Unlike 3D printers, CNC is a subtractive manufacturing method that removes material from a solid mass. It’s often considered faster and cheaper than 3D printing because it uses readily available materials like wood or plastic sheets. Since the starting material is a solid block of material, the resulting piece can be very strong. Most CNC machines can cut plastics, hard and soft wood, aluminum, and sometimes even steel.

A CNC machine opens up massive opportunities for DIY projects large and small, from building your own furniture to carving out game boards. CNC machines have gained popularity as a way to make your own custom clocks, signs, and even topographic tables.

The downside is that CNC machines cut in profile, meaning up and down. Typical 3-axis machines cut vertically, meaning they are incapable of cutting parts obscured by solid material. Some shapes can be rotated to grant access, but 3-axis machines are constrained to simpler designs with no hidden geometry.

There are a variety of budget CNC machines that are plug-and-play or kit-based, however, those machines can be limited in dimensions. Explore some of the premade options and check out our article on The Best CNC Routers – Buyer's Guide.

For those who want a larger machine or want to build one themselves, a 3D printed design may be right for you. These machines rely on 3D printed parts to cut down on the cost of custom-made metal or wood components. Printed parts are easy to upgrade, and can be replaced quickly, without the hassle of shipping.

Interested in a machine you can build yourself? This list has the best designs the internet has to offer.

Considerations

To compile the best machines from across the web, we kept a few things in mind:

- 3D printed components: Each machine has to rely on 3D printed pieces. Printed pieces reduce cost and provide an accessible alternative to machined wood or metal components. To adapt to the 3D printed parts, each CNC machine uses unique designs created to minimize the load on a printed piece. All machines on this list recommend using PLA+ or another rigid filament for all connections, or where sheer strength is needed, PETG or other high-strength materials.

- Variety of features: Building a CNC machine is a large and expensive project, so it needs to be built to last. The options included below prioritize rigidity for accurate, detailed cuts with a bed large enough for a variety of projects. The listed machines cut many different materials, including all types of wood and even aluminum.

- Community support: Every option has a community of people who have built, are building, or preparing to build the machine of choice. These forums often provide additional build guides, videos, and a plethora of resources.

- Ease of assembly: It is important that the creator provides a documented build guide, in text or video format, along with a comprehensive bill of materials essential to any successful build. Creators often include additional information with links and alternative build guides on websites or social media platforms to further aid the building process.

For each project, we’ll list a build difficulty, but keep in mind that any DIY CNC machine will be a large, expensive project that can take months to assemble. The difficulty ranking is only a means to compare the depth of assembly instructions and design intricacies of projects on this list. Projects ranked as “easy” will still require experience with machinery and electrical components to get up and running. Be sure to do your homework before choosing your machine.

With that said, let’s get to the machines!

MPCNC

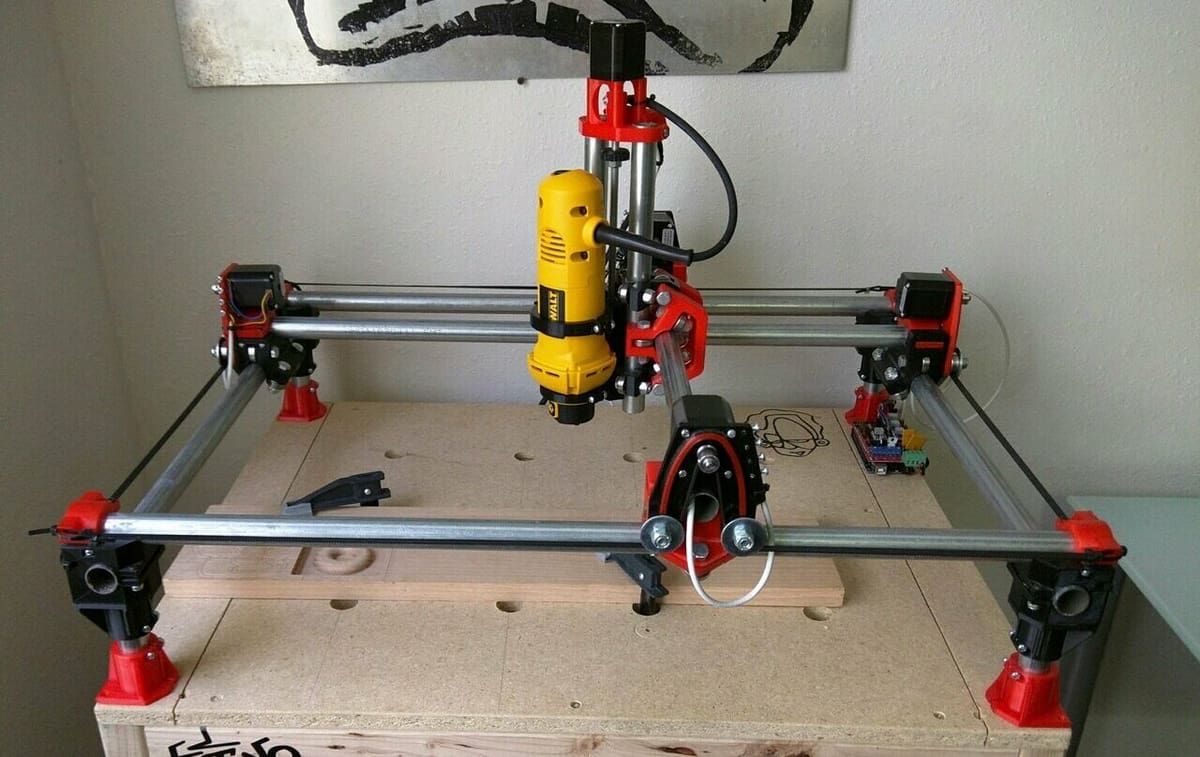

The MPCNC is a versatile design that provides lots of capability for a great price. The length and width of the build area can be near any size depending on the length of the metal frame and the timing belt connecting the stepper motors to the central column.

While the working space can be made any size, it is important to know that the larger the space, the less accurate the machine will be. Large distances increase the amount of sag and flex in both the belt and the frame. Conversely, smaller beds will be able to operate faster and more precise.

The default kit comes with enough belt for a 600 x 600 mm space that can used for a wide variety of projects. This capable machine greatly cuts down on the amount of complex parts needed through the use of steel tubing and printed parts. It’s no surprise that this device is among the most budget-friendly on the list.

Designed as an open-source, stand-alone CNC machine, the tool head can be converted into a milling machine, 3D router, 3D printer, laser cutter, vinyl cutter, or CNC plasma cutter. This is ranked as an easier build due to the segmented assembly guide and detailed electronics and programming information.

- Build difficulty: Easy

- Workable materials: Plywood, softwood, hardwood, soft plastics, hard plastics, plexiglass, aluminum

- Features: Independent CNC frame can modified for other functions, inexpensive, lots of documentation

- Cost: ~$600

- Project page: V1 Engineering

RS-CNC32

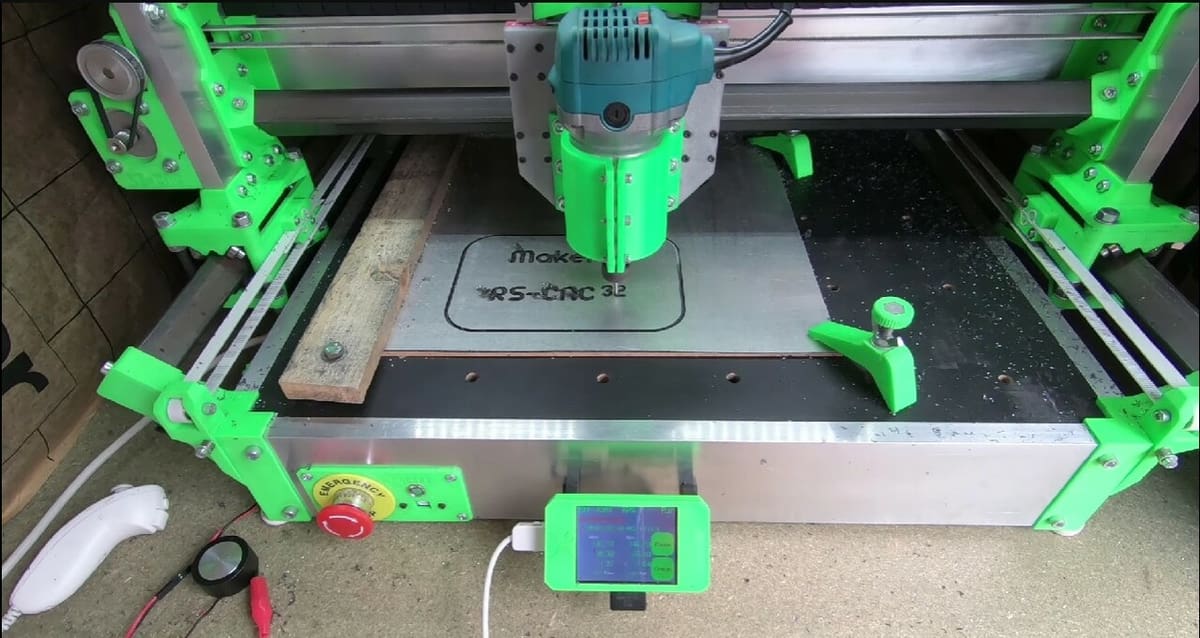

The RS-CNC32 is a touchscreen, Wi-Fi-capable CNC machine with a robust design. Using a GRBL 32-bit board kit developed and sold by MakerFr, the machine can operate without a computer, via USB, or over Wi-Fi. This open-source machine can be built with a work surface from 550 x 570 mm up to 1000 x 1000 mm.

This machine ranks as an easier build due to the clear directions in the assembly guide for both mechanical and electrical components. It’s the most budget-friendly machine on the list thanks to its emphasis on 3D printed parts. The majority of connections are made with printed pieces, and the large base is hollow aside from some support struts.

With a robust but inexpensive frame, the RS-CNC32 is a great budget option for any creator. A comprehensive build guide and bill of materials that include every detail are included online.

- Build difficulty: Easy

- Workable materials: Plywood, softwood, hardwood, soft plastics, hard plastics, plexiglass, aluminum

- Features: Wi-Fi connectivity, cheap, allows belt tuning, easy-to-find information

- Cost: ~$450

- Project page: MakerFr

PrintNC

Based on a sturdy steel frame, the PrintNC is the only machine on the list capable of cutting steel. This capability is possible due to the reduced use of printed parts in an effort to increase rigidity.

The machine is equipped with a 950 x 600 mm workspace, high torque Nema 23 motors, and open-source code. The entire Fusion 360 assembly is available online for easy modification. You’ll also find a huge online community of makers going through the build process as well.

This is an easier build because it includes a variety of assembly guide videos in addition to a detailed set of instructions. The steel pieces cut down on the number and variety of pieces, although they increase the cost to build. For those looking for the most capable machine, this project might just be worth it.

- Build difficulty: Easy

- Workable materials: Plywood, softwood, hardwood, soft plastics, hard plastics, plexiglass, aluminum, steel

- Features: Open source, simplistic design, sturdy steel frame

- Cost: ~$1,500

- Project page: ThreeDesign

Root 4

The Root 4 is the most capable evolution of the Root CNC series that began in 2016. As the flagship model, the Root 4 boasts new capabilities like rotary and tangential cutting. Being another scalable machine, the creator of the Root 4 built his version with a whopping 1204 x 1190 mm workspace.

Related machines include the Root 3, and the newest model, the Root 4 Lite. The Root 4 Lite is designed as a slimmed-down version of the Root 4 and features near the same functionality, but with a smaller bed and more limited spindle options.

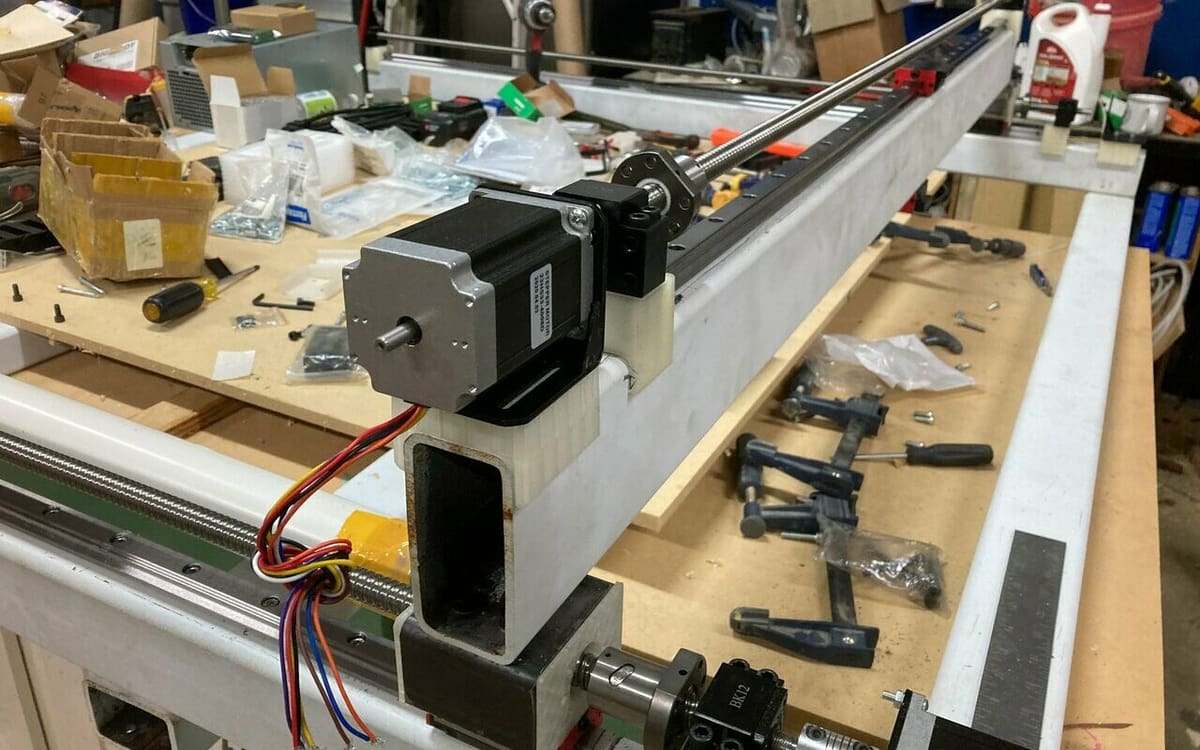

As the flagship model, the Root 4 machine uses high-torque Nema 23 motors for enhanced control and a ball screw motion system for increased accuracy and efficiency. This is the largest upgrade from the previous models using belts and lead screws. It’s listed as an intermediate project because the build guide assumes some proficiency in building such devices.

- Build difficulty: Intermediate

- Workable materials: Plywood, softwood, hardwood, soft plastics, hard plastics, plexiglass, aluminum

- Features: Lots of documentation, scalable, open source, massive workspace

- Cost: ~$2,000

- Project page: Root Cnc

Miranda Machines MK II

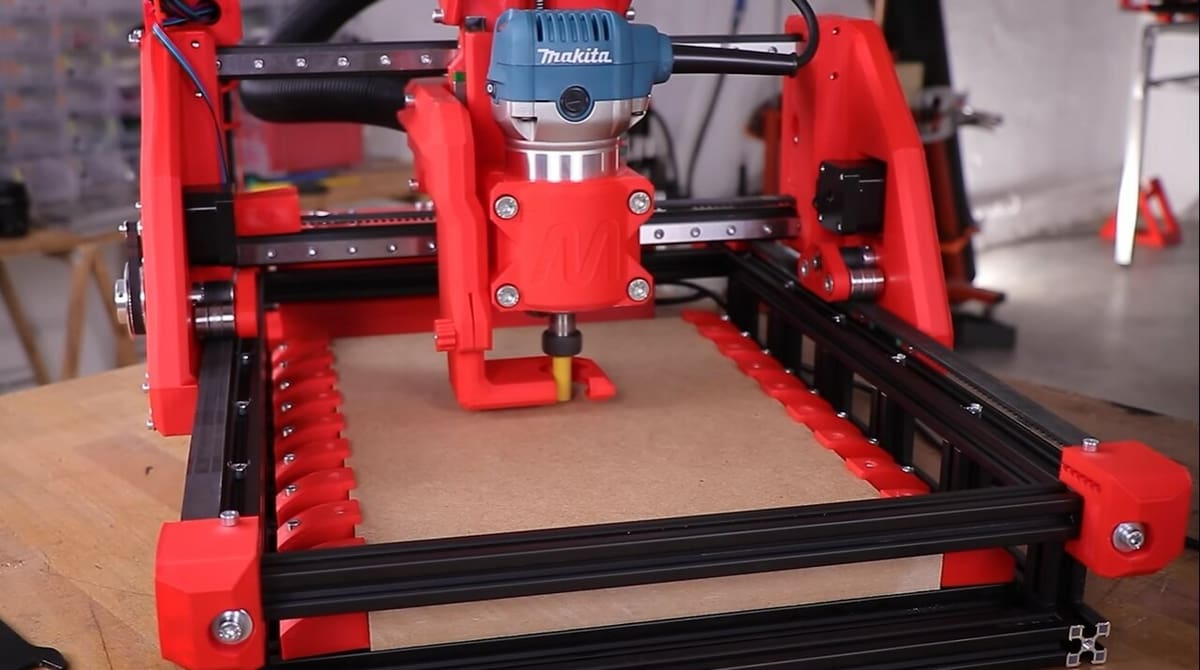

The Miranda Machines CNC MK II is a desktop router using large printed braces to cut down part costs. With a working space of 225 x 325 mm, this printer can fit into any workshop. Although files are $25, the bundle includes the full Fusion 360 assembly with hardware, pre-sliced STLs, and a complete bill of materials with size and quantity.

This particular model has a comprehensive step-by-step video guide on Ivan Miranda’s YouTube channel that covers nearly everything one needs to know to recreate the build.

Unfortunately, this build is ranked difficult as Miranda provides no detailed information on the electrical work in the assembly video, site, or purchased files. (There is, however, “guidance” on what needs to be done.) This is no doubt a very capable machine, but will require some skills that go beyond the assembly guides.

- Build difficulty: Difficult

- Workable materials: Plywood, softwood, hardwood, soft plastics, hard plastics, plexiglass, aluminum

- Features: CAD files included in purchase, gantry clearance of 85 mm, compact

- Cost: ~$750

- Project page: Ivan Miranda

License: The text of "The Best 3D Printed CNC Machines" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.