Orthotic devices, commonly referred to simply as “orthotics”, are wearables used to support body parts during the rehabilitation process. They can be used for a wide range of debilitating conditions, from limb immobilization and recovery to full-body instability and improved mobility.

For these devices to be effective, they need to be custom-designed. This is one of their major drawbacks, as they can be extremely time-consuming to manufacture. Traditionally-made orthotics often require frequent fitting sessions, which can lead to several months of waiting before the user can wear the final piece.

Thanks to its affordability and ease of use, 3D printing has simplified the entire orthotic fitting and customization process. 3D scanning and modeling significantly reduce the amount of time required to produce and deliver orthotics to patients.

In this article, we’ll take a look at some of the most promising 3D printed orthotics companies and projects.

If you already have a custom orthotic designed and ready but don’t have access to suitable 3D printing equipment, consider using a 3D printing service. Through Craftcloud, you’ll have access to a wide range of materials and finishes. You’re also guaranteed to benefit from professional production and expertise.

Now, let’s get to those revolutionary 3D prints!

Insoles

One of the most well-known types of orthotic devices is the insole. Insoles are removable inserts that can be placed inside a shoe to improve support and foot comfort.

While common insoles may not be considered orthotic devices, 3D printed insoles are tailored to an individual’s foot shape and size. They’re designed to correct or alleviate pain caused by one or more conditions, such as heel spurs or plantar fasciitis.

The process of creating a custom-fit insole varies but usually involves some sort of data collection that relies on methods such as 3D scanning, regular photographs, and even manual measurements.

Ordering custom 3D printed insoles is quite easy, and as of 2023, there are plenty of companies specializing in it. You can also potentially custom-design your own with one of the tools described below.

FitMyFoot

FitMyFoot is a Canadian company that produces custom-fit shoes and insoles. Through its smartphone app, users can take a few pictures of their own feet for data collection, then purchase insoles of different colors and prints on the website.

The insoles are 3D printed in nylon 12 plastic with polyurethane foam as the middle layer. According to the company, their insoles can alleviate foot conditions such as flat feet, high arches, and plantar fasciitis, thus increasing the user’s comfort.

ME3D by SUPERfeet

Superfeet is a US-based company established in 1977 as the Sports Medicine Division of Northwest Podiatric Laboratory. It specializes in insoles of all types, including orthotic 3D printed ones known as ME3D.

According to the company, each custom-made insole has five independent support zones that are adapted to the foot’s geometry and can respond to the way the user moves. Potential customers must visit physical ME3D retailer stores to get their feet measured (which is only available in the US) and receive the custom orthotics at home.

Gensole

Instead of purchasing a 3D printed insole, how about designing it and printing it on your own? This is what the free browser-based tool Gensole allows makers and researchers to do, at least the design bit, for non-commercial purposes.

This tool creates digital models optimized for FDM 3D printing with flexible filaments such as TPE and TPU. To make it custom-fit, the user must import a 3D scanned model of their foot, which is used to create the personalized model. The basic workflow and instructions are further explained on Gensole’s website.

Braces and Supports

Braces and medical supports are devices designed to provide stability and support to specific areas of the human body. They can alleviate pain and improve mobility for certain born or acquired conditions, the latter of which include injuries and chronic pain.

Braces can be used for several parts of the body, including knees, hips, ankles, hands, and even for the torso to support the spine. The materials used in traditional braces and supports are usually plastic and metals.

When 3D printed, these devices can be custom-made to fit the patient’s shape and size for maximum comfort and effectiveness. Due to 3D printing’s geometric freedom, they can also be designed to be lightweight and with a combination of different materials.

Augo

Augo specializes in creating 3D printed trans-tibial (TT) prosthetic sockets. Prosthetic sockets are part of a prosthetic limb that connects the prosthesis to the residual limb of the patient, securing the prosthesis in place while providing comfort to the user.

Augo uses 3D scanning and SLS 3D printing technology to design and manufacture its custom prosthetic sockets. They’re said to be extremely lightweight and come lined with a soft inner layer for maximum user comfort.

Piro

AFO (ankle-foot orthosis) and SMO (supra-malleolar orthosis) are both lower-limb orthotics used to support and stabilize the ankle and foot. These devices are often required for children with cerebral palsy and similar conditions to improve mobility and provide support.

And this is what Piro does with the help of 3D scanning and 3D printing technologies. The geometric freedom provided by 3D printing allows these orthoses to be breathable and thin enough so infants can use them with their regular shoes.

Evoke

OssKin’s Evoke is claimed to be “the world’s first SLS 3D printed custom unloader knee brace.” This orthotic device is a type of knee brace specifically designed to alleviate pain and improve mobility in people with osteoarthritis and other knee-impairing conditions.

The custom-fit and lightweight design also features an aircraft-grade polyamide 2200 material and OssKin’s patented hinge system that tracks the natural motion of the knee.

Remolding Helmet

Many newborns experience a deformation of the skull caused by laying on one side for prolonged periods. The technical name for this condition is plagiocephaly, also known as “flat head syndrome”.

Perhaps the most effective way to correct this condition is via orthotic treatment. By wearing a custom-fitted helmet, the child’s head is gently corrected as it grows over a relatively short period of around six months.

Conventionally, these devices are made using a costly and time-consuming process that involves polymer foam milling. However, the following companies have developed innovative solutions for designing and producing such devices.

Talee

Talee is a cranial remolding orthotic device that works like this: First, the baby’s head is 3D scanned, and a digital model is customized to address the patient’s specific needs.

Then, the helmet is manufactured via a 3D printing technology known as Multi Jet Fusion, which allows the helmets to be lightweight and breathable. Talee claims that more than 15,000 infants in over 30 countries have already been successfully treated with this 3D printed orthotic.

Chabloz Plagio

Chabloz Plagio is a French company that also produces orthotic helmets for babies born with plagiocephaly. The process is similar to the Talee helmet, relying on 3D scanning to optimize the helmet’s shape and Multi Jet Fusion to manufacture it.

Chabloz’s remolding helmet is printed in a biocompatible nylon PA12 material and lined with a breathable fabric that can be removed for washing. It also features a patented latching system that prevents the helmet from being too tight and limiting the natural growth of the infant’s skull.

Immobilization Devices

Immobilization medical devices are intended to replace those itchy and uncomfortable plaster casts used for post-traumatic and fracture recovery. They keep a specific limb in a fixed position and restrict its movement to help the bones and tissues heal properly.

Like other 3D printed orthotics, custom-made immobilization devices are more comfortable and ergonomic for patients. Compared to traditional plaster casts, the 3D printed devices can be adjustable to some extent and allow for more personalized treatment.

Another advantage of 3D printed immobilization devices is that patients can potentially take them out and put them back in. The only downside is that you can’t get all your buddies to sign their names on it.

ActivArmor

ActivArmor is an American company that provides custom 3D printed immobilizations for wrists, elbows, hands, fingers, and ankles.

These custom-fit devices offer the best comfort for patients, and their lightweight design allows the skin to breathe. They’re also waterproof, eliminating the need for removal before showering or during doctor’s visits.

The company has an iPhone-exclusive app for 3D scanning purposes, but due to high demand in early 2023, patients are now required to visit a partner clinic in the USA to get their limbs scanned and order the parts.

XKSoft

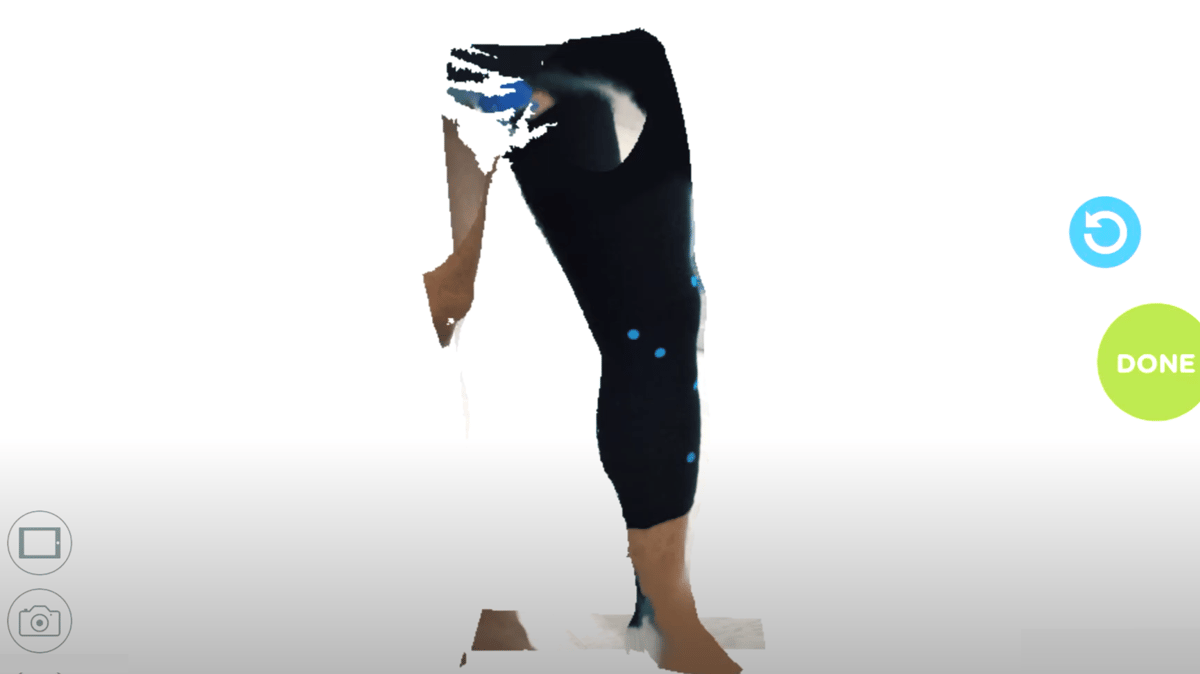

Spanish company Xkelet is dedicated to developing innovative solutions for custom-made orthotics and prosthetics. It offers a myriad of products, but most notably, its smartphone and tablet app called XKSoft.

The app is an all-in-one solution that can quickly 3D scan the patient’s limb (usually an arm or a leg) and automatically create a custom-fit immobilization for it. The company claims the entire process doesn’t take more than 5 minutes. The final design is then sent directly to a 3D printing service, which produces and delivers the device to the patient.

License: The text of "3D Printed Orthotics: Most Promising Projects" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.