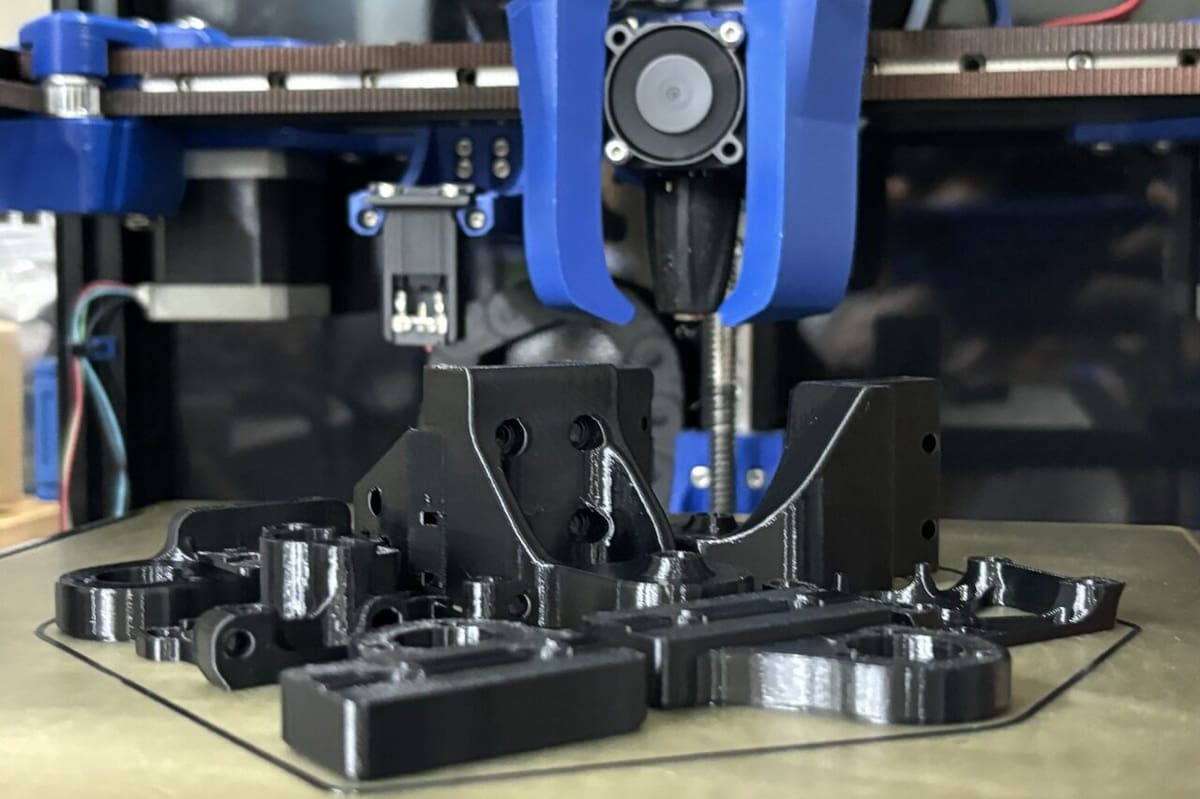

Today, access to 3D printers is widespread. Fused Deposition Modeling (FDM) and some types of resin 3D printing are now widely accessible due to their inexpensive prices and ease of use.

These technologies are easily affordable and used by hobbyists at home, allowing everyone to prototype and produce end-use parts for their projects. Despite this, one might still choose to opt for a 3D printing service instead, depending on specific part requirements.

In this article, we’ll examine whether you should 3D print at home or through a 3D printing service for a variety of scenarios. Let’s start with some key considerations to inform your decision.

Considerations

Deciding whether to 3D print a part at home or through a 3D printing service depends on the answers to several important questions:

- What will the part be used for? Is it a prototype or end-use part?

- What 3D printing technology or technologies can or should be used to produce the desired part?

- What material can or should be used to print the part?

- How experienced is the user in the 3D printing technology and operation?

- What are the post-processing requirements of the intended part?

- How soon is the part needed?

- How much is one willing to spend on the part?

Below, we’ll consider each of these questions in more detail, helping you to decide which route to take for your 3D printing projects. Let’s dive in!

Use Case

Addtive manufacturing is very versatile, allowing users to produce parts that can be used for both prototyping – hence, it’s also known and widely used for “rapid prototyping” – and end-use parts.

If the part is a prototype, one might choose to print the part themselves. Most of the time, prototypes don’t require specialized technologies, materials, or post-processing, so you can easily print it yourself. It’s also faster and cheaper to do so!

If the part is an end-use part that can be manufactured at home, it’s an obvious choice to do so too. For example, if the part is a simple bracket to hold up a shelf, printing it yourself will be easy and hassle-free.

However, if you need to produce an end-use part that requires specialized or expensive 3D printing technologies, materials, or post-processing (many of which are inaccessible for hobbyists to own and operate at home), using a 3D printing service would be the better, if not only, option.

Technology

The 3D printing technology needed will determine whether your part should (or rather, can) be printed at home.

Virtually any 3D printing technology other than FDM and consumer-level resin printing is out of reach of most people due to budget and equipment requirements. For example, most polymer powder bed fusion (PBF) printers run easily above $50,000, and metal ones, above $150,000 – and that’s not even taking into account the powder handling stations or other machines and facilities needed to operate it.

The technology intended to manufacture the part is typically already pre-decided in the design stage; parts are designed to be manufactured using specific method(s). For 3D printing, you can design your part to be manufactured on either the printer you have at home or a highly specialized 3D printer. Frankly, you could do both: Design your prototypes to be printed yourself and the end-use part to be printed using a specialized technology through a 3D printing service.

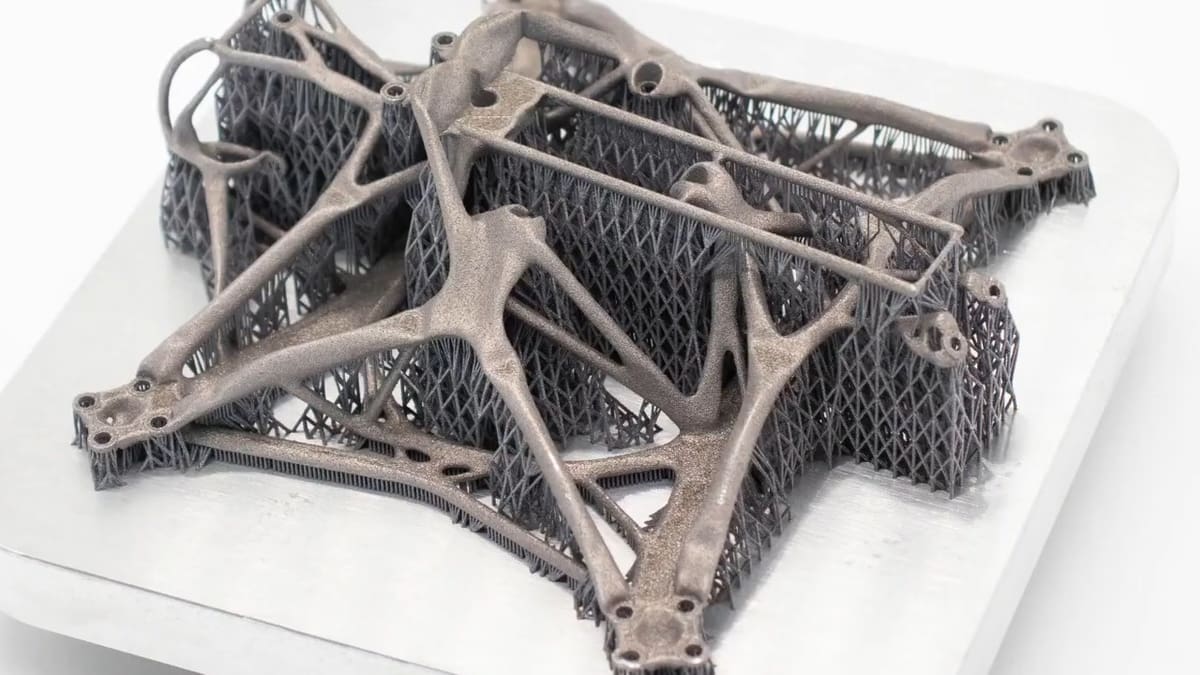

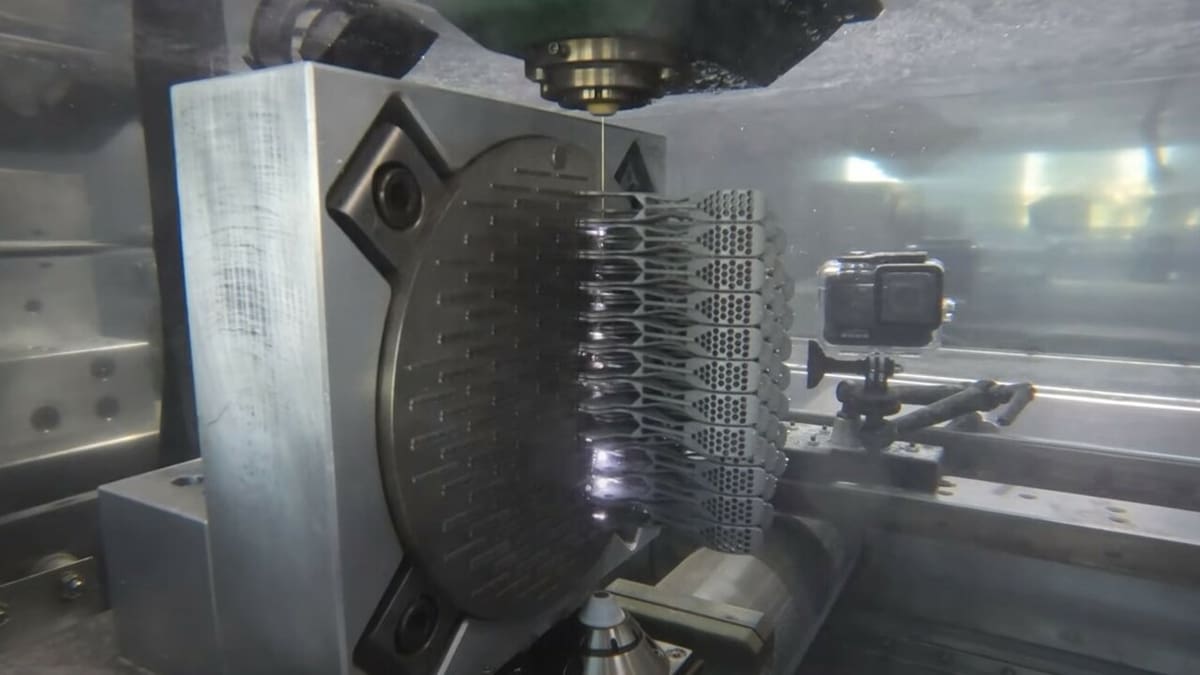

If you’re designing a part that calls for very advanced 3D printing technologies, you’ll have no choice but to use a 3D printing service. For example, a lightweight, high strength-optimized, and geometrically complex drone frame – such as the one designed by Till Blaser (pictured above) – most likely needs to be produced by technologies such as Selective Laser Sintering (SLS) or Selective Laser Melting (SLM). Users will probably also choose specialized materials like CF nylon, aluminium, or titanium for this application. These technologies and materials are definitely out of the reach of consumers.

Material

The operation of the part depends highly on the material used to manufacture it, and this is normally already decided upon in the design stage.

An important thing to note is that different 3D printing technologies cater to different materials. Most low-cost hobby machines only print PLA, PETG, TPU and some resins, while more sophisticated ones can handle some engineering materials like ABS, ASA, PC, nylon, and fiber-reinforced blends.

For more advanced materials like metals or high performance FDM polymers (e.g. PEI and PEEK), you’ll likely need specialized printers and a 3D printing service for fabrication of the part.

Again, prototypes often don’t require the use of the final intended material, so you can choose to print prototypes at home and use 3D printing services and specialized materials for the final product. Functional or testing prototypes, however, may require the use of the final material.

Experience

Before making a decision, do consider your experience in 3D printing.

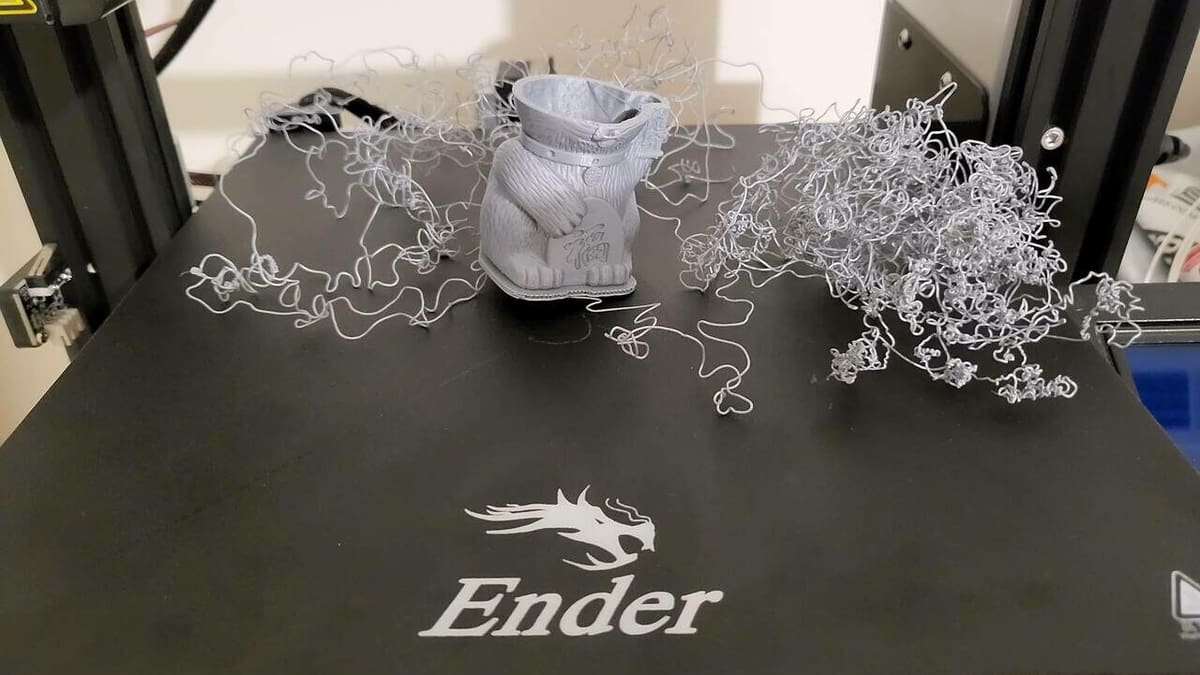

If you’re a beginner, it’s likely that your project won’t require highly specialized or expensive technologies that require a 3D printing service. Prototyping your own parts is fun, educational, and rewarding. You’ll learn to troubleshoot and tune your printer for quality parts, too!

It’s also a great way to learn various skills, such as design for manufacturing (DFM) or, in this case, design for additive manufacturing (DFAM). Different design techniques will be needed for different 3D printing technologies, so this skill is very valuable.

Post-Processing

From printer to use, some parts need post-processing to meet specified requirements such as surface finish and dimensional tolerance. Post-processing equipment can be expensive, but the good news is, the cost of post-processing is often proportional to the cost of the 3D printing technology.

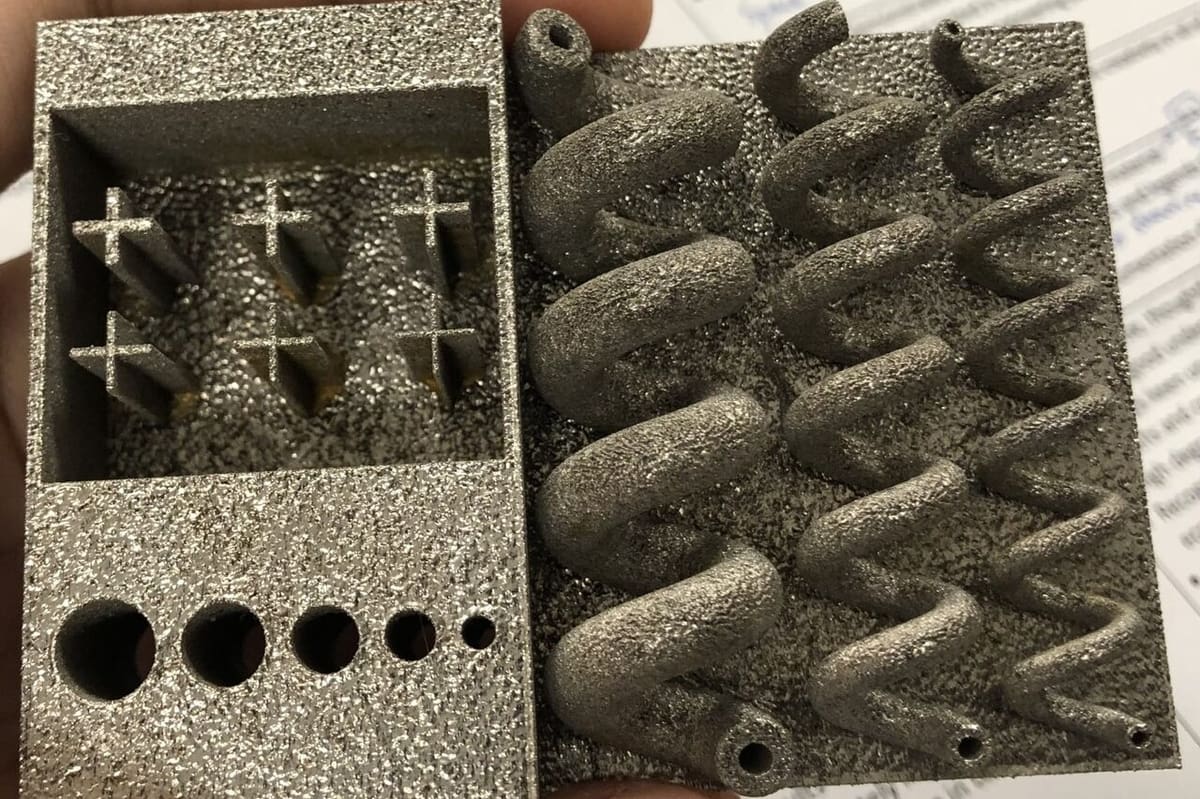

For example, post-processing steps and equipment for an expensive 3D printing process like SLM are comprehensive and expensive. Prints first need to be cut off the build plate using electrical discharge machining (EDM), then supports have to be removed and cleaned up, the part media blasted, and heat treated. Even more post-processing steps, such as polishing and post-machining for exact tolerances, might be required.

On the opposite end of the spectrum, for FDM and resin prints, expensive post-processing equipment is not neccessary for the most part, and relevant post-processing can also be done in your home relatively easily.

So, if you need the use of complex 3D printing technology and post-processing, you’ll need a 3D printing service. They typically provide post-processing services as well. If you’re able to fabricate the part yourself at home, you’re likely able to post-process it too.

Lead Times

Lead times are a major consideration in any project. Here, printing a part at home has an edge, as it will almost certainly be faster than using a 3D printing service. The print just needs to be started, and once done, you’ll have access to it.

On the other hand, using a 3D printing service will require your part to be checked for manufacturability (also called a design-for-manufacturing check), placed into the print queue, printed, checked, then shipped to your doorstep. This will means a significantly longer lead time.

Faster lead times are very helpful for rapid prototyping a project. You can quickly go through many iterations of parts instead of waiting days for a part to arrive.

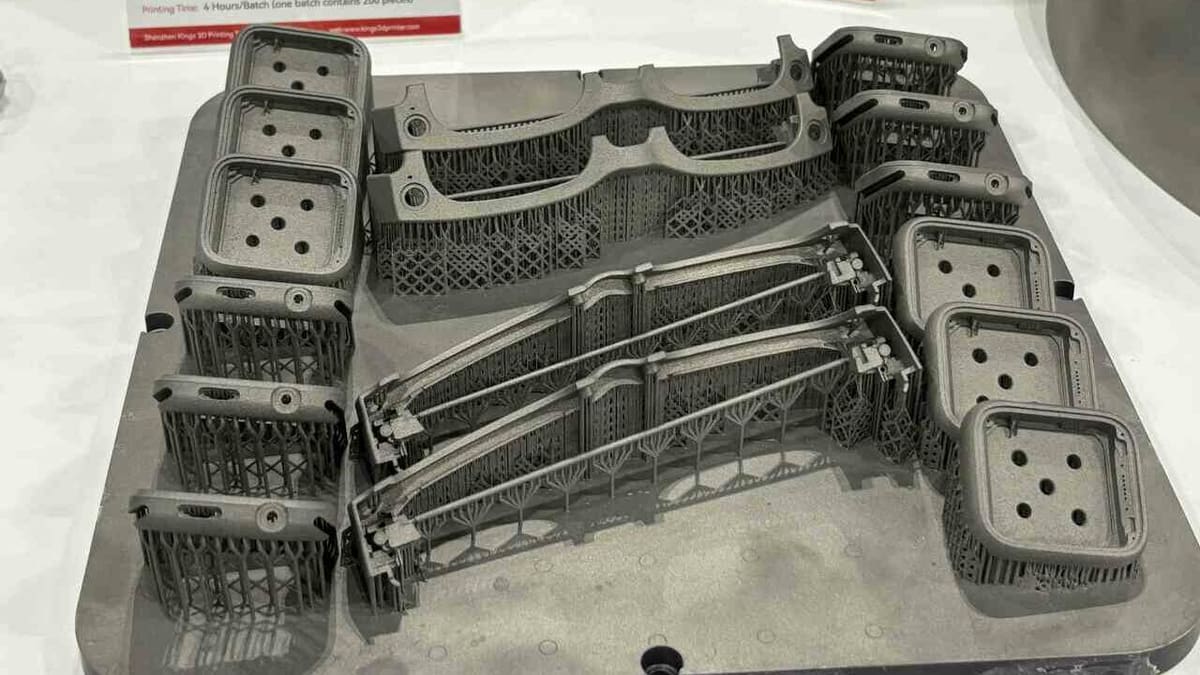

Of course, this also depends on the quantity you need. If you’re 3D printing a higher volume of complex parts for production (especially if printed using a more specialized technology), the large fleet of printers available to 3D printing services is more likely to produce your parts more quickly.

Budget

Last but not least, let’s consider the elephant in the room: cost.

Here, 3D printing at home will certainly be cheaper than using a 3D printing service – that is, for a part that can be printed at home. For specialized parts that can’t be manufactured at home due to technology or material limitations (as discussed earlier), using a 3D printing service will be inevitable.

If a 3D printing service is a must, use it only when you need it. When the project allows for it, consider printing the prototypes at home. That way, you save a few bucks and a lot of time in the process.

Verdict

In summary, whether you print at home or through a 3D printing service comes down to the application and needs of the project you’re working on. Fortunately, it’s not an either-or situation. A hybrid approach combines the best of both worlds: prototype at home, then print the end-use parts using specialized technologies and materials through a 3D printing service.

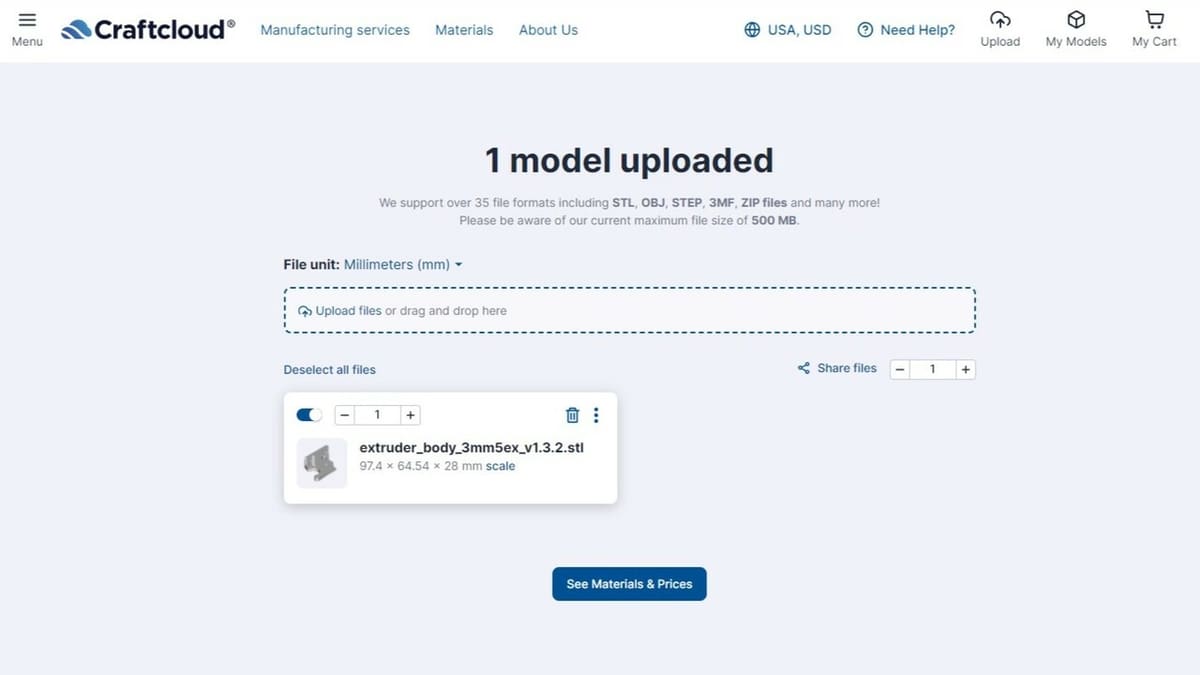

Printing parts through Craftcloud, for example, gives you access to over 150 vetted manufacturing partners worldwide and one of widest selections of technologies and materials available. New materials and technologies are added regularly. Besides both traditional and additive manufacturing services, on demand design services are available as well, thanks to Craftcloud’s partner CADmore.

After uploading your file and selecting material and finish, Craftcloud shows you the most afforable and fastest options available to you. You can select the best offer that suits your needs. The Craftcloud team then takes it from there, managing the entire process from order to delivery to ensure your parts are printed and shipped to your satisfaction.

License: The text of "3D Print at Home or Through a 3D Printing Service?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.