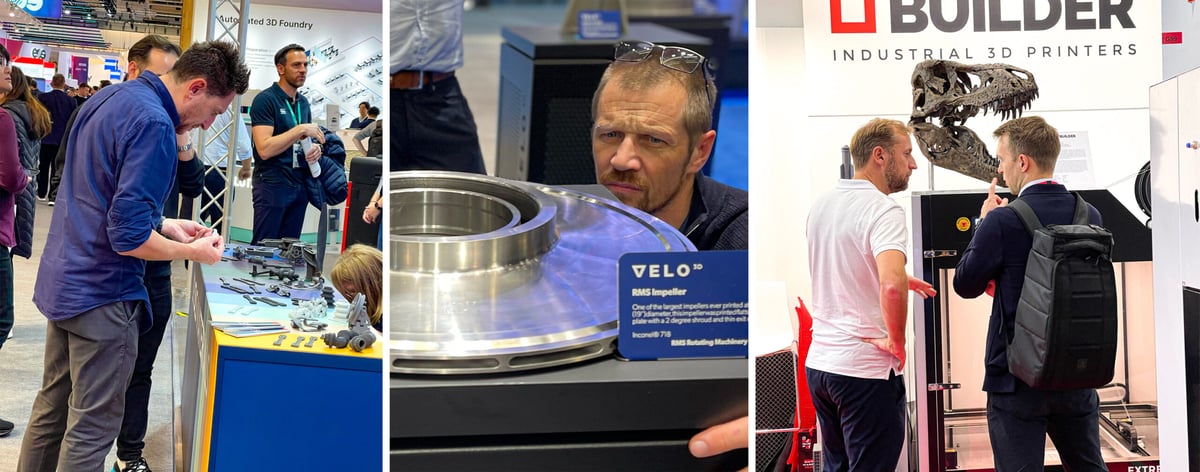

Walking the aisles of Formnext, the world’s largest expo for 3D printers, visitors were invited to touch, handle, and attempt to bend hundreds of various 3D printed objects. From massive metal aerospace parts to small prototypes made from sustainable polymers, the product, not the process, was the star of Formnext again this year.

Behind the part displays, of course, were the machines, most of which were humming along fabricating more parts for visitors to handle. Rarely stood a printer idle or unplugged.

Notable news buzz at the show not directly related to machines were some well matched brand mergers, such as the BigRep and Hage3D marriage and the Nexa3D and Essentium merger. Overall buzzwords and trends included the not unfamiliar “production” and “sustainability” along with more talk of price-per-part. Printer makers of all sizes were presenting how their machines enable users to scale their 3D printing and how it may help manufacturers lower their carbon footprint.

From automation to acquisitions, materials to software, the list of those who didn’t have news at Formnext might be shorter. There we several intriguing software- and AI-related developments that we’ll cover separately, but below is our annual look at the most promising and notable printer debuts of Formnext. Keep in mind that few of these are currently available. They’ll be rolled out with more detail in the next three to eight months, and we’ll add them to our new printer guide like the one below for all the new printers in 2023:

New FDM 3D Printers

The material extrusion debuts at Formnext overwhelmingly focused on automation and lowering the price per part. The idea is to make these industrial machines as push-button-simple as possible while lowering the time operators need to calibrate, monitor, and tend to the systems’ health.

Onboard the new offerings from Stratasys, Markforged, MiniFactory, and Aon3D are more sensors connected to more software that monitors the print in real time to identify and sometimes prevent defects, such as cracking, over or under extrusion, thermal variations, and internal defects while establishing a print quality document. Industrial FDMs no longer have to just make good parts, they have to prove they made a great part.

Markforged FX10 For Factory Tools

The second FDM 3D printer in Markforged‘s FX series (after the FX20) is the new FX10. It is also a continuous carbon fiber printer, but it’s smaller than the FX20 and larger than the X7. Markforged offers eight carbon fiber 3D printers, so what niche is the FX10 filling, you may ask. According to what Markforged told us at Formnext, the FX10 is the company’s factory line workhorse. In other words it’s meant to continuously churn our essential jigs and fixtures, tools, and spares for long periods of time with no manual intervention. It achieves this through nearly “a hundred” sensors and automation. There are print head-mounted optical sensors that can verify dimensional accuracy of parts as they print, other sensors to assess device health and performance, and more automated features for calibration and material changeover. In a nutshell, it’s not as big or hot as the FX20, which Markforged aims at aerospace applications, but it’s more automated and larger than the X7, plus it has a new modular architecture designed for upgradability.

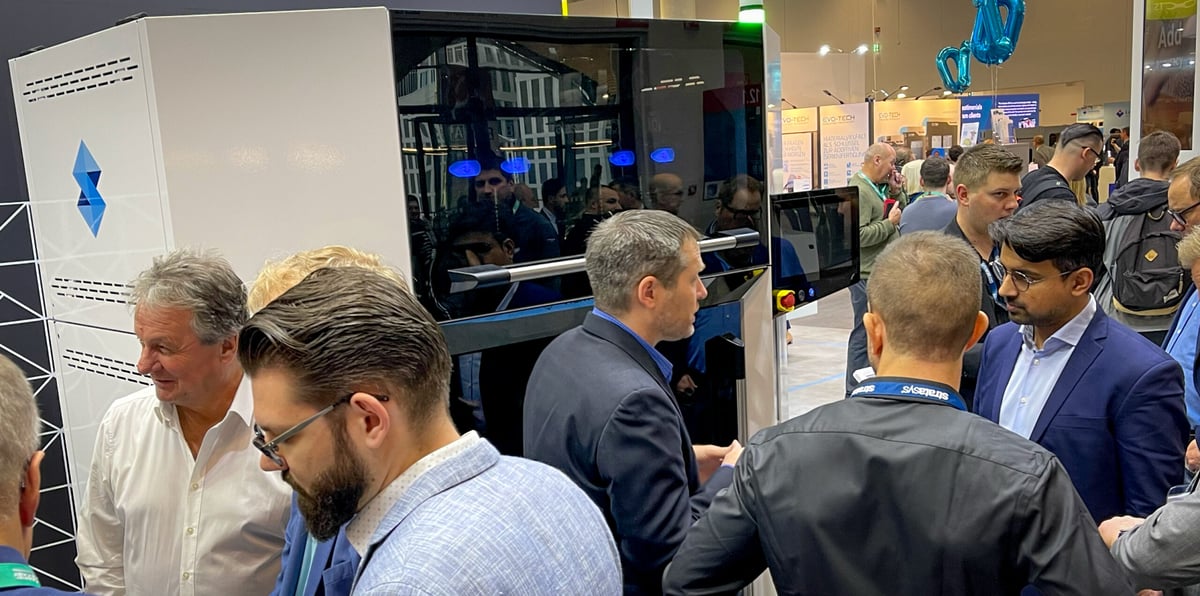

Stratasys F3300 Focuses on Automation

Stratasys says it is reclaiming its status as the cutting-edge innovator in FDM machines with the new F3300, which debuted at Formnext. The company calls it the most sophisticated FDM systems they’ve ever made. No full spec sheet has been released yet, but Stratasys says the F3300 delivers twice the speed and throughput of the F900 (which isn’t going away). Print speed is up to 500 mm/s with a 270 cubic cm/hour throughput on the extruder. There are multiple extruders, an automated tool head changer, and four onboard material dryers. Stratasys just announced that Toyota has signed to purchase one. The F3300 features linear motors, more sensors, and more automation for 24/7 production.

Like the Markforged above, the Stratasys F3300 is aimed a minimizing operational labor requirements; a real pain point for companies that 3D print all day, every day. There’s a generous build volume (600 x 600 x 800 mm) and, although the chamber and extruder temperatures haven’t been released, your materials options run from ASA and carbon fiber-infused nylon to Ultem.

Something Big from MiniFactory

MiniFactory, the maker of the high-temperature Ultra 2 industrial FDM printer, launched its second machine called Ignite at Formnext. Also a high-temp FDM, the Ignite has almost twice the build volume of the Ultra 2 at 600 x 400 x 400 mm while offering about the same chamber temp (200°C+) and extruder temp (480°C). Materials range from ABS and ASA to Ultem and PEEK, plus, with an open material system you can choose your preferred supplier. It’s a dual extruder so you can print various support materials. Ignite also features an integrated drying solution.

Just as the Markforged and Stratasys above, the MiniFactory aims to deliver parts with less overall monitoring. It offers what it calls “real-time quality assurance technology” through its sensors that track the print as it’s made, and even offers a manufacturing document that highlights the entire printing process.

Aon3D’s High Temp “Smart” FDM

Aon3D has come out with a new printer called Hylo that replaces its previous one, called M2+, which we had on several of our top-picks lists. The Hylo is a high-temp FDM, like the three above, that focuses on a range of applications including tooling, jigs and fixtures, end-use parts, and industrial rapid prototyping.

Unlike the offerings from Stratasys and Markforged, the Hylo like the MiniFactory is an open material platform so you can pick any material brand for carbon fiber composites and high performance polymers, including PEEK.

With an expansive 650 x 500 x 500 mm build volume, the Hylo boasts print speeds of up to 500 mm/s and IDEX-enabled duplication and support modes. Beyond its tech specs, Aon3D is calling it a “smart” 3D printer because it features 25 integrated sensors for process controls and monitoring. Along with the machine, Aon3D introduced a forthcoming software solution called Basis “intelligent-slicing and in-process monitoring” that it says will turn process variability into part confidence.

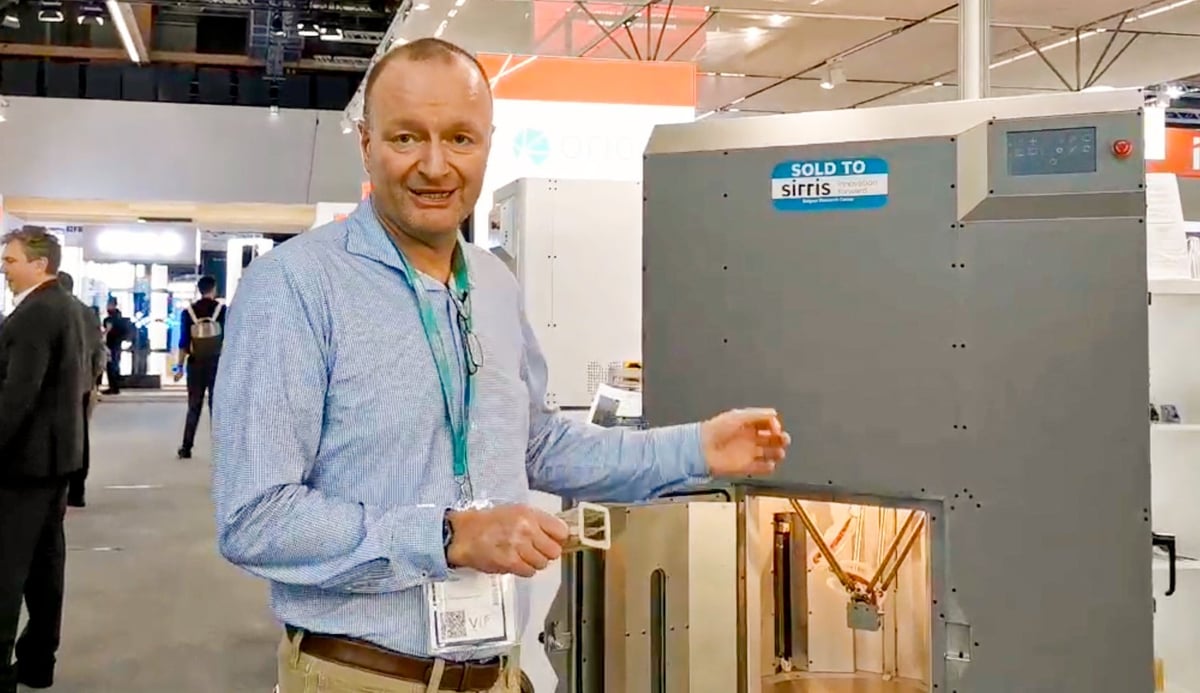

Prusa Pro HT90

Prusa says it brought a new FDM to Formnext from its Prusa Pro line called the HT90. In fact, Prusa’s been working on this machine for a while ever since it acquired the machine’s developer TriLab in 2021. This delta-style, single-extruder printer is constructed to make the most of engineering-grade materials with a heated chamber to 90°C and a nozzle that reaches 500°C, which is ideal for carbon fiber-infused nylon, PEI, and even carbon-fiber PEKK. Although the company doesn’t boast a specific max print speed, it does say the HT90 can deposit 1kg of PETG or ABS filament in just eight hours. Expect it to be commercially available sometime in late 2024.

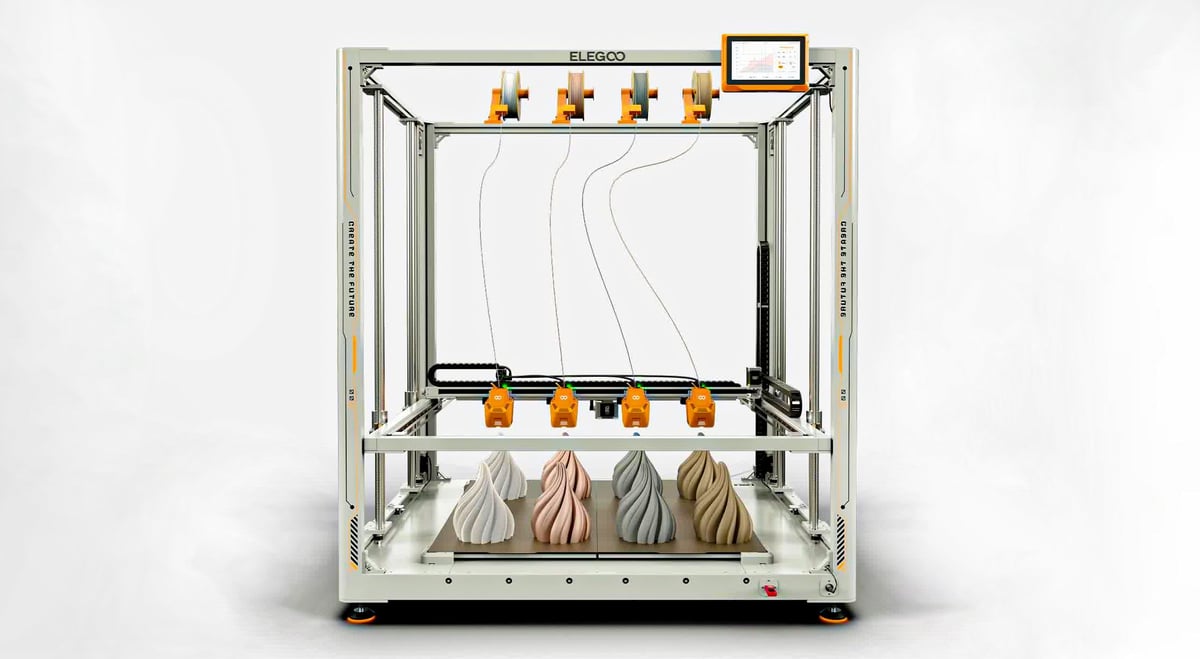

Elegoo’s OrangeStorm Giga FDM

Debuting what the company calls its first professional printer at the company’s first-ever booth at Formnext is the popular consumer brand Elegoo. The large-format OrangeStorm Giga FDM isn’t professional just because of its size; it has features. There are four 300℃ extruder nozzles that work simultaneously, so you can print four identical models or experiment with different colors and materials without worrying about nozzle drips or complications. The maximum print speed is a nice 300 mm/s.

The printer’s heated bed has four independent and individually heated PEI magnetic, high-temperature platforms, so when you’re not printing huge parts, you can focus your printer on a quarter or half of the bed. There’s also one-click automatic bed leveling, filament detection, power loss recovery, double-sided powerful cooling fans, a portable 7-inch HD screen, and caterpillar cable tracks.

Plasmics’ Delta Aimed at Orthotic Makers

Technically it didn’t debut at Formnext (it was at the Hannover Messe in April) but we hadn’t gotten wind of it before, so we’re adding it to our finds. The Delta S is another delta-style single extruder from start-up Plasmics. The company says its core mission is to service the prosthetics and orthotics industry with multi-material 3D printing that eliminates entry barriers. Whenever you see a 3D printer with a woodgrain exterior finish, you can guess it’s going to be a type of display item. Here, the idea is that orthopedic brace makers would have one humming away in their workshops. The added bonus is the Delta S’ induction-heated print head which the company says heats up rapidly and can better control the temperature of extruded material. Not available yet, but could launch in 2024.

Orion AM’s New High-Temp, Larger Delta

The third new delta-style FDM we spotted at Formnext is from start-up Orion AM, which specializes in high-temperature machines. Its new Orion A460 has the same unique tech as its AM150, which uses thermal radiation to heat the part and the chamber during printing. This way, PEEK prints get the heat they needs to have strengths and densities surpassing injection-molding, the company says. The A460 with a build volume of 350 x 300 x 500 mm sports an integrated filament dryer and a open material system.

Venox Shows Off Its V-Rex Potential

Early start-up company Venox Systems showcased what it called “the potential of its latest 3D printer, V-REX,” at the Austria technology booth at Formnext. What that means is that in a few years we could see an interesting systems that can “lay continuous fibers freely in space.” With a five-axis design, the printing direction can be adjusted in all the fiber directions required, enabling a load-path compliant fiber layout, the company says. In addition to carbon fiber there’s the potential to print and embed optical glass fibers and copper wires. We’re keeping an eye on this one.

Pellet Extrusion Head from WASP

WASP is one of the original large-format extrusion 3D printer makers and they even have a large construction 3D printer. At Formnext they previewed a potentially interesting extruder head — something that will fit on a robotic arm — called Metamorfosi. The company calls it a “multimaterial and multicolor pellet extrusion system,” but hasn’t released specifics.

Something Small from BigRep

Although not a new printer, BigRep announced at Formnext that it has acquired fellow German 3D printer maker Hage3D, the AM subsidiary of manufacturing machine maker Hage. These are excellent FDM machines lost in the shadow of their parent company’s other pursuits that can now get the attention they deserve. If you’re looking for something new from BigRep, you won’t have to wait long.

New Resin & SLS 3D Printers

If your polymer needs are more in the resin or powder variety, there were not many new launches at Formnext, although there were several new materials focusing on flexible and elastic properties. In addition to the machines we take a look at below, three interesting post-processing solutions launched.

First, from Formlabs an SLS cleaning device called the Fuse Blast that can take parts from printed to finished in 15 minutes with a menu of automation features designed to eliminate the polymer powder mess. Another SLS processing machine from 3D Systems is a new powder recycling station that accompanies its rebranded WeMatter entry level machine, now called the SLS 300. Lastly, Nexa3D launched a new resin curing device called the xCure it says can reduce post-processing time by as much as 80%.

Let’s take a look at the top new printers that caught our eye.

Raise3D DF2 Solution

Yes, Raise3D went resin! Perhaps they thought there weren’t any ways left to optimize their popular FDM solutions, so why not take on an entire new technology. It is a bold move to enter the crowded pro-desktop resin market but, as with everything Raise3D does, it approached resin with the end-user in mind and a focus on usability.

The company’s new DF2 Solution is just that, a “solution” for manufacturers who 3D print all day and are exhausted by the process hassles of tracking parts and loading and cleaning resin bins. Sure the DF2 DLP 3D printer has quality components and the high resolution you’d expect, but the key to this offering is the completeness of the package, which includes a washing unit, a curing unit, software, and material cartridges.

The solution boasts “traceable workflow” features, which include a “smart build plate” that integrates with both post-processing devices and has an embedded RFID tag that records the type of resin being used, in addition to washing and curing settings. This allows various operators to manage the washing and curing phases regardless of their familiarity with the products being produced.

3D Systems’ Mysterious PSLA 270

3D Systems previewed its new PSLA 270, that won’t be out for a while and they didn’t disclose many details. It will be a “projector-based polymer 3D printing platform,” which is about a vague as you can get. In person they couldn’t tell me much more on the record, but in 2024 all shall be revealed, they said. This 3D printer is engineered to deliver larger end-use parts more rapidly than with 3D systems other platforms.

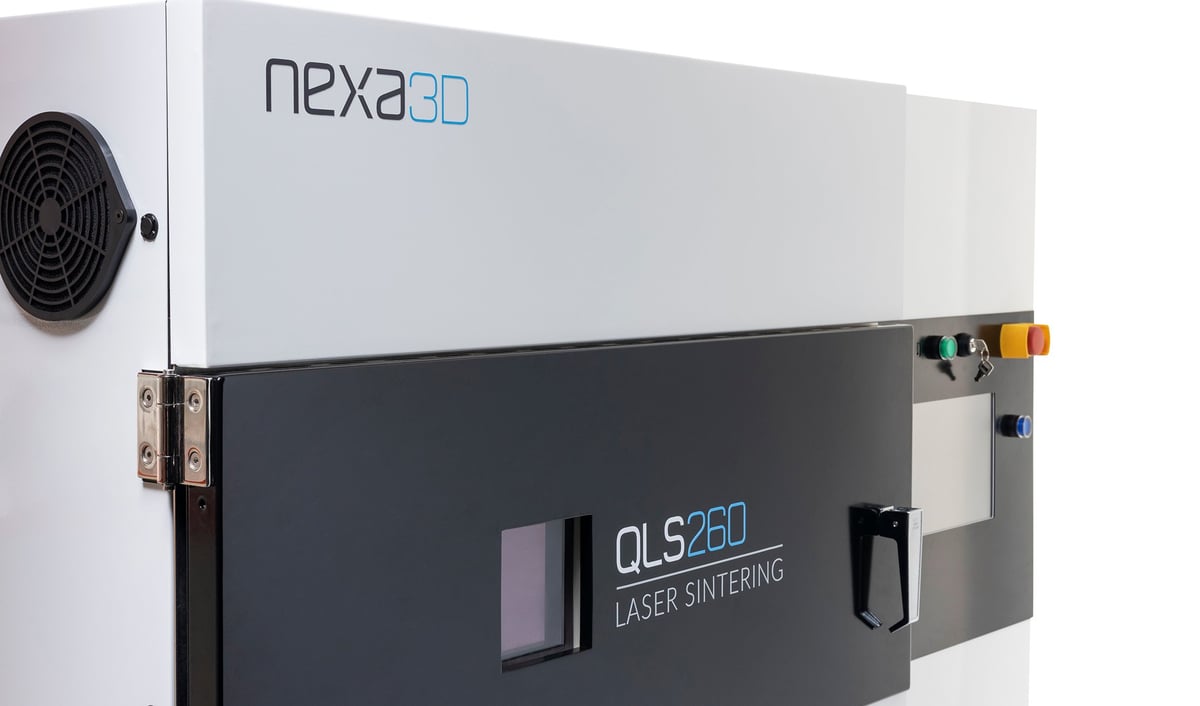

Nexa3D’s New SLS Solution

Nexa3D, which just bought FDM printer maker Essentium to round out its technology offerings, also added a new SLS it its menu that’s fits in between the existing 230 and 820. The QLS 260 is an industrial laser sintering system for both powder and metal. Just a touch bigger and a touch faster than the 230, the new 260 has a 60-watt laser compared to the 230’s 30-watt and the 820’s 4 x 1,000-watt. Distinguishing it further from the rest of the QLS family is its on-board nitrogen generator. Nexa3D also announced the availability of a new flexible TPC for SLS developed by Evonik, called Infanam TPC 8008 P. The QLS 260 is an open platform with more than 16 qualified materials including the patented metal powders from Headmade Materials.

Tangible’s Solidator 8K SOL400

Tangible Engineering showed off its Solidator 8K resin 3D printer it says has a production rate of up to 9,157 cm³ per hour, which translates to a Lego brick in 5 seconds according to Tim Fischer the company’s managing director. The Solidator is an LCD (or masked stereolithography) resin printer with a large build volume of 330 x 185 x 400 mm. The company is targeting this solution at any application that needs fast, detailed volume, such as dental models. Another advantage is that there is no need for a material reservoir the size of a building space, as is the case with SLA 3D printers. Instead, a low filling level of 800 ml is sufficient in the material tank, the resin is constantly refilled via an automatic refill system. Intro price is $18,000, but will likely increase as companies snap up this ultra-fast machine.

Resin Materials, Rather than Machines in the Spotlight

Although there were not many entirely new resin 3D printer at Formnext, the focus was more on new materials.

- Carbon was showing off their new EPU46, which is a variable stiffness elastomer, which means proprietary tweaks to the formula and you can have super soft to highly impact absorbing products, and in any color.

- Nexa3D launched three new resins at the event: a flame-retardant resin (xPRO9400-FR), a bright white modeling resin (PRO9499 White), and a biocompatible dental resin (Saremco Print Crowntec).

- Stratasys launched four new DLP resins for its Origin One printer: Somos WeatherX 100 is for environmentally durable applications, Somos PerFORM HW for injection molds or high stiffness fixtures, P3 Deflect 190 ESD has electrostatic dissipative properties and high stiffness, and lastly the P3 Stretch 80 is ab elastomeric prototyping resin similar to a TPU.

- Henkel Loctite launched four new photopolymer resins at Formnext: Pro9274 is a durable dark gray resin that enables fast printing of highly detailed parts, Ind3380 is a specialty resin with electrostatic dissipative properties and a high Heat Deflection Temperature of 190°C, Ind5714 is a gray elastomer resin with high rebound properties, and Med9851 is a high performance, medical material ideal for an extensive variety of impact resistant medical device applications, the company says.

- 3D Systems released Accura AMX High Temp 300C, a new unfilled SLA resin material with a heat deflection temperature of 300°C. The new chemistry of this material does not require a thermal post-cure, the company says, thus enabling a more streamlined workflow and reduced time to part-in-hand.

New Metal & Ceramic Printers

Massive metal 3D printing systems are the giants of the show every year and attendees marvel at the 3D printed heat exchangers, manifolds, rocket thrusters, and other tools and spare parts on display. In addition to promising new metal machine technologies, there were a flock of upgrades to already popular models, such as Trumpf‘s TruPrint 2000 3D printer that now has more laser power — 500 watts instead of 300 watts — and a square build plate instead of a round one. There’s also a new motorized beam expander that automatically adjusts the laser spot diameter (55 or 80 microns) according to the task at hand.

Metal LBPF printer maker Renishaw launched software called Tempus that uses a new scanning algorithm for its RenAM 500 series that enables the laser to fire while the recoater is moving, saving up to nine seconds per build layer or 50% of the overall build time.

There were a few brand new machine launches and a promising casting technology. Let’s take a look.

A Fresh Approach from Foundry Lab

The new solution from start-up Foundry Lab is designed to appeal to manufacturers who need low-volume or unique parts cast quickly and with a low financial and energy impact. The printer’s technology debuted at last year’s Formnext, but this year, the start-up is actually taking orders for the commercial version so more attendees took a closer look. This really clever idea for additive manufacturing works like this: a digital file of a mold is created and fed to the side of the printer that does ceramic binder jetting. Once this mold is 3D printed and post-processed in a special microwave, you insert a Foundry Lab metal slug (proprietary zinc or aluminum, with other metals on the way) and put it back in the microwave, where the metal is melted into the mold. “No need to pour hot metal or touch metal powders,” the company says.

EOS Focuses on Lowering Cost of Aluminum and Copper

Metal laser powder bed fusion giant EOS has added a new machine to its M300-4 line, this time with up to 4 x 1,000-watt lasers. The new M300-4 1KW system has a niche focus, EOS said at Formnext, specializing in aluminum and copper applications at the moment. What this new machine delivers is a lower cost-per-part, the company says, made possible by its already-established technology to reduce support structures and the machine’s new modular approach. Take a look below at the prints EOS had at their Formnext booth from the new printer. Left is a build of 24 aluminum cylinder heads for a customer that makes gardening tools. The entire build took 36 hours, and for 30,000 parts, the cost was comparable to die-cast, according to EOS, but with 250kg less CO2 production. Right is a copper cold crucible used for melting metals for high-tech applications from start-up Addtoshape. The production of the crucible not only takes less energy, but it will require less energy in its use.

Additec’s New Multi-Hybrid Metal Part Maker

Further evidence that there was no theme or trend to the technology debuted in the metal segment of the Formnext show, apart from the sustainability factor, is this new machine from Additec. The 3D printer manufacturer’s newest machine, the Hybrid 3, combines liquid metal jetting, laser direct energy deposition, and CNC into one platform. The process starts with standard commercial welding wire, lowering costs. The metal jetting offers high details, while the laser DED offers accelerated build time for larger parts. The CNC is the last step for tight tolerances. In all, it’s a recipe for large parts fast. This was also the theme of the company’s new “deployable” solution, the AMDroid. This robotic arm DED is containerized in a mobile unit aimed at military and industrial applications. The AMDroid will be available in early 2024.

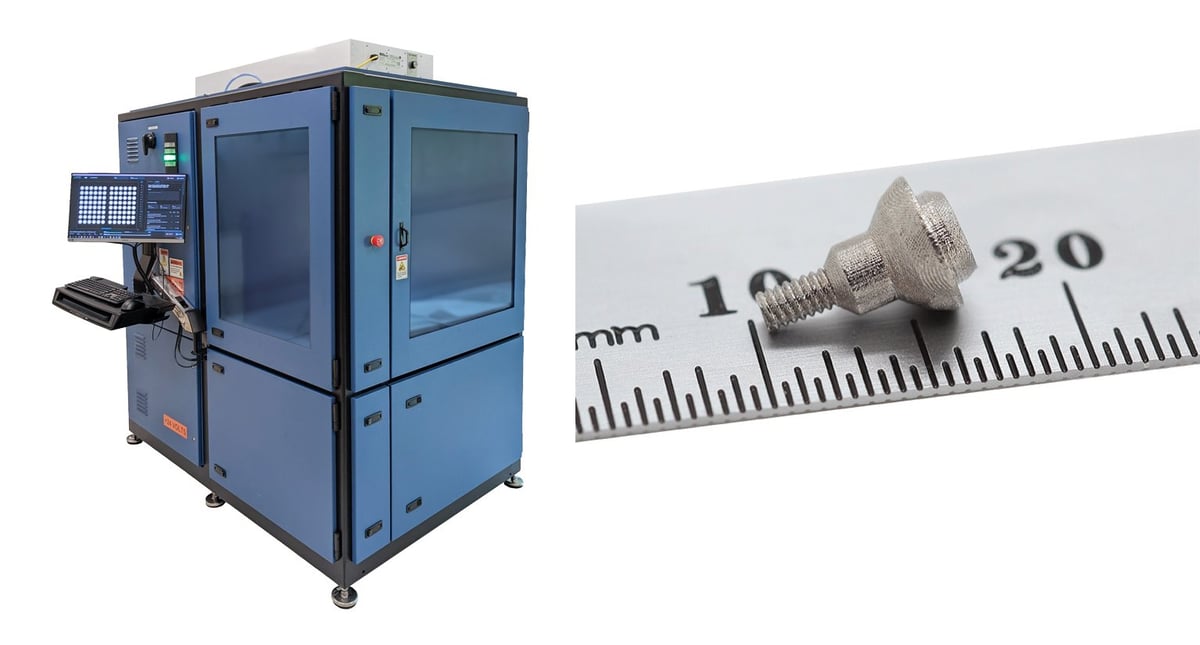

Holo Offers Its Metal Lithography

Proving that you don’t have to have a booth at Formnext to announce news, Holo co-founder Arian Aghababaie walked around Formnext with a handful of printed parts in his pocket. Fortunately, Holo specializes in very small metal parts with a fine surface finish. Although the company’s metal lithography technology isn’t that new, previously it was only offered as a service, but now the company is offering its Holo H200 for commercial sale. The H200 produces parts with 50-micron details and within 25-micron tolerances. Final parts match the surface smoothness of commercial metal injection mold parts, the company says. Speed is another hallmark of the system; the dental abutment pictured above was printed in just eight seconds.

Look for more new printer details here on All3DP as they become commercially available. If you missed some of the other great machines introduced this year, check out our coverage of everything launched in 2023 here:

License: The text of "Top 3D Printers Launched at Formnext 2023" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.