No one wants their 3D printed part to break. Whether you’re printing a ping-pong paddle or a rocket thruster, you want a strong material.

Yet, strength can mean hardness, impact resistance, load-bearing ability without breaking, or several other properties you may want your part to have. Your part’s design and how you 3D print it are major factors in strength, but what you print it in is the most critical.

There is a wide range of scientific measurements around strength that you’ll see listed on your 3D printing materials under terms such as “tensile strength” and “flexural strength”. So how do you choose?

Instead, let’s look at the essentials of strength in 3D printing materials and some of your strongest options.

Understanding Material Strength

There are several measures of strength and it’s handy to have a general understanding of each one because these measurements appear on your 3D printing material’s datasheet, enabling you to compare options. You’ll see measurements for tensile strength and Young’s modus, for example. These measurements relate to the type of force on your part and how the material will withstand the force.

When it comes to materials, all measurements for strength vary depending on the material’s manufacturer, the specific composition of the material, and the printing parameters used. So, note that our charts below are generalizations. For example, not all maraging steels are stronger than all stainless steel, but the strongest maraging steel is stronger than the strongest stainless steel, so it’s higher on our list. Likewise, not all carbon fiber nylons will resist bending more than carbon fiber PEEK materials, but this is usually the case. As you can see, ranking materials by strength is not as clear as it would seem.

Yet another point to consider is environmental conditions on your part. A standard carbon fiber nylon is as strong as a carbon fiber PEEK, but would fall apart in a humid or corrosive environment. All strength data is measured at standard temperature and pressure (STP), but most applications need strength under temperature, UV light, or chemical conditions.

For the measurements below, we used a variety of sources, including the handy Senvol database of 3D printing materials, but always go directly to the material maker’s datasheet for the most accurate information on the latest version of their materials.

Tensile Strength (Resistance to Pulling Apart)

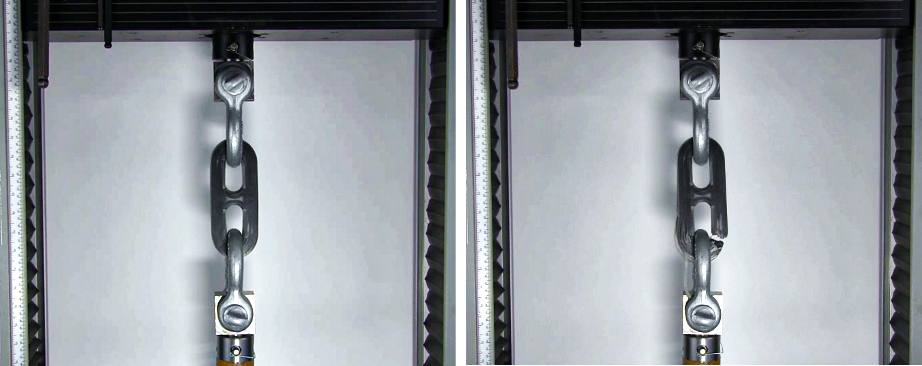

If you’re 3D printing a part where the main force is pulling on the part, such as a type of hook used to lift a heavy object, you’ll want a high tensile strength. Tensile strength refers to the tension or stress a material can take before breaking. Measuring a material’s tensile strength involves literally putting a sample of the material in a vice-like machine and pulling it in opposite directions. In practical terms, this measurement relates to how quickly your part will break or its brittleness. For reference, stainless steel has a tensile strength of 860 MPa, while glass is 33 MPa, and consumer-grade PLA is about 53 MPa.

There are important related terms to tensile strength, such as ultimate tensile strength (UTS), which is the actual breaking point, and tensile yield strength, which is when the material has permanently deformed, in most cases rendering it useless, even if it hasn’t broken yet.

The top materials in tensile strength are metals but don’t count out polymers, especially carbon-fiber or kevlar-filled varieties. These materials are often used to replace metal in applications where the lighter weight of polymers is a benefit.

Flexural Strength (Resistance to Bending)

If your part needs to bend a little to withstand forces without breaking, for example, a 3D printed chair, you’ll want a high flexural strength material. Flexural strength represents the maximum stress a material can withstand before it fails in bending.

The higher the flexural strength, the more resistant the material is to bending or flexing forces. So, if you did want to print something like the chair above, you’d want to select a flexural strength proportional to the amount of force you expect on your chair — and probably not the material with the highest flexural strength. The chair pictured above was printed in a PLA with a flexural strength of 102 MPa.

Don’t confuse this with flexural modulus, which is how much a material will resist bending or its stiffness. Parts with thin walls, such as tubes or containers, would benefit from high flexural modulus to prevent buckling under external forces.

Tensile Modulus (Elasticity)

Elasticity (also known as Young’s modulus, tensile modulus) evaluates the elasticity of a material, which is a ratio between the deformation of a material and the power needed to deform it.

Typical TPU filament, for example, has a low tensile modulus of around 70 MPa (very elastic), while most PEEK filament has a high tensile modulus of 3,720 MPa (not elastic). In material selection, elasticity is one of the measurement considerations often used alongside strength. Another measure that’s important if you want to determine how far your part can stretch without breaking is “elongation at break”, which is usually a percentage of the part representing the change in length of the sample at the point of breaking. For example, a TPU might have an elongation at break of 400%.

Below we list the top most elastic materials for 3D printing, but it’s important to note that 3D printing resins, which can be very elastic, typically don’t provide their chemical recipe. Some products claim to be a type of TPU or that they are “silicone-like”, but it’s only when looking at the material data sheet that you can get a sense of their true elasticity, listed under tensile modulus.

Impact Strength & Hardness

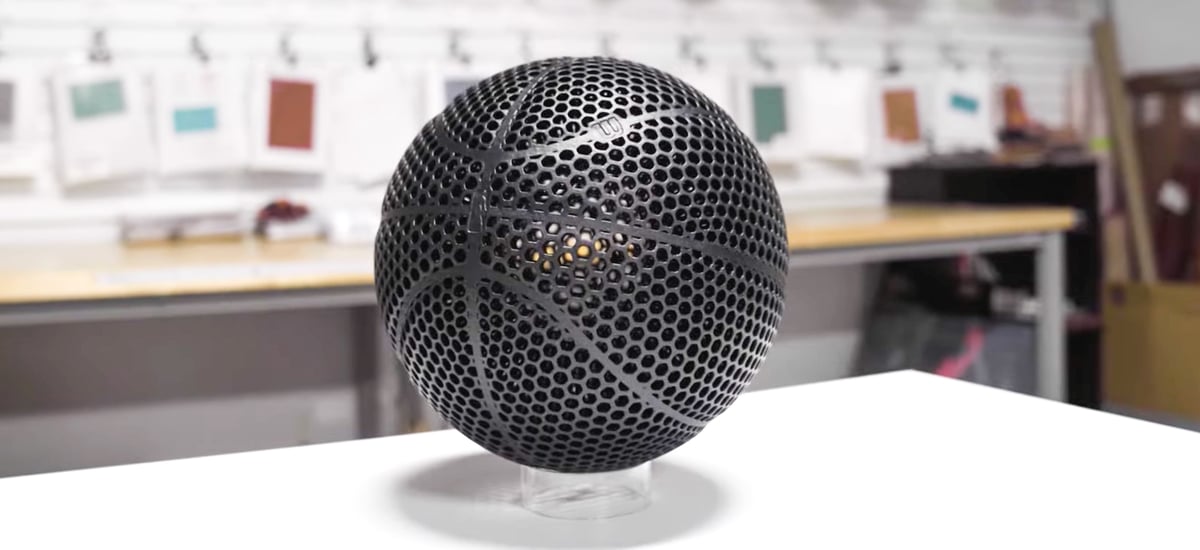

Impact strength (also known as Izod or Charpy impact strength or, generally, as toughness) is your part’s ability to withstand fracturing if you drop it or how it will resist breaking or cracking when force is applied. Think, 3D printed bicycle helmet. You’ll see these measurements of force in either joules per square meter (J/m2) or foot-pound per square inch (ft·lb/in2). The Izod test is the more popular method for plastic materials, whereas Charpy is common for metals.

Hardness can seem like a vague term, especially when talking about metals. It can refer to scratch resistance, wear and abrasion resistance, or the part’s ability to be dented. Hardness of plastics is often shown as a Rockwell or Shore value, which can have little to do with a material’s strength or flexibility. Shore hardness is a common term you’ll hear when it comes to polymers, but it’s more general than the measurements above. For example, all elastomers and flexible filaments, such as TPU, would be Shore A, and within the A category, they would have individual values, such as Shore Hardness 95A.

Which Is Stronger: Metals, Ceramics, or Polymers?

You’d be wrong to assume that all metals are stronger than all polymers. In fact, 3D printing with a strong material such as PEEK can replace the use of metal in many high-temperature environments for the right applications. Polymers are often used to replace metals in aerospace applications because they are lighter and often more resistant to corrosion. When comparing polymers with metals, most polymer suppliers use a Specific Tensile strength, which is the material strength divided by the density.

Many technical ceramics are also stronger than metals in certain ways, such as in tensile modulus (or resistance to deformation under force). Technical ceramics, such as silicon nitride (Si3N4), alumina (Al2O3), and zirconia (ZrO2) are remarkably strong in terms of stiffness but can have limitations in terms of brittleness.

You might also want ceramics or polymers instead of metals because of their resistance to wear and abrasion.

How You 3D Print Really Matters

Your part could break along a layer line or a corner that has nothing to do with the material but rather the part design or a failure in the printing method. Everything from part orientation to infill to post-processing affects the strength of your final part, which is why it pays to brush up on the various ways to strengthen your parts, including:

- The Strongest Infill Patterns

- Heat and Annealing for Strength

- 3D Part Design to Eliminate Warp

- Orientation Tips for Strong Parts

- Wall Thickness Tips for Strong Parts

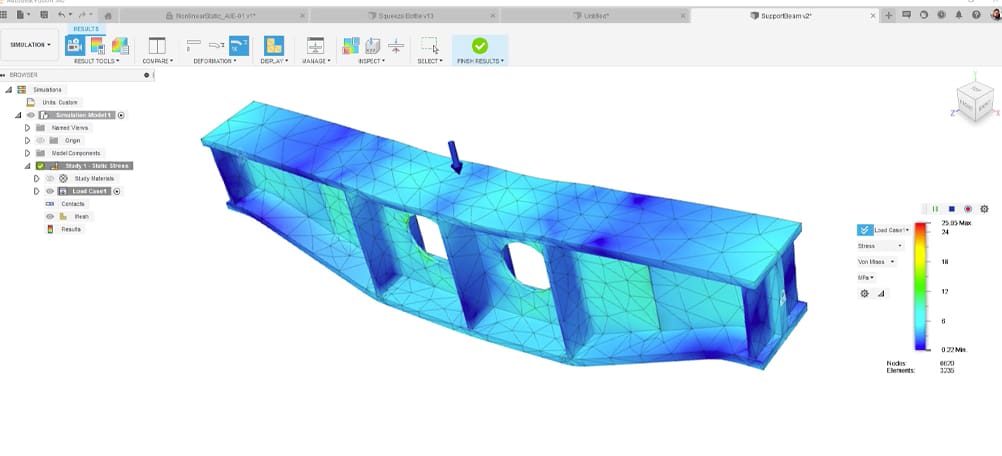

Using simulation software is an even better way to test whether your part will fail under stress before you even print it. When designing a functional part, destructive testing of prototype after prototype wastes enormous amounts of time, material, and money. Sure, some field testing is necessary, but software simulation today can dramatically reduce the time you spend reengineering parts and components.

You can choose from several programs that can account for specific methods of 3D printing and enable you to reinforce, redesign, or reconsider your approach. You can test your part for specific stresses, such as static stress and structural buckling, as well as how it will react to heat and impact.

Some Really Strong 3D Printed Parts

3D printing is used by NASA and SpaceX for rocket parts. It’s used for Formula 1 engine parts and as joint replacements in people. Any question about whether 3D printing is strong has been long dispelled. Yet, because 3D printing encompasses such an immensely broad range of technologies and materials, when it comes to questions of strength, the answer is often “it depends”.

Here are just a few icons of strong 3d printed parts you can point to the next time the question come up: Just how strong are 3D printed parts?

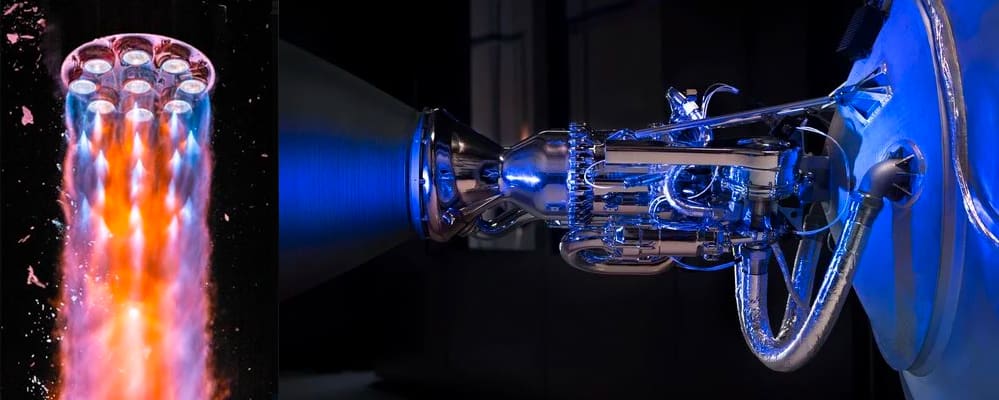

The 3D printed Terran 1 rocket from Relativity Space, which launched on March 23, 2023 — not achieving orbit but passing maximum dynamic pressure — included nine 3D printed engines made of an innovative copper alloy developed at NASA. The metal is a combination of copper, chromium, and niobium called Glenn Research Copper, or GRCop-42. It can withstand engine temperatures approaching 6,000ºF.

Nancy Smith Kilkenny at NASA’s Glenn Research Center says Relativity Space has shown these higher-performing rocket engine components, produced by additive manufacturing with GRCop alloys, could be used in future missions to the Moon, Mars, and beyond.

Terran 1’s fuselage was also 3D printed using a method called wire arc additive manufacturing and withstood the immense pressures of launch intact.

Huisman, the Dutch maker of heavy industrial construction equipment, 3D printed this crain hook using wire arc additive manufacturing in steel. The hooks are about 170 cm by 130 cm and weigh about 1,700 kg each, and have a loading capacity of 350 megatons.

Technical Sources:

All data and information provided are for general informational purposes only. The data provided is believed to be accurate to the best of our knowledge.

License: The text of "The 10 Strongest 3D Printing Materials" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.