Positive Plastic

In the wake of the global climate crisis, many aspects of the natural world are being affected in ways we never predicted. Some of the most drastically affected regions have been the oceans, as the delicate ecosystems are being disrupted by the slightest changes in water temperature.

The warming of oceans cause a stress reaction in corals that prompts them to eject the cells of algae living inside them. They need they algae to produce energy for themselves, so this reaction kills both the algae and the coral, leaving only a bare white skeleton.

This phenomenon, known as bleaching, has been destroying coral reefs across the world. Many of the world’s most magnificent and diverse reefs, including Australia’s Great Barrier Reef, are being reduced to these lifeless, bleached, graveyards. As the situation worsens, it becomes more and more clear that something needs to be done. Some believe that the solution lies with 3D printing coral reefs.

The major benefit of 3D printing coral reefs is the flexibility with design. The technology allows researchers to mimic the complex natural shape of coral that makes it so appealing to sea life. Given rapid developments in bio-printing, it is also possible that in the near future reefs could be 3D printed from live coral.

There are limitations to this technology as a reef’s survival is ultimately dependent on healthy, growing coral. Simply providing more structure for the coral to grow on doesn’t guarantee any solution. 3D printing also is limited in the scale it can amount to.

However, 3D printing coral reefs is a fantastic temporary solution that helps educate researchers and the public alike about the problems affecting our oceans. While addressing climate change is the only way to truly fix the problem in the long term, engineers have developed many intriguing designs to help mitigate the problem in the short term. Here we have 4 of the most promising projects.

Boskalis

The very first 3D printed coral reef was made by the Dutch marine company Boskalis. At the end of 2017 they made history, printing six massive reefs alongside the Prince Albert II of Monaco Foundation.

The reefs were submerged in the Monaco Larvotto Reserve and are continually being monitored to measure the affect on marine life. Each reef weighs 2.5 tons and took 13 hours to print.

Unlike the other reefs, this was not created using FDM technology. They used binder jetting technology, an ingenious alternative to FDM for this application. It combines dolomite sand and seawater to produce a stone-like structure, perfect for mimicking a natural reef.

Unfortunately, as this organization does not focus on reef restoration, these six reefs are the only ones they have printed. They will hopefully still provide an abundance of information on the effectiveness of this technology for future researchers.

Reef Design Lab

By far the largest initiative involving 3D printed reefs is being carried out by the Australian group Reef Design Lab. The entire organization was founded around the technology, and they have already made great strides with the technology.

Their largest development has been the Modular Artificial Reef Structure – MARS. MARS is based on the premise that reef installation needs to be an easy and low budget process.

They accomplished their goal by designing reef structures that are composed of many separate interlocking parts. Each piece is printed in hollow ceramic, then filled with concrete.

In August 2018, they submerged their reef in the Maldives. Because of the MARS, they were able to install it by hand with only a small boat. No crane or barge was needed, and it took only two hours.

Within minutes of its installation workers observed that marine life was attracted to the structure, and it soon was inhabited by thousands of creatures.

Reef Design Lab members have stated that it already is serving as a means to obtain very much needed research on reef restoration.

Their reef in the Maldives is currently the largest in the world, and they continue to work on creating these reefs, and helping others to build their own.

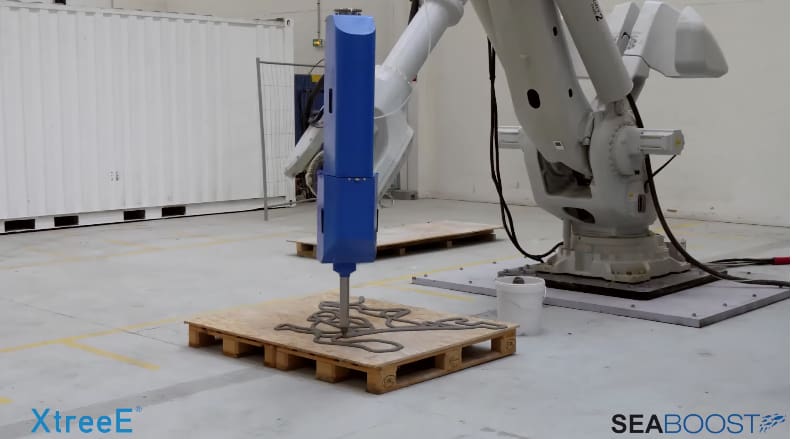

XtreeE and Seaboost

The french marine life restoration company Seaboost has partnered with the 3D printing service XtreeE to explore other methods of 3D printing coral reefs.

To best imitate the natural composition of reefs, they are utilizing a sand based concrete. A concrete printer builds the full size reefs in one piece, and all materials can be sourced from the local environments.

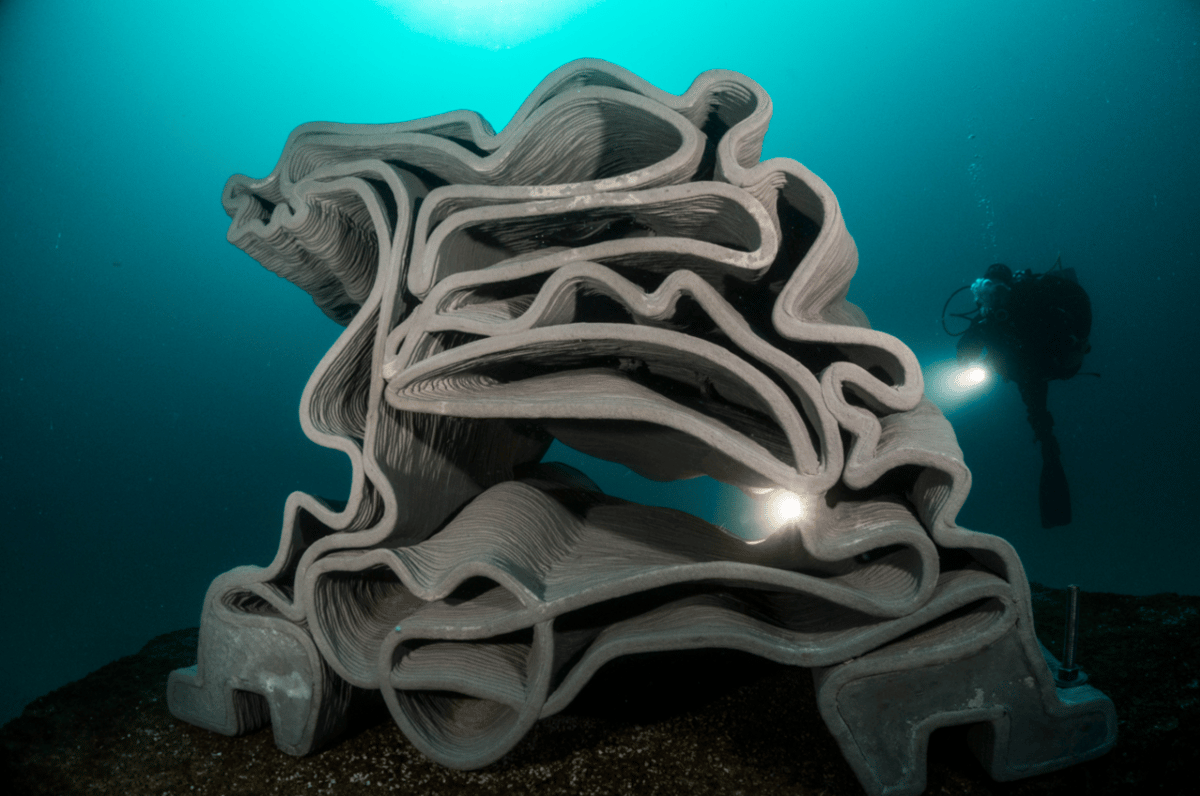

The benefit of this method is that it allows for a reef that impersonates natural coral structures very well. They obtain scans of native reefs, and they are able to accurately replicate the intricate shape. This helps the reef best fit into its environment, optimizing its appeal to marine life.

Their first reef rests in Calanques National Park in France, and will hopefully serve as a proof of concept. If they prove to be successful, then they will turn to their goal of aiding the regrowth of reefs in the Mediterranean Sea.

They explain “Using XtreeE’s 3D-printing technology, this biomimetic but porous reef mimics one of the richest habitats in the Mediterranean Sea – The Coralligenous. This marine habitat -made of a structurally complex and dense biogenic substrate- took hundreds of years to form and was no mean feat to simulate.”

So far their reef has shown promising results, and will hopefully continue to thrive in the following months.

Project Reef

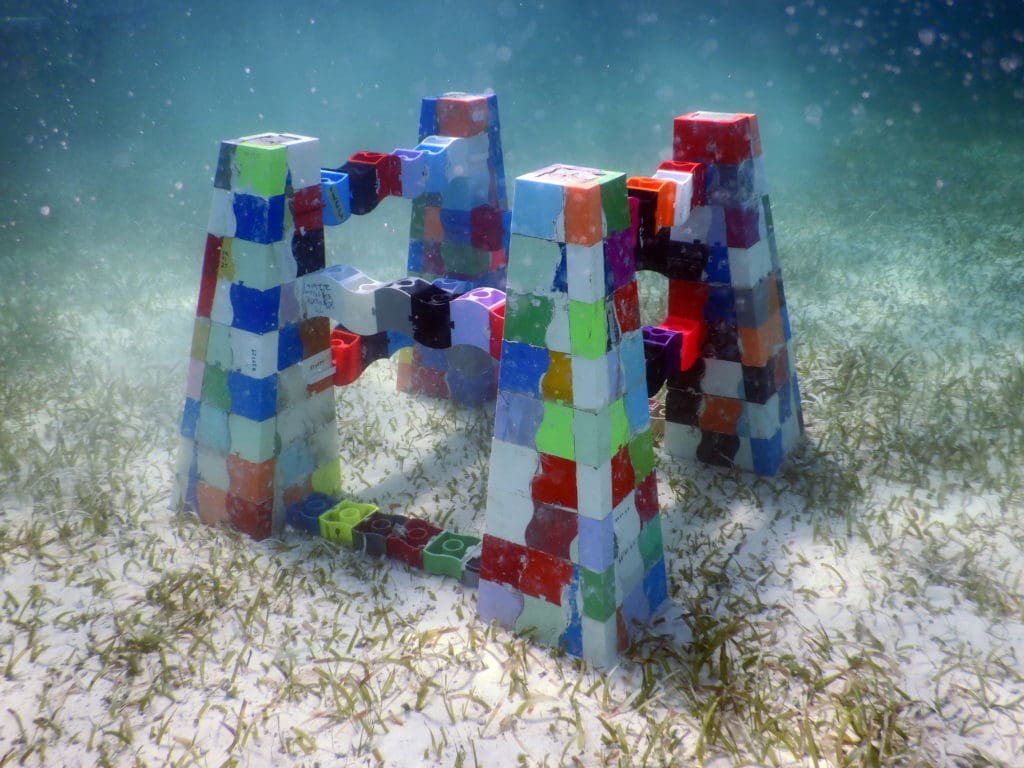

The organization Hope3D is taking a different approach to 3D printed reefs. They crowd-source all of the parts they need, drastically reducing costs.

Anyone with access to a 3D printer can participate. Simply visit their website and enter your email. You’ll soon receive a message with a file of your unique reef part. It can be printed on virtually any desktop 3D printer, in PLA plastic.

Because PLA is a starch based material, it is bio-friendly, and will naturally biodegrade into the ocean over time. This allows anyone to participate, as PLA is both cheap and abundant, and it still serves a an ecologically conscious alternative to some materials used in non-3D printed artificial reefs.

This particular initiative, Project Reef, is currently being carried out at the Hol Chan Marine Reserve in Belize. The 3x 3 x3 ft reef is composed of 400 individual segments printed by hobbyists around the world. They were able to build their first reef in a very short amount of time, showing the effectiveness of their crow-sourcing concept.

According to their website “This project aims to produce a massive crowd-sourced artificial coral reef that will surmount the habitual approaches that are detrimental to the environment.”

Feature image source: Reef Design Lab