All3DP’s editors spent four days walking the aisles of the world’s largest expo for 3D printing and additive manufacturing, Formnext in Frankfurt, Germany. We saw hundreds of machines in action, thousands of 3D printed products, interviewed dozens and dozens of companies, and got the scoop on what’s new, what’s planned, and what turned heads.

Let’s start with the two words that were on the lips of nearly every major AM company we spoke to: productivity and efficiency. For 3D printer makers, this means new software, processes, materials, and consulting, but not necessarily new hardware. In fact, there were surprisingly few machines launched at Formnext this year — overall there were about 35 major machine launches so far in 2024, and just a handful at Formnext. As one major brand told All3DP: “We have enough hardware, now it’s about helping customers get the most out of it.”

This diminishing focus on hardware in the industrial sector, made room for desktop brands to take the launch spotlight. We found new machines launching at Formnext from Anycubic, Prusa, Creality, and Rat Rig’s new Disrupt Engineering brand.

So what we’ll add to this year’s annual “machine” feature is what we did see a lot of at Formnext: material innovation.

Below is our annual look at the most promising and notable printer debuts of Formnext. Keep in mind that few of these are currently available. They’ll be rolled out with more detail in the next three to eight months, and we’ll add them to our new printer guide like the one below for all the new printers in 2024:

New FDM 3D Printers

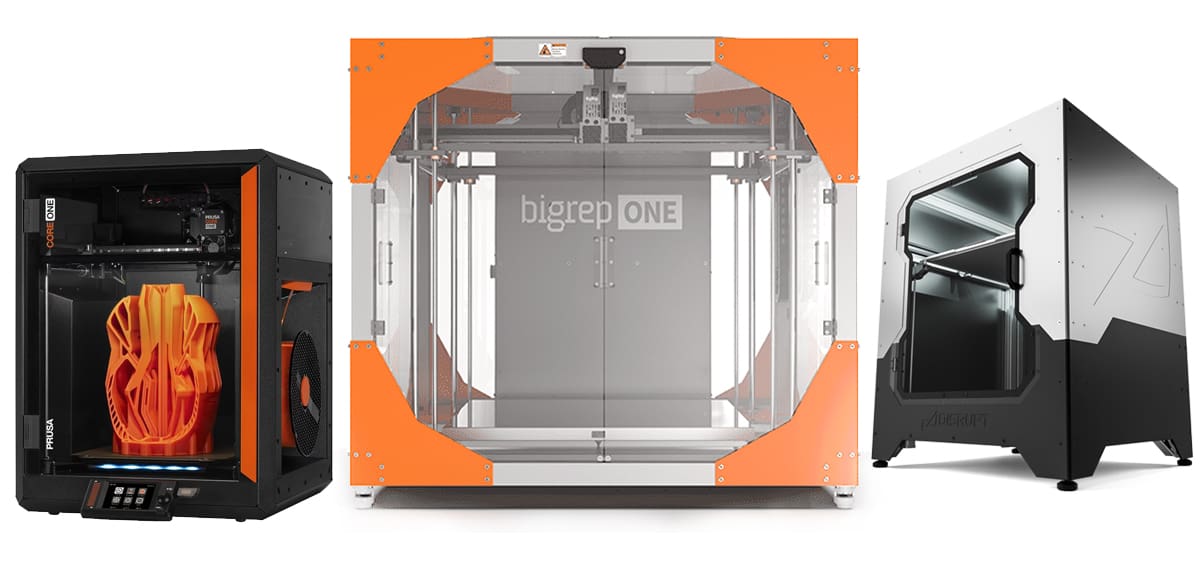

The ones: material extrusion debuts at Formnext ranged from the desktop Prusa Core One to the large-scale BigRep One.5.

Prusa Surprise Launches Enclosed CoreXY 3D Printer

The media is usually informed in advance about new machines launching at Formnext, but companies like Prusa are often very tight-lipped. This was the case with their new Core One.

The Core One is Prusa’s second CoreXY system after its Original Prusa XL launched last year. Despite a heated enclosure (up to 55°C) and notably condensed footprint (compared to the MK4S), it boasts a larger 250 x 220 x 270 mm build volume. The system has an active chamber temperature control, which Prusa says eliminates the need to open doors or top covers for prints with low-temperature materials like PLA or PETG, thanks to two high-performance fans.

BigRep Boosts Throughput with New Extruders

Berlin-based BigRep logged its fourth launch of 2024 with upgrades to its popular large-format FDM, the One.

Now One.5, the printer boast a 40% higher flow rate and greater material compatibility in the same footprint. It is still not compatible with pellet materials, which seems like a missed opportunity.

Thee BigRep One.5 integrates dual PEX2 extruders that the company says can process a broader range of thermoplastic materials. Both extruders can print at once in twin mode to boost productivity. It’s still an open material solution, so you can use and tune any material you like. There’s also a Keep Dry Box that can fit two 8-kg spools.

There’s not a lot new to the One, which originally launched in 2014 with a major upgrade (v3) launching in 2019, so the “.5” addendum to the name is about right. Price? They wouldn’t say, but the 2019 version was in the $40,000 ball park.

Anycubic Promotes New Printers Suited for Multi-Color Business Applications

Anycubic’s showcase at Formnext was clearly the Kobra S1 Combo, the company’s first multicolor FDM printer using CoreXY structure. Supporting up to 8-color printing, the Kobra S1 Combo is equipped with the Anycubic Color Engine Pro that also features drying during the printing process. The printer also boasts a 320°C hotend.

Anycubic also launched the Kobra 3 Max with a large build size and also 8-color printing capability. The company promotes it as ideal for tools and spare parts.

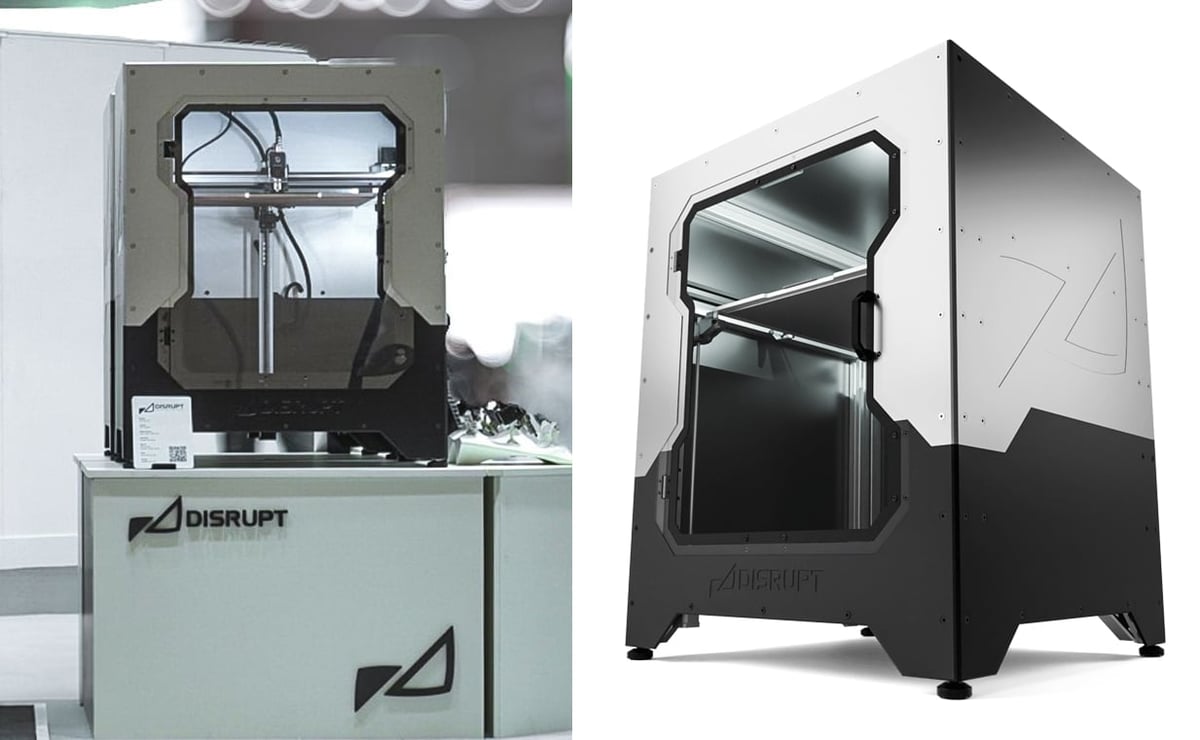

Rat Rig: Another Consumer Brand Goes Pro

Disrupt Engineering, a new brand from Portuguese company Rat Rig, is bursting into the professional segment of 3D printing with its V0 (vee-zero) “concept machine.” The company, known for its DIY 3D printers says the V0 brings all of the features of its popular V-Core 4 to a professional format with higher-grade components.

“Our design philosophy emerges from one single focus: driving down the cost per printed part, to reduce your payback period and get you to ROI faster than you ever thought possible,” the company says.

Read All3DP’s exclusive interview Disrupt Engineering company founder Sonat Duyar below.

New FDM Materials

What Formnext lacked in FDM machine debuts, it made up for a bit with interesting material launches.

One of the more unique filaments that caught our eye in the Startup Zone was the silicone filament from a company called Filament2. It’s not filament in the traditional sense, but rather a hollow tube filled with paste material, that enables you extrude it using standard FDM printers. This “paste filament technology” only requires that you swap in a proprietary nozzle for use with the filament. Although the company is debuting with silicone, the technology could be used for a range of materials from chocolate to technical ceramics on any FDM printer vastly lowering the costs of many phases of R&D.

Price? “We don’t have yet a price,” the company told All3DP, “but we want to keep it as low as possible so people will be able to afford it, and … use it on the Prusas, Bamboos, or even in professional markets.”

Finally, Some Well-Thought-Out Filaments to Fill the Gaps

Veteran Italian material maker Xenia, which just recently expanded from injection molding materials into pellets for 3D printing, showed off a new filament range designed for large-format industrial production. The first four materials in the new line (under a new business unit called 3DF Materials) are not the copycats we’ve seen in the past few years (think CF nylon). These seem to have some uniqueness that, while relegates them to niche applications, may address the needs of manufacturers looking for just these combinations of attributes.

The four new filaments are a 15% carbon-fiber filled, bio-based PA11; a high elasticity polyether block amide (PEBA); a 10% carbon-fiber filled polyvinylidene fluoride (PVDF) for industries like chemical processing and electronics; and a 100% recycled, 20% carbon-fiber filled PETG.

Markforged Launched Nylon White For Food Production Applications

When All3DP visited the bustling Markforged booth, we were directed to a small display of a new filament the company is very keen to show off. This Nylon White FS is an unfilled, non-abrasive nylon that is certified for use with food production equipment. It’s a material the company says customers have been asking for because it opens up a vast amount of operations applications on food and beverage factory floors where the use of a food-contact certified material is required or preferred.

To certify Nylon White FS, regulators performed a rigorous audit including material formulation, toxicology, and cleanliness review as well as a manufacturing facility audit.

More Interesting New Materials

- Stratasys Unveils PC-ESD: 3D printing giant Stratasys launched a new PC-ESD filament (for the Fortus 450mc and F900 printers) aimed at electronic applications like housing and finally came out with a filament drying cabinet.

- Spectrum Group is another established material maker seeing market potential in 3D printing filament, this time on the affordable end. Under a new brand called simply, The Filament, it offers a made-in-Europe option fo basic materials — PLA, PETG, colored carbon fiber PLA — set to retail at about $16 a kilo. The spools are made from recycled plastic.

- Polymaker‘s new polycarbonate (PC) pellets in PolyCore line are designed for large-format project like lamp shades and signage.

New Resin & SLS 3D Printers

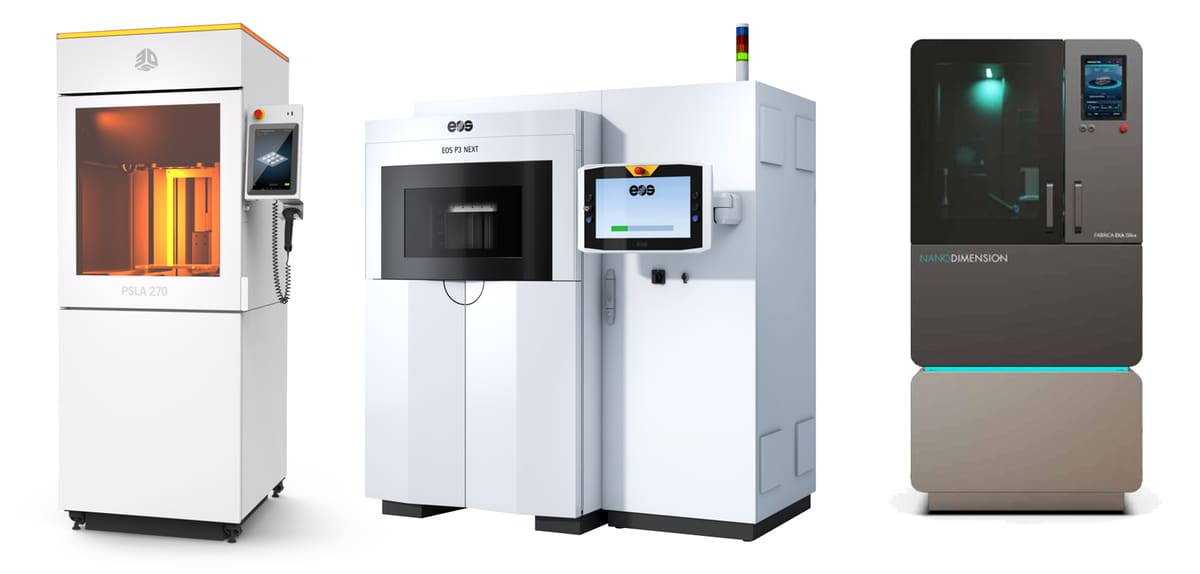

If your polymer needs are more in the resin or powder variety, there were not many new launches at Formnext, yet major players EOS and 3D Systems debuted significant advances.

Productivity Spotlight at 3D Systems with New Resin Machine

All3DP got a personal tour of the new PSLA 270 at Formnext 2024 by company VP Marty Johnson who walked us through the highlights and the impetus for the innovation. This new resin 3D printer is the company’s fastest and really focuses on the productivity buzzword. Not only can you print more faster, but critical minutes are trimmed off production time by having better thermal management and a build vat that you can just roll out and insert a new one.

The PSLA 270 is, technically, a digital light processing (DLP) 3D printer featuring two projectors (no lasers). 3D Systems like to use the term “projection SLA” since, again technically, DLP is a term owned by Texas Instruments who makes a lot of the projectors. Names aside, the PSLA 270 is raising the bar for production-level resin 3D printing. Get more details at our exclusive coverage below.

Polymer Powder Gets More Productive at EOS

EOS, the German-based manufacturer of some of the world’s most popular industrial 3D printers, launched a new generation of its polymer selective laser sintering (SLS) platform to focus on productivity and cost efficiency, while maintaining its established reputation for part quality.

The new EOS P3 Next, is just that: the next version of EOS’ P 396 launched in 2016, but it’s more than an upgrade. The new system promises a 50% increase in productivity and a 30% reduction in costs compared to the P 396. Key features include a 36% faster “layer creation time”, the ability to swap out a build units, and a high material reuse rate (80% with the new ALM PA 950 HD nylon 12 and 70% with EOS PA 2220 HighReuse).

Virginia Palacios, the chief business officer of EOS’ polymer solutions, told All3DP that this new machine hits an important target for volume manufacturing: machine uptime. She says the P3 Next delivers more than 90% machine availability.

Farsoon Surprise Launches New Quad-Laser SLS

Our favorite buzzwords of the show popped up again with the late debut from Farsoon that “sets new benchmarks in productivity and operational efficiency,” the company says. The Flight HT601P-4, launched on Nov. 21, boasts a large build volume of 600 × 600 × 600 mm (216 liters), four 300W fiber lasers, and scanning speeds of up to 20 m/s.

We have to admit we didn’t make it over to the Farsoon booth to investigate since the launch was a third-day surprise, but we’ll dig a little deeper in our updated guide to SLS 3D printers come out next month.

Nano Dimension Unveils Bigger Micro 3D Printer & Talks Consolidation

Nano Dimension (the company that this year acquired Desktop Metal and is finalizing its acquisition of Markforged) released a new machine in it’s polymer micro-3D printing specialty. The Exa 250vx is a digital light processing (DLP) 3D printer is for micro applications, such as connectors and other miniaturized components for electronic devices, optical uses, and even the jewelry sector, but at production volumes.

Exa is compatible with Nano Dimension’s range of existing proprietary resins for its other Fabrica system. There are no details yet on the use of third-party resins.

When All3DP was interviewing Nano Dimension’s senior VP Nir Sade, who is the general manager of the AM division, we had to ask about the plans to combine Desktop Metal, Markforged, and Nano Dimension’s other brands. Although he couldn’t go into much detail since these are publicly traded companies, the vibe was major consolidation. This makes sense after any merger, but considering the depth of talent at these companies, it’s likely to position the merged entity as a new force in the industry after the dust settles. We’ll have more from Sade in our 2025 industry outlook next month.

UpNano Launches Higher Precision Micro 3D Printer

Another new resin 3D printer for micro-scale parts debuted from Austria-based UpNano, which specializes in research 3D printers using micro-scale two-photon polymerization (TPP). The company released its new NanoOne Green, which uses a laser with a wavelength of 515 nm, which falls within the green region of the visible light spectrum. It’s designed to address an increasing demand, according to the company, for enhanced transparent material versatility and higher resolution for use in optics and microfluidic applications. The new levels of detail in this type of resin 3D printing come from the new laser, which delivers 30% higher resolution than traditional TPP 3D printers with 780 nm wavelength lasers, the company says.

The NanoOne green, like the existing NanoOne models, is a compact desktop system that incorporates high-performance vibration isolation, a built-in cleanroom with a HEPA filter, and full compatibility with all existing NanoOne accessories.

Xolo’s Resin Volumetric 3D Printing Is Ready for R&D

Berlin-based startup Xolo launched a new bioprinter called Xell, which uses a proprietary technology for support-free 3D printing with high-viscosity resins. The company’s volumetric 3D printing has been in development since 2020 and now its moving from scientific concept to practical application with the Xell focusing on uses from tissue scaffolds to custom hydrogels.

Xell is a research tool yet Xolo says its plug-and-play design and ready-to-use bio-inks are “designed to make volumetric bioprinting accessible to every lab.”

Sharebot’s New SnowWhite HT for Research

Italian company Sharebot launched its SnowWhite HT (high temperature) selective laser sintering machine at Formnext. Compared to other SLSs on the market, Sharebot would be still the economical pick for universities and research centers. This has always been the company’s niche and it doesn’t seem to be expanding. The SnowWhite HT has the open parameters that researchers engaged in the study or development of new polymers and composites would want.

New Resin Materials in the Spotlight

Although there were not many entirely new resin 3D printer at Formnext, we did find some interesting new materials.

- Stratasys says it is bringing more than 30 additional materials to its Open Materials list for the Origin P3 resin platform, including a ceramic-filled material for injection mold tooling.

- Evonik released a PA12 carbon black powdered polymer with a “relatively substantial amount of carbon black in the core of each particle,” the company says.

- Nano Dimension debuted a new resin, Ataru, designed for digital light processing (DLP) 3D printers.

- Henkel launched a new resins: Loctite 3D Ind6845, for 385nm and 405nm systems, which is a TPO-free formulation providing an combination of toughness and heat deflection (HDT).

- Carbon launched EPU Pro, a “next generation of elastomeric resins” that incorporate foaming agents, resulting in parts that expand during cure to achieve better resolution and novel haptics.

New Metal & Ceramic Printers

Massive metal 3D printing systems are the giants of the show every year and attendees marvel at the 3D printed heat exchangers, manifolds, rocket thrusters, and other tools and spare parts on display.

More metal 3D printers launched this year than polymer and there were a few new faces among the old standards keeping alive the promise that AM is still start-up friendly.

Let’s take a look.

Metal Part in Less Space with More Flexibility From Farsoon

Farsoon unveiled its FS191M at Formnext, a compact metal laser powder bed fusion (LPBF) 3D printer with open parameters. The Chinese additive manufacturing company says the new metal powder bed system aims to “elevate productivity, enhance cost-performance, and simplify operations’” for users working on early-stage projects and low-volume manufacturing.

Building on the original FS121M launched in 2016, the FS191M has nearly four times the build volume in a similar footprint. The FS191M features a standard ⌀191 x 199 mm build cylinder and a single 500W fiber laser. If you’re looking for a metal LPBF device for R&D, the FS191M can be equipped with a much small build platform to reduces material costs.

This new machine also has the features you may be used to from Farsoon’s long line of metal printers, including in-chamber monitoring cameras and open parameter strategy for full customization .

WAAM3D’s new RoboWAAM XP Makes Quicker Work of Large Metal Parts

WAAM3D, a UK-based maker of, you guessed it, leading WAAM (wire arc additive Manufacturing) 3D printers launched the new large format RoboWAAM XP. This fully integrated system (robotic arm, tool head, software) boasts fast rates of up to 15 kg per hour.

Users can build parts of up to 2 x 2 x 2 m weighing up to 2,100 kg in alloys of iron, aluminium, nickel, and copper.

BLT Debuts Upgraded BLT-S450 with Eight Lasers

Bright Laser Technologies (BLT), based in China, debuted its upgraded BLT-S450 metal laser powder bed fusion machine. The BLT-S450 has a 450 x 450 x 500 mm build size; four, six, or eight 500W lasers; and an automated powder circulation system for efficient powder recovery. It also features single-blade bidirectional dynamic powder spreading and standard long-life filters with a lifespan of over three years.

Renishaw’s New Dual Laser RenAM 500D Metal Machine

UK-based Renishaw launched the latest offering in its RenAM 500 series of metal LPBF machines at Formnext. The new RenAM 500D has the same Tempus technology that allows the lasers to fire while the recoater is moving, improving overall efficiency. The machine has two 500W ytterbium fiber lasers, a beam focus diameter of 80 μm with dynamic focus, and a build volume of 250 x 250 x 350 mm.

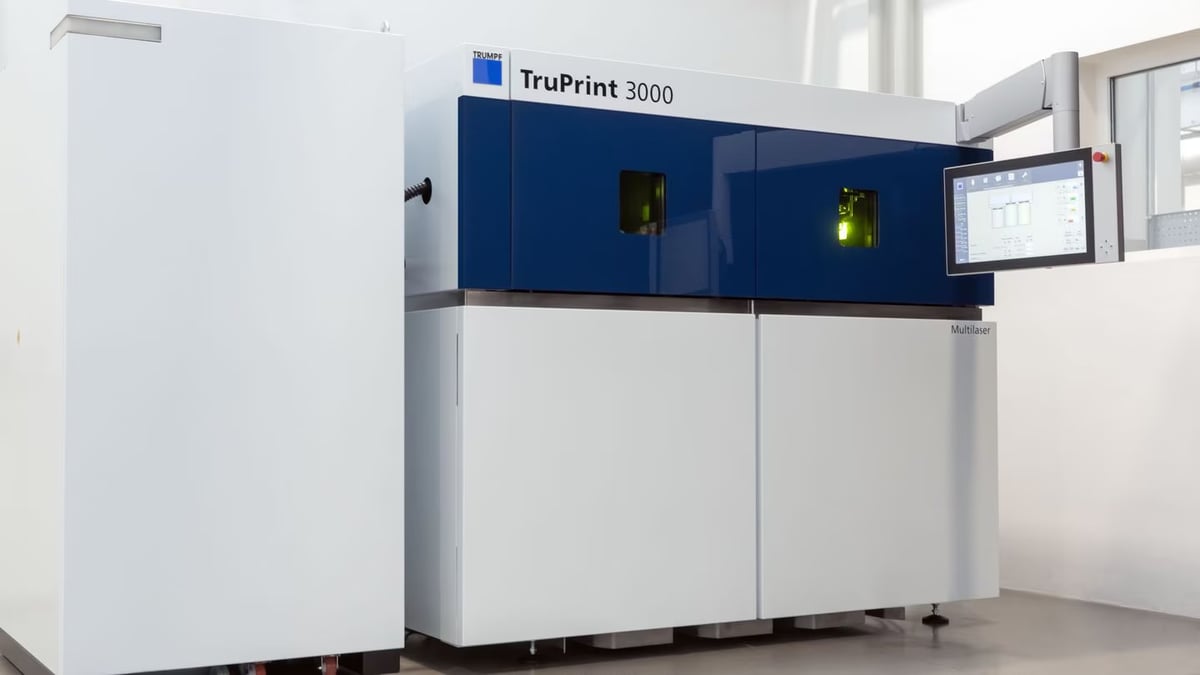

Trumpf Showcases Upgraded TruPrint 3000

Trumpf from Germany showed of its updated TruPrint 3000 at this year’s Formnext 2024 which it says is more (buzzword) productive. The company has equipped the TruPrint 3000 with an integrated cooling system for the build platform and increased the power of the two 700W fiber lasers.

Trumps says a unique feature is temperature control that allows the 3D printer to use the full 700 watts of laser power without overheating the material during the printing process. The powerful lasers can also increase the size of the machine’s two laser spots from 80 to 200 microns using special optics.

Addimetal Shows Off Its Budget Binder Jetting Machine at Formnext 2024

Starting at $200K with open-material compatibility, this new 3D printer aims to disrupt the stat quo and bring down the price of metal binder jetting.

French 3D printing start-up, Toulouse-based Addimetal is launching its first machine at Formnext: a metal binder jetting solution that’s more affordable than the competition. It features open perimeters, and is open to third-party binders and metal powders from the metal injection molding industry.

After four years of development and a year of beta testing, the K2-2 offers manufacturers what the company is calling a “breakthrough solution” to produce complex metal parts with precision and speed.

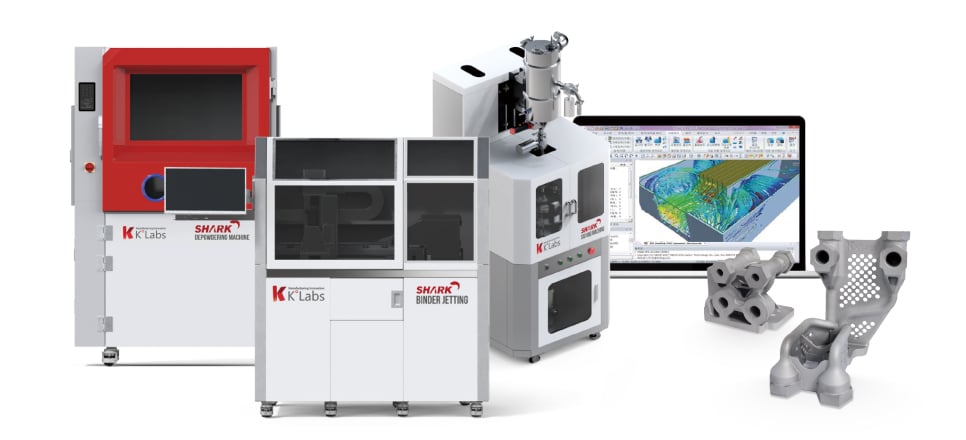

KLabs Aims to Swim with the Shark

A metal binder jetting system (printer, sieving, and depowdering) called the Shark caught our attention at Formnext from South Korean company KLabs. It’s new and not widely available, say the representatives at the KLabs booth, yet, it looked like a potential entry level to MBJ technology.

KLabs is a 3D printing and designing service, and a Korean reseller of some top American and European 3D printers. This binder jetting solution, however, was developed with KLabs’ own technology.

The Shark features a single-pass binder application through 3,200 nozzles with open parameters. Both organic and inorganic binders are available and the company says there are no restrictions on the choice of materials because any material that can be powdered is available. Looking forward to hearing more about this machine in the years to come.

Look for more new printer details here on All3DP as they become commercially available. If you missed some of the other great machines introduced this year, check out our coverage of everything launched in 2024 here:

License: The text of "Top 3D Printers Launched at Formnext 2024" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.