Every iteration of Rapid + TCT, North America’s most important and largest 3D printing and additive manufacturing event, has a different vibe. This year, in Los Angeles, attendees, exhibitors, and speakers were more optimistic than in years past. Although the economy has slowed investment in additive manufacturing at many major companies, the machines, materials, and software are advancing full steam ahead.

Notable news buzz at the show was the focus on affordability, which meant new, smaller versions of existing popular printers.

Stratasys went small, 3D Systems went small, Spee3D went small, and Colibrium Additive went small-er — all taking their current technology and cramming it into more compact machines offered at a lower initial investment. A move surely designed to attract more companies — on the fence about additive manufacturing — to adopt the technology.

Overall trends included the not unfamiliar “production” and “sustainability” along with more talk of price-per-part. Printer makers of all sizes, even some of the top consumer brands (Elegoo, Creality, Bambu Lab) were presenting how their machines enable business customers to launch more efficient manufacturing processes and more economical prototypes.

Along with printer launches (or debuts in the American market), there we several intriguing material development that we’ll also cover below. But first, our annual look at the most promising and notable printer debuts at Rapid + TCT 2024.

Keep in mind that a few of these are currently unavailable. They’ll be rolled out with more detail in the next three to eight months, and we’ll add them to our new printer guide like the one below for all the new printers in 2024.

New FDM 3D Printers

The material extrusion debuts at Rapid + TCT overwhelmingly focused on heat and speed. It’s not enough anymore to have engineering-grade materials and high resolution, you have to do it quickly. Then, there the idea is to make these industrial machines as push-button-simple as possible while lowering the time operators need to calibrate, monitor, and tend to the systems’ health.

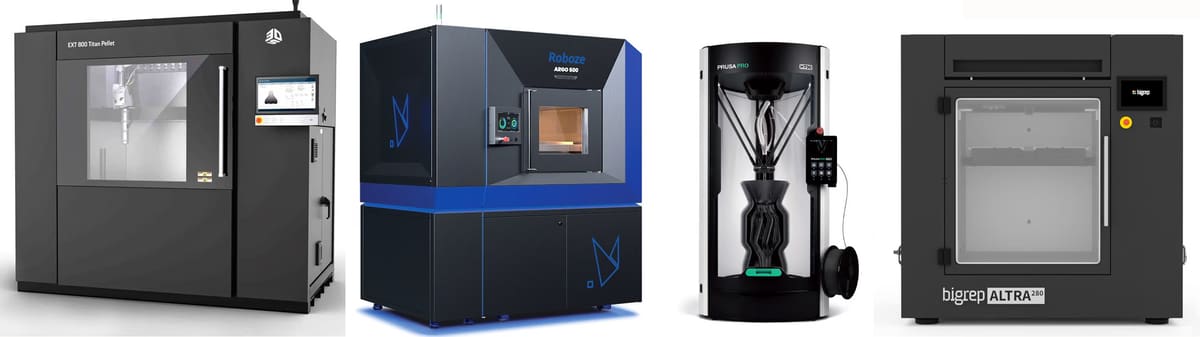

3D Systems Launches Smaller Pellet FDM with Big Features

The economy and speed of 3D printing with pellet materials has attracted a lot of attention over the past few years as robotic arms enable larger and larger 3D printers. Yet, pellet 3D printing offers a wide range of benefits for mid-size and even small parts. The new Ext 800 Titan Pellet from 3D Systems is still large by polymer extrusion standards (800 x 600 x 800 mm), but is the smallest in the now three-member Titan family. It boasts 10-times the output of competing extrusion printers that use filament and up to 10-times less material costs, according to 3D Systems. Like the two other Titan pellet extrusion systems (1070 Titan Pellet and 1270 Titan Pellet) the 800 is aimed at industrial production with applications from foundry patterns and manufacturing fixtures to prosthetics and durable goods.

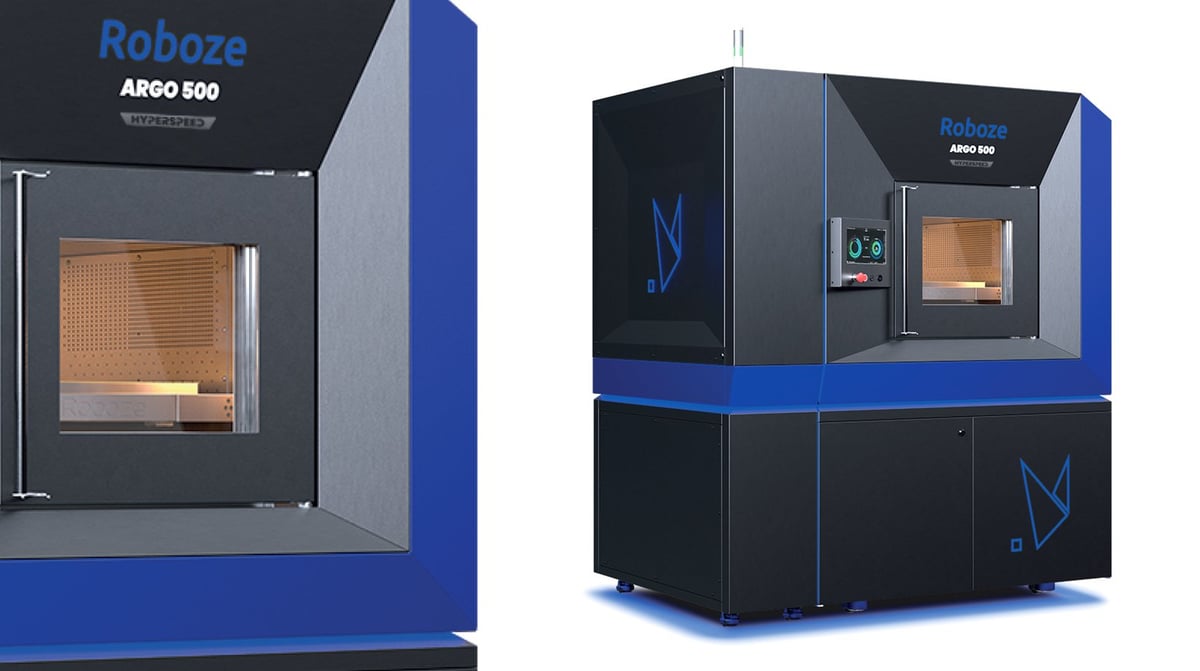

Roboze Argo 500 Hyperspeed

The high-temperature industrial Argo 500 Hyperspeed FDM from Roboze is not only faster, it includes software and hardware advances making it vastly more efficient than the original Argo 500. Not only is there a lot of new software and firmware, there’s new hardware and other patent-pending elements thrown in. It replaces the existing Argo 500.

Comparing the Hyperspeed edition to the older version reveals a doubling of the maximum printing speed to 120 mm/sec from 60 mm/sec. This translates into a 25% faster print time using a single extruder and up to 62% faster print time using dual extruders. As with almost all 3D printers, high speed and high resolution are mutually exclusive, so the Hyperspeed print profile is aimed at delivering faster prototypes. Roboze still offers its Ultra Quality, Quality Speed, and Productivity profiles on this new machine.

Faster prints ultimately save you money in the form of time, but the new Argo 500 Hyperspeed also uses 10% less compressed air, reduces filament waste (purged filament) by 37%, and the machine’s gear system is expected to last 1,000 hours which is 300% longer than the previous version of the Argo 500.

Prusa Pro HT90

Yes, technically we wrote about Prusa’s new high-temp FDM, HT90, and the company’s first steps into the professional market in our 2023 Formnext even coverage, but we now know a lot more about it, and this was its first time shown in the USA. Plus, it’s now actually available to order.

This delta-style, single-extruder printer is constructed to make the most of engineering-grade materials with a heated chamber to 90°C and a nozzle that reaches 500°C, which is ideal for carbon fiber-infused nylon, PEI, and even carbon-fiber PEKK. Although the company doesn’t boast a specific max print speed, it does say the HT90 can deposit 1kg of PETG or ABS filament in just eight hours.

BigRep Gets Hot with New High-Temp 3D Printers

Although we wrote about this in late May, the BigRep booth at Rapid + TCT was crowded with people curious about the very un-BigRep-looking machines. The company’s recent move into high-temp, large-scale FDM with the new Altra 280 and the Ipso 105 enables it to address industrial applications in aerospace, defense, and automotive.

The highlights of the BigRep Altra 280 are the large, heated 280-liter build chamber (500 x 700 x 800 mm), that reaches temperatures up to 180°C and quad extruders reaching up to 450°C, and the fully automated quick start. With up to four extruders, which the company calls DSX (Direct Synchronized Extruders), the Altra 280 is designed to achieve reliable dual extrusion safeguarded by backup extruders.

Although smaller, the BigRep Ipso 105, is what the company is calling a “tool maker’s tool”, with a heated build chamber of 400 x 600 x 440 reaching up to 100°C, and a print bed heated up to 180°C. It features dual extruders capable of printing high-performance materials up to 450°C. The 3D printer shares some of the key features with the Altra 280, such as the fully automated calibration and pre-heating processes, allowing users to start printing at the push of a button, plus a wide angle color HD camera for real time remote monitoring.

Making more of a debut at the BigRep booth was the Viio 250. This new industrial, heated-chamber, large-format FDM offers some interesting new features. It has a novel backup extruder functionality called Relay Mode that enables a standby extruder to take over should a clog or malfunction happen with the first extruder. Extending uninterrupted printing even more is a new auto filament spool switch-over feature that detects imminent material outages and loads the next of four 8-kg spools.

Elegoo Unleashes the Centauri Carbon

Revealed at Rapid + TCT and joining the fray of compact, CoreXY-style 3D printers, Elegoo’s Centauri Carbon has big boots to fill. Although it has yet to make its official debut, a demo unit caught our eye at the Elegoo booth. When we sat down with Elegoo co-founder and vice president Kevin Wang, he positioned the new FDM as not only for hobbyists, but also for professionals.

Wang indicated that the printer Elegoo is aiming to release soon ticks all the boxes for the printing of tricker materials that require active heating and hotter print temperatures. Ease of use in the printing may come by way of magnetically attached nozzles, letting the user make quick swaps for a cleaner and more effortless experience jumping between such material types.

New Resin 3D Printers

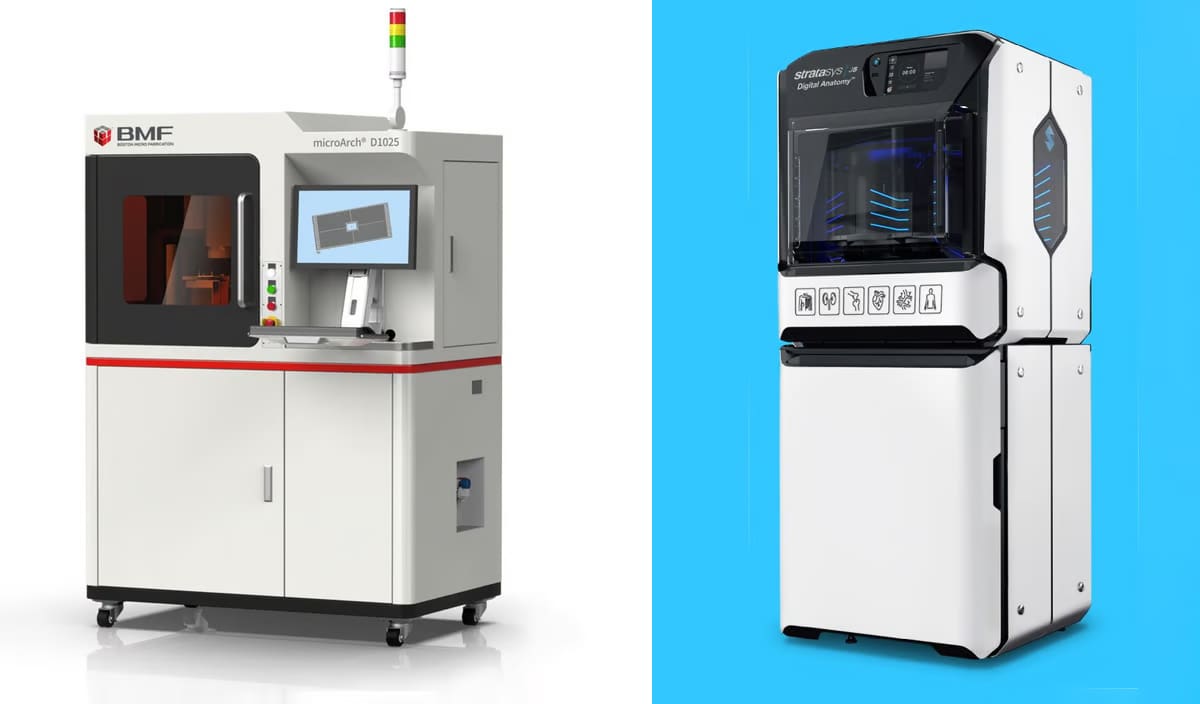

If your polymer needs are more in the resin variety, there were not many new launches at Rapid + TCT 2024. But we were impressed with the smaller and cheaper medical model printer from Stratasys, which should appeal to a much wider audience of healthcare professionals. Then there’s the new micro-stereolithography from BMF (Boston Micro Fabrications). All3DP sat down with BMF CEO John Kawola at the show for an in-depth conversion on the growing applications and opportunities for micro-stereolithography, which we’ll be publishing in the coming weeks.

Stratasys’ New Affordable, Compact 3D Printer for Full-Color Medical Modeling

Multi-color, multi-material anatomical modeling just got more accessible with the new J5 Digital Anatomy from Stratasys. The company just launched what could be described as a smaller version of its J850 Digital Anatomy 3D printer in hopes of luring more medical industry professional to adopt 3D printing.

If the J5 Digital Anatomy looks familiar, perhaps exactly like the company’s J5 MediJet, there’s an easy explanation. These two J5s offer near identical capabilities, build volume, and resolution, but with a few new features in the “Digital Anatomy” version. In fact, if you have a J5 MediJet you can upgrade it to become a J5 Digital Anatomy for $60,000. Digital Anatomy offers more materials, for example, a third biocompatible material called Digital ABS Plus, a second rubber-like material called ElasticoBlack, and four anatomy-specific materials: TissueMatrix, GelMatrix, BoneMatrix, and RadioMatrix for visibility under X-Ray and CT scan. These materials can be Gamma sterilized, which is also new.

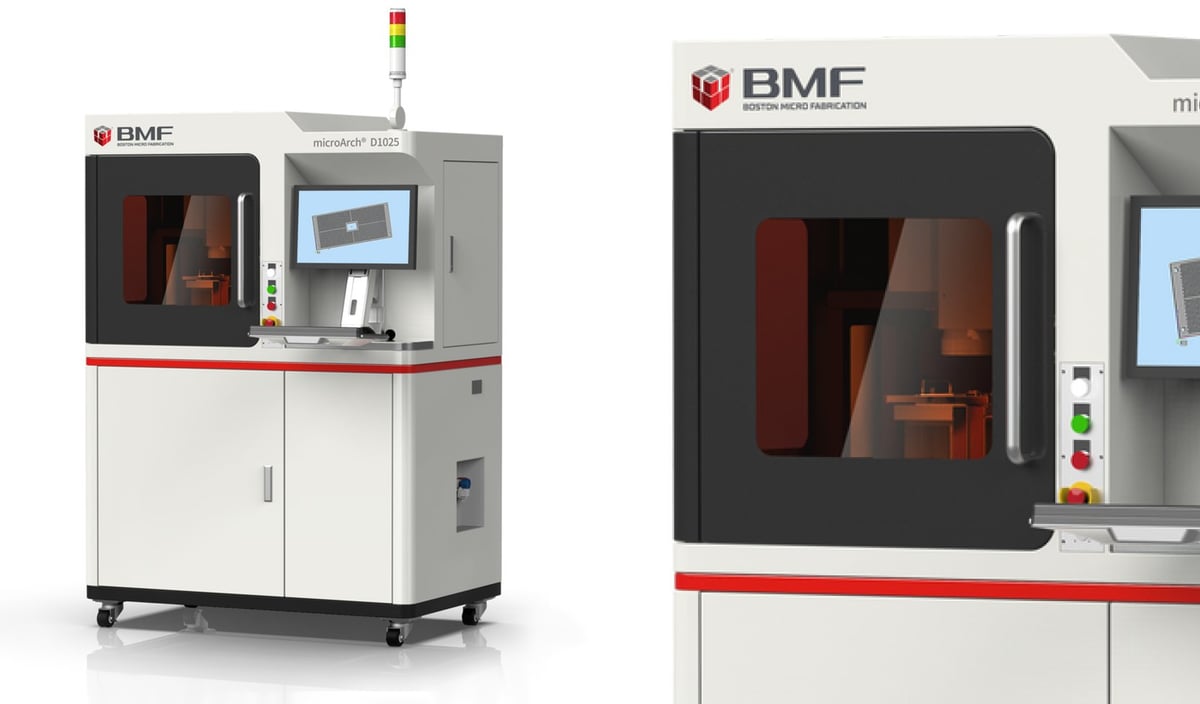

Meet the MicroArch D1025 High-Precision Micro 3D Printer

BMF showed off its latest machine, MicroArch D1025, which is powered by micro-stereolithography (PµSL) technology and based on BMF’s new hybrid resolution technology. The MicroArch D1025 prints in either 10 µm or 25 µm resolution, or in hybrid mode with both resolutions in the same print layer or in different layers.

Using the company’s own specially formulated liquid polymers (or the material of your choice), MicroArch D1025 features a highly automated process boosting accuracy.

New Metal 3D Printers

Although you won’t see the same type of massive metal 3D printing systems churning away at Rapid + TCT that you do at Formnext, the printer makers were on hand. The two words on everyone’s lips when it came to metal 3D printers was “entry-level” — with the notable exception of EOS, which boosted its laser power.

EOS Adds More Laser Power to its 290 Series

The new EOS M 290-2, launched June 5, has two 400-watt lasers and is offered alongside the full EOS M 290 Series — the original EOS M 290 build has just one laser. The 290-2 has the same build volume (250 x 250 x 325 mm), materials, and process parameter sets. Its dual lasers have full-field overlap.

An early adopter of the EOS M 290-2, Nordic-based 3D printing service company AMEXCI says it attained a 76% reduction in cost-per-part for a tested application against the original EOS M 290 build with just one laser. The EOS M 290-2 400W will be available for purchase beginning summer 2024 through EOS and its authorized partners.

Colibrium Additive Launches Entry-Level Electron Beam Melting

With the new, smaller titanium EB-PBF, Spectra M, Colibrium Additive – a GE Aerospace company – hopes to lure more medical device makers to additive manufacturing.

Colibrium Additive launched Spectra M at the event, which is latest addition to its Spectra portfolio of electron beam melting (EB-PBF) metal 3D printers printers is a response to additive manufacturers interested in a smaller build volume, the company says. Its smaller build volume makes the Spectra M an attractive entry option for additive users in the medical and orthopedic implant industry looking to further reduce cost-per-part and additive production costs, according to Colibrium, which is already one of the biggest names in EBM technology. When US industry giant General Electric acquired the lone wolf Arcam AB and its EBM machines in 2016 it kept the Arcam name until April 2024, when GE launched a stand-alone additive manufacturing division called Colibrium Additive.

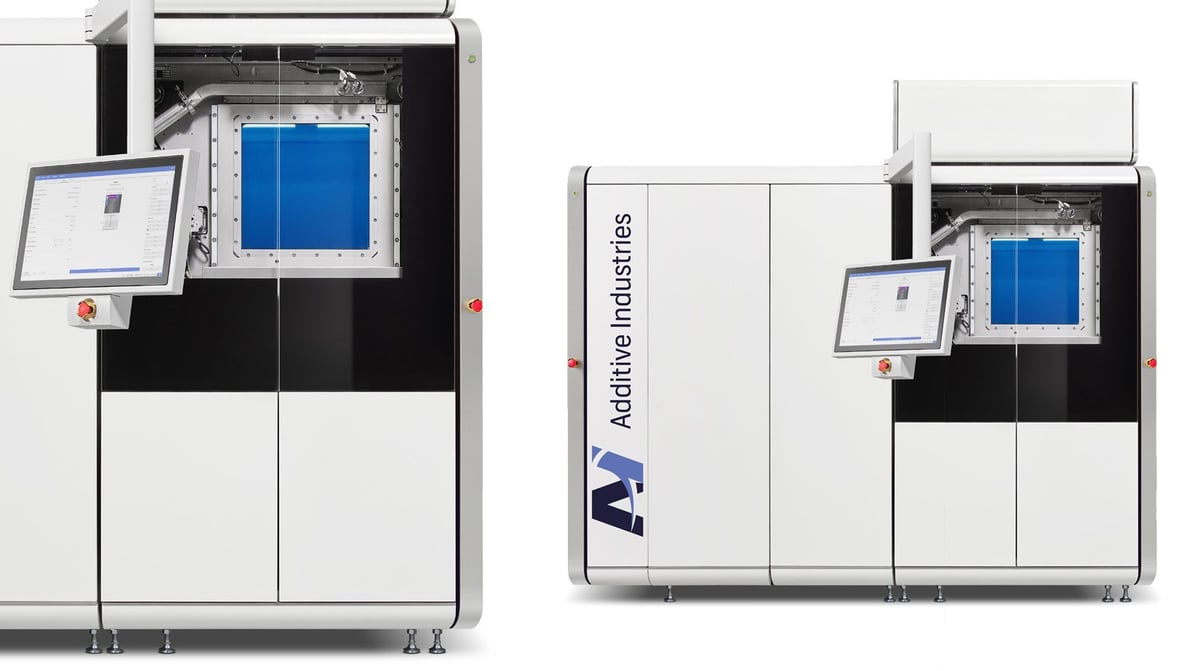

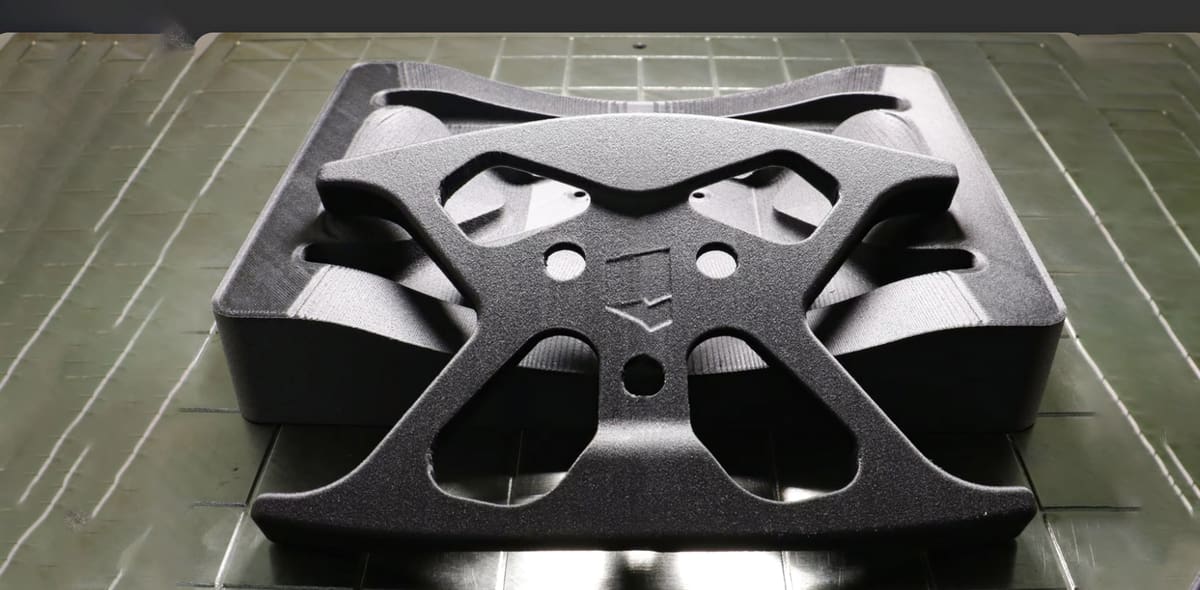

Additive Industries’ New Variable Print Volume Metal 3D Printer

A new mid-size metal laser powder bed fusion (LPBF) machine from Additive Industries boasts optional build envelope expansion. Netherland-based Additive Industries hopes its affordable and flexible new printer will be enough to attract more companies to adopt the technology.

The unique feature on the new MetalFab 300 Flex is its ability to grow its print volume. Shipping with a sizable 300 × 300 × 400 mm build envelope, customers can buy a license to expand that capacity to 420 x 420 x 400 mm on demand. Yet, starting at $730,000, the MetalFab 300 Flex is hardly an insignificant investment. In fact, it’s about six times more expensive than other “starter” LPBF machines, such as the One Click Metal MPrint+ at around $100K or the Xact Metal XM200G at around $150K. These two machines, though, have much smaller build volumes (about a third of the MetalFab 300 Flex) and less laser power.

Under the hood, the MetalFab 300 Flex has two 500-Watt lasers with the option for four lasers. These lasers are tuned to the base build volume with the flexibility to scan the fuller volume with the upgrade package, which is a monthly or lifetime licenses available to increase the scan field on-demand.

Spee3D’s New Titan, Overcoming the Challenges of Large-Scale Metal 3D Printing

The Spee3D team did not have its giant TitanSpee3D on hand at the show because it was just too big, but you could take a look at the machine’s product: massive metal parts.

All3DP had a chance to sit down with company co-founder and CTO Steven Camilleri just before the show to go in-depth into the technology behind large-scale metal 3D printing using the cold spray method.

The TitanSpee3D 3D printer from Spee3D is essentially the company’s existing technology in a large form with a few changes to the way it operates. For example, to better account for the weight of the large metal parts, it is not the deposition head that’s stationary, but rather the part is stationary and the cold spray nozzle works around it on a robot arm. Most of the new technology in the Titan is in its software and control systems that enable planing and remediating the various stages of the part build as it’s printing.

New Materials

A wide range of material makers and hardware makers launched new filaments, powders, and resins at the show. Most notable might be the new additions to Polymaker’s Fiberon and Panchroma families of filament.

Fiberon, and the name suggests, are composite filaments, suitable for both entry-level and professional applications, as the company’s Luke Taylor explained to All3DP at the event. Three new fiber-reinforced materials: PET-CF17, PETG-rCF08, and PPS-CF10, join the existing composite filaments. Panchroma is latest “aesthetic-focused” product family offering color consistency spool after spool. Select your Panchroma by surface finish — marble, satin, etc. — and then you choose your color, so there’ll be 190 different combination options of filaments available. The company’s new recycled carbon-fiber PETG is made from end of life wind turbine blades.

“It’s not like one is business and one is consumer because a lot of professionals are buying colorful stuff and a lot of consumers also need high performance stuff, so we wanted to to focus these two product families a little bit more,” says Taylor.

Carbon, Carbon, and More Carbon

Wait, Nexa3D makes FDMs? Oh, right, last autumn Nexa3D acquired high-temperature industrial FDM maker Essentium. The newest material for the former Essentium machines, HSE 180 and HSE 280, is called Xyon, which is a carbon fiber-filled … nylon? Actually, Nexa3D doesn’t say it’s nylon but it is positioned as a challenge to Markforged’s Onyx carbon-fiber nylon and is being marketed for both desktop, think Bambu Lab, and industrial applications.

“Xyon gives you the wonderful aesthetics that people love from from Onyx and Markforged, and from a mechanical standpoint, very similar,” a Nexa3D rep told All3DP at the show, “it’s gonna have a slightly lower modulus in exchange for a little bit more rigidity.” Xyon is prices at $130 a kilo compared to Onyx’s $190 a kilo.

Farsoon launched a new carbon-fiber reinforced PA6 polymer powder, FS6130CF-F, for its industrial SLS 3D printers. The company says FS6130CF-F reduces material waste and cost due to its 20% refreshment ratio.

New Metal Alloy

Alloyed, the UK custom metal material maker, released a new nickel superalloy ABD-1000AM, which is the latest in its range of alloys developed specifically for additive manufacturing. The company says compared to cast alloy Ni247LC, the ABD-1000AM alloy offers near-equivalent stress rupture life while allowing crack-free additive manufacture and heat treatment, enabling complex part design for components within the aerospace, power, automotive, defense and space industries.

Look for more new printer details here on All3DP as they become commercially available.

_____________________________

Never Miss Any News:

License: The text of "Top 3D Printers Launched at Rapid + TCT 2024" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.