Why 3D Print Organs?

Today, we see a surging demand for organ transplantation worldwide. Despite continuing efforts to educate people on organ donation, the gap between organ needs and availability is widening.

For this reason, there’s been a considerable increase in research on regenerative medicine, which can be defined as “a process of replacing, engineering or regenerating human cells, tissues or organs to restore or establish normal function” (Chris Mason & Peter Dunnill).

Regenerative medicine is said to be advancing thanks to new manufacturing techniques, including 3D printing. Bioprinting, in a few words, is the utilization of layer-by-layer fabrication techniques to combine cells and biomaterials to produce organic-like parts that function. As one can imagine, it’s not a simple process since human tissues are extremely complex both in structure and composition. The development of biomaterials, along with micro 3D printing, is proving to be a huge challenge.

3D Printed Kidneys

Problems

The kidney is by far the most needed organ for transplant. In fact, in the USA in the last 30 years, more kidney transplants have been performed than all other organ transplants combined.

According to the National Kidney Organization, more than 3,000 new patients are added to the kidney waiting list each month. This number alone can explain why it’s so imperative to develop regenerative medicine and bioprinted kidneys.

There are many technical challenges holding back the progress of 3D printing kidneys. Probably the biggest impediment is that, currently, no technology is capable of mimicking the architectural complexity of this organ. Other obstacles include the lack of controlled cell distribution systems and high-resolution cell deposition for vascularization and innervation.

Solutions

The 3D printing method most known for bioprinting is the extrusion of liquid material, here known as bioink. Stereolithography could represent a more suitable technique, due to its high-detail capability for printing intricate shapes, however, this fabrication process can be harmful to living tissue, and potentially cytotoxic.

Surprisingly, inkjet printers are commonly used as biological printers, mainly because of their low cost and wide availability. These systems, however, often suffer from mechanical issues and constant nozzle clogging, making them unreliable for large-scale bioprinting applications.

While it seems that bioprinting kidneys is still very much in its infancy, there has been a significant increase in the development and considerable progress made utilizing this technology. In this article, we’ve selected the three most promising institutes and companies around the globe and compiled their latest advancements.

Lewis Lab at Harvard University

Perhaps one of the biggest names in bioprinting, the award-winning Lewis Lab at Harvard University has been consistently advancing in kidney 3D printing. The laboratory’s name comes from Professor Jennifer A. Lewis, who leads the research group. According to its website, the laboratory works with 3D printing of soft functional materials for microvascular architectures for cell culture and tissue engineering, among other applications.

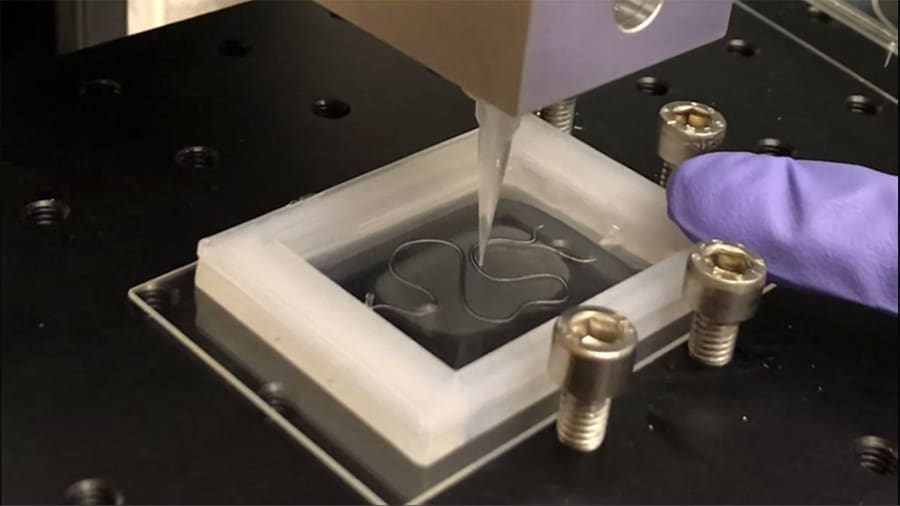

In 2016, Lewis’ lab published a paper that demonstrates how 3D printing was used to build proximal tubules, a small segment of a nephron. Nephrons are responsible for filtering and absorbing nutrients from our blood, and therefore are found in millions in human kidneys. As mentioned in the paper, this development could be immediately used for “drug screening, disease modeling and, ultimately, kidney organ engineering.”

The continuing efforts of the research team have led them to publish a new paper in March 2019, entitled “Renal reabsorption in 3D vascularized proximal tubule models“. Their main development is the fabrication of a micro blood vessel that runs side by side with a proximal tubule. This enables the recreation of “active reabsorption of solutes via tubular–vascular exchange”. In layman’s terms, this means that the nutrient exchange between blood vessels and nephron structures could be reproduced in 3D printed tissues.

This new advancement has immediate applications for drug testing and no doubt represents a step further in 3D printing a fully functional kidney.

The Wake Forest Institute for Regenerative Medicine

The Wake Forest Institute for Regenerative Medicine aims to develop laboratory-grown tissues and organs for various applications. Located in Winston-Salem, North Carolina, their scientists and physicians are responsible for the first successful implant of lab-created organs in humans. Led by Dr. Antony Atala, the institute works in the development of more than 30 different tissues and organs.

In past studies, institute scientists have successfully grown kidney cells that were later implanted in animals. These cells eventually formed kidney structures and were even able to partially function in a “mini kidney”. On the bioprinting side, the Wake Forest Institute initially used a modified desktop inkjet printer to produce 3D structures with grown cells. Then, in 2016, they successfully 3D printed living tissue structures using a specialized printer, designed by the institute’s own scientists.

With this new equipment, Dr. Atala and his team were able to develop a material that would hold cells together during and after the printing process. The next step was to 3D print a structured model of a kidney. Although only a macrostructure, or “prototype” as they called it, it could pave the way for developing a fully-functional kidney in the future.

Additionally, the institute researchers have been working with yet another approach for treating chronic kidney diseases. In a 2019 paper, Dr. Atala and his colleges showed that fluid stem cells injected into a diseased kidney can lead to improved kidney function.

Organovo

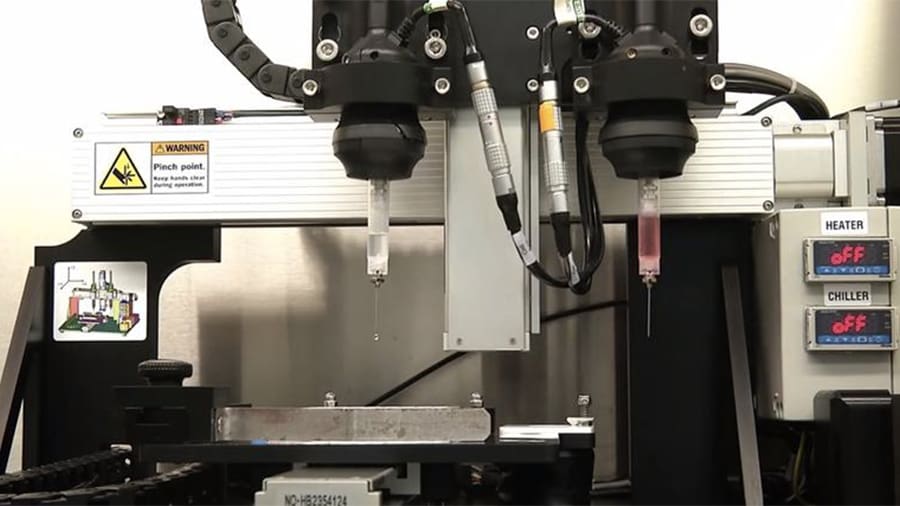

Rather than an institute, Organovo is a publicly-traded medical company launched in 2007. Located in San Diego, California, the company is dedicated to developing functional human tissues using 3D printing techniques. Their main goal is to use lab-grown tissues for accelerating pre-clinical drug testing, but there’s also a handful of regenerative medicine research, too. Towards this end, Organovo has developed its own bioprinter, the NovoGen MMX.

Organovo’s bioprinter is an extrusion-based printer. It includes two print heads, allowing the simultaneous use of both human cells and support structures (like scaffolds and hydrogel). The printer was recognized as one of the “Best Invention of 2010” by Time Magazine.

In 2015, Organovo announced the fabrication of (proximal tubular) kidney structures. The tissue was said to be only cell-based, with no scaffolds, showing real connections and architecture. In that same year, the company partnered with the University of Queensland’s Institute for Molecular Bioscience, which in turn had shown the means to create a complete “mini kidney”.

In June 2019, the company announced the development of a process for automated production kidney organoids, potentially enabling the treatment of real patients with chronic renal disease. Organovo is now leading a research collaboration along with Murdoch Children’s Research Institute, the Royal Children’s Hospital in Melbourne, and Ton Rabelink at Universiteit Leiden in the Netherlands.

(Lead image source: theengineer.co.uk)

License: The text of "3D Printed Kidney: The Latest Advancements" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.