Innovation and Multimedia Spaces in Public Libraries

Digital workspaces in libraries are getting bigger, better, and adding new equipment. In Toronto, the newest Innovation Hub at North York Central Library has added a digital embroidery machine and some industrial sewing machines to their collection of old and new 3D printers.

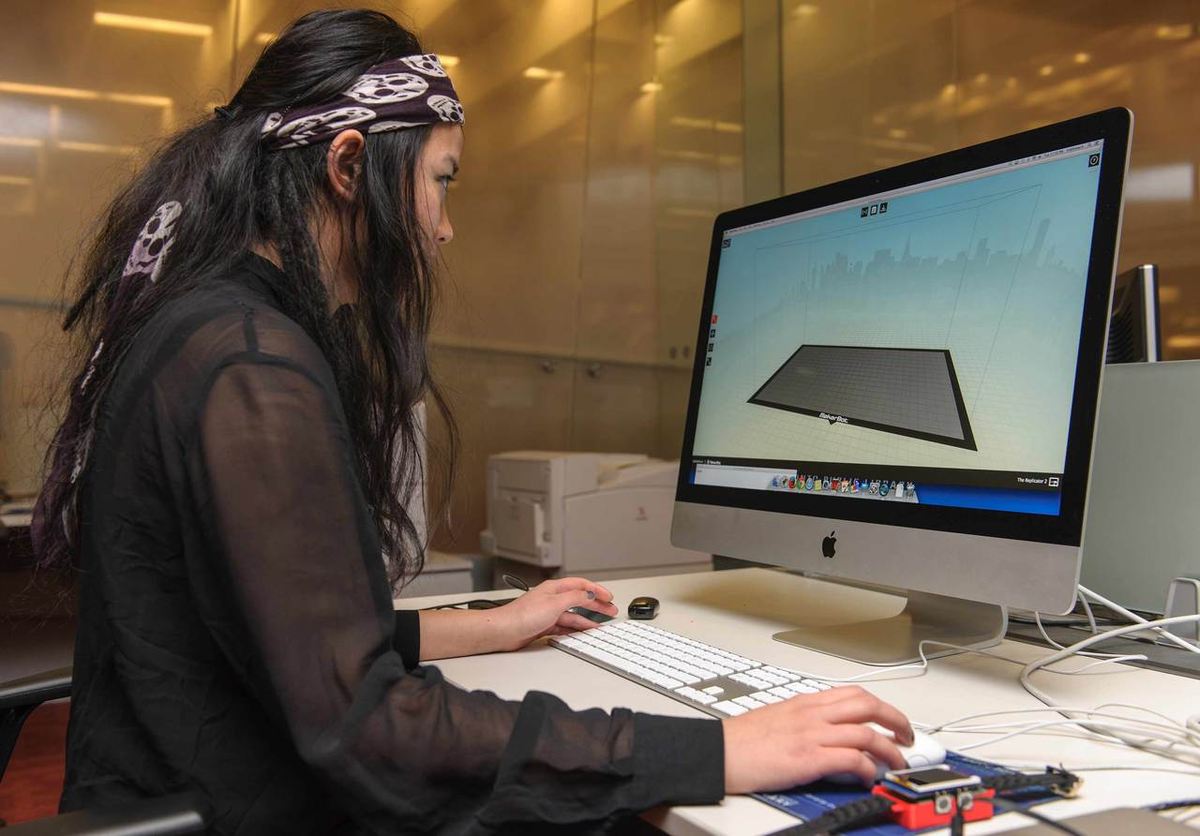

Access to machines in public libraries may be limited to allow everyone a chance to make something. Toronto’s libraries, for example, have a two-hour printing limit and their machines can usually be reserved using membership cards. 3D scanners and workstations with 3D modeling and slicing software are also on hand. A few “all-day” machines can be used on a first come, first serve basis.

Print costs at the Toronto Innovation Hubs are .10 a gram, so many things can be done for under a dollar. There really are no reasons not to try 3D printing in a library if there’s one in your city.

Safety First

One of the biggest factors in adopting publicly accessible machinery is safety, to the users and to library staff. In many cases, before users can access machines, there may be some insurance-mandated training and certification.

Fumes, particulates, and solvents are a prime concern, especially for staff, who will be exposed to these potential hazards on a regular basis. As such, ventilation and high-grade filtration are usually required. Organic compound filters with activated charcoal can be one alternative to boring holes through concrete.

PLA is the least toxic filament for 3D printing and is the only material available in the Toronto libraries.

A Good Place to Bring the Young Ones

Maybe your kids have done their research and are eager to hold a newly 3D printed model in their hand. In that case, the library is the perfect place to whet their appetites. Just pull a model of their favorite movie character from Thingiverse and get printing!

A productive first session can energize a young mind. Library staff and other users are on hand for support. Many facilities even offer scheduled classes and demonstrations.

Best Use of Library Time and Resources

To make the best use of library resources, book a 3D printer only after your 3D models are saved, downloaded and prepared. This will save time downloading, adjusting, and slicing your files.

Once the STL file is ready, any time restrictions are usually enough to realize an idea. Slicing software parameters can also be tuned to fit this limitation.

Especially if it’s a new or untested design, a “stripped down” version — low infill, thin shell, fast print speed, no support, reduced scale — should be good enough for a prototype. It’s also usually enough to encourage an impatient new user, allowing them to quickly see the results of their first print. Models can also be “Swiss cheesed”, maintaining structural and fitted elements, for a faster test fit.