There’s nothing like a side-by-side comparison of features when deciding which to buy, but UltiMaker’s value goes deeper than technical specifications. The S8 delivers speed, the S7 launched a new efficiencies, and the Factor 4 is aimed at industrial applications with a more robust chamber and repeatability features.

Let’s not forget the S5, which is still quite popular, especially at schools.

UltiMaker Printer Value Statements

Below we dive deeper into comparisons of these machines and provide some context for how UltiMaker is innovating.

Which One Is the Best?

Let’s start off with the bottom line. UltiMaker offers these four 3D printers to address specific applications and budgets.

- Pick the Factor 4 if you need high-temperature engineering filament at your company. The Factor 4 will be the best bet since it is a more heat-controlled machine to prevent part warping.

- Pick the S8 if your printing material needs are more in the carbon-fiber nylon family. The S8 has the advantage of speed over the Factor 4.

- Pick the S7 or S5 if you have a strict budget cap that doesn’t enable you to purchase the S8. Since they have a lot in common, you won’t be disappointed with the S7 or the S5.

Speed & Efficiency

It was only with the S8 that UltiMaker put a print speed in its machine technical specifications. Before that — and before speed capabilities of FDMs in general spiked — the company was more focused on communicating quality and reliability, not that they aren’t still.

At 500 mm/h, the S8 is the company’s fastest 3D printer comparable to Bambu Lab X1C. The speed boost comes from new technology in the printers motion control called Cheetah and other advances that, working together, boost speed without sacraficing quality, the company says.

Yet, when it comes to dual-material prints, such as a base material and a supporting materials, UltiMaker has always been faster considering that it has dual extruders.

UltiMaker still does not release speed information for its machines older than the S8. The company did tell All3DP that the Factor 4 has a 50% increase in productivity compared to the S7.

Materials

UltiMaker S series 3D printers (S5, S7, S8) support the same wide range (300+) of filament materials, including:

- PLA (Polylactic Acid) – Easy to print, good for general use.

- Tough PLA – More durable than standard PLA.

- ABS (Acrylonitrile Butadiene Styrene) – Strong and heat-resistant, requires an enclosed build chamber.

- PETG (Polyethylene Terephthalate Glycol) – Durable, chemical-resistant, and slightly flexible.

- Nylon (Polyamide) – Flexible, wear-resistant, absorbs moisture.

- CPE (Co-Polyester) – Similar to PETG, but more chemical-resistant.

- CPE+ – More temperature-resistant than standard CPE.

- TPU 95A (Thermoplastic Polyurethane) – Flexible and rubber-like.

- Polycarbonate (PC) – High strength and temperature resistance.

- PP (Polypropylene) – Lightweight, fatigue-resistant.

- PVA (Polyvinyl Alcohol) – Water-soluble support material.

- Breakaway Support Material – Alternative to PVA for easy removal.

Third-Party & Experimental Materials:

UltiMaker printers also support third-party filaments, including metal, such as stainless steel, and advanced composites, such as carbon-fiber-reinforced filaments, wood-filled PLA, and specialty engineering-grade materials.

Taken together, UltiMaker’s materials plus third-party materials for which there are print-profiles available, you have one of the longest menus of materials of any FDM.

The Factor 4 focuses on engineering-grade materials so you don’t have the full 300+ range of the S series, but you get high-temperature materials like PPS-CF and PEKK.

Metal Filaments

The S5 and the S7 can print stainless steel parts with the optional UltiMaker Metal Expansion Kit. It’s not clear whether the S8 is compatible with the Metal Expansion Kit. The Factor 4 can print with stainless steel filament natively without an expansion kit of any kind.

UltiMaker Material Station

Although materials changers have become ubiquitous with FDM 3D printing today, UltiMaker’s was one of the first. The UltiMaker Material Station is a filament management system for the S5, S7, and S8 3D printers. It’s the same unit for all three printers and it’s an optional accessory retailing for around $3,500. The Factor 4 has a different type of material changer and it’s built into the machine, whereas with the S series the material changer is optional.

Note that the UltiMaker isn’t a material changer like those offered by Bambu Lab, Prusa, or Creality, that enable you to print with three, four, or even 8 materials on one time. All UltiMaker printer can only print with a maximum of two materials at a time.

One of the key features of the Material Station is its ability to hold up to six spools of filament simultaneously. This allows for automatic filament detection, loading, and switching, and eliminating manual intervention. When one spool runs out, the system automatically switches to another.

Humidity control is another crucial advantage of the Material Station. It maintains a controlled environment with humidity levels below 40% RH, which helps protect moisture-sensitive materials like PVA and nylon from absorbing water.

The Material Station integrates with UltiMaker Cura software, supporting both UltiMaker-certified and third-party filaments.

Tech Specs & Price

On paper, the S series printer are very much alike. The S7 is 90% the S5 with boosted reliability and productivity for power users; the S8 expands on this with added speed and accuracy. The Factor 4, as we’ve mentioned, is in a class by itself, focusing on being an industrial version with a sturdy steel and aluminum chassis, an actively heat-controlled chamber, triple-insulated build volume, a direct-drive extruder with a bigger motor, and a nozzle temperature that can reach 340ºC to enable engineering grade materials.

They all have the same print volume.

Notably, the S5 does not have any air filtration unless you purchase the optional air manager that sits on top.

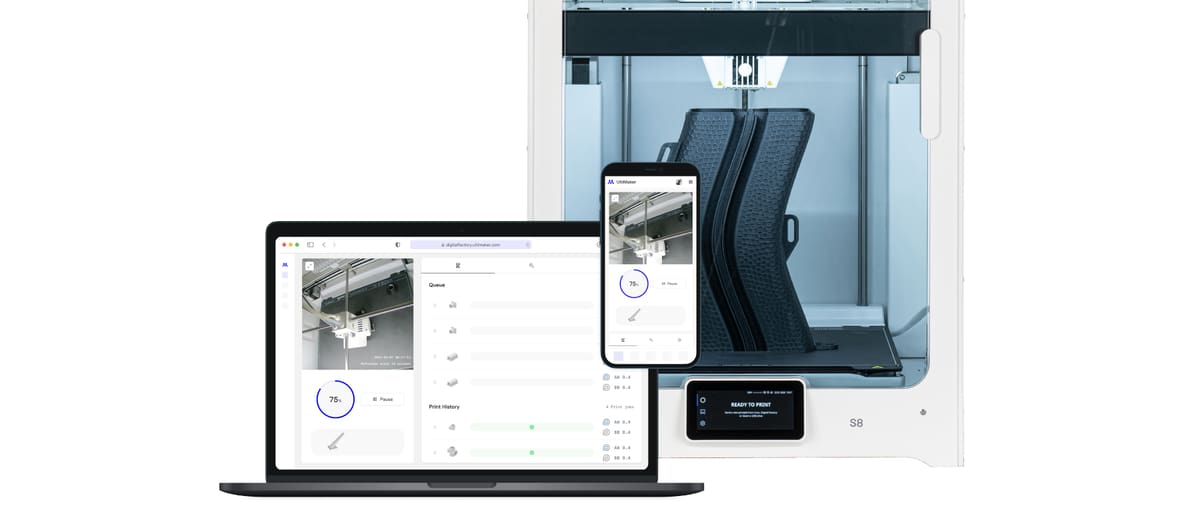

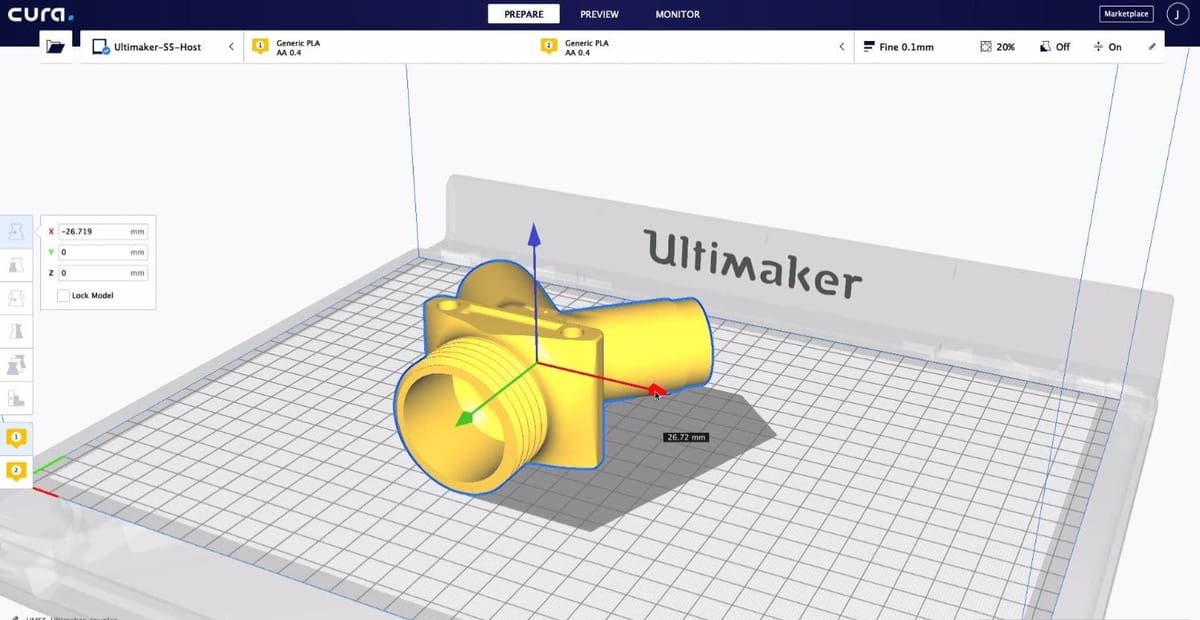

Software

All UltiMaker machines can take advantage of the same software, but Digital Factory print management and the Cura slicer. There are different subscription levels to Digital Factory but they are not machine specific.

You May Also Like:

License: The text of "UltiMaker 3D Printers Compared: S8, S7, S5 & Factor 4" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.