A curvy, shiny 3D printed steel bridge spans an Amsterdam canal in 2021, and suddenly the world takes notice of an emerging metal manufacturing technology called wire arc additive manufacturing or WAAM. Interest has been soaring ever since.

This method of 3D printing has actually been employed in heavy industry and aerospace for years. In the 1970s, it was called shape welding, but it’s come a long way since then. Today, it’s being eyed as a way manufacturing, heavy industry, defense, and aerospace can produce large metal parts at a fraction of the time and cost of traditional forging, castings, or machining. It also may be a solution for clogged industry supply chains, market pressures to innovate, sustainability targets, and faster repair and spare part delivery.

Below we take a look at the technology called WAAM, its strengths and challenges and the latest applications, but if you’re already familiary, feel free to skip down to the equipment section where we feature the latest WAAM 3D printers.

What is WAAM?

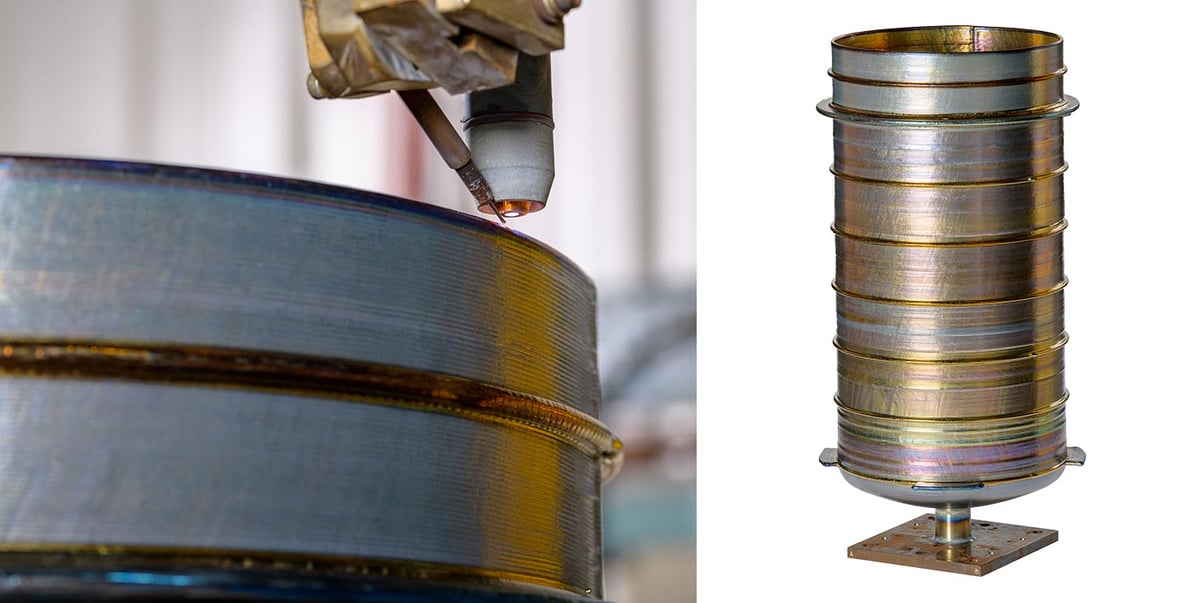

Wire arc additive manufacturing uses metal wire as the material and an electric arc as an energy source, similar to welding. The arc melts the wire as it’s deposited layer on top of layer by a robotic arm onto a surface, such as a multi-axis turntable. As with welding, an inert gas prevents oxidation and improves or controls the metal’s properties.

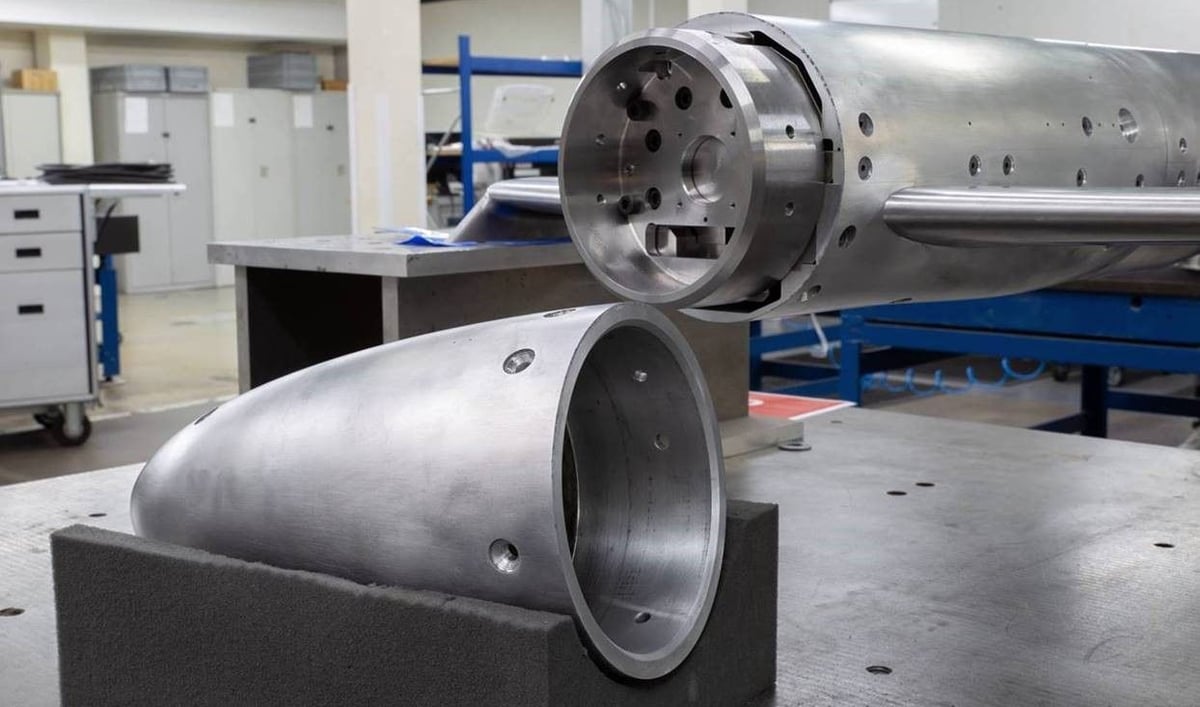

The process gradually builds material into a complete 3D object or a repair of an existing object. There are no support structures to remove, and finished parts can be CNC machined to tight tolerances if necessary or surface polished. Typically, printed parts receive a heat treatment to relieve any residual stresses.

WAAM builds upon the well-established and known methods and material results of welding. Although WAAM uses complex software to control a menu of variables in the process, there’s a familiarity with the general method that’s attracting more companies to the technology.

You’ll hear WAAM called by other names as companies in this field jockey to promote their technology above the competition. However, methods that use a laser or an electron beam with metal wire instead of an electric arc are another distinct technology under the same directed energy deposition (DED) 3D printing category.

WAAM is considered the most cost-effective option among the DED technologies because it can use existing arc-welding robots and power supplies, plus it uses readily available welding materials, so the barrier to entry is relatively low. WAAM’s electric arc technology – including plasma arc – is less expensive and safer than the lasers and electron beams used in other types of DED and doesn’t require a vacuum chamber for non-reactive metals. However, an inert gas environment usually made from argon or nitrogen is still needed for reactive metals like titanium or aluminum to avoid chemical reactions with atmospheric gases.

The main selling point of WAAM is to print big metal things fast and economically, but there’s more to the technology’s appeal.

- WAAM is used with any weldable metal

- WAAM has a high deposition volume and rate (it builds up parts fast)

- WAAM drastically reduces the amount of raw material used and wasted

- WAAM uses existing arc welding technology

- WAAM can build very large parts

- WAAM enables design freedom and complex geometries

- WAAM tech is based on arc welding, so material and process behavior is known

A growing number of companies today make WAAM 3D printers, and an even larger number of companies provide on-demand WAAM metal 3D printing services. Let’s look closer at the applications and the WAAM 3D printers on the market now that make this technology an accessible solution.

Why Use WAAM?

There’s no shortage of industries that could benefit from large metal parts and faster replacements. From defense and marine to architecture and aerospace, WAAM is used

- to quickly make large metal parts

- to remanufacture heavy-industry parts

- to create one-of-a-kind metal features

- to repair molds and dies

- to repair or repurpose metal parts on-site

- lower waste and meet sustainability goals

With your own WAAM 3D printer or using a local print service, supply chain issues are eliminated and metal parts can be put into service faster.

“Because WAAM lends itself to very large structures that normally are forged only in a few parts of the world, we are seeing more demand and I think it’s just going to get larger,” says Filomeno Martina, CEO and co-founder of printer manufacturer WAAM3D.

For example, if you’re in the oil and gas indy and need a unique metal replacement part fast, WAAM can fabricate a near-net shape of the part at a rate of about 600 cm³ per hour. That near-net shape can then be CNC machined to exact tolerances.

Australian WAAM start-up AML3D did just this, creating a 940-kilogram piping spool component used in the oil & gas industry. It was the first of its type to be WAAM metal 3D printed and independently pressure tested. At 850 mm long and 450 mm wide, the 41 mm thick high-pressure piping spool was printed according to the stringent and newly released American Petroleum Institute Standard 20S and met all test acceptance criteria. The component also passed industry-standard high-pressure testing.

WAAM has been proven to cut months off of part production time, but material conservation and sustainability are other important attributes of the technology. WAAM produces a part close to the final dimensions using only the material necessary, resulting in very little waste compared to forging or CNC machining. This is especially important when using expensive materials, such as titanium.

Metals most used in WAAM today include:

- Titanium (TI-6Ai-4V, Grade 5, Grade 23)

- Steels (Maraging Grade 250, Duplex 2205, 2507, Martensitic 410, Austenitic 420)

- Stainless Steel (316L)

- Aluminum (2319, 4043, 5183, 5356, 5087)

- Nickel Alloys (Inconel 625 & 718, FeNi36 (INVAR), NiAiCu (NAB)

With the rising interest in WAAM, material choice is also expanding. For example, material supplier Alloy Wire International offers a range of specialty aerospace alloys, including Monel, Nimonic, Nitronic, Waspaloy, and Phynox and expanding their offer to more than 60 different materials.

As a 3D printing technology, WAAM can produce unique shapes and infills not possible with forging. Because it doesn’t require molds, dies, or tools, every print can be customized. This dramatically reduces the cost of creating unique replacement parts, low-volume parts, or even artistic parts like the architectural beam bracket below.

As with other 3D printing technologies, with WAAM engineers can take what was a multi-component system and redesign it to be printed as one piece, eliminating the need for assembly or welded seams.

WAAM is fast and economical, but what about quality? Parts as good as or better than forging are what WAAM printer makers boast.

When it come to sustainability in metal manufacturing WAAM shows a 50% reduction in carbon emission and 40% reduction in energy consumption over forging, according to 2023 research comparing WAAM vs. forging of a specific titanium component. The largest difference is in the material waste, with a 55% reduction in discarded material.

WAAM Material Properties & Industry Standards

One way to tell if an emerging technology is destine for wider commercial application is too see how much research is being done on its properties and processes. WAAM is lighting up the scientific journals with a vast amount of work underway to qualify and optimize it. You can find more than 1,000 studies in the past two years alone on WAAM technology as it pertains to specific metals like stainless steel or titanium or metal properties such as strength or corrosion.

WAAM parts qualify for use in several regulated industries where there are certifications and standards, including the American Petroleum Institute, Lloyd’s Register, The Welding Institute, American Society of Mechanical Engineers, Bureau Veritas Marine & Offshore, DNV GL, and others.

Any last doubts over the technology’s material properties were eliminated in 2023 when Relativity Space successfully launched its Terran 1 rocket. Made from 85% 3D printed parts, many of which were manufactured with the company’s proprietary Stargate WAAM 3D printer, the rocket managed to reach space but ultimately failed to reach orbit. Nonetheless, the engineering feat shows the potential of WAAM manufacturing and its ability to withstand even the most extreme conditions.

Parts produced with WAAM are particularly notable for their high density and strong mechanical properties. Because the wire feedstock is already a dense input material, there’s little porosity induced in the fabrication process. One 2024 study out of the Department of Metallurgical and Materials Engineering, at Istanbul’s Gedik University, found WAAM stainless steel 316 parts had higher yield and tensile strength than cast parts, and higher corrosion resistance.

According to recent research by Kai Treutler and Volker Wesling, “the key to understanding wire arc additive manufacturing is deep knowledge of the used welding processes. The differences between additive manufacturing and joint welding are based on the differences in the thermal conductivity, which is significantly lower for thin-walled structures. This makes thermal management the key factor to achieve the desired part geometry and material properties.”

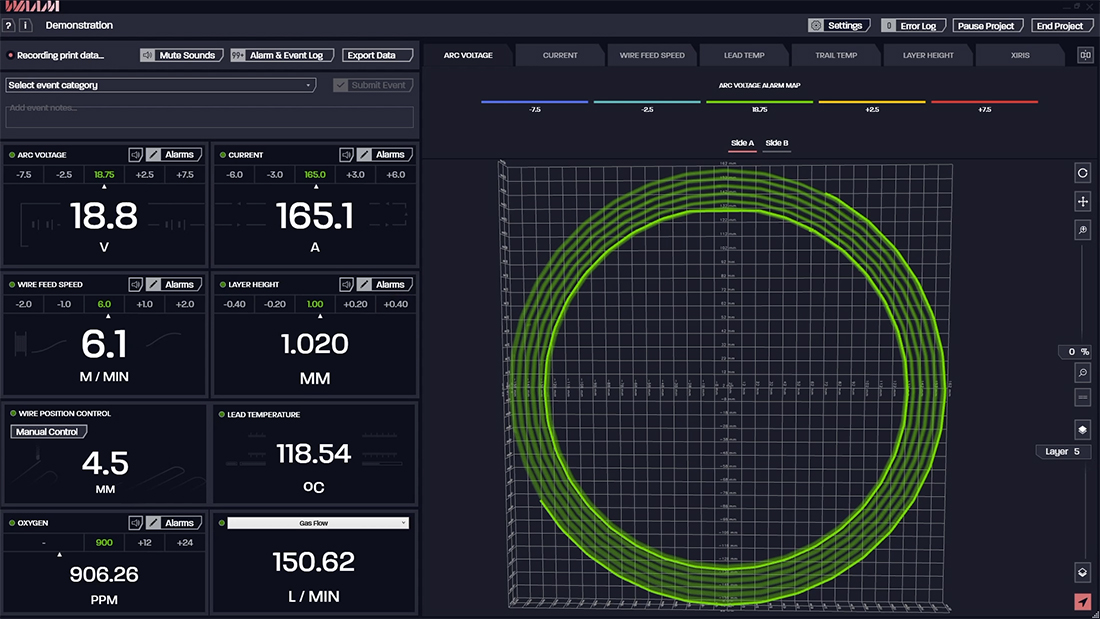

Precise thermal management is where the WAAM machine software comes in.

Precisely controlling the heat, bead size, layer height and width, the power of the current, speed of deposition, the movement of the robot, plus how to combine each of these parameters depending on the material and shape of the final part, is the success story of today’s WAAM machines.

The lack of sophisticated control software kept WAAM from being commercialized until relatively recently and is the differentiating point between the products on the market today.

Parts for WAAM are designed in any CAD or CAM software, then imported into the proprietary software of each WAAM printer.

WAAM3D, for example, comes with software for a range of processes: the WAAMPlanner does slicing, build strategy, and tool path planning among other tasks; WAAMCtrl commands your printer and monitors the build process; and WAAMSim is the virtual environment for collision detection and tool path validation. More than controlling the parameters, WAAM3D’s WAAMCtrl gives you an auditable trail of the manufacturing process.

WAAM printer manufacturer Gefertec offers CAM-3DMP modular software for tool path generation and developed an integration together with Siemens Digital Industries to perform the complete CAD/CAM process chain in the Siemens NX platform.

WAAM Challenges

WAAM is making inroads into traditional manufacturing, but it’s not entirely without its challenges. Efforts to increase speed and simplify the software are underway, along with R&D to turn WAAM from a one-off or low-volume production method into volume production manufacturing.

WAAM is not the economical choice for higher volume parts compared to traditional methods because, once the forging or casting mold is created, churning out hundreds or thousands of parts is faster with casting.

WAAM can’t compete with powder bed fusion technologies on accuracy, yet it isn’t mean to. Post-printing CNC maching is used for tight tolerances.

For now, WAAM is focused on growing adoption for the applications where the time and cost of metal forging and casting is hampering supply chains. As moving production closer to the point of need becomes more economically and environmentally critical, such as in the oil & gas and marine industries, WAAM offers a solution that’s proving itself with every new application.

“Adoption of WAAM is just a matter of time,” says Wei Ya, co-founder of RamLab, a WAAM printer maker and research facility in Rotterdam. “Like any other new concept or new method, on one hand, it will take time for the industry to establish common standards, regulations, and rules; on the other hand, it will also take time for people to get a better understanding of the technology, become more familiar with it, and, eventually put it to use.”

WAAM Machines

WAAM 3D printer technology comes in a wide range of configurations, from turnkey self-contained pods to systems that augment your existing arc welding robots. Typically running hundreds of thousands of dollars, WAAM machines are often customized to your needs and applications.

Recent trends also show that companies with robotic arm additive manufacturing capabilities are trying to enter the WAAM market. Caracol for example recently teased the expansion from robotic arm plastics manufacturing towards WAAM technology. For now, here are the top machine providers already operating systems in the field.

AML3D

AML3D is an Australian WAAM 3D printer maker founded in 2014 that just opened a US headquarters in Stow, Ohio this past spring. The company’s Arcemy 3D printer produces large industrial products in various metals and alloys, including titanium, aluminum, nickel, stainless and carbon steel for aerospace, defense, and marine industries.

The company has landed several defense contracts in the past few months

Arcemy comes in four editions: EDU, Small, Enterprise, and X. The systems are designed dot be scaleable.

Arcemy combines welding science, robotics automation, materials engineering, and proprietary software to produce parts by depositing molten wire layer by layer.

AML3D calls its WAAM technology WAM, or just wire arc manufacturing. Like WAAM, WAM combines an electric arc with welding wire as feedstock to produce medium to large-scale free-form parts or repairs.

WAAM3D

WAAM3D was founded in 2018 and grew from research conducted at the UK’s Cranfield University. Company founders have decades of research backing up their solution that hinges on proprietary software.

In May 2024, the company launched a smaller edition of its 3D printer to appeal to companies that want to seamlessly integrate WAAM technology into their manufacturing workflow. MiniWAAM, is also designed for R&D and prototypes as the “perfect companion for process development, metallurgical characterization, production of mechanical test pieces, exploration of new wires, and testing of new sensors,” the company says.

WAAM3D’s RoboWAAM turnkey system features Kuka robotic motion systems, a choice of power sources to match the material and process requirements, end-effectors with their suite of sensors, plus proprietary software. RoboWAAM’s print volume is 2,000 x 2,000 x 2,000 mm.

The entire system can be controlled from the operator’s desk with the WAAMCtrl software package, which complements the WAAMPlanner for path planning and parameter allocation.

RoboWAAM also has various shielding solutions, an automatic fume management system with filtration and recirculation, automatic purging for an inert atmosphere, and additional safety systems.

Gefertec

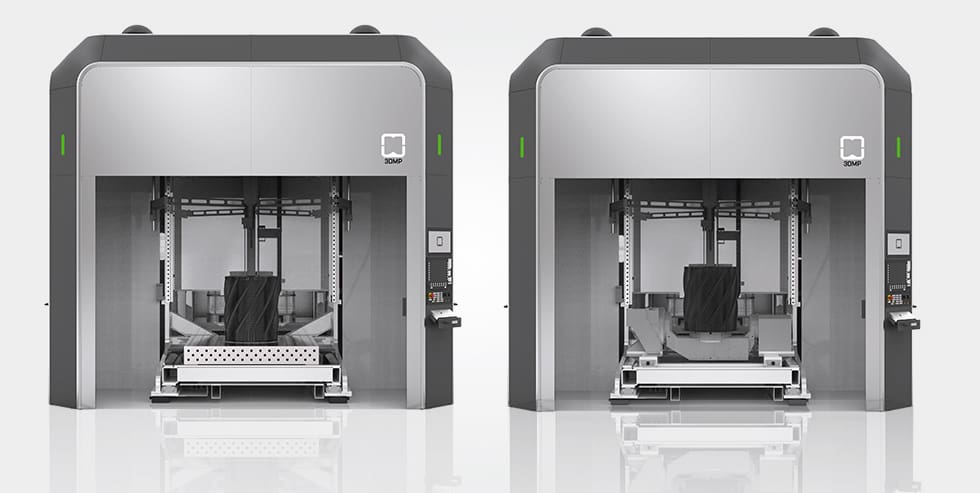

Germany-based Gefertec calls its version of WAAM, 3DMP or 3D Metal Print technology. It integrates arc welding technology and specially developed CAM software with controls from Siemens into a series of 3D printers. The company says anyone who works on a machine tool can immediately operate the Arc machine series.

Its newest and largest machine, the Arc80X, was launched in March 2024. This series boasts a larger assembly space, functions for automated production, and a module for working with titanium. A comprehensive service package supports companies that lack in-house experts.

In the 3-axis version of the Arc80X has an assembly space of 2 x 2 x 2 m and can produce parts with a total mass of up to 8,000 kg. The 5-axis version prints parts with a diameter of up to 0.9 m and a height of up to 1.4 m.

The other arc machines – Arc40X and Arc60X – designed for the WAAM process are also available as 3- and 5-axis versions and can print components up to 3,000 kg with a max size of 3 x 3 x 3 m. Around 30 alloys (aluminum, steel, nickel base, titanium) are currently available with process reliability.

The Arc WAAM printers feature temperature tracking by integrated sensors, a cooling system for local cooling by cooling gas, an automatic welding torch cleaning system, and a separate titanium module.

Gefertec’s integration partnership with Siemens NX CAM software enables streamlined manufacturing and process-related quality monitoring.

Norsk Titanium

Norsk Titanium, based in Norway, calls its WAAM process rapid plasma deposition (RPD) since it uses plasma arc welding to form titanium wire in an inert, argon gas environment.

Focusing, as you might have guessed, exclusively on titanium, mainly for the aerospace and defense industry, Norsk boasts the precision of its platform that results in less machining time. The company has delivered FAA-approved structural titanium items and says it offers a 50% to 75% improvement in buy-to-fly ratio compared with conventional manufacturing methods.

The company’s newest WAAM printer is the Merke IV. The current production envelope, with the company’s state-of-the-art Merke IV machine, is 900 x 600 x 300. New-generation machines will have larger production envelopes. Production capacity includes four machines in Norway and nine in the US to service its current client base.

MX3D

Dutch company MX3D, who printed the metal bridge at the top of this story, offers the M1 WAAM printer and the MX Metal AM System, released in September 2023.

Unlike the system it used to print its metal bridge in Amsterdam, the M1 is an enveloped system featuring an 8-axis ABB robotic WAAM setup, a Fronius GMAW/CMT welding machine, and the MX3D Control System software. The M1 also features interchangeable tool attachments to transform existing equipment into a hybrid additive and subtractive system.

The MX can make metal parts as large as 6 x 1.5 x 3.6 meters out of any weldable metal. It’s aimed at manufacturers in marine, energy, oil & gas, construction, and heavy industry. Just like MX3D’s smaller system, the M1, the MX is highly customizable. Customers have a choice of power source and 8-axis heavy-duty industrial robotic arm brand (ABB, Kuka). The robotic arms are offered in your choice of reach, payload, force, and accuracy.

The MX3D software, MetalXL, manages tool path generation and converting designs into machine instructions and printing strategies. Robot kinematics control to transform all programming into physical motions.

Recently, MX3D sold its first M1 system to Canada, showing that the company is able to provide its services in markets far away from its Dutch home base.

RamLab

RamLab, in the Netherlands, began as an initiative of the Port of Rotterdam to 3D print ship spare parts and components and has grown to offer printing services and the MaxQ WAAM monitoring and control system.

MaxQ consists of a sensor and software suite that can be integrated with your existing Panasonic welding robots to effectively turn them into WAAM machines.

MaxQ automates the production, quality inspection, and certification process for WAAM, robotic welding, and repairs. If you don’t have your own hardware, RamLab works with Valk Welding to offer MaxQ with standardized and custom-designed Panasonic welding systems.

The MaxQ system features anomaly detection and alerts, welding parameter analysis (including current, voltage, speed, wire feed speed, gas flow, etc.), and automatic data logging and reporting for evaluation and certification.

The MaxQ Repair edition is designed for repair shops and field workers who need a ready-to-use solution in the field that starts working in minutes. It’s compact, taking up less than 2 square meters, and fits easily onto any shop floor or can be taken to on-site repair jobs.

At RamLab, Autodesk’s software products PowerShape and PowerMill are used for creating CAD and CAM files. PowerShape is used for the (re)design of components for WAAM, while PowerMill is used for tool path planning and simulation. The tool path made with PowerMill can be uploaded directly to the MaxQ app using a web browser, where production is initiated.

MetalWorm

Relative newcomer to the WAAM space is Turkey-based MetalWorm, which offers computer-controlled, high-volume robotic WAAM systems.

In two primary systems, MetalWorm provides 11 configurations with a range of monitoring and controlling options for the manufacturing of parts in various dimensions.

Just released in June 2024, the MW-Lab is what the company is calling the “world’s most affordable wire arc additive manufacturing system” aimed at universities and research centers. Designed to accommodate workpieces up to ⌀500 x 500 mm with a payload capacity of 250 kg, the MW-Lab features the Fanuc CRX-5iA Cobot and Fronius CMT Technologies’ TPS400i or iWave 500i power sources.

The proprietary MetalWorm Diagnostic and Tool Path Planning Software are supported by various sensors and cameras for real-time process monitoring and control. The MW-Lab prints in aluminum alloy, steel, stainless steel, Invar, aluminum nickel bronze, and nickel alloy.

With its own unique software, the MetalWorm system can generate alternative toolpath strategies and robot codes for various geometries depending on the material used.

WAAM Services

Some companies, particularly those with a long history in welding services, have adopted WAAM technology to offer as a service. These companies either manufacture parts with one of the machines featured above or have developed their own software and systems.

License: The text of "WAAM! What Is Wire Arc Additive Manufacturing?" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.