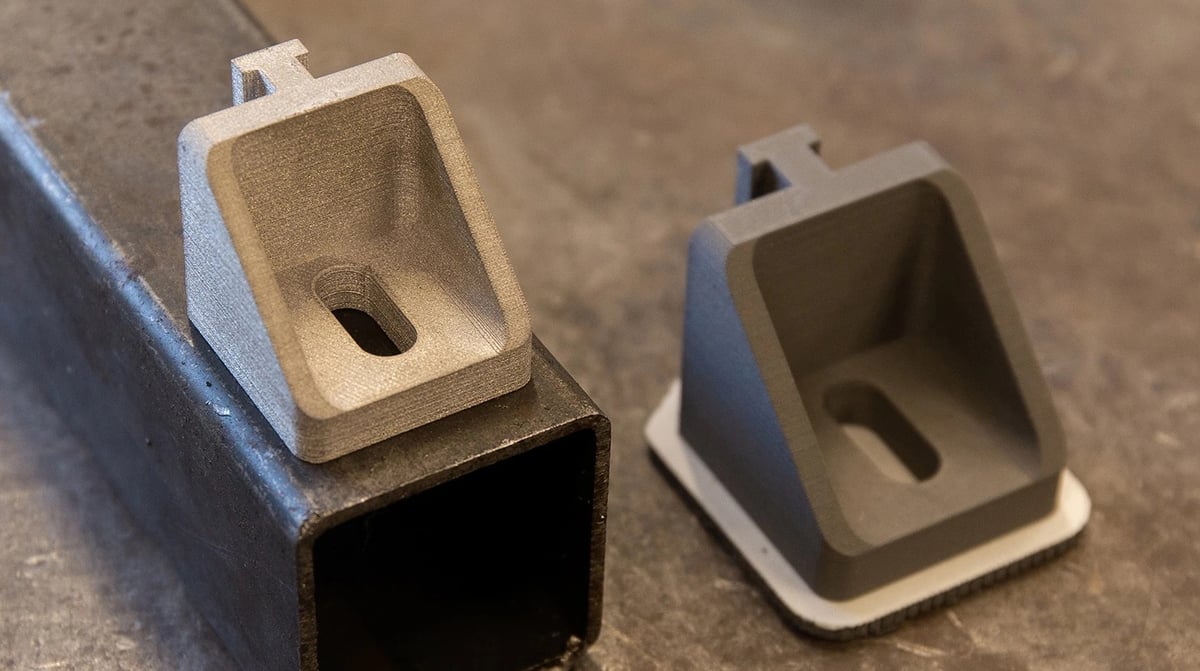

Liebherr Components develops and produces components for the aerospace and energy industry, among other sectors. It uses a unique assembly tool to precisely locate the injection bridle during diesel engine assembly operations. To operate correctly, this tool needs tight clearances and thin-walled features.

Typically the thin features and custom shape would require a 5-axis CNC machine, instead the company printed the part in stainless steel on its UltiMaker 3D printer.

Leibherr says it saved 50% when compared to CNC machining. The print time was almost 6 hours plus post processing time for a total cost, the company estimates, of $33.58 per part.

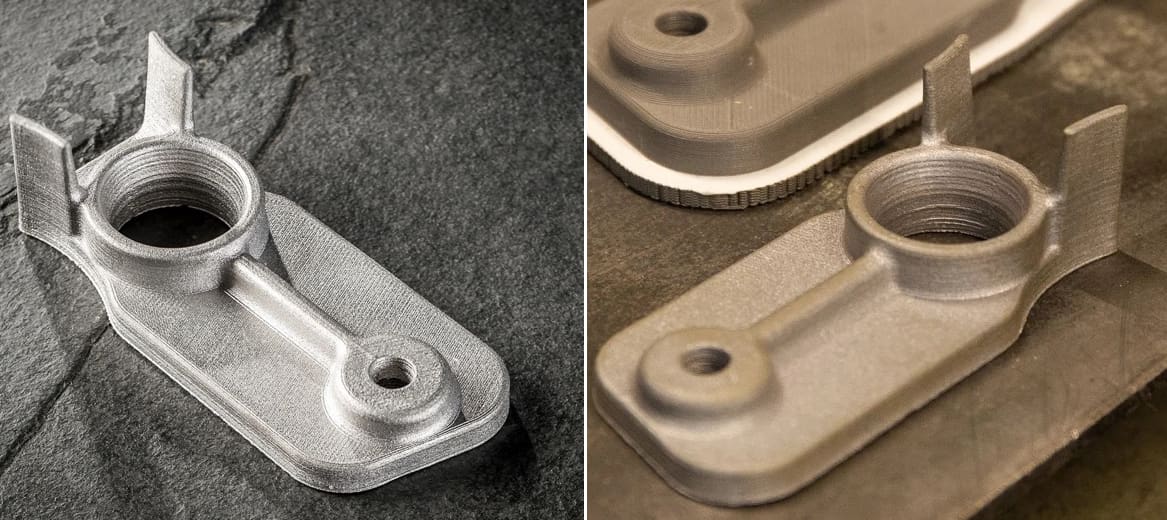

Alstom, a mobility solutions company developing high-speed trains and infrastructure, needed to produce a customizable, visible doorstopper part for certain trains in a low quantity. The part needed to last the service life of the train. On top of that, since it would be seen inside the train compartment it needed to have the desired aesthetics. Because the production of small batches is very expensive with lengthy delivery times, the company says, 3D printing provided a much cheaper alternative by getting rid of fixed costs like molds and tools.

Working with 3D printing service bureau Replique, the company selected Ultrafuse 316L stainless steel printed on Epsilon W27 printers from BCN3D.

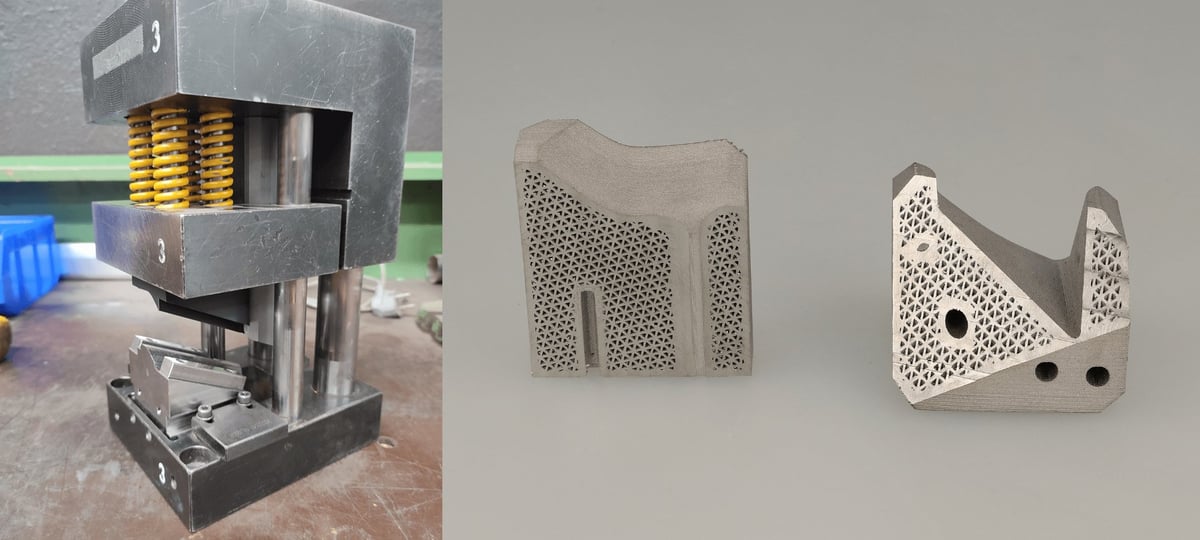

WKW.automotive is a global supplier of metal parts to automotive OEMs. Before serial production of decorative and functional aluminum parts, it provides its customers with prototypes. Each prototype requires its own tool for fabrication. Because these metal forming tools can go through several iterations based on the OEM’s feedback, machining was too expensive and slow.

WKW.automotive turned to BASF Forward AM’s Ultrafuse 17-4 PH stainless steel printed on a printer from Raise3D.

“By eliminating intensive production steps like eroding and milling, pre-serial-tools for prototypes parts can be realized faster and a significant cost reduction can be achieved,” says Michael Hoinka, Head of Product Development WKW Engineering. “Geometric freedom for drawing-tools as well as shorter lead times for pre-serial-parts are further important advantages.”

Most Affordable Metal 3D Printers

Zortrax M300 Dual

Zortrax is another 3D printer maker that working with BASF Forward AM to develop a packaged solution that enables metal 3D printing on its dual-extruder M300.

Called the Full Metal Package, available in 316L stainless steel or 17-4 PH stainless steel, the kits contains a 1kg spool of Ultrafuse filament, the Ultrafuse Support Layer, a Magigoo Pro Metal adhesive, a M300 Dual hotend module with steel nozzle, and a PTFE tube with adapter. For shipping your printed parts to a third-party there’s also included a voucher good for 500 grams of metal parts and bubble wrap to secure your 3D printed parts for transit.

The Full Metal Package is also available for the Zortrax Endureal 3D printer ($58,000), the company’s higher-temp, more industrial FDM. The Endureal package costs around $800.

UltiMaker S5

UtliMaker took its time developing a metal material ecosystems to accompany its popular S5 3D printer. To ensure quality metal parts, UltiMaker started with the BASF Forward 3D metal filament, then added a print settings in its Cura software for optimized metal part slicing, it says.

The bundle that turns the standards S5 into a metal 3D printer is called the UltiMaker Metal Expansion Kit. It includes one roll of BASF Forward AM Ultrafuse 17-4 PH, the BASF Forward AM Ultrafuse Support Layer filament that created easy breakaway supports for metal parts (only available in Europe), packaging and a voucher for sending one set of green parts to a third-party post-processer (for debinding and sintering), the Ultimaker Print Core CC 0.4, and Ultimaker Print Core DD 0.4 (only available in Europe), and Magigoo Pro Metal adhesive. In addition, you’ll get access to metal e-learning content on Ultimaker Academy.

The one-hour e-learning course covers the full metal 3D printing workflow. By the end of this training, UltiMaker promises, you’ll be fully equipped to create high-quality metal parts with an UltiMaker printer.

The UltiMaker Metal Expansion Kit is also compatible with the company’s S7 3D printer and its MakerBot Method.

BCN3D Epsilon W27

The Metal Pack is BCN3D upgrade offers to the current Epsilon series that opens up metal part production. The parts produced by this process have practically identical behavior to those produced by MIM or CNC, BCN3D says.

The Metal Pack includes both Ultrafuse 316L and 17-4 PH (3kg spools), two metal hotends, Magigoo Pro Metal adhesive, two brass wipers, and an activation code for post processing.

BCN3D has developed a specific metal printing profile for the BCN3D Stratos Slicer that avoids the internal stresses of the printed part during the printing process, the company says. Once printed, debinding and sintering processes can be performed externally through Forward AM’s current network of service providers, which is the same for practically every printer on this list.

Metal Pack is also compatible with BCN3D’s larger (420 x 300 x 400) Epsilon W50 at $8,500.

Raise3D Forge1

The Forge1 from Raise3D is a large-format metal 3D printer designed to print with the BASF Forward AM Ultrafuse stainless steel filament so there are no accessory kits to buy. The Forge1 printer boasts a dual-extruder, automatic bed leveling, filament run-out sensor, and HEPA filter with activated charcoal.

Unlike the desktop FDM printers mentioned above, Raise3D is the first company out of the gate with a complete three-part solution (printer, debinder, and sintering oven) for metal 3D printing so you don’t have to send your parts to a third-party provider for post-processing. Of course, you can send your parts to a third-party if you don’t want to buy the company’s other equipment.

The three-part metal solution is called MetalFuse includes the Forge1 3D printer, the D200-E debinding device that removed the polymer from the green part creating a brown part, and the company’s S200-C vacuum sinter furnace that can reach 1,500 ℃, which turns your brown parts into solid metal parts, all in-house. Note that the printer alone is $10,000, the full suite of equipment is around $130,000.

Raise3D also includes software that automatically accounts for print shrinkage so that the final size after debinding and sintering will be accurate, it says.

Metal 3D Printing Services

Investing in a metal 3D printer is no small decision, and part of any good due diligence is ordering sample parts. You can order these from the manufacturer, but many printer manufacturers on this list also offer print-on-demand services. For smaller projects, one-offs, and tests, outsourcing your 3D prints to a metal 3D printing service can dramatically save on the capital cost and overhead of operating your own system.

Third-part print services, such as Shapeways, i.Materialise, Sculpteo, and 3D Hubs, also offer metal printing. But choosing the right printing service for your needs can be a challenge. The best first step is to visit Craftcloud, the 3D printing service marketplace where you can instantly compare metal 3D printing prices for multiple parts in the same basket. The Craftcloud platform mixes and matches offers to give you the lowest cost and quickest turnaround time.

License: The text of "The Most Affordable Metal 3D Printers" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.