One thing we at All3DP have always appreciated about polymer filament — compared to photopolymer resin — is its practical naming structure. Filament names, such as PLA or PETG, describe which type of polymer it’s made from. Resins by contrast don’t have to divulge their contents, and can be called simply “standard” or “tough.”

Yet, this is why one polymer filament growing in popularity is confounding. What is PAHT-CF?

You may be thinking it’s high-temperature (HT) nylon (PA) with carbon fiber (CF), but that’s where it can get confusing. As it turns out, PAHT has become a generic term for a host of polyamides marketed as engineering-grade options for both consumer and professional use. Let’s take a closer look.

HT Means High Temperature

One thing generally agreed upon by manufacturers is that HT refers to high temperature. This is an indication that parts made from PAHT filament can withstand high temperatures and maintain their mechanical properties.

To get a little more technical, you can expect higher measurements in two key areas on the technical data sheets of PAHT: glass transition temperature (Tg) and heat deflection temperature (HDT).

Glass transition temperature (Tg) is the temperature at which a polymer starts to transition from a rigid state to a more flexible state. Heat deflection temperature (HDT) is the temperature when a polymer starts to deform under a specific stress. It’s also known as Temperature of Deflection Under Load (TgUL). So you’ll often see the HDT temperature coupled with a stress measurement, like 1.8 MPa. On your filament’s technical data sheet, you may find both of these measurements or just one.

Below we show the HDT, where available, of six brands of PAHT-CF, which are generally much higher than those of PLA (averaging around 50-60 ºC ) and PA (65-100 °C) depending on the type.

*Annealing (post-heat treatment in an oven for several hours) is often used with nylon materials to boost strength yet it can lead to some shrinkage.

But as the chart shows, there’s a wide range of HDT, which brings us to the PA part of the material.

Which Type of Nylon Is In PAHT?

Some of the wide ranging technical data and material characteristics of various PAHT materials is due to the wide range of nylons — and blends of nylon and other polymers — that the material can be based on.

First, let’s clear up what nylon is. Most filament makers use the term PA to refer to nylon, either PA6, PA66, PA11, or PA12. But to be more specific, PA really refers a category polymers called polyamides. All nylons are polyamides (PA), but not all polyamides are nylons.

So when it comes to PAHT, the PA could be PA6, PA66, PA11, PA12, or the one you may not have heard of PPA (although some may argue that PPA isn’t even a nylon in the strictest sense).

Polyphthalamide (PPA) is a high-performance polyamide with excellent thermal stability and chemical resistance. It typically (although not always) has higher tensile strength and stiffness than nylon 6, 66, 11 or 12. Another of PPA’s distinguishing characteristics is that it has a higher Tg, melting point, and temperature resistance than other nylons. In fact, it was once commonly known as the “high-temperature nylon” so there may be a lingering assumption that PAHT is just another term for PPA.

“In recent years, the term PAHT (polyamide high temperature) has emerged in the 3D printing industry, initially referring to PPA-based filaments,” says Mark Peng, founder of filament maker Siraya Tech. “However, it’s important to note that the use of this term has become somewhat ambiguous. Some manufacturers now use PAHT to describe filaments made from other high-temperature resistant polyamides, such as PA12 (Nylon 12) or PA6, which are not strictly PPAs.”

Siraya Tech is set to launch a new PPA-based PAHT-CF at the end of November 2024 that features 25% carbon fiber. Called Core Black ($99/kg), the carbon fibers in are more concentrated in the filament’s core, thus the name.

It’s also interesting to note that Bambu Lab makes a PAHT-CF, where the nylon is mostly PA12, but also just launched a PPA-CF, which has a much higher HDT, strength, and stiffness.

Polymer Compositions of PAHT-CF

So your PAHT could be various nylons, or in the case of Bambu Lab and Luvocom, a blend of nylon types, but how much does that really matter? Let’s look next at the mechanical properties (strength, flexibility, impact resistance) of various PAHTs.

PAHT's Range of Mechanical Properties

The mechanical properties of your PAHT-CF should closely mirror the type of nylon it’s based on and how much carbon fiber it has. For example, PA6 generally has a lower tensile strength (45-80 MPa) than PPA (80-120 MPa), yet the PA-blend-based Luvocom has a higher tensile strength than the PPA-based QiDi Tech.

PAHT-CF Boasts:

- High strength

- High toughness

- High rigidity

- High impact resistance

- Chemical resistancet

- Heat resistance

- Abrasion resistance

- Matte surface effect

- Antistatic

- Excellent printability

The Bambu Lab material also has an uncommonly high flexibility (elongation at break + Young’s Modulus) for a carbon-fiber infused nylon, which could be attributed to the base material being PA12 and “other long-chain PA,” according to the TDS.

(*eSun uses Chinese testing standards rather than ISO.)

What all of these various measurements underscore the fact that filaments are material blends and no two formulations will be the same, which is why having a complete TDS is so important.

So if different brands of PAHT-CF can have different properties, what do they have in common or why even use PAHT-CF?

The Real Attractive Properties of PAHT-CF

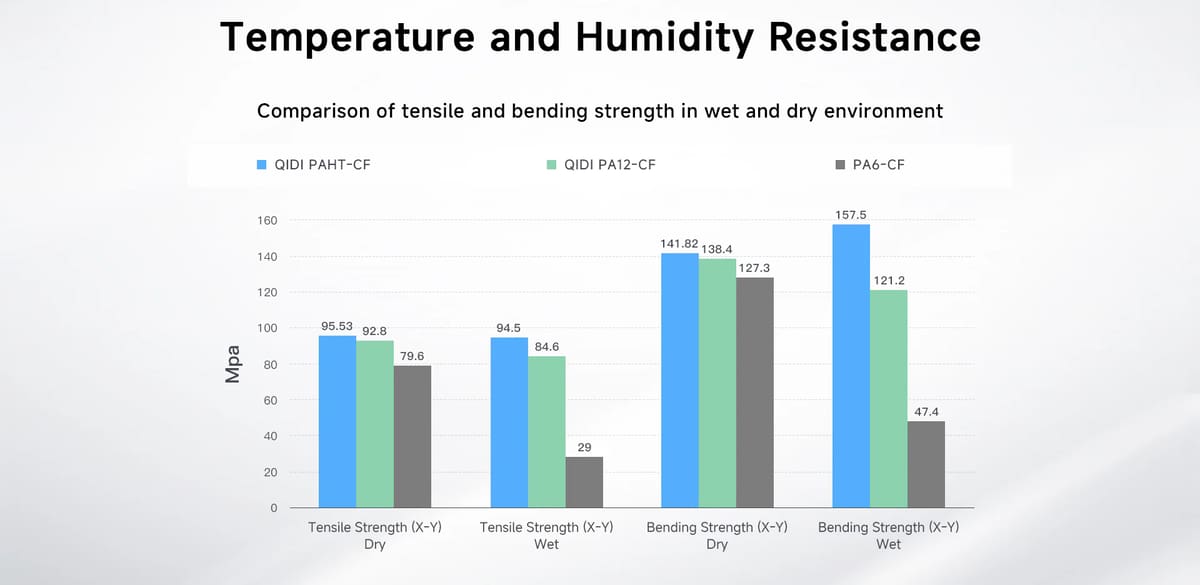

Bambu Lab discontinued its PA-CF in favor of PAHT-CF in 2022 while other filament makers typically compare PAHT-CF to PA-CF to highlight one main attribute: extremely low moisture absorption rate.

If you’re someone who doesn’t like to dry your materials, then you’ve probably never had much success with any type of nylon.

It is typically recommended to keep nylon dry and to dry it before use since it tends to absorb moisture from the air. Even with drying, it can be challenging to rescue nylon left out in a humid environment. PAHT is a much more forgiving nylon when it comes to moisture. It can have as much as 50% lower water absorption rate compared to normal PA-CF, but that doesn’t mean you never have to dry PAHT. It is still recommended to keep it dry.

Yet, be cautious of over drying nylon. If the filament is already dry, subjecting it to high temperatures for hours can cause the PPA to crystallize, as it would during an annealing process, notes Peng. This can make it too stiff and unprintable.

“The importance of keeping nylon/PAHT dry cannot be overstated,” says Peng. “To effectively remove moisture, temperatures above 100 °C are required for several hours, but most filament dryers on the market only go up to 70 °C, which, as you can imagine, isn’t sufficient for drying PA filaments.”

This is why it’s crucial to keep your PAHT dry and sealed if you do not have the necessary equipment to remove moisture effectively.

In addition to the moisture resistance, of course there’s PAHT parts’ ability to withstand higher temperatures compared to PA-CF, but again the mechanical characteristics vary depending on the type of PA used.

How to Print PAHT-CF & What to Expect

Each filament manufacturer will have different parameters for 3D printing PAHT-CF and parameters may vary from machine to machine, but what they all have in common are that PAHT-CF:

- Requires a hardened steel nozzle

- Requires an enclosed chamber

More PAHT-CF Printing Tips

- When printing a model with support, remove support structures within 2 hours after printing to prevent them from sticking after absorbing moisture. If sticking occurs, dry the model to ease the removal.

- Always reseal the filament packaging promptly after use to prevent moisture absorption.

Printing Results from PAHT-CF

At All3DP we really started to get excited about PAHT-CF after using the Bambu Lab version on the company’s X1E 3D printer. It was very easy to print and the strength of the material was impressive. It also had the layer-line-hiding effects of the carbon-fiber for an impressive surface finish.

Because PAHT filaments tend to boast lower moisture absorption they produce overall better results.

You May Also Like:

License: The text of "What is PAHT-CF Filament & Why Print With It?" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.