The Voxelab Aquila S2 is the newest entrant in Voxelab’s Aquila budget 3D printer series, this time with a direct extruder and hot end capable of temperatures up to 300 °C. The high-temperature capabilities are crucial here, as they’ll enable the printer to work with complex materials like polycarbonate and nylon, but we’re also happy to see another direct extruder come stock on a 3D printer in this price range.

Voxelab, a Flashforge subsidiary, has now released five printers in the series of Ender clones, all featuring the same body with minor changes to essential components. We found the original Aquila, a printer with near feature parity to the Ender 3 V2, to deliver great results for such a cost-effective machine and subsequently recommended it as our Editor’s Choice for 3D printers under $200. Unfortunately, it was found to have severe thermal safety issues requiring a firmware update to fix.

According to Voxelab, the S2 has remedied the original Aquila’s shortcomings and, though its price hovers above the exceedingly low cost of its predecessor, its features may be enough to entice consumers. Especially the ability to print at temperatures up to 300 °C, which we rarely see out of the box on printers in the S2’s price bracket.

The Verdict

Pros

- Great prints out of the box

- Capable of 300 °C printing on a budget

- Direct extruder is reasonably lightweight

Cons

- Poor build plate adhesion, even on fairly large-based parts

- Price difference for the new extruder isn’t so appealing

- Proprietary nozzles and mismatched spares

In the Aquila S2, Voxelab has managed to produce an excellently priced 3D printer capable of reaching temperatures normally the fare of more expensive machines. It’s a tempting offering for anyone looking to pick up a 3D printer for projects with strict mechanical requirements. However, a frustrating PEI-coated (Polyethylenimine-coated) print bed stifles the success of delivering a great budget option for high-temperature printing. It has serious adhesion difficulties and a proprietary extruder that compromises nozzle compatibility, while Voxelab only offers limited nozzle options itself.

Ultimately, if you have a tight budget, need high temperatures, and are looking to avoid any modding, the Aquila S2 is a good option. Unfortunately, even at the machine’s very attractive ~$250 price point, buying the original Bowden Aquila with a tempered glass build plate and adding an after-market high-temperature hot end or direct extruder is an even more affordable option without compatibility restrictions on consumable components like the Aquila S2’s nozzle.

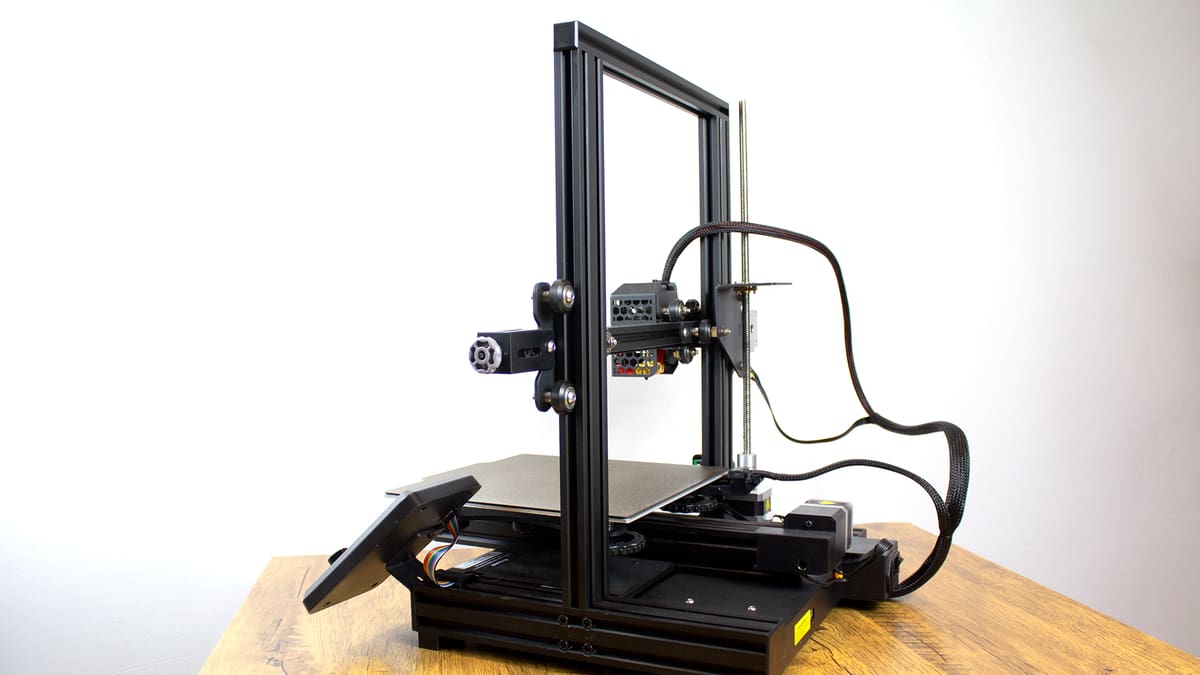

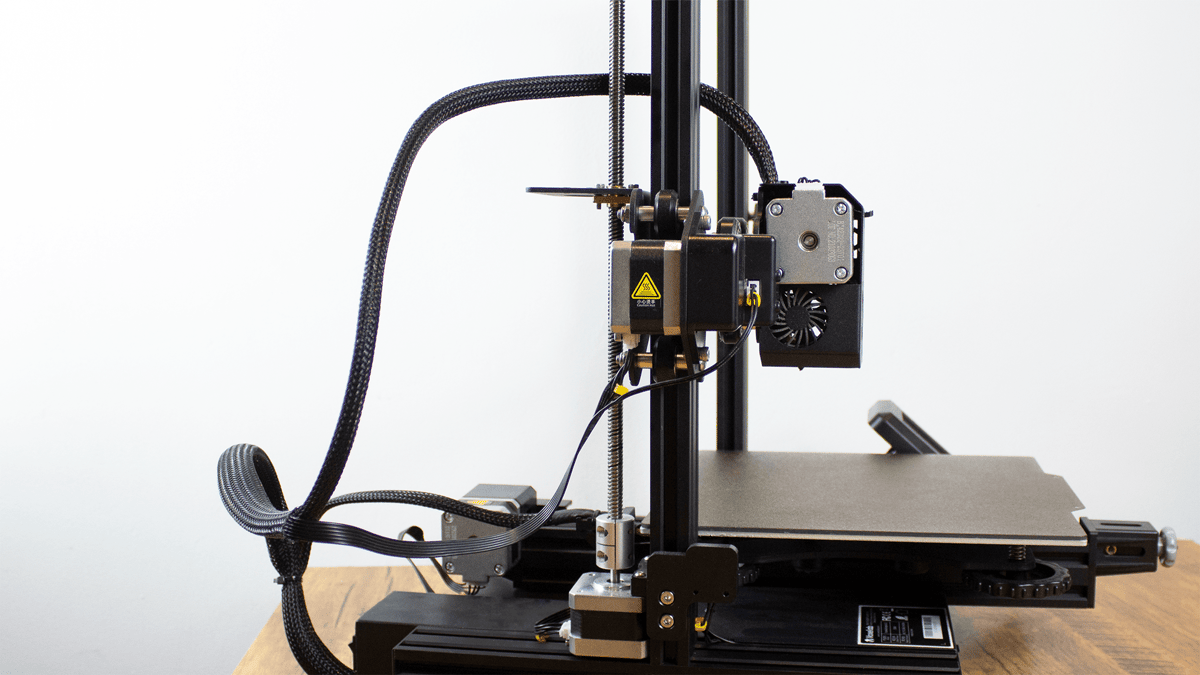

The Tech

The Voxelab Aquila series is about what you would expect from an Ender-3-like budget 3D printer, sharing its popular composition. In a typical Cartesian-XZ-head arrangement, it’s comprised of four aluminum V-slot extrusions carrying the printhead along the X-axis and the Z-, with the help of a single lead screw, over a build plate that moves along the Y.

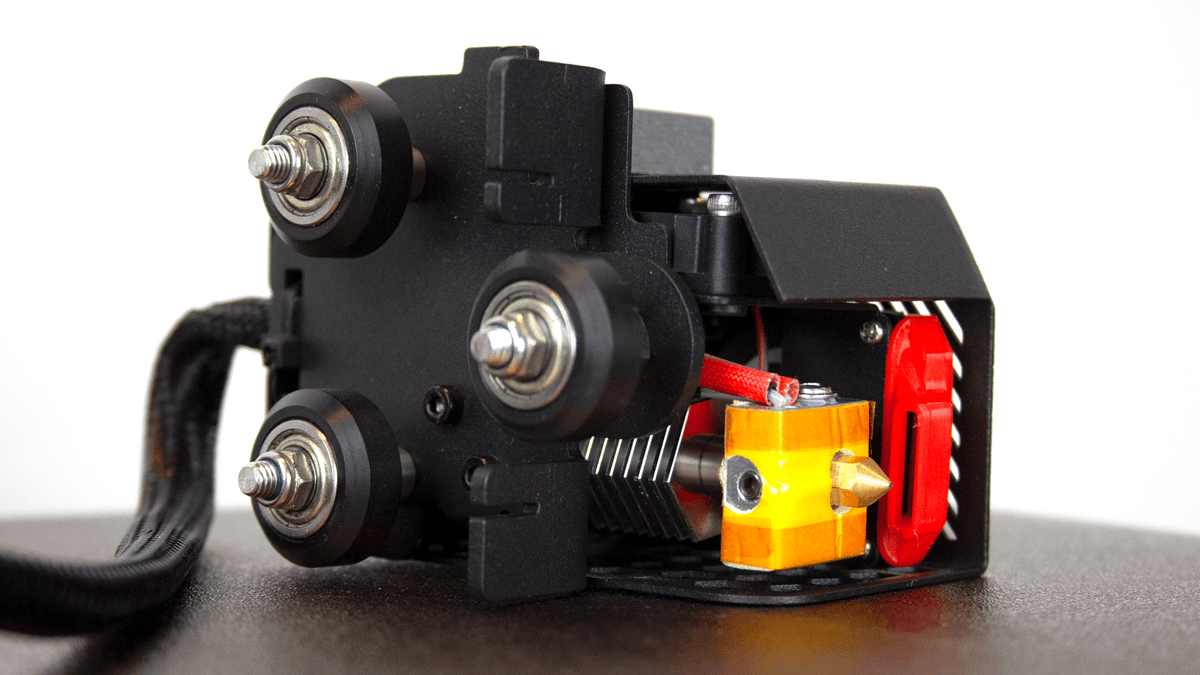

Though mostly a straight continuation of the first Aquila, the Aquila S2 differentiates itself in two ways: a direct extruder capable of high-temperature 3D printing (up to 300 °C), and a new PEI-coated magnetic print bed.

New Tech

If you’re buying an Aquila S2 over the original Bowden Aquila offered for ~$90 less than the S2, you’re probably doing it for the direct extruder.

Direct extruders are handy for exercising fine control over filament since the source of force is closer to the hot end. This increased control and lower travel distance makes direct extruders generally more reliable for printing with flexible materials, but some people prefer them all around. As such, upgrading to a direct extruder is fairly commonplace.

Voxelab takes the value of its direct extruder a little further by making it capable of reaching 300 °C in the hot end. This allows the Aquila S2 to work with high-temperature filament like nylon and polycarbonate – high-strength materials used in more demanding applications than your day-to-day 3D printing. It’s relatively uncommon to find a 3D printer in this budget price range able to print at such high temperatures since it requires a heat break designed to keep PTFE (polytetrafluoroethylene) at safe temperatures, or to forgo Teflon entirely (which the S2 does not), so it’s a highlight feature for the Aquila S2.

The manufacturer has also made a go of magnetic spring steel for the Aquila S2’s print bed, coated with a textured PEI surface. Flexible spring steel is always a nice touch, making it easy to remove tricky and wide-based parts with a little bend. But, unfortunately, we found the S2’s print bed is prone to adhesion difficulties reminiscent of the Ender 3 Pro(the horrors).

For a time, the Aquila S2 came with Voxelab’s H32 mainboard (like on the Aquila X2) that is modifiable with Eclipse or Keil development tools. Now, it’s only available with an N32 mainboard that is modifiable with VSCode. Both are 32-bit and loaded with open-source firmware that can be found on Voxelab’s Github.

Thermal Safety

It’s important to note that the Aquila line has an unfortunate history with thermal safety. The original Aquila was found to have a dangerous flaw, notably reported by Thomas Sanladerer. On a thermistor break or internal short the Aquila’s firmware freezes but the hot end continues heating, Sanladerer said, resulting in thermal runaway while protections are unavailable. This sort of thing can easily result in a fire or other hazards.

We reached out to Voxelab, who confirmed that some original Aquila users who experienced a thermistor break faced this issue. In response, Voxelab says it promptly updated its firmware and quality control procedures. To prevent a repeat or similar problem on later Aquila systems – both the S2 and preceding X2 – a watchdog timer was added and stricter component sourcing was applied.

While we haven’t heard any alarms raised about the Aquila S2 or earlier X2 thermal safety, users are, oddly, sometimes reminded of the Aquila series’ earlier failing. When using the Aquila S2 with Octoprint, for example, users are prompted with a warning: “Your printer’s firmware is known to lack mandatory safety features.”

Because of the original Aquila hazard, Octoprint checks for its firmware by querying “MACHINE-TYPE” over a serial connection. Out of the box, the Aquila S2 seems to be returning the same string as the original Aquila: “VOXLAB-1 V1”. You’d think Voxelab would have changed this at the very least system-to-system, but updating the firmware to version 6.1.3 sees this oversight taken care of.

Printing & Usability

Setting Up

The Voxelab Aquila S2 comes partially assembled but leans a little heavier on the DIY side than most 3D printers. Customers will find the printer base pre-assembled with the mainboard and power supply installed in the factory, but users will be left to assemble the upper portion. Like any partially assembled 3D printer, the process is straightforward and doesn’t require experience with electronics. The Aquila S2’s manual is detailed enough for those just getting started with 3D printing to follow along easily.

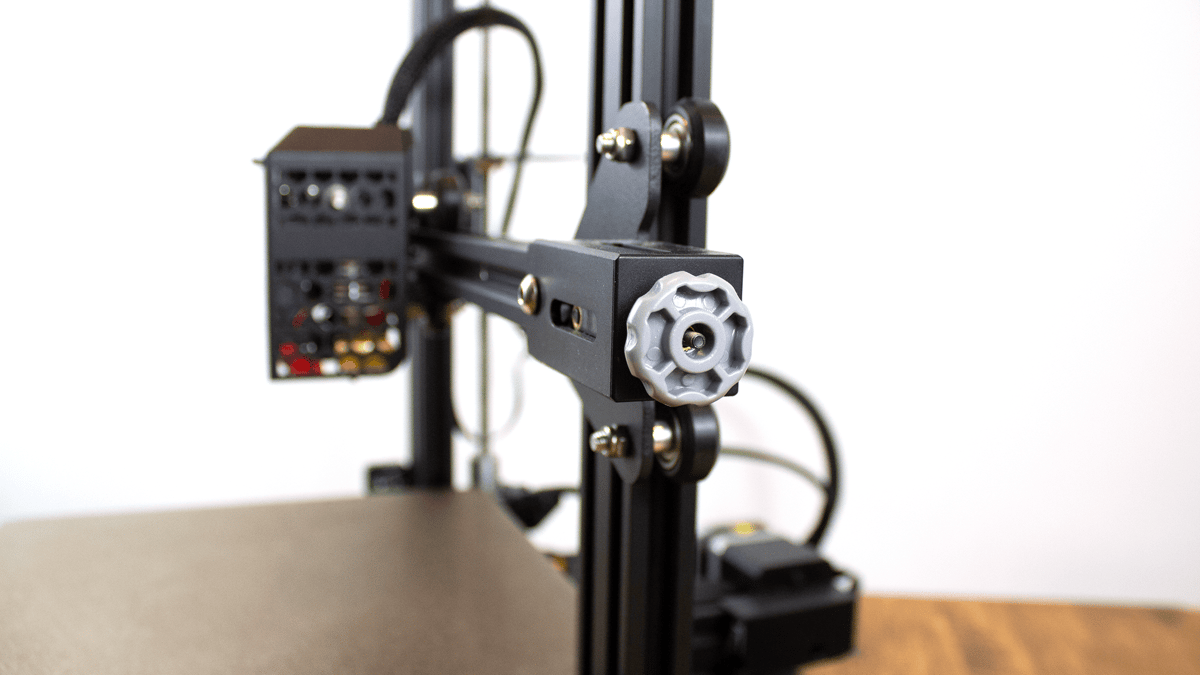

Like the preceding Bowden Aquila and the Ender 3 V2, the Aquila S2 is a manually leveled printer with belt tensioners and a color LCD screen controlled with a rotary knob.

The Aquila S2 comes with Voxelab’s own slicer, VoxelMaker, and an installation of Cura with an Aquila Cura profile. Coming with Cura and a profile is a breath of fresh air for a manufacturer who has tended to push its own slicer, which is substantially less feature-rich than Cura, in the past. But, it’s a half-hearted effort. You can tell from settings the profile isn’t catered to the Aquila S2 — its direct extruder isn’t even reflected in the retraction settings. Still, at least the manual walks users through getting an S2 machine profile setup in Cura. If you’re here looking for tips to move the Aquila S2 from VoxelMaker to Cura, just lower your retraction settings to reflect the direct extruder and you’ll be in decent shape.

For its limitations, VoxelMaker is an okay bit of software. It’s a fine place to start for those new to 3D printing. Its simplicity makes it easy to use and it covers most basic settings you’ll need while having a default profile that is tuned well for the Aquila S2 (retraction settings and all).

The Experience

Right off the bat, loading filament presented us with some mixed feelings about Voxelab’s new direct extruder. Voxelab says that filament can be loaded into the Aquila S2 “with a light press”; which we take to mean just pressing the filament to the extruder’s material pathing without pressing the idler arm and feeding it in manually — and this is true. Pressing “automatic load” and lightly holding filament to the extruder will see it gripped and pleasantly fed with little effort from the user. The Aquila S2 is far from the only printer with this kind of luxury loading, but it’s very much appreciated as a quality-of-life feature.

But it’s especially appreciated given the idler arm’s poor design. The arm protrudes just slightly from the boxy printhead’s thin aluminum shroud and is quite tense. Pressing the idler arm requires enough force to bend the printhead and, unfortunately, there’s not a suitable place to brace with another finger except the bottom. Close to the sometimes 300 °C nozzle. It’s not a stretch to imagine some absent-minded burns coming from this.

While the Aquila’s “automatic loading” should see the idler arm as a non-issue, Voxelab seems to have forgotten about the Aquila S2’s high-temperature compatibility when designing the feature. The load filament command will always set the hot end temperature to 235 °C — even if it’s been previously set higher. Fortunately, this wasn’t show-stopping when loading nylon and PC filaments. Despite both materials having much higher printing temperatures, they loaded fine. That said, it easily could stop high-temperature materials from loading properly with Voxelab’s handy soft-touch method, and possibly cause a clog — bringing the idler arm oversight back to the forefront.

But Voxelab isn’t just forgetting its new extruder’s temperature capabilities. It seems to be forgetting its components, too. Like other Aquilas, the S2 comes with a few select spare parts and a generous amount of filament samples — but the company has sorely mismatched both.

First and foremost, the spare nozzle provided isn’t the right size for the S2’s direct extruder. Voxelab opted to use a proprietary nozzle with an 11 mm thread, but the spare is a standard nozzle with a 5 mm thread. The shorter standard nozzle is even depicted in the manual. To top it off, though Voxelab is generous with its material samples, the S2 came with 0.05 kg each of PETG, PETG-CF, PLA-CF, PAHT. All but the first of these are carbon fiber materials, but the S2’s included nozzle is a soft brass. Printing with these materials will quickly wear the S2’s nozzle and, without a spare on hand, you’ll need to order more from Voxelab, which it’s currently charging ~$20 a piece. But the real cherry on top here is that Voxelab isn’t offering a hardened nozzle suitable to these kinds of materials yet. A compatible hardened steel nozzle will only be available later this year, Voxelab told us, but the 3D printer has been on the market for over six months at the time of writing.

The PEI-coated spring steel print bed was underwhelming, to put it simply. We had serious adhesion difficulties that saw smaller prints consistently fail, making batches difficult to finish even with generous brims. We ended up reducing our batch sizes and applying some good ol’ glue to the bed. Beyond even batches of smaller parts, we faced warping difficulties from any parts that had an extremity from a larger base. We ended up printing most of our models with a raft, even large-based ones that should have been easily printed without aid. Even still, the rafts suffered from some warping too.

We understand the appeal of easily removable spring steel, but it’s beyond us why manufacturers repeatedly tack a lackluster PEI coating onto these sheets when a textured spring steel surface – heck, even a smooth one – does the job better. We still prefer a good textured glass.

The Prints

These oversights and nuisances aside, parts came out from the Aquila S2 in stellar quality with little-to-no tuning.

After pumping out Voxelab’s pre-loaded test print, a few XYZ cubes, and a couple of Benchys to get a feel for things, we printed this simple model: the Moai Statue by Julien Dacosta. It came out great, with no adhesion issues and with promising results on its (admittedly easy) overhangs.

To ramp things up a little, we moved on to the Melanistic Fox by Loubie3D. This lovely model features a wide base, like the Moai statue, but includes some thinner extremities from it. Here we started facing the Aquila S2’s adhesion issues.

The nose of the fox would consistently warp, curling up and bringing it to a thin point at its tip. It would occasionally be accompanied by some warping on the small feet, but the nose was consistently a problem. After a few attempts playing with settings, we opted to print the model on a raft, and it came out stunning. Going forward, this was our immediate reaction to adhesion difficulties.

It’s worth noting, on some of these fox prints we found poor overhang performance despite the Melanistic Fox having much milder overhangs than even the Moai Statue. This was usually only an issue when slicing with Cura. Slowing down printing would help, but oddly both files from Cura and VoxelMaker were set to the same speed with 100% fan speed. Our final model pictured here was printed with VoxelMaker. We’re not sure where the significant quality difference came from.

Overall, we were impressed with the Aquila S2’s results. Tolerances were great, allowing fun articulated models like the Ancient Guardian Articulated by Crafty Sven to come out clean. The joints were perfectly loose, and all the details came out impressively clear.

While this model demands some top-notch adhesion to print well, and so it wasn’t much compromise to apply a raft here, we were still frustrated to find the raft suffered from warping. The long arms were prone to it here, we suppose.

The only surface defect we saw with some consistency was small pock marks across the surface of most prints, regardless of the slicer and only somewhat managed by settings. This issue was less prevalent with some models than others but was always present to some extent (you can see it above on the Fox and Moai to a much lesser extent). Mostly, it wasn’t present enough to merit mentioning. But, on some models, such as the Jointed Hand by BQEducation, was very present.

However, the issue was easily addressed by slowing down retraction and can likely be managed further by reducing retraction distance. Where we’ve seen this problem before, disabling coasting was a saving grace. But coasting wasn’t enabled here to begin with.

We were pleased to find that printing high-temperature materials on the Voxelab Aquila S2 was a pleasant and easy experience. In typical fashion with these tricky materials, we found a brim and bonding agent were required — a glue stick was fine. Fortunately, our Prusament polycarbonate blend came with some we could use. These were, somewhat surprisingly, some of the better of our 3DBenchys, with even a very clear stern nameplate. Within its temperatures, the Aquila S2 definitely handles its high-temp materials well.

Is It Worth It?

It may come as a surprise given the low-low ~$250 price tag and accompanying features, but we actually don’t find the Voxelab Aquila S2 to be an especially compelling deal. But, that’s largely because Voxelab has managed to make the original Bowden Aquila so affordable.

If you’re okay with a little bit of modding, the S2’s price compared to Voxelab’s original Bowden Aquila just doesn’t justify what is, ultimately, a disappointingly limited extruder. Not in that it doesn’t work just fine but, being proprietary, the nozzles restrict users in frustrating ways. Such as by removing any option for a hardened nozzle out the gate. Add to that thought, if Voxelab were to stop producing these consumable parts, you’ll be stuck. It’s likely we’ll start seeing third-party clones at some point, but it’s less likely we’ll see quality alternatives — so you might end up swapping the extruder eventually anyways.

With that in mind, a cheaper alternative to the S2 would be to grab a regular Aquila with the Bowden extruder and fit a third-party direct extruder. Heck, if you go with a Biqu H2 for ~$80 you’ll get a direct extruder that reaches 500 °C, has a bi-metal heat break, and even shave $10 off the Aquila S2’s price. You’ll also have the original Aquila’s tempered glass bed, which we find preferable to the S2’s PEI-coated bed.

So who is the Aquila S2 for? Well, if you’re new to 3D printing, not planning to get your hands dirty with heavy modding, and are in the market for a budget option with direct extrusion and the potential to work with high-temperature materials, the Aquila S2 is offered for a great price. Despite compromises around nozzle compatibility, it’s ultimately a good bit of kit that delivers great results without much work from the user.

But, if we’re being honest, swapping out an extruder isn’t a particularly difficult mod. If you’re new to 3D printing, getting your feet wet with the original Bowden Aquila and upgrading later seems like the right move. You save a buck and will inevitably learn a lot by changing things out.

Features

High-Temperature Direct Extruder

The Voxelab Aquila S2’s direct extruder takes the filament directly from the spool and heats it as high as 300 ℃. Direct extruders have long been associated with superior handling of flexible filaments, such as TPU.

300 ℃ is a high temperature to find in a 3D printer in this price range and should allow you to work with more exotic filaments such as PC and nylon. When fitted with tougher nozzles than the default brass, it should also work with more abrasive materials like carbon fiber. That said, Voxelab has yet to release a hardened steel version of its proprietary nozzle.

PEI Magnetic Build Plate

PEI (Polyetherimide, not the island in Canada) is a thermoplastic with strong resistance to low and high temperatures and chemicals. You’ll find it in all kinds of industries including automotive and aerospace, so you can bet your behind it’s suitable for 3D printing.

A sheet of sticky PEI used to be the go-to material for 3D printing in times of yore. These days, glass is more in vogue but some printers, like the Aquila S2, have begun applying it to magnetic build plates. Like some similar surfaces we’ve seen, this print bed was underwhelming and suffered from frustrating adhesion difficulties.

Build Volume

Opting for an Aquila S2 over the normal, base Aquila loses you 10 mm in the Z-axis to compensate for its lower-hanging direct extruder. Its build volume of 220 x 220 x 240 mm is a fairly standard Ender 3-y build size, though. This is just what you should expect for space with these kinds of machines.

Color UI with Rotary Knob

Returning from other Aquilas is the color UI that isn’t touchscreen, but that doesn’t matter because the rotary knob works just fine and the UI is clear, easy to navigate, and easy to understand. Languages provided are English and Chinese only though, so speakers of other languages may struggle to understand the menus without a little lesson in one of those tongues.

You may have noticed the UI with this Aquila is portrait instead of being horizontal like it was on the original Aquila. This first appeared in the X2 model.

32-bit Mainboard Options

The Aquila S2 launched with two different 32-bit mainboards, the H32 and N32, but is now only available with the latter. Both are open source and support DIY mods. There’s really only one difference between them, which is the development tools they require to carry out those mods. The H32 mainboard will be modifiable with Eclipse or Keil development tools, while the N32 will be modifiable with VSCode.

Tech Specs

General Specifications

- Technology: Fused deposition modeling (FDM)

- Year: 2021

- Assembly: Partially assembled

- Mechanical arrangement: Cartesian-XZ-head

- Manufacturer: Voxelab

3D Printer Properties

- Build volume: 220 x 220 x 240 mm

- Feeder system: Direct

- Printhead: Single nozzle

- Nozzle size: 0.4 mm

- Max. hot end temperature: 300 ℃

- Max. heated bed temperature: 110 ℃

- Print bed material: PEI-coated spring steel

- Frame: Aluminum

- Bed leveling: Manual

- Connectivity: USB, microSD

- Print recovery: Yes

- Filament sensor: No

- Camera: No

Materials

- Filament diameter: 1.75 mm

- Third-party filament: Yes

- Filament materials: PLA, ABS, PETG, Flexibles, Carbon fiber, PA, PC

Software

- Recommended slicer: Cura, Simplify3D, VoxelMaker

- Operating system: Windows, Mac OSX

- File types: STL, OBJ, AMF

Dimensions and Weight

- Frame dimensions: 485 x 344 x 382 mm

- Weight: 9.4 kg

Similar Printers

Why not have a stroll down Best 3D Printers Guide Street and check out the stiffest competition that the Aquila S2 will be facing. There’s some seriously good machines in there. We’ve also picked out the three machines below as viable alternatives to the new Aquila too.

Voxelab Aquila

Sure, it’s missing that high-temperature direct extruder and might catch on fire without a firmware update, but the basic $160 Voxelab Aquila prints great with ABS and PLA stock and is super easy to learn the ropes with if you’re new to 3D printing. If you tack on an aftermarket direct extruder like the Biqu H2, you’ll get everything you’re missing from the S2 (and more) for around the same price — and a more appealing glass print bed.

Biqu B1

For around $250, the Biqu B1 gives you a larger print area than the Aquila S2, easy upgradability, funky LED lighting, and a hot pink livery. It also has a 32-bit mainboard and a magnetic springy print plate that we found much more appealing than the S2’s. Unlike the S2, though, it also dual-wields operating systems, allowing you to use Biqu’s touchscreen UI or the classic Marlin setup complete with rotary knob.

Creality Ender 3 S1

The recent Creality Ender 3 S1 has created a bit of excitement. It comes Creality’s new lightweight direct extruder, automatic bed leveling, a PC-coated spring steel sheet that we found to perform excellently. It’s a 220 x 220 x 270 mm build volume and is compatible with an optional laser engraving tool head. It’ll cost you around ~$150 more than the Aquila S2, however.

Lead image source: All3DP

License: The text of "Voxelab Aquila S2 Review: Aquila’s Heel" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.