Metal 3D printing uses a wide range of metal powders, wires, filaments, and even metal-infused liquid resin. Virtually any metal can be 3D printed, from stainless steel to nickel-based alloys, but in practice, about 10 are most commonly used.

The most common question about metal 3D printing is: Will my final part have the same mechanical characteristics as a machined, molded, or forged metal part?

The quick answer is generally yes, and sometimes even better mechanical qualities, but it depends a lot on which metal 3D printing technology you use (there are about 10), what type of feedstock you start with, post-processing, and part shape. In addition, comparisons depend on which aspects you focus on, such as tensile strength, strength at static load, high cycle fatigue, etc.

“Because more and more 3D printing metals are used in load-bearing structures, their mechanical properties have recently received great attention,” notes Gonghe Zhang, et al., in their recent study. These researchers concluded that because 3D printing is a layer-by-layer process, all metal 3D printed parts will have some degree of anisotropy in their strength. (Anisotropy refers to the possible weaker properties along the layers.) But these measures are predictable and manageable by how you print your parts.

One study showed that under certain conditions stainless steel parts made on LPBF 3D printers were up to three times stronger than stainless steel parts made by conventional techniques.

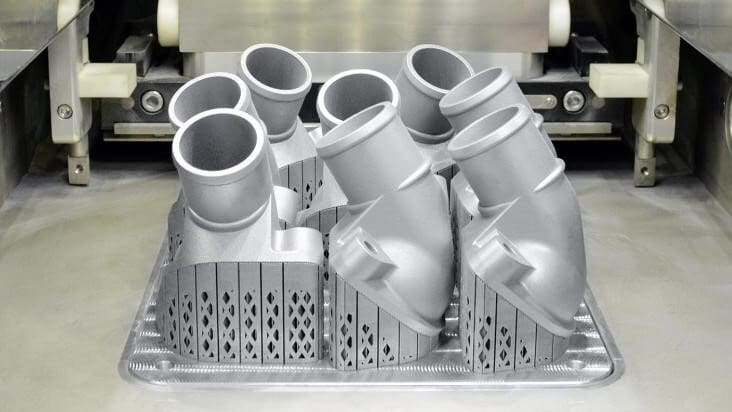

Overall, the material properties of metal parts made with metal binder jetting are equivalent to metal parts produced with metal injection molding, which is one of the most widely used manufacturing methods for the mass production of metal parts.

From functional aluminum prototypes to titanium hip replacements, metal 3D printing is proving its applicability to an ever-growing list of common uses.

Metal 3D Printing Materials

Why These Top 10?

As metal additive manufacturing evolves, so do the metal materials. The uniqueness of the 3D printing processes, from laser-based to binder jetting, have been shown to respond particularly well to new metal alloys and even metal powder particle sizes. We won’t dive into the details here, but these new ways of making metal parts have ignited a whole new industry in metal materials leaving customers to question their traditional metal choices.

As more industries transition key applications to 3D printing, new material opportunities emerge. Below we feature the 10 most-used metal categories today, taking some liberties in grouping some and breaking out others.

These 10 are just the starting points for what’s possible today as metal material producers keep pushing the boundaries and custom-tuning metal alloys for specific needs using specific metal 3D printing technology.

(The above infographic is not an exhaustive list of the sub-types of 3D printable metals.)

Stainless Steel: All-Rounder

Stainless steel, naturally, is not one material but many alloy varieties commonly used in 3D printing. The top two are are 316L and 17-4 PH, but you can also 3D print with 304L, 15-5PH, 420, 254, PH1, GP1, 630, and 410, plus custom blends produced by your material maker.

These steels are specifically designed for corrosion resistance. They are a lightweight and affordable metal ideal for 3D printing. Today, manufacturers 3D print stainless steel because it’s faster and cheaper than traditional methods for low-volume and intricate parts. For companies that need one end-of-arm tool or a just a few replacement parts, 3D printing is the go-to choice.

You can use stainless steel in almost every type of 3D printing, from economic filament for extrusion 3D printing on desktop machines to powder for binder jetting and laser powder bed fusion, and even resin.

Tool Steel: High Hardness & Wear Resistance

Tool steel, like stainless steel, comes in varieties boasting different levels of tensile strength, ductility, hardness, and other characteristics. Tool steels are a variety of alloy steels specifically designed for making tools. They are known for their hardness, resistance to abrasion, and ability to retain a cutting edge at high temperatures.This 3D printed steel is often used for making injection mold inserts, aerospace components, military applications, manufacturing tools, and in architecture and construction.

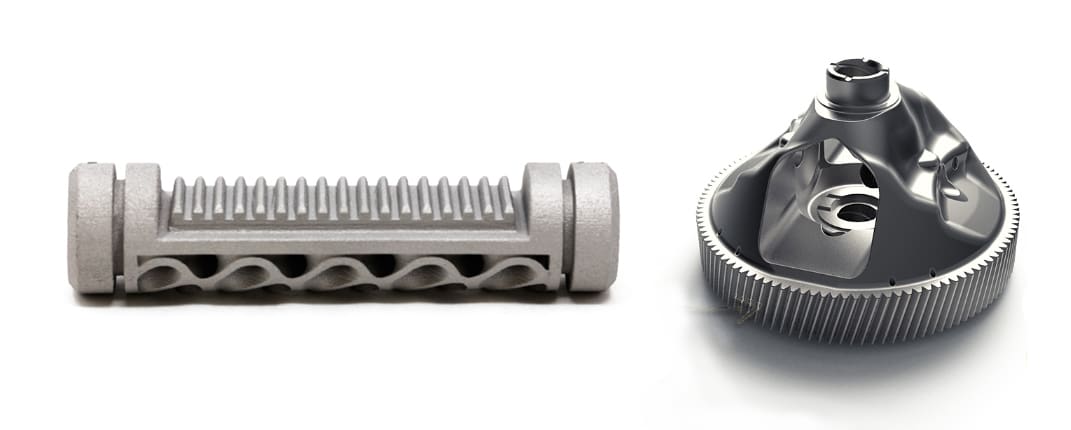

The main advantage of 3D printed tool steel is not only its strength, but the unique ability to create parts with internal channels (such as conformal cooling channels in molding tools) and lattice infills, that are impossible to manufacture with traditional methods.

3D printing steel is not intended to replace traditional methods in every application, but it can be the better choice for a wide and growing range of uses.

Low-Alloy Steel:

All 3D printed steels are alloys, but this category includes steels that have a low level, or less than 5%, of another element. These low-alloy steels are designed to achieve even higher mechanical properties and greater resistance to wear and corrosion compared to other steels. Low-alloy steels are commonly used in automotive, aerospace, and structural applications.

Low-alloy steels are heat treatable, adding to their manufacturing use flexibility.

Another type of steel gaining ground in additive manufacturing is maraging steel, which is not a low alloy steel since it can contain up to a 25% nickel, but we’re putting it in this bucket because of its application. Maraging steels have exceptional strength and toughness, making them suitable for aerospace and high-stress applications.

Aluminum: Lightweight & Corrosion Resistant

For aerospace, automotive, and industry, the lightweight and chemical-resistant attributes of aluminum parts are further enhanced by the design freedom and cost efficiency of 3D printing. Aluminum and aluminum alloy use in 3D printing is surging because this metal is economical and easy to 3D print.

As with most metals, aluminum is available as a filament, powder, or wire for various 3D printing technologies. There has been considerable R&D effort in aluminum alloys for additive manufacturing and today these materials are particularly tuned to take advantage of the unique melting processes of laser and electron beam additive manufacturing.

Aluminum alloys feature good chemical resistance, are very lightweight, and feature one of the best strength-to-weight ratios of any metal. Combined with silicon and magnesium, it’s the choice of many in the aerospace and automotive industry for its ability to withstand harsh conditions.

There’s such a range of aluminum materials to 3D print with that we created a complete aluminum guide, linked below.

Titanium: Lightweight & Biocompatible

Titanium – strong as steel but half as heavy – is a complex metal to work with, but it is practically born to be 3D printed.

Titanium has become one of the most commonly used metals in additive manufacturing, widely employed in aerospace, joint replacements and surgical tools, race cars and bicycle frames, electronics, and other high-performance products.

Titanium and titanium-based alloys offer high mechanical strength, a high strength-to-weight ratio, and better corrosion resistance than stainless steels. It makes rockets and planes lighter, which saves fuel and increases payload capacity. In the aerospace industry, several titanium-based additively manufactured parts approved by the US FAA are currently in commercial and military use, with numerous other prototypes making their way toward certification. 3D printed titanium is prized for its low “buy-to-fly” ratio.

In the medical industry, 3D printed titanium implants have been successful across spine, hip, knee, and extremity applications due to the metal’s inherent biocompatibility and good mechanical properties combined with 3D printing’s ability to tailor porous structures enabling bone integration and mass customization for better patient outcomes.

There’s such a range of titanium materials to 3D print with that we created a complete titanium guide, linked below.

Copper: Electrical & Thermal Conductivity

3D printing with pure copper and space-age copper alloys is possible with a range of metal 3D printers and services. You can create quick copper prototypes with copper filament on an FDM 3D printer and large copper rocket thrusters using copper alloys on laser powder bed fusion 3D printers. There’s also copper wire and copper resin, which is used for micro 3D printing.

In fact, copper plays a huge role in global sustainability objectives as a key part of electric motors, charging infrastructure, solar power, and batteries.

There’s such a range of copper materials to 3D print with we created a complete copper guide, linked below.

Nickel Alloy: Resistant to Extreme Environments

Nickel-based alloys and “superalloys” are known for their excellent high-temperature strength, corrosion resistance, and oxidation resistance. These alloys maintain their strength and mechanical properties at elevated temperatures. They are commonly used in demanding applications such as aerospace, gas turbines, chemical processing, and marine environments. In recent years, these alloys have also gained popularity in 3D printing, particularly in the aerospace and automotive industries.

You may hear the term Inconel when it comes to nickel alloys. Inconel is a trademarked name for a family of nickel-chromium-based superalloys, including IN625, IN718, and IN939.

Nickel alloys are generally more expensive than other materials like steel and aluminum, and may not be suited for cold-temperature applications.

Bronze: Wear & Spark Resistant

Although bronze is an alloy of copper, it deserves its own entry for its wide range of industrial applications, as well as decorative arts, such as statues, trophies, and jewelry.

In industrial settings, bronze is often important for its spark-resistant qualities in settings where the generation of sparks could pose a fire or explosion hazard. Mining, defense, and aerospace are all sectors requiring bronze tools and components, like this aluminum-bronze gunner’s ratchet (pictured above) 3D printed using cold spray technology by Spee3D. Aluminum-bronze is also highly corrosion resistant and especiallyprized in marine environments.

Bronze is also mixed with other metals and materials for specific additive manufacturing applications. Phosphor bronze, which contains copper and various amounts of tin and phosphorus, is highly resistant to fatigue and wear. Silicon Bronze consists of copper, with a small amount of silicon and other elements like manganese, tin, or zinc, and used for pump and valve components, as well as in the chemical and food processing industries. Nickel bronze is known for its excellent corrosion resistance while also having good thermal and electrical conductivity.

Cobalt Chrome: High-Temp & Corrosion Resistant

3D printed cobalt chrome offers a high strength-to-weight ratio and excellent corrosion resistance, making it a good material choice for aerospace components and industrial machinery. It’s also biocompatible and often used in orthopedic implants, dental prosthetics, and medical instruments where long-term contact with biological tissues is required.

Cobalt-chrome alloys can be processed using additive manufacturing techniques such as selective laser melting (SLM) or electron beam melting (EBM). This allows for the production of complex geometries and customized parts with minimal material waste, making them attractive for industries adopting advanced manufacturing technologies.

Gold & Silver: Beautiful & Biocompatible

3D printed gold and silver, like other precious metals, are growing in popularity. Although custom jewelry typically may involve a 3D printed casting mold, directly 3D printing with gold and silver powder is done using laser bed powder fusion (LBPF) technology and binder jetting is another less used option.

Gold and silver can form alloys with a wide range of other metals, enhancing their properties for specific industrial applications.

The metal used in 3D printing is not 100% gold because pure gold is a soft metal that requires alloying in order to make it the durable material that we’re familiar with. For this same reason, the intense lasers in LBPF used for sintering steels would nearly vaporize gold.

According to EOS, a German manufacturer of all kinds of metal printing technologies that partnered with Cookson Precious Metals to improve the gold printing process, the best results for gold jewelry require a specialty machine with an appropriate laser and suitable gold powder that can hold up against the power of the laser.

Gold has several industrial applications in space tech, renewable energy, and manufacturing for its electrical conductivity, resistance to corrosion, and biocompatibility.

3D printed silver parts also use laser powder bed fusion or binder jet 3D printer, but other niche methods, such as silver photopolymer slurry molten metal extrusion using a silver wire are also showing potential.

Custom jewelry companies and high-end fashion houses are adopting 3D printing with silver and gold powder because it accelerates custom part production for small to medium volumes. In one print run, companies can print a dozen rings or more where each one is different. There’s also the ability to print only on-demand, which eliminates stock and enables jewelry companies to react quickly to the latest jewelry and fashion trends.

Although silver is perhaps most commonly associated with decorative items, it does have various industrial uses in including in solar panel, medical, and microwave applications.

License: The text of "10 Most Used Metal 3D Printing Materials" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.