If you need to 3D print with the strongest material you can find, you’ve come to the right place.

PEI (poly-ether-imide), also know by the brand name Ultem, is a top-tier plastic prized for its outstanding thermal, mechanical, and electrical properties that’s also a lighter weight replacement for stainless steel and aluminum.

Because PEI is strong, lightweight, and resistant to extreme conditions, it’s ideal for high-stakes industries — aerospace, oil & gas, defense, food processing, and healthcare — where failure isn’t an option. Not only is PEI significantly stronger and more rigid than ABS, PETG, and even carbon-fiber nylon, but one of its most sought after traits is its extremely high heat tolerance, making it ideal for high-temperature environments. It’s also highly resistant to chemicals, fuels, and solvents, unlike ABS and PLA, which degrade more easily.

Feed this plastic into a 3D printer and you’ll get the material characteristics it’s famous for plus the lightweighting, part consolidation, and design advantages that only 3D printing delivers. This combination is making PEI a popular choice for parts used in all types of manufacturing and industrial equipment from satellites and oil pumps to automotive parts and medical applications.

Unlike “consumer filaments”, PEI requires high-temperature 3D printers with an all-metal hotend and heated chamber.

Not All PEI Is the Same

Blends vary and it pays to ensure that the plastic you buy can deliver all of the attributes your part needs. Skip to the end where we define the different types of PEI — 1010, 9085, etc. There are also new polymers challenging PEI, such as Tullomer, that may be able to offer similar industrial-grade characteristics at a lower price.

| Filament | Type of PEI | Price per 0.5 kg |

|---|---|---|

| Prusament PEI 1010 by Prusa Polymers | PEI 1010 | $139 |

| 3DXTech ThermaX PEI 1010 | PEI 1010 | $88 |

| 3DXTech CarbonX PEI 9085+CF | PEI 9085 + Carbon Fiber | $160 |

| Fiberlogy PEI 9085 Natural & Black | PEI 9085 | $150 |

| Formfutura PEI Ultem 9085 | PEI 9085 | $135 |

| Nanovia PEI Ultem 1010 | PEI 1010 | $115 |

| Stratasys Ultem 9085 | PEI 9085 | (sold per cubic inch) |

PEI Mechanical Characteristics & Printing Perameters

Although not all PEI is the same there are baseline characteristics of the material in its more “pure” form. PEI may be blended with other polymers and fibers, or produced in a way to, for example, make it absorb less moisture from the air and be easier to 3D print. These augmentations can come at the cost of certain mechanical properties.

For pure PEI, expect a tensile strength of 90 MPa and a Young’s modulus of elasticity around 2.8 GPa.

Properties of PEI include:

- outstanding temperature resistance

- outstanding chemical resistance

- good UV-light resistance and weatherability

- outstanding wear resistance

- outstanding resistance to hydrolysis

- excellent mechanical properties

- very good electrical properties

- very good radiation resistance

Print Requirement of PEI:

- Bed Temp.: 150 ± 10 °C

- Print Surface: Powder-coated Steel Sheet

- Extruder Temp.: 410 ± 10 °C

- Chamber Temp.: 90-190 °C

- Printing Speed: 20 – 60 mm/s

PEI is highly hygroscopic, which means it absorbs moisture for the air. Manufacturers recommend active drying before each use in addition to keeping the filament in a dry box or cabinet away from moisture.

Filament Makers Report Mechanical Properties Differently

A frequent hurdle that consumers — and we at All3DP — run into when trying to compare filament properties is that the manufacturers don’t all use the same testing methods or report mechanical properties in the same way. One manufacturer might report tensile strength at yield according to the ISO standard and another might report only tensile strength at break according the ASTM standard.

For the filaments in this guide, we’ve listed the mechanical properties that the manufacturers provide, but note the differences when you’re comparing.

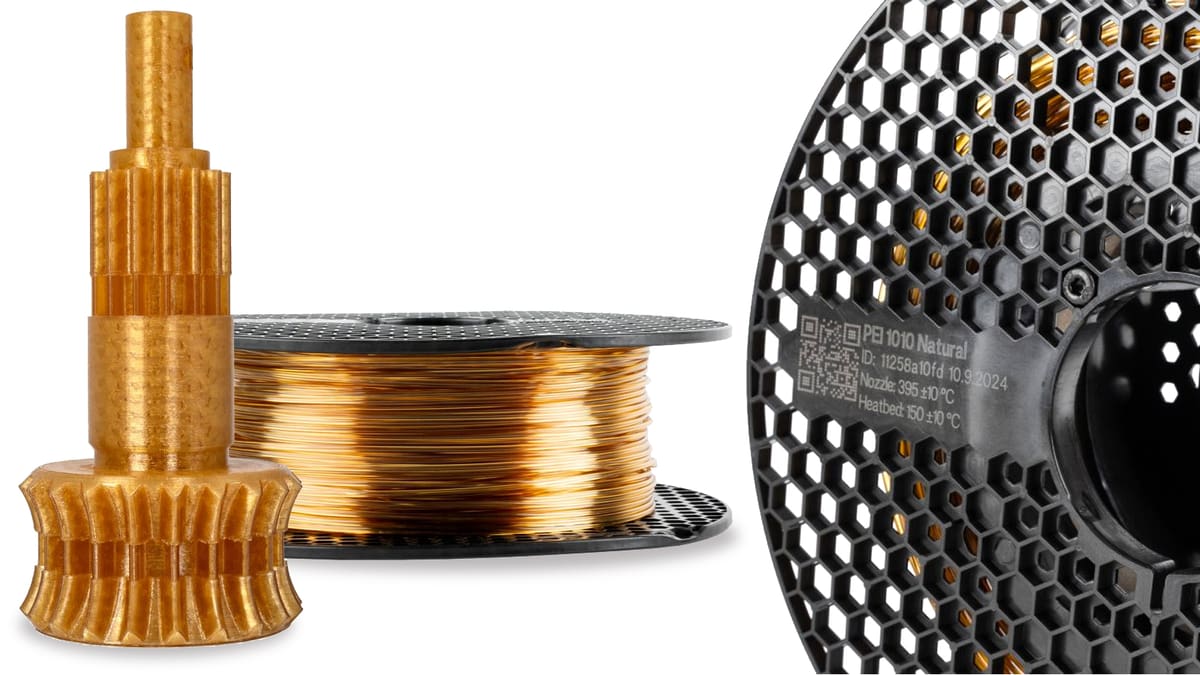

Prusament PEI 1010 by Prusa Polymers

Prusa Research launched Prusament PEI 1010 in Sept. 2024 to complement the release of its new “industrial-lite” FDM printer, Prusa Pro NT90. The material is manufactured by Prusa Polymers itself, like all Prusa materials.

PEI 1010 is a glass-filled grade of PEI for extra stiffness.

Prusa cautions that Prusament PEI 1010 is not a “plug and print” material and is not even suitable for the regular Original Prusa printers since it requires very high temperatures (420 °C for the hot end, 150 °C for heatbed, and at least 90 °C for the chamber).

As you’ll hear from all PEI manufacturers, the absolutely key prerequisite is to keep the filament perfectly dry (a professional dry box and dryer are necessary). Prusa published an online help article to accompany Prusament PEI 1010.

Mechanical properties of 3D printed testing specimens:

3DXTech ThermaX PEI 1010

3DXTech’s ThermaX PEI 1010 filament is formulated for applications that require extra tensile strength. Manufactured in the US, this PEI 1010 is a glass-filled grade of polyetherimide (PEI) for extra stiffness.

Available in natural (golden) or black.

Even though PEI 1010 is already a glass-filled version of PEI, 3DXTech also makes Fibrex PEI+GF30, which contains more glass fiber (30%) resulting in more than doubling the tensile modulus and flexural modulus (the measure of stiffness or resistance to bending).

Mechanical properties of 3D printed testing specimen:

Results are from a specimen in XY Flat orientation.

3DXTech CarbonX PEI 9085+CF

3DXTech ratchets up the mechanical properties of PEI with the addition of chopped carbon fiber particles. CarbonX PEI+CF is made using Sabic brand Ultem 9085 PEI and 15% carbon fibers.

The company says the addition of carbon fiber reinforcement greatly increases the stiffness and modulus of the PEI material as well as improving the dimensional stability during and after 3D printing.

3DXTech Ultem 9085 is FAA-approved for FST applications (Flame/Smoke/Toxicity) and meets FAR 25.853 and OSU 65/65 standards.

Mechanical properties of 3D printed testing specimen:

Fiberlogy PEI 9085 Natural & Black

Filament manufacturer Fiberlogy offers a PEI 9085 in both natural and black.

Fiberlogy says its unique filament combines the strength of steel and the lightness of aluminum, making it ideal for creating parts that can withstand the toughest of conditions. Ideal for applications in the automotive, railroad and aerospace industries, where parts printed with this material can replace metal components.

The material is non-flammable (UL94 V0), has high dielectric strength and good thermal conductivity. It is also resistant to abrasion, high temperatures up to 180 °C, solvents, and UV rays.

Mechanical properties of 3D printed testing specimens:

Fiberology issues one technical data sheet for both the natural and black.

Formfutura PEI Ultem 9085

Material manufacturer Formfutura offers PEI Ultem 9085, which it says combines exceptional dimensional stability with good chemical resistance.

The company’s PEI Ultem 9085 is a flame retardant filament with low smoke evolution and meets the UL 94 V-0 and 5VA ratings. The material has excellent layer bonding, the company says, plus dimensional accuracy, a high impact resistance, durability, and a high tensile strength.

Nanovia PEI Ultem 1010

PEI filament from materials manufacturer Nanovia is based on Ultem 1010 plastics, allows for high heat resistance and thermal stability. Nanovia PEI is resistant to autoclave operation, sterilisation cycles, and adapted for tooling able to resist high temperatures.

Nanovia’s PEI also comes in a carbon-fiber filled version that’s more rigid than native PEI.

Mechanical properties of 3D printed testing specimens:

Stratasys Ultem 9085

Ultem 9085 filament from Stratasys is compatible with the company’s Fortus 400, 450, F900, Fortus 900, and the F3300 FDM 3D printers (likewise for Stratasys’ other PEI filament, Ultem 1010 and Ultem 9085 CG).

For industries that require material traceability, Stratasys’ Ultem 9085 CG (Certified Grade) comes with traceability documentation and, the company says, and meets more extensive and stringent test criteria than its standard Ultem 9085 resin filament. The Ultem 9085 CG is only available in Natural, but the non-CG Ultem 9085 in red, white, grey, gunship grey, aircraft gray, and black.

Mechanical properties of 3D printed testing specimens:

Values were measured as printed on the F900 with a 0.254 mm (0.010 in.) layer height in XZ and ZX orientations.

Common Types of PEI

PEI 1010 is a glass-filled grade of polyetherimide (PEI), meaning it contains glass fiber reinforcement, while pure PEI (also known as unfilled PEI) does not have any fillers.

PEI 9085 has higher impact strength and toughness than pure PEI but tensile strength and lower impact resistance compared to pure PEI. It’s considered easier to 3D print and process than pure PEI.

Major Differences Between PEI 1010 and PEI 9085

You May Also Like:

License: The text of "Ultem (PEI) Filament Buyer’s Guide: Take Your Extrusion to the Extreme" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.