At the 2019 TCT Show in Birmingham, Dutch 3D printer manufacturer Ultimaker announced its latest addition to its professional ‘S’ line of fused filament fabrication 3D printers. Dubbed the S3 and priced at $4,395, the new machine presents a more affordable proposition to that of the larger S5 model, which currently retails for around $5,995.

Fundamentally though, the machines are almost the same. Read on, as we review the specs and spell out what’s what, how the S3 marginally differs from the S5, and where it now sits in Ultimaker’s expanded ‘S’ lineup.

Features

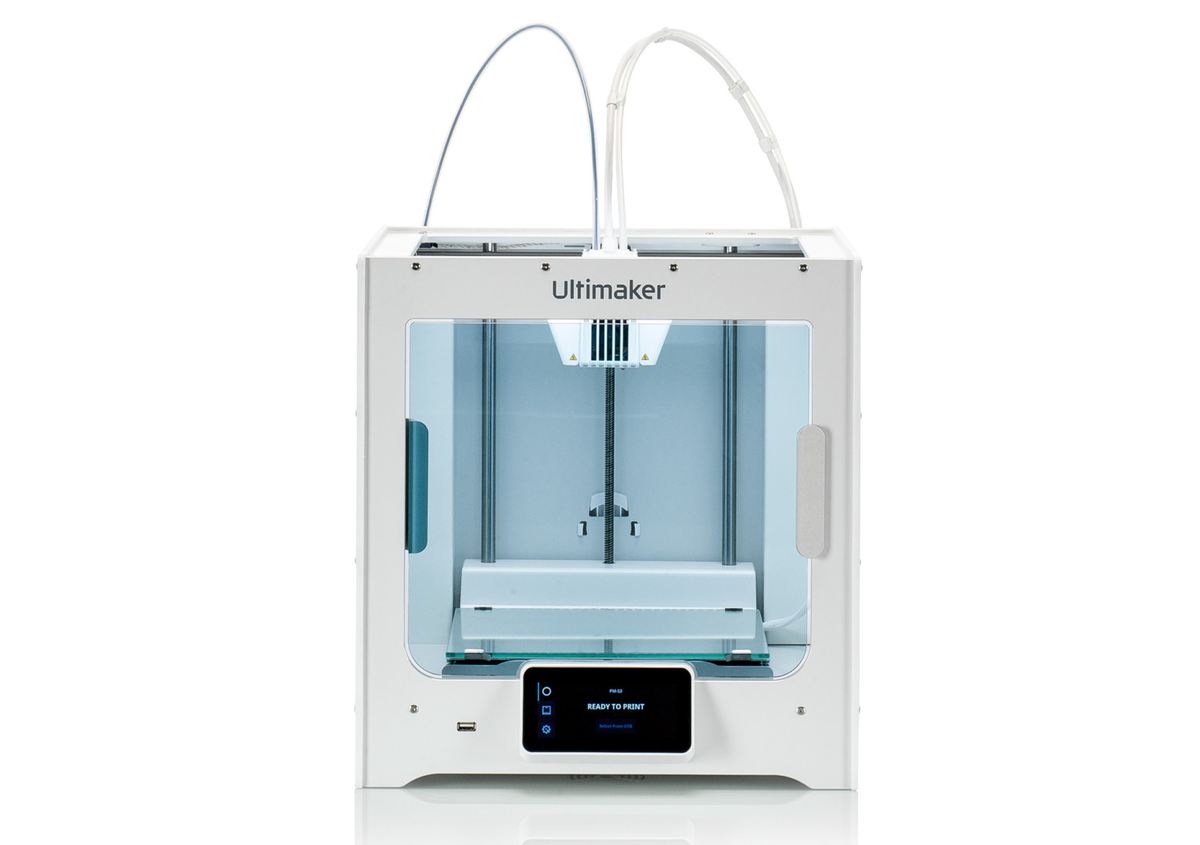

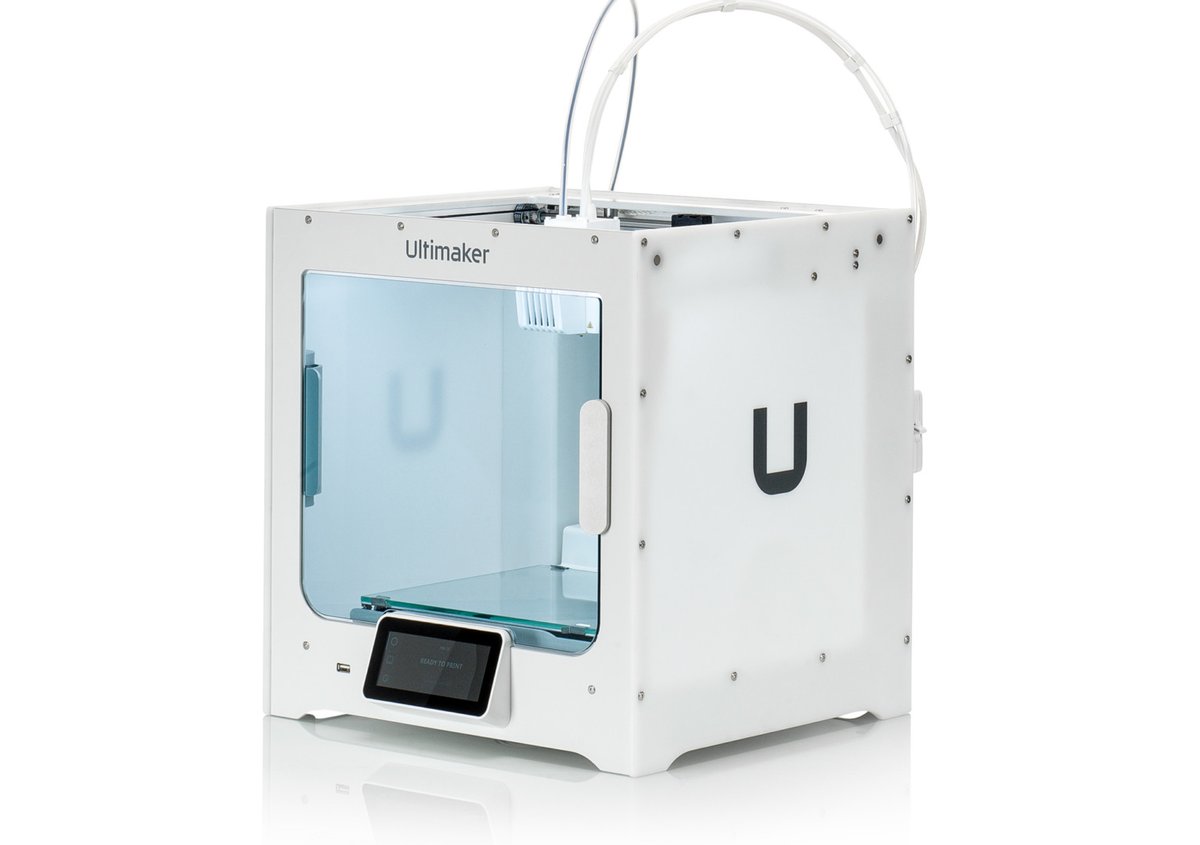

The Ultimaker S3, Ultimaker claims, is the most accessible entry in its current lineup of 3D printers. Superseding the Ultimaker 3 with a number of high-level features carried across from its flagship S5 3D printer, it presents a professional desktop 3D printing experience that, based on our experiences with the S5, is ready for fast prototyping, tooling, and end-use part production.

Dual Extrusion Using Print Cores

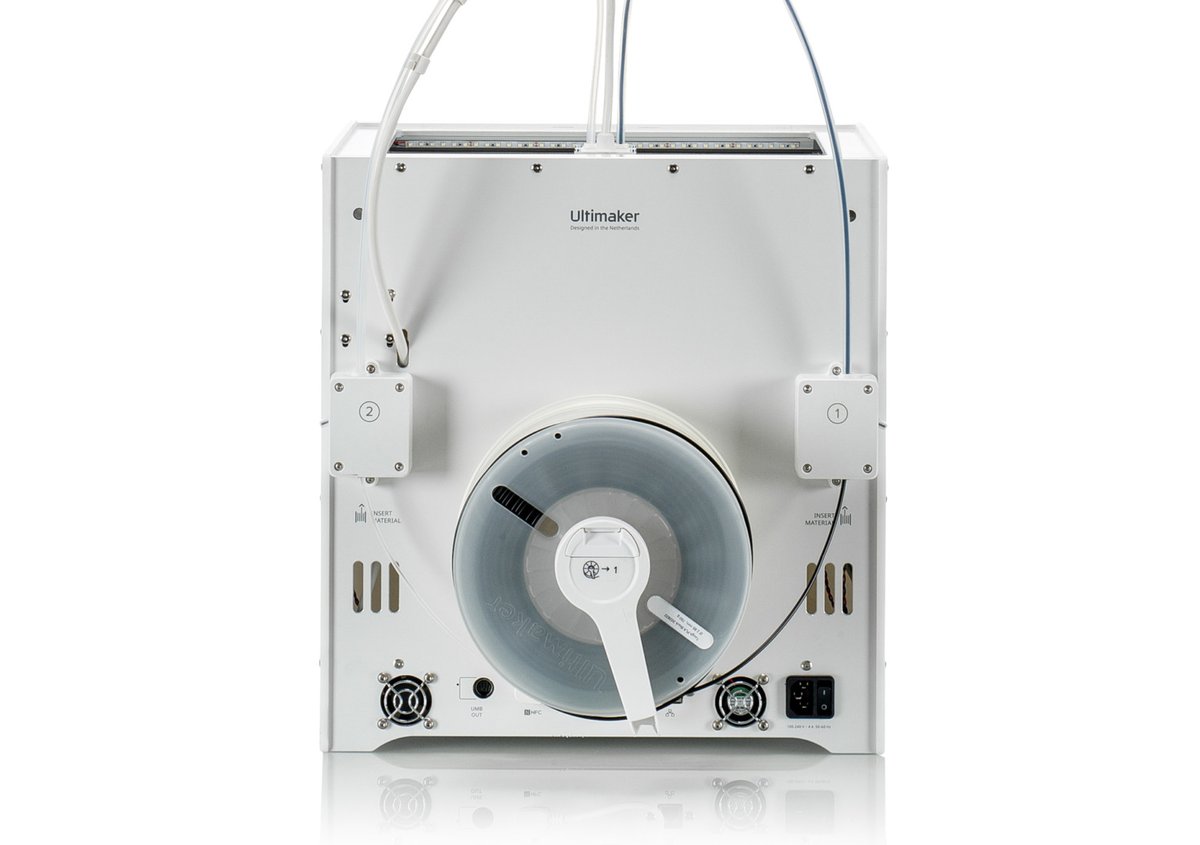

Perhaps the defining feature of recent Ultimaker machines is their ability to print two materials in the same job. This is enabled through the use of Ultimaker’s proprietary print cores – a multitude of drop-in hot ends tailored to specific materials and their print properties.

These print cores click in place with the push of a button, making the S5 and, by extension (providing Ultimaker hasn’t messed things up), the S3, effortlessly simple to maintain and configure for a variety of printing tasks.

Shipping with Ultimaker’s AA and BB print cores, the vanilla S3 should be able to handle your run of the mill materials such as PLA and ABS without any hassle, plus soluble support materials for tricky to print and otherwise precarious print jobs.

An abrasives-resistant print core – CC Red 0.6 – is also available as a separate purchase, making the S3 capable of reliably printing carbon and glass composites.

While the two print cores share a print head, only one nozzle is ever active at the print bed level. Between material changes, the print head retreats to a park position to mechanically flip a switch that lowers or raises the print cores as needed.

Overall the print core concept is a smart and well-executed one. An unsung perk to the system is that Ultimaker has virtually eliminated wastage from material purges when printing. There’s no strict need for a purge tower when printing dual prints. This conclusion is drawn from extensive experience with the S5, but there’s little to suggest anything has changed between that machine and the S3.

Glass Bed, Automatic Bed Leveling

Underpinning the S3’s build volume is a heated bed topped with a 230 x 190 mm removable glass sheet. Paired with a Z-axis travel of 200 mm, this gives the S3 a not inconsiderable build volume that isn’t too far out from the S5’s 330 x 240 x 300 mm.

Bed leveling in the S3 is handled by what Ultimaker calls Active Bed Leveling. After initial calibration to set the desired nozzle height, before each print the S3’s print head probes a grid across the build plate, detecting its distance from the bed and automatically compensating for any variances in the level across its area.

Semi-Enclosed Build Volume

Like the S5 before it, the Ultimaker S3 features a partially enclosed print chamber, with a glass door protecting the front of the machine. Theoretically, this contributes to a more stable atmosphere inside the printing area and is better for materials that are particularly sensitive to temperature changes while printing. Certainly, Ultimaker puts a lot of stock in its material profiles and print settings, so it a sure thing that the design of the enclosure is just as the company wants it to be.

Large Touchscreen Interface

The front of the Ultimaker S3 is adorned with a 4.7-inch color touch screen interface that gives the user access to the printer configuration (loaded print cores and materials), maintenance, and directly queue prints from an attached USB pen drive.

Connectivity

Since the launch of the Ultimaker 3, all of the Ultimaker’s newer 3D printers benefit from a great degree of connectivity through the company’s Cura Connect portal. In essence, any Ultimaker 3D printer (from the Ultimaker 3 and up) can serve as a network host, connecting any compatible printer on its local network, pinging print jobs to machines that have the correct print cores and materials loaded for the job.

A further layer on top of this is the Cura slicing software’s printer monitoring abilities. The S3 can connect to Cura over your WiFi network, allowing for the wireless sending of print jobs, remote viewing of the print in progress using an embedded camera, plus print queue management.

In all, it positions the S3, much like the S5, and an incredibly sophisticated tool that actually requires very little time to be spent hands-on working with the printer.

CAD Integration

Further to the connectivity options above, the S3 also benefits from direct CAD/CAM integration with SolidWorks, Siemens NX, and Autodesk Inventor thanks to plugins available on the Cura Marketplace.

High Resolution

Ultimaker claims the S3 is capable of a 20-micron layer resolution – a remarkably fine layer height to offer. It’s not crystal clear if this is referring to the possible layer height – looking at the most recent version of Cura, the finest minimum layer height offered as standard in Ultimaker’s own print profiles is 0.06 mm – 60 microns.

Our assumption here would be that the machine is capable of finer layers, but such use would be subject to extensive experimentation on the user’s part.

Material Compatability

Out of the box, the Ultimaker S3 will be compatible with a great number of filaments both third-party and Ultimaker’s own brand. The latter offers an advantage in that the spools contain NFC chips that allow them and their settings to automatically populate the S3’s configuration on loading – a low effort and highly integrated way of doing things.

Alternatively, select third party materials should be almost as easy, with Ultimaker’s Material Alliance program seeing handfuls of chemical companies and filament producers making lab-tested profiles for their materials available for download on the Cura Marketplace. Typically for engineering materials that offer desirable properties, these ready-to-run profiles strengthen the S3’s positioning as an accessible option.

On the mechanical side of things, the S3 benefits from tougher filament feed gears than the Ultimaker 3 it is loosely replacing. These tough gears can handle the use of abrasive carbon and glass composite materials.

Material Sensors

Less exciting that near-magic connectivity, filament flow sensors positioned along the extrusion path serve the purpose of catching a print that has run out of material, or suffers from a blockage, pausing the print and alerting the user of the need to take action.

Technical Specifications

GENERAL SPECIFICATIONS

- Technology: FDM

- Year: 2019

- Assembly: Pre-assembled

- Mechanical arrangement: Cartesian-XZ-head

- Manufacturer: Ultimaker

3D PRINTING PROPERTIES

- Build volume: 230 x 190 x 200 mm

- Layer height: 20 microns

- Feeder system: Bowden

- Extruder Type: Dual (Print Core)

- Nozzle size: 0.4 mm

- Max. printing speed: > 24 mm3/s

- Max. extruder temperature: 280 °C

- Max. heated bed temperature: 140 °C

- Enclosed print chamber: No

- Auto-leveling: Yes

- Connectivity: WiFi, LAN, USB Card

- Build-in camera for monitoring: Yes

- Average operating noise: <50 dB

MATERIALS

- Filament diameter: 2.85 mm

- Third-party filament: Yes

- Filament materials: PLA, ABS, Nylon, CPE, PC, PP, TPU, PVA

SOFTWARE REQUIREMENTS

- Operating system: Windows, MacOS, Linux

- Recommended Slicer: Ultimaker Cura

- File types: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG, G, G-code, UFP

Where to Buy

The Ultimaker S3 can be found at the retailers listed below.

License: The text of "Ultimaker S3 3D Printer: Review the Specs" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.