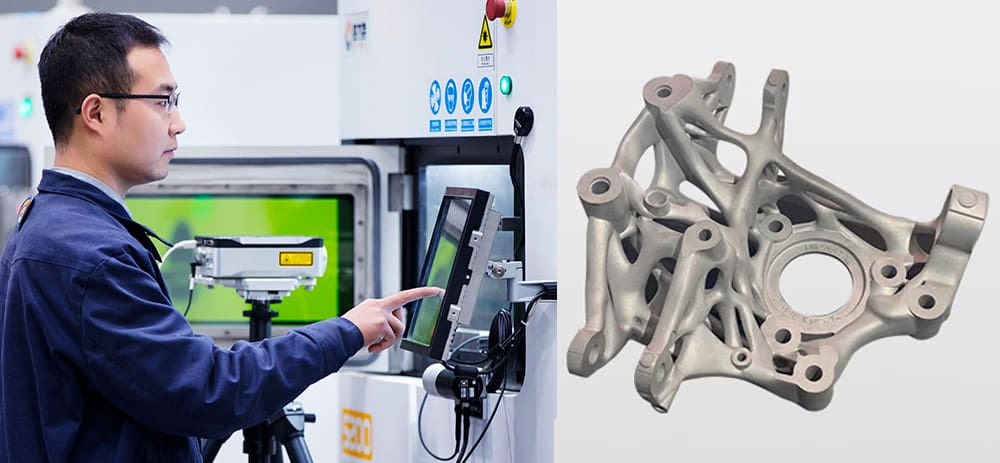

Demand for metal 3D printing has skyrocketed thanks to advancements in technology, new metal materials, the lower price of metal 3D printers, and more recently the need to dodge tariffs by getting parts produced closer to the point of need. But still, for many engineers and industrial designers, investing in their own metal 3D printers is not in the cards.

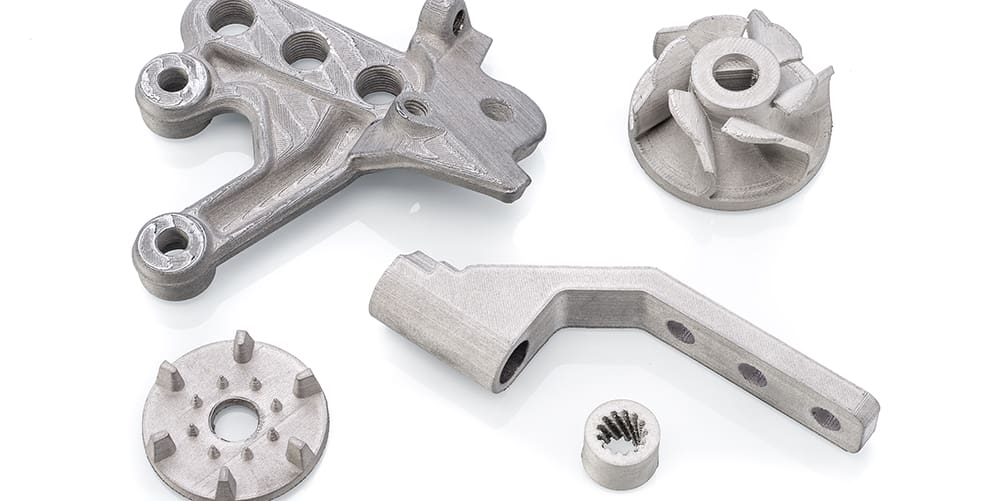

Fortunately, there’s a growing number of contract manufacturers with fleets of metal 3D printers and the expertise necessary to custom print your part, whether it’s one prototype, hundreds of final functional tools, a unique spare part, or a work of art. You don’t even need to know much about metal 3D printing to get parts custom made to your specs.

The metal 3D printing industry is projected to reach a value of $3 billion by 2030, in part because metal 3D printing has proven to be faster and cheaper than traditional metal manufacturing methods for specific yet common applications, such as single replacement parts, low-volume of parts, injection molds, and prototypes.

But the real advantage of the technology is in producing complex shapes with attributed unattainable by other methods, allowing for consolidated assemblies into fewer parts, space savings, reduced weight, and enhanced performance.

Entire manufacturing sectors, such as the shipping industry, are turning to metal 3D printing in order to offer digital inventories (rather than physical inventories) of common replacement parts that can be ordered and 3D printed anywhere in the world.

In this guide, we not only present our picks for the top companies offering metal 3D printing services, we also cover:

| Company | Service Area | Metals | Technology | Services | Response Time |

|---|---|---|---|---|---|

| Craftcloud | Global | Steel (stainless, maraging), aluminum, copper, titanium, brass, Inconel 625, precious metals, metal filament | Laser powder bed fusion, metal binder jetting, metal filament | Prototyping, design consultation, post-processing, 3D modeling, CNC, injection molding, sheet metal fabrication, lost-wax metal casting | Instant quote. Product from 5 days. |

| Materialise | Global | Stainless steel, aluminum, titanium, Inconel IN718, precious metals | Laser powder bed fusion | 3D modeling, white labeling, manufacturing partnerships, design consultation | Instant quote. Product from 11 days. |

| FIT | US, Europe, Japan | Titaniums, alumiums, aluminum alloys, Iconel, stainless steels | Laser powder bed fusion, wire arc additive manufacturing, electron beam melting, cold spray | 3D modeling, design for AM, concepting, prototyping, iterative design, post-processing, CNC, assembly | Instant to same day quote. Product from 5 days. |

| Forecast 3D Powered by GKN | Global | Stainless steels, iron alloys, nickel alloys, aluminum alloys, copper alloys, dual phase alloys, custom alloys | Laser powder bed fusion, metal binder jetting | Design for AM, post-processing, 3D laser scanning | Instant quote. Metal product from 11 days, polymer product from 1 day. |

| Oerlikon AM | Europe, US, China | Aluminum alloys, nickel alloys, cobalt chrome, steels (maraging, stainless, tool), titanium | Laser powder bed fusion | Custom materials testing and development, prototyping, design and application engineering, industry expertise, post-processing | NA |

| Protolabs | Global | Steels (maraging, stainless), aluminum, Inconel, titanium, cobalt chrome, brass | Laser powder bed fusion | Post-processing, CNC, learning materials, 3D laser scanning, anodizing, chrome plating | Instant quote. Product from 1 day. |

| Quickparts | Global | Maraging steel, stainless steel, nickel alloys, titanium, aluminium | Laser powder bed fusion | Prototyping, design and application engineering, industry expertise, post-processing, machining, injection molding, urethane casting | Instant quote. Product from 2 days. |

| Addman | US | Steels, titanium, aluminum, copper, tungsten, cobalt chrome, magnesium, nickel alloys, niobium alloys, rhenium, tantalum | Laser powder bed fusion | Design for AM, post-processing, testing and quality assurance, reverse engineering, custom material development, injection molding, CNC machining | NA |

| Xometry | Global | Stainless steel, aluminum, titanium, Inconel, cobalt chrome | Laser powder bed fusion, metal binder jetting | Additive manufacturing, CNC machining, sheet and tube fabrication, plastic and metal part production, supply-chain solutions | Instant quote. Product from 5 days |

| BLT | Global | Steel (stainless, tool, high-strength), titanium, aluminum, copper, tungsten, Inconel | Laser powder bed fusion, wire arc additive manufacturing | Testing and quality assurance, post-processing, design for AM, process and software developmen | Product from same day. |

Best Metal 3D Printing Services

Now, let’s have a look at our favorite top performers. We used the following evaluations to make our picks:

- Services: Offering additional services, such as design, on top of printing demonstrates the company’s ability to serve various customer groups and guide you to the best solution for your needs.

- Service area: A company that can serve a wider area is a stronger contender.

- Range of materials: With more materials comes more expertise on which materials are best for your application.

- Range of technologies: There’s more than one way to print metal. Companies that offer a range of technologies can give you price, speed, and quality options.

- Lead and quote response time: You can’t rush quality, but faster response and lead times are guaranteed to keep customers happy.

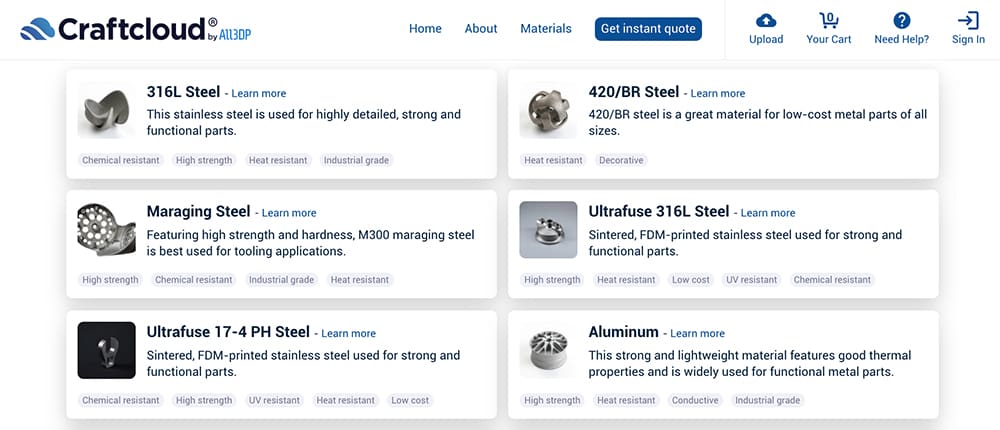

Craftcloud

Craftcloud is more than just a metal 3D printing service. It enables you to compare prices and services from different custom manufacturers and find the right one at the right price.

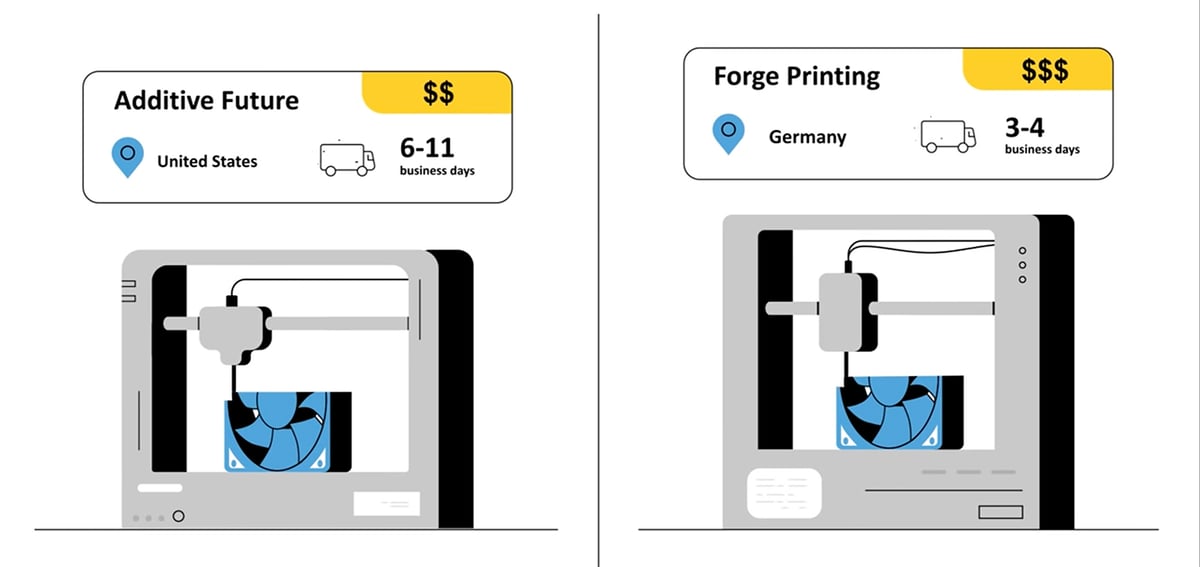

With over 150 partners around the world, Craftcloud presents you with the best services in terms of price and lead time, with no additional fees. Having a geo-flexible manufacturing strategy — where you can print the same parts at a wide range of manufacturers around the world — you can lessen supply chain disruption, shipping, and import fees.

If you have a digital part file, you can simply upload it to Craftcloud. Quotes are generated in real-time based on your uploaded models, materials, and location. Using the platform is as simple as any other 3D printing service, but with many more options available, we’ve found. For example, you can choose the manufacturing partner by price, speed, location, and see customer reviews of each partner.

For your metal parts, you can choose from common metals like aluminum, titanium, and steel, or precious metals like sterling silver and gold. Depending on the material you select, you can also request a particular finish, such as polished or matt.

Other helpful features of Craftcloud are its resources and support staff. If your part isn’t suitable for printing, or you simply don’t have a design, experts and professional partners will help you get your design off the ground. And if you’re having trouble with the order or delivery processes, you can reach out to the Craftcloud team regardless of which manufacturer you’ve selected to print your part.

What We Like: What’s particularly good about Craftcloud is that it’s not just one manufacturer; it’s a network of more than 150 manufacturers, and you get to choose which one best suits you. They don’t hide who is actually producing your part, but you’re not handed over to them for customer service, Craftcloud manages everything from ordering to delivery to your final satisfaction with your parts.

Materialise

Based in Belgium with a manufacturing facility in Michigan, Materialise is best known for its 3D printing software, yet also offers both a rapid prototyping and on-demand additive manufacturing for volume production. Both options offer metal.

The Materialise portal features an automated check for the 3D printing suitability of your part and optional consultation with engineers. Their services are structured by industry, having set up a department for each major client group, including healthcare, optics, and jewelry.

There are also several business integration solutions, like manufacturing partnerships and white-label integration. This makes it easy for your firm to partner with Materialise to provide parts and services for your customers under your own name. If you sell your own digital 3D models, there is even an integration partnership that enables you to offer your customers a way to order a print of your models from Materialise, and you get a cut.

What We Like: What’s particularly good about Materialise is the amount of information they provide in advance. They share a lot regarding the technology used for each type of metal, the maximum sizes of objects that can be printed, their estimated delivery times, and useful tips on how to design your 3D model.

The company also provides full service consulting, so you can bring them your basic questions or your complex problems and they’ll let you know if metal 3D printing even makes sense for your part or your business.

Certifications: ISO 9001, ISO 13485:2016, EN 9100, ISO 14001:2015, ISO 27001

Case Study: One project that shows off the depth of Materialise’s services was a 3D printed titanium bridge for a new pair of smart glasses. The manufacturer, Vuzix Shield, worked with Materialise to find a solution to stabilizing the frames. Having identified the main issue — the rigidity of the top of the frame — and knowing what was required of the design — strength, stability, and style — the two soon began testing and evaluating materials. 3D printed titanium is famously strong and lightweight, making it an obvious choice.

FIT

FIT is a German additive manufacturer that’s been delivering custom metal parts and components globally for more than 20 years. They have facilities in the U.S., Japan, Russia, and Europe.

When it comes to metals, FIT offers a wide range of materials and technologies and several conventional production technologies as well. Together with their development expertise for 3D printed components and their extensive post-processing possibilities, they offer metal additive manufacturing for everything from medical implants and aerospace parts to spare auto parts and sculpture.

What We Like: FIT shines when it comes to expertise and has 250 employees on the job. They boast that they make the entire value chain of 3D printing available to customers – from product design through to engineering, production, and post-processing. As a development and implementation partner, they’re not an upload-and-order shop like Sculpteo or Protolabs. They’re more of a guide for additive manufacturing that can show you the best path to reach your project goal.

They provide individual consultation and training services on the topic of additive manufacturing if you need to bring your whole company on board. And, because they know additive manufacturing is not always the best solution in every single case, they also have numerous conventional technologies, such as CNC milling, injection molding, vacuum casting, or elastomer manufacturing.

Certifications: ISO 9001, ISO 13485, FDA,TISAX

Case Study: Ascent Aerospace approached FIT with a problem: Its drill jig was heavy, unwieldy, and consisted of several solid aluminum plates that were conventionally milled and joined. The jig was used to precisely drill holes for the guide rails of airplane landing flaps. FIT presented a lighter and more ergonomic design that was still able to be integrated into the existing manufacturing process and available quickly. The resulting part was 45% lighter, one piece, 3D printed in aluminum alloy (AlSi10Mg), and delivered in 30 days.

Forecast 3D Powered by GKN

Founded in 1994, Forecast 3D grew from a single-car garage to occupy more than 49,000-square-feet of a Carlsbad, Calif., manufacturing space featuring more than 30 pieces of additive and subtractive manufacturing equipment. Then the huge metal powder supplier GKN, purchased the 3D printing service and it became Forecast 3D Powered by GKN.

GKN specializes in metal powder production and metal, as well as design and manufacturing services. Together, the group offers one of the world’s largest global networks of industrial 3D printers serving clients in the aerospace, automotive, industrial, healthcare, defense, electronics, and consumer products markets. From an intricate surgical device to a large intake manifold for a jet engine to a production run of 4,000 metal parts, GKN has the technology and experience to deliver, they say.

There’s no instant quote option, but if your register on the site you can begin a dialog with their customer care folks to narrow down your needs.

What We Like: The undeniable strength of GKN Additive is it’s expertise in metal materials and the specific metals that are and can be 3D printed. If you’re not sure which metal you need or you know your application may require a custom material, GKN has the expertise to share.

Certifications: ISO 14001:2015, ISO 50001:2018, ISO 45001:2018, IATF 16949:2016

Oerlikon AM

Oerlikon AM is a division of the Swiss technology giant OC Oerlikon that was set up in 2016. Although it has production centers in Europe, the U.S., and China, it recently consolidate its AM production to Huntersville, North Carolina, since the U.S. is its largest growth market.

In materials, Oerlikon relies entirely on its alloy powders, developed in-house. Although the selection isn’t quite as varied as with some other services, having their own proprietary materials allows Oerlikon to make precise material recommendations for your specific needs. The on-site material production allows them to even create customized materials for their customers. They’re also able to provide in-depth engineering and design consulting from concepts to production, in addition to post-processing and testing services.

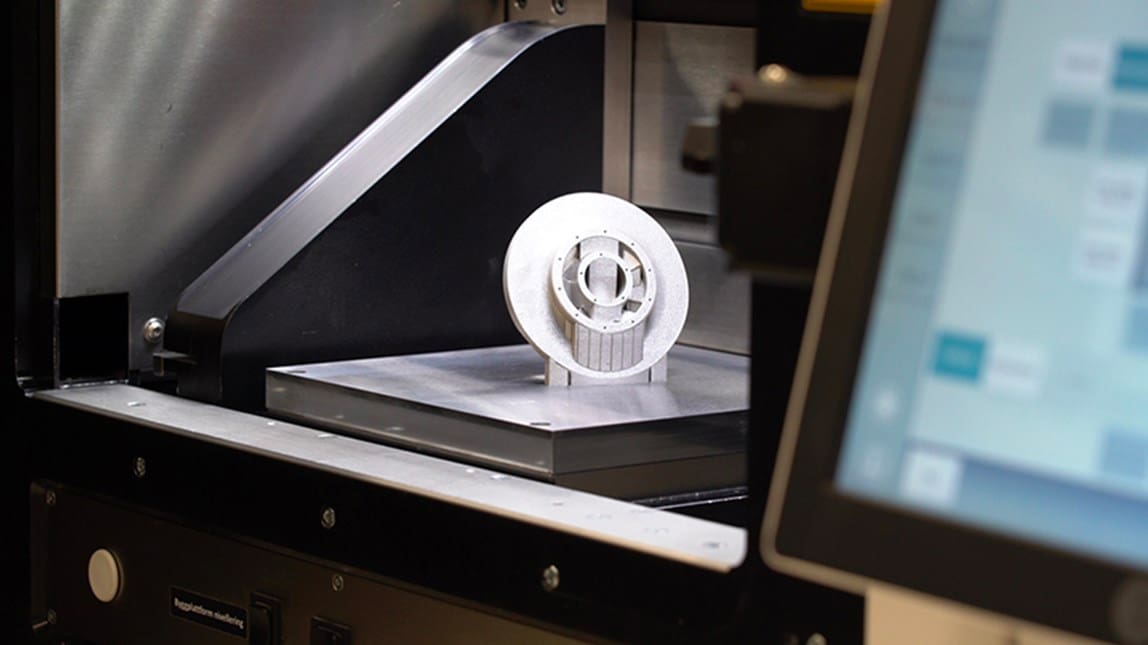

The company has a varied fleet of metal 3D printers including 11 EOS machines of various sizes, three Trumpf TruPrints, 5 TruPrints, Concept Laser M2s, and a 3D Systems DMP Factory 500.

What We Like: Although Oerlikon has extensive experience in additive manufacturing across various industries – like aerospace and automotive – it has a narrower service scope than some other providers. That’s not a bad thing, though – they know exactly what they’re good at and are making the most out of it. One big focus, the company says, is additive manufacturing in the semiconductor industry.

Certifications: ISO 9001, ITAR

Protolabs

Minnesota-headquartered Protolabs makes their claim to fame with speed. The company promises very short lead times. They also have a digital quoting platform, which provides not only instant quotes but also design analysis — to make sure what you want to print is printable. Back in 2021, Protolabs joined forces with the online manufacturing platform Hubs, which has greatly enhanced its production capabilities. The Hubs division changed its name to Protolabs Network in 2024, but its services stayed the same.

In Nov. 2023. Protolabs opened a new 120,000-square-foot facility in North Carolina primarily dedicated to metal 3D printing.

Although Protolabs doesn’t provide 3D modeling services, if you have questions after the online quotation process, their expert engineers will walk you through your material and design choices, but this option is for companies that already know exactly what they’re looking for and want the convenience of a user-friendly online platform.

In addition to 3D printing, the company offers CNC machining and sheet metal fabrication services.

What we like: Protolabs offers a suite of services around the certification of your part so you feel confident that it will perform as intended, including material traceability, which can be very important in regulated industries. When you receive your metal part you can also get a detailed analysis of the metal powder used and an inspection of the part’s mechanical properties.

Certifications: ISO 9001:2015, AA9100D, ITAR

Quickparts

Quickparts is a full-service additive manufacturer that grew from printer maker giant 3D Systems. Based in Seattle, Washington, with a global presence, they offer printing and consultation services and can also provide additional services like CNC machining and casting patterns.

Because of its 3D Systems pedigree, Quickparts only offers metal 3D printing on 3D Systems’ laser powder bed systems machines, which isn’t necessarily a drawback considering that 3D Systems are some of the most popular machines on the market.

They have experienced engineers, dedicated project managers, and five well-equipped facilities to handle your low-volume production, although for mass-production, it relies on its casting and injection molding services.

The company has engineers stationed in several facilities around the globe and has decades of manufacturing experience.

What we like: Although we haven’t tested it out for ourselves, we like the idea behind Quickpart’s “Lifecycle Support.” The offering promises to provide you with a dedicated program manager to oversee your part from design to prototype and through to the final parts and evening scaling up to full production.

Certifications: ISO 9001:2015, ITAR

Addman

A relative newcomer to 3D printing as a service, Addman, founded in 2020, seems to have jumped in with both feet, acquiring a stable of existing additive and traditional contract manufacturing companies to quickly build up its machine inventory and service menu. In 2022, it acquired Castheon, a leading provider of metal additive manufacturing technologies for mission-critical space applications.

The Florida-based company offers metal and polymer 3D printing, CNC machining, and other post-processing at six facilities across the U.S.

When it comes to applications and industries served, Addman says it covers aerospace, medical, energy, and industrial and produces everything from rocket thrusters to tooling to mission-critical hinges. They’ll even send you a free part sample.

The company’s metal 3D printing is carried out on an enviable collection of the industry’s top laser powder bed fusion printers, including a Velo3D Sapphire, a collection of EOSs, and machines from 3D Systems, GE Additive, and Renishaw. Engineers on staff can guide you to the right machine, materials, and post-processing for your application. In fact, the engineering consultancy can start with your part requirements and develop your part’s application-specific design, material, and manufacturing process.

What we like: Throughout the Addman website, you’ll see 3D printing compared to the other manufacturing technologies that the company offers, but in a very matter-of-fact way. They let you know that they believe CNC machining is better for your fixture if you need very precise geometries but 3D printing is the better choice if you have a more complex geometry.

Certifications: ISO 9001:2015, AS9100D, ITAR, ISO 13485:2016, ISO 14001:2015, SEP: ISO 50001

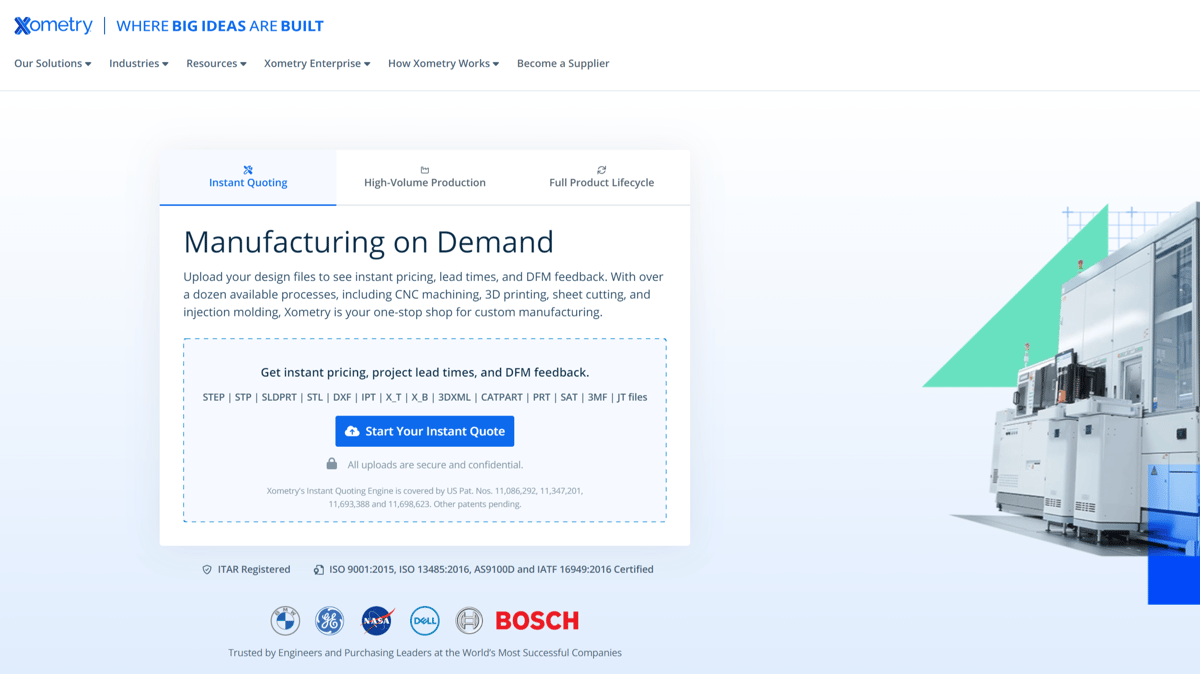

Xometry

Founded in 2013, Xometry has become one of the world’s largest online 3D printing service, utilizing a nationwide network of manufacturing partners. It provides instant quotes for many projects filtered by production method, material, and lead time. Beyond 3D printing, Xometry offers a wide range of pro-manufacturing services like CNC machining, sheet metal parts, injection molding, supply-chain solutions, and services you need for high-volume production.

When it comes to 3D printing metal parts, Xometry has the most common technologies in store, namely metal binder jetting and direct metal laser sintering. Material-wise, you get a broad choice of materials like stainless steel, aluminum, titanium, Inconel, or copper, with a variety of finishes.

Using the service is straightforward, but registration is mandatory to get a quote from Xometry. Also, their price transparency isn’t as open as, for example, Craftcloud’s overview of production partners. Nevertheless, big business clients find Xometry’s features to their liking. Its Instant Quoting Engine, geared towards industrial clients, includes a printability check and part certifications.

Certifications: ISO 9001:2015, ISO 13485, ITAF 16949:2016, AS9100D, ISO 14001:2015, also ITAR/EAR Controlled Handling

What we like: With additive manufacturing being just one of its services, Xometry offers a vast range for any professional client.

BLT

Founded in 2011, BLT serves the metal additive manufacturing market primarily in China, but they deliver for international clients as well. BLT has established itself, particularly in the aerospace industry, delivering monthly parts for such giants as Airbus since 2021. All in all, the company has clients in Asia, Europe, and the US.

They’re not just about airplanes, though. BLT serves a wide variety of other industries, including automotive, medical, dental, and artistic segments. Recently they established an R&D center to explore a range of industries that make use of metal additive manufacturing technologies.

With its proprietary printers, BLT is able to harness several technologies for various applications, including selective laser melting, laser solid forming, and wire arc additive manufacturing. They offer five or six available materials and are the only company on this list printing with tungsten.

On top of metal 3D printing, BLT offers a slew of additional services, including design consultation, testing, and quality assurance. BLT is even able to provide its customers with customized process parameters and software solutions that are tailored to the customer’s specific needs.

For those active in Chinese or wider Asian markets, or the aerospace industry, BLT offers a comprehensive service package.

What we like: Because BLT is a metal 3D printer maker as well as a print service provider, the have expertise in their machine’s capabilities and the ability to alter the machine to your needs if required. The company offers some of the largest metal 3D printers ever made, so naturally, volume is no problem for BLT.

Certifications: Nadcap, ISO 9001:2015, AS 9100D/EN9100:2018, GJB9001C-2017

Tipps on 3D Printing Metal Parts

How to Order Metal Parts

If you’re unfamiliar with metal 3D printing, aim to familiarize yourself with the material options and types of printer technology before ordering. Of course, the experts at any of the printing companies below can also guide you through the options, but in general, you’ll want to consider the mechanical and aesthetic qualities that your final parts must have. These will inform which material is used, the printing process, and the post-process finishing.

For example, if you need a functional metal prototype, such as a bicycle crank, to test under real-life conditions, you’ll want a metal that meets your strength requirements but is still affordable, such as tool steel. However, if you’re looking for a final functional part, such as for an induction coil, that needs high-heat and corrosion resistance, you’ll want to consider copper.

Quote, Costs & Processes

Metal 3D printing services have various business models. Some will work with you to design or redesign your part and hold your hand through the entire process. This is ideal if you’re new to metal 3D printing. For instance, if you have one broken but essential metal factory machine part you need to be recreated faster and cheaper than by machining or casting, but you don’t have a digital file, look for a full-service provider.

But if you’ve 3D printed metal before or your in-house metal 3D printers are at capacity and you have a digital file, you may want a service that enables you to simply upload your digital model, select a few parameters and get your part in the mail in a few days.

In general, almost all metal printing services offer an online quoting platform, or they will provide a quote after their metal printing experts evaluate your project. The more complex your project, the more personalized consulting you may need.

If you want to know exactly how much a metal part costs, we took four projects to several services to see who has the best price.

The Workflow

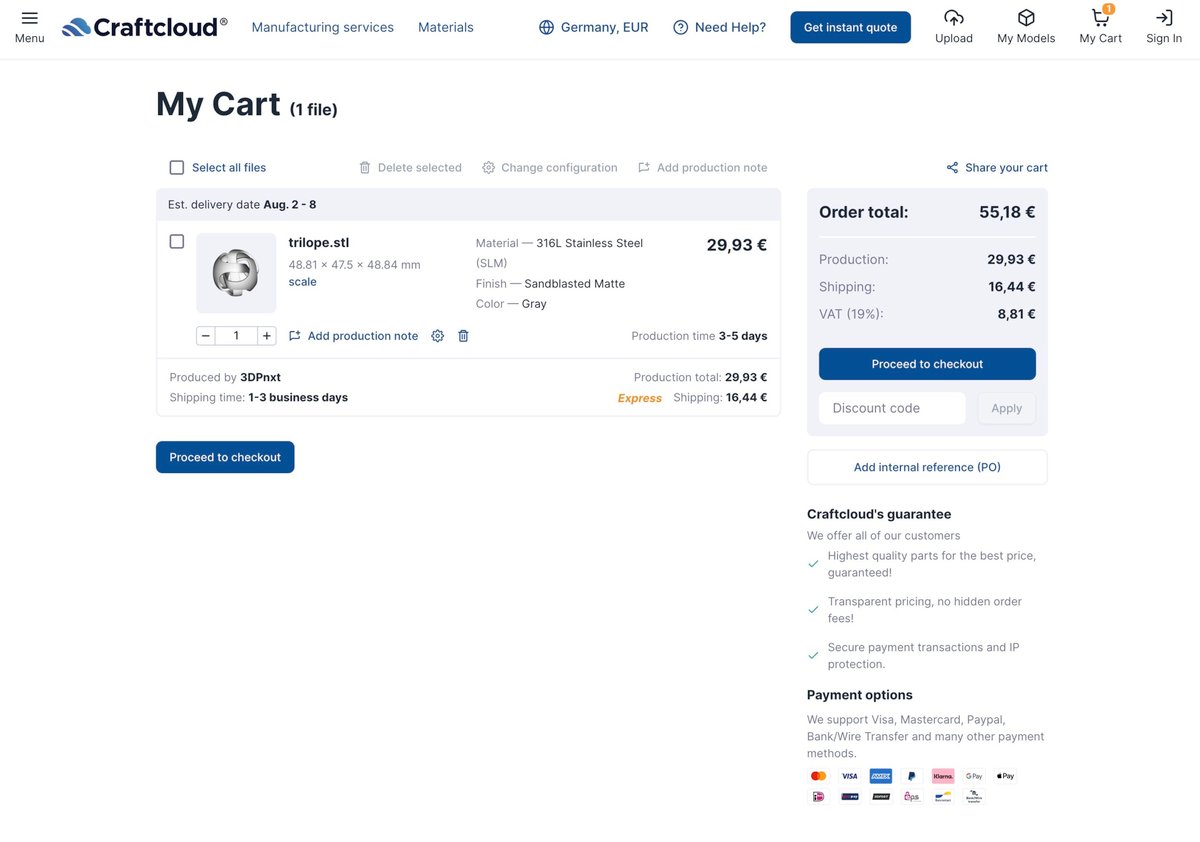

The majority of metal 3D printing services are very much alike to use. Due to its ease of use, we show you how to order a metal part through All3DP’s marketplace Craftcloud.

1. Create an account and sign in

You will need to have your 3D model ready. Most 3D printing services want you to register. Only a handful – like Craftcloud – allow you to use the service without making this step a prerequisite.

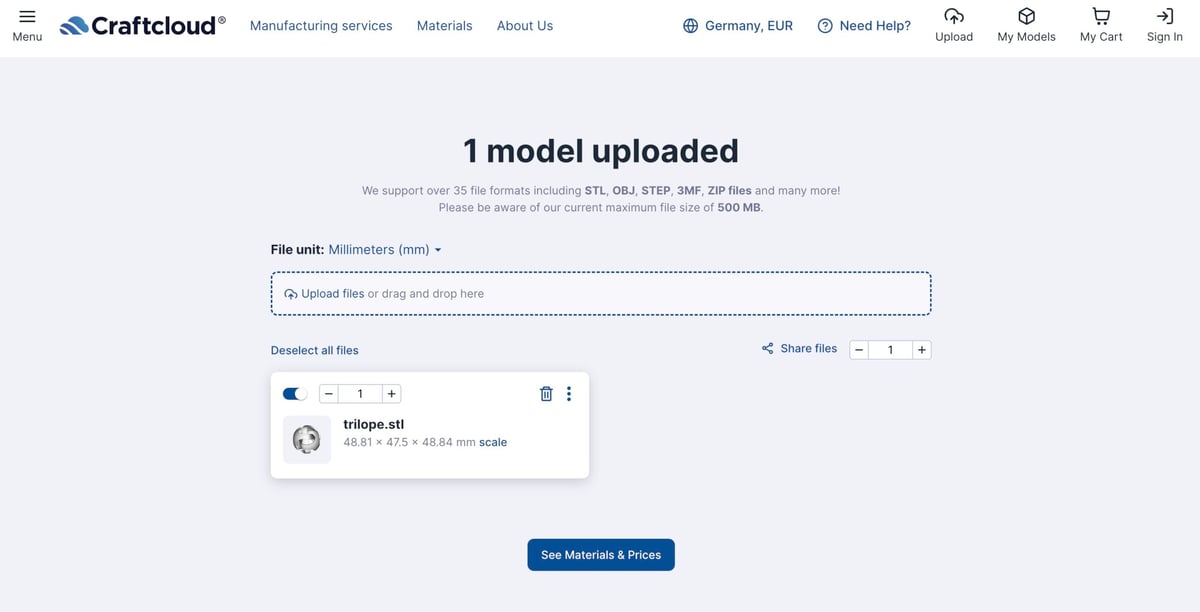

2. Upload your 3D model

Uploading is as simple as dragging the 3D print file into the browser. The upload takes a few seconds, while the service fetches the price estimates. In most cases, you will see the prices after 5-10 seconds.

If you have additional requirements, best reach out to their sales staff directly.

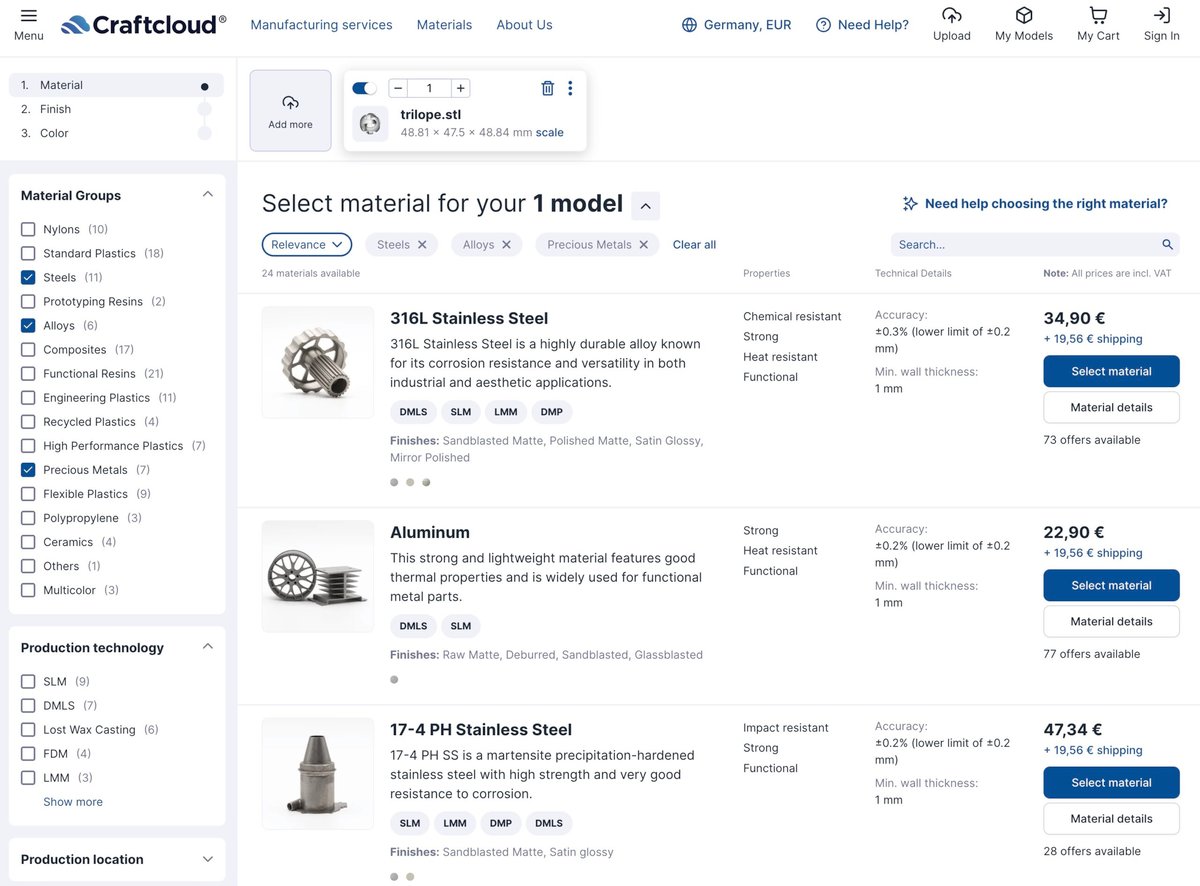

3. Choose your desired material and finishing details

Most metal services offer a wide variety of materials. The best 3D printing services will offer you not only a broad selection of materials but also different production technologies for you to choose from.

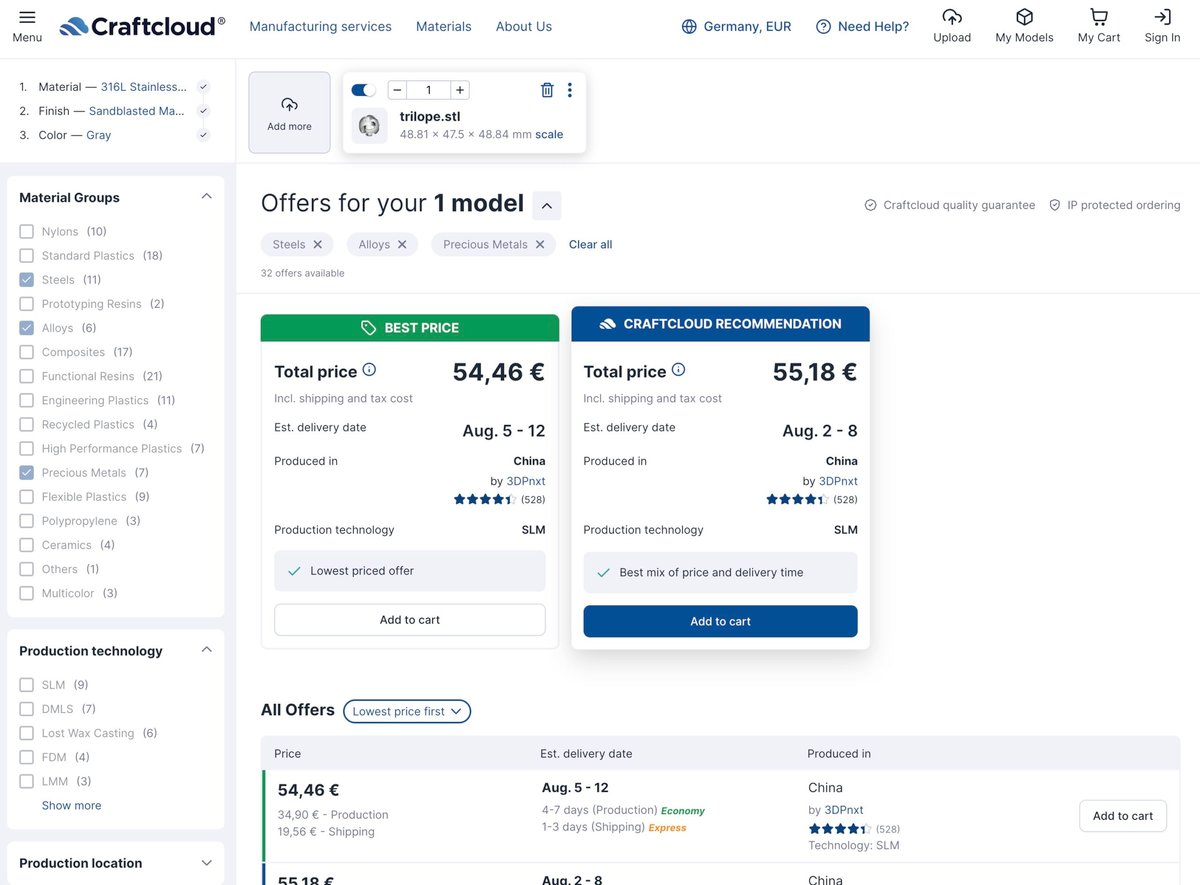

4. Review your pricing quote

The quote is generated either instantly or after expert evaluation. If you want full transparency, you should get offers from different manufacturing partners, as you can see in the image above.

5. Place the order

Once you have chosen the shipping method and placed the order, your metal part will be manufactured. You should also be able to save your parts so you don’t have to re-upload them again.

Which Metal Printing Method is Right for Me?

As we mentioned, you don’t need to know anything about metal 3D printing to order a part, but it couldn’t hurt to familiarize yourself with the basics of the different methods and what they’re used for.

If you’re in a specialized industry, such as medical equipment or aerospace, there are a few metal 3D printing companies that specialize in these areas. We haven’t included them in this guide. However, if you’re looking for 3D printing in precious metals, there’s Cooksongold; for medical implants and surgical tools, check out Tangible Solutions, Amnovis, Materialise, and Zenith Technica. Specialty on-demand manufacturers for aerospace, hypersonics, and defense include Beehive Industries, Sintavia, and Morf3D.

There are many ways to 3D print metal parts. Selecting which metal technology to use is a balance of needs Your printing provider may ask you what your intended use of the part is to determine the best method, yet in some cases you upload your digital file yourself and select a method.

Yet, the vast majority of metal parts are printed using metal laser powder bed fusion (M-LPBF). Confusion can arise in the fact that not all services call the technology by the same name. Some will refer to it as SLM (selective laser melting), some may call it DMLS (direct metal laser sintering), and you may even hear laser melting, but they are all the same technology.

If you need a small metal prototype that won’t be put under extreme stress, low-cost metal extrusion (or metal FDM) might fit. If you need 1,000 metal parts, metal binder jetting would be a good option.

All of the current metal technologies have pros and cons when it comes to detail, size, strength, type of metal, cost, printing speed, and volume. Unfortunately, no method 3D prints super-strong parts quickly, cheaply, and perfectly, so pick your priorities. Your metal service provider is able to guide you through the technologies and explain your options but take a look at our individual metal technology guides linked below for a grounding in the various methods.

- Laser powder bed fusion (LPBF), which is also called selective laser melting (SLM), is the most common type of metal 3D printing.

- Metal binder jetting is the second most common and prized for speed.

- Metal extrusion, which is also called fused deposition modeling (FDM) with metal filament or metal rods, is the most affordable.

Less frequently used metal 3D printing methods:

- Electron beam melting (EBM) is used in implants, aerospace, and defense applications, often with copper or titanium.

- Wire arc additive manufacturing (WAAM) produces large metal parts for industry and oil & gas with a rough surface that often needs machining.

- Directed energy deposition (DED) is conducted with either an electron beam or a laser beam and is used for restoring or repairing worn or damaged metal parts.

- Cold spray is also used for metal repair and rapid fabrication of metal tools, often in the defense industry.

- Metal lithography and metal micro 3D printing are used in specialty industries.

Are You Sure You Want That in Metal?

Before you jump at metal 3D printing, you should ask yourself one vital question: do you really need your part printed in metal?

You may have always used machined metal parts for a certain application in the past, so it only seems reasonable that you should go for metal with 3D printing as well. However, that’s not always true. Often, an engineering-grade plastic part can provide similar or even better functionality, while at the same time cutting down part weight and manufacturing costs. Plastic is often cheaper than metal, after all.

Only an expert additive manufacturing engineer can make the call on what would be the best material. This is why partnering with a 3D printing company that provides in-house design and engineering consultation is so valuable. They will be able to tell what the most suitable material for your application is.

Not only that, a full-service design and printing company can guide you through the entire process. You only need to have your part concept, and they can advise you on the best design, material, and post-processing options. If they offer services such as iterative design and topography optimization, they might very well be able to produce a more durable and cheaper part out of materials you didn’t even consider.

That said, it might be that you actually have a decent bit of metal 3D printing experience. Maybe you’ve used several printing services, or even used to have a printer of your own, and you know exactly what you need. In such a case, you can safely opt for a printing service that offers less comprehensive additional services. This can often bring the printing cost down as the company doesn’t have as many experts on its payroll.

Practically all of the printing services listed above provide at least some kind of design consultation, and a few also have extensive material guides and learning resources available. It’s a good idea to start by reading up on what they’re saying about your application. And when in doubt, you can always simply contact a couple of services about your project. They will be ready to help you, and if they’re not, you will know that one wasn’t the right partner for you.

Reverse Engineering Your Metal Part

One of the most common reasons companies turn to metal 3D printing is to create a replacement of a metal part that’s no longer available to order. For this, reverse engineering is often the only way to create a 3D printed part when you don’t have a digital file of the original.

On a broad level, reverse engineering is the act of dismantling an object to see how it works. On a practical level, reverse engineering is measuring a physical object and then reconstructing it as a digital 3D model, which can then be 3D printed or manufactured another way.

Although we won’t go into all of the details here, know that many companies, including some mentioned above (Craftcloud, Materialise, and Sculpteo) specialize in creating a digital model from an existing part. First the original part is 3D scanned, then that scan file is manipulated in computer aided design software to exactly match the original or introduce enhancements or improvements. You can find a list of top design companies in our guide, “The Best 3D Printing Design Services.”

If you’d like to know more about how the reverse engineering process is conducted, check out the article linked below.

Lead image source: 3D printed cemented carbide parts by Sandvik/BeamIT

License: The text of "Best Metal 3D Printing Services: Our 10 Top Picks" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.