Our autonomy is something of immeasurable value, and for individuals with limb differences, protheses can play a role in securing independence as well as other quality-of-life benefits. While many people manage to live their lives fully without prostheses, some require greater assistance.

Despite their benefits, the high cost of specialized prostheses can exclude those without access to adequate medical care. Further, the latest innovations in the field of prosthetics are not always available in all regions of the world. Much still needs to be done to expand access to prostheses at a reasonable and fair price.

3D printing has emerged as a disruptive solution by reducing costs and production time, simplifying processes, and bringing forth new possibilities. In this article, we’ve compiled a list of innovative 3D printed limb projects that have the power to transform lives.

Read on to discover the designers and organizations whose greatest ambition is to change the world for the better right now, and not in a distant future!

Keep in Mind

Despite the great advances and commendable results, keep in mind that this list isn’t exclusively for free, ready-to-use designs, but rather includes innovative ideas and projects that can sometimes be in the development phase or cater to very specific circumstances. Some are more recent, and others are more popular and mature, but they all have great potential to transform lives.

In this sense, take into account that DIY projects need to be evaluated with due caution and medical supervision. Materials must be rigorously tested and reinforced to avoid accidents. No matter how notable an initiative may be, the particularities of each patient need to be carefully evaluated in a safe environment and by someone with the proper expertise.

Below, we have separated the projects into four categories for different parts of the body to facilitate navigation, but keep in mind that some projects encompass more than just a specific limb solution.

Hand

Even with so much technology available, the complexity of a human hand is very difficult to replicate, but thanks to 3D printing (and sometimes a few more components), barriers are being overcome!

Lunet

Our hands can play an essential role not only in performing tasks but also in helping transform the reality around us. Despite advancements in technology and medicine, losing a finger or being born with limb difference can have a significant impact across all aspects of life. However, many are seeking viable solutions to to mitigate the impacts, such as this fully 3D printed hand.

David Edquilang is a young industrial designer who graduated from the University of Houston and has been honored with several awards for his creation “Lunet“. It promises to be an affordable, open-source, fully 3D printable option that will cost no more than $3,000 per finger. One of the most noteworthy features of this project, besides the cost, is the fact that it doesn’t require the use of metals for its mechanical parts, making everything simpler for those who need it.

Check out the video for a demonstration of the project. Although there isn’t a specific date for releasing the open-source project to the public yet, the designer hopes to share it via GitHub later this year so that anyone can download and modify it for their own use. Although the Lunet in itself is already a great achievement, the young designer is still looking to go further with an even more ambitious project: a prosthetic arm that is accessible and low-cost.

- Where to find it? Coming soon to GitHub (no specific date yet)

- What stage is it at? Awaiting publication of project and files

- Who made it? David Edquilang

The Victoria Hand

The Victoria Hand Project is a charity by Nikolai Dechev based in Canada, which operates in many countries such as Nepal, Cambodia, Guatemala, Haiti, and Ecuador. This project brings hope to patients who are unable to resort to conventional treatments and solutions; it does so with prostheses made using 3D printers such as the UltiMaker. The project relies on donations and supporters around the world to bring hope to people in developing countries and currently also helps patients who are victims of the war in Ukraine.

The Victoria Hand prosthesis was one of the first options of this type and has several functions and adjustments that adapt to the needs of patients. It features a rotating thumb, locking mechanism, rotating wrist, and adaptive grip. The manufacturing process uses 3D printing and laser cutting for internal steel parts. As it’s a low-cost solution, each prosthesis uses simple mechanisms that can be mechanically activated by the movement of other parts of the patient’s body instead of electronic and motor components.

In addition to hand prosthetics, they also produce trans-radial and trans-humeral suspension prostheses. Since 2015, more than 250 patients have benefited from the project, which includes several models such as the Voluntary Close Hand (VC300), Small Hand (VS300), and Voluntary Open Hand (VO300), as well as an ultra-light passive and aesthetic LimbForge arm that’s entirely made with printing 3D. The project also develops assistive add-ons that are compatible with these models and increase ease of access to tasks and activities.

- Where to find it? The Victoria Hand Project

- What stage is it at? Available to request

- Who made it? The Victoria Hand Project

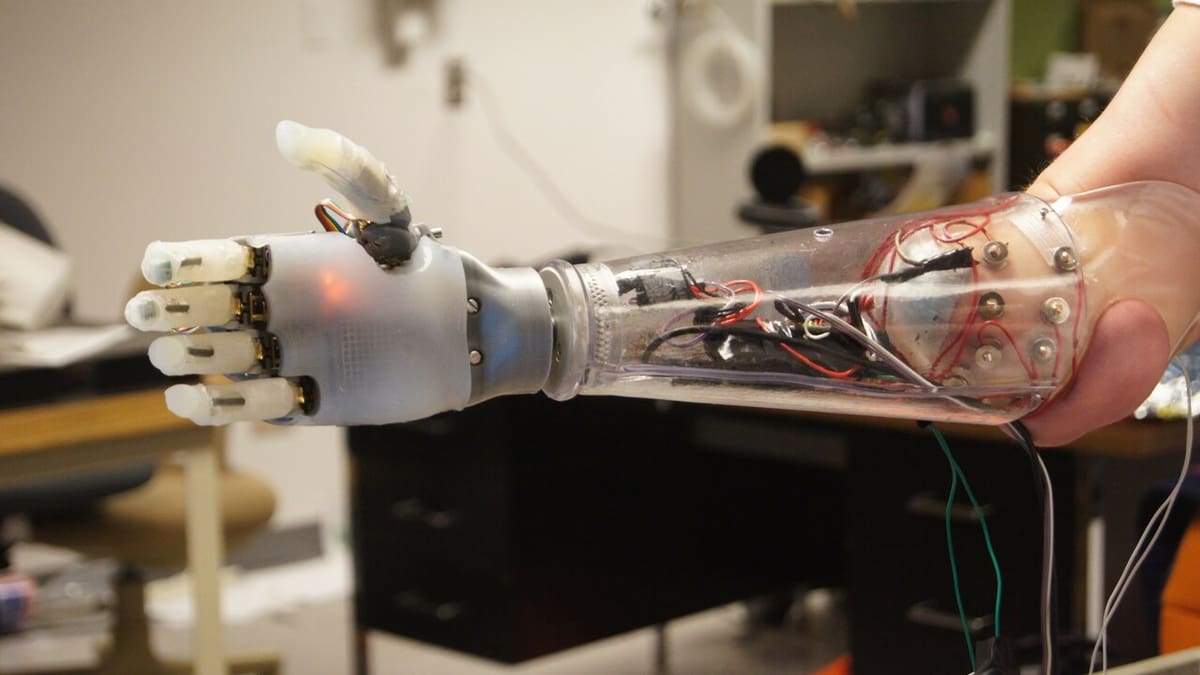

DIY Sensory Feedback Hand

This sensory feedback prosthesis was developed by KyungYun as a low-cost functional project and an advanced solution for patients who demand something more affordable, as it can be built for less than $550. The project is made with three main types of mechanical parts, which are rigid, semi-rigid, or soft.

Although the project initially focused on using most of its parts made from 3D printing, the project’s author is committed to increasing strength and durability with other materials and manufacturing techniques.

One of the most impressive aspects of this prosthesis is the integration of pressure sensors and EMG (electromyography) electrodes, which enable sensory feedback. These sensors capture information about the contact and force applied by the fingers, transmitting these sensations to the user. This is achieved through an advanced microcontroller, such as the Teensy, which processes sensor data and adjusts motor movements in real time. The system not only improves the functionality of the prosthesis but also increases the naturalness of movements, allowing users to perform delicate tasks with greater precision.

The development of this prosthesis included significant international collaboration, including a field test in Quito, Ecuador, in partnership with the non-profit organization Range of Motion Project (ROMP). During the testing phase, the team was able to adapt the prosthesis to the specific needs of local users and refine the design based on real patient feedback. This practical approach allowed the creators to identify areas for improvement and ensure that the prosthesis not only functioned well in a controlled laboratory environment but also met the demands of everyday use.

The project represents a promising advance in the field of prosthetics, with the potential to significantly improve the quality of life of many people around the world.

- Where to find it? Instructables

- What stage is it at? Available to download (Excel BOM) and DIY

- Who made it? KyungYun

Arm

The absence of a limb like the arm has a huge impact on anyone’s life, but thanks to 3D printing, the challenges can be lessened.

ArmPO V2

The ArmPO V2 is a mechanical prosthesis for trans-radial amputees, developed by the Po Paraguay group. This prosthesis is designed to be activated by the body and can be used by children and adults: By flexing the elbow, the fingers can be controlled to close.

At time of writing, the latest version of the ArmPO features stronger joints, eliminating the need for wrist piercings and removing protruding pins in the elbow that were previously prone to breaking. The design was inspired by several sources, including the Unlimbited Arm team’s thermoforming technique, the Funmove forearm system, GiveMeFive’s flexy arm, the work of Christian Silva, and GyrobotUK’s flexyhand.

To assemble the ArmPO V2, it’s necessary to thermoform the parts according to the size of the user’s limb. There are specific parameters for layer height, infill, and printing speed for each part to ensure greater quality and durability. The process also includes securing the wires using tensioners and thermoforming a cover to join the forearm. Additionally, the elbow patch should be adapted with neoprene and Velcro straps for a comfortable and secure fit.

Po Paraguay continues to update and improve its designs. It’s possible to customize the prosthesis for specific users by contacting quiero@po.com.py. Users can expect a functional, affordable, and continually improved device, reflecting the developers’ commitment to providing effective and innovative solutions for trans-radial patients.

- Where to find it? Thingiverse

- What stage is it at? Available to download and DIY

- Who made it? poparaguay

e-Nable

The e-Nable Community began in April 2011 when Ivan Owen created a metal mechanical hand for a steampunk convention. After posting a video of the device on YouTube, he was contacted by Richard, a carpenter from South Africa who lost his fingers in an accident. Together, they collaborated remotely to create a prototype mechanical finger, using common and improvised materials. The partnership resulted in the creation of a functional prosthesis and inspired the creation of e-Nable, a community that grew quickly by sharing its designs.

In November 2012, Ivan traveled to South Africa to work one-on-one with Richard and met Liam, a 5-year-old boy born without fingers due to Amniotic Band Syndrome. Ivan and Richard adapted their designs to create a complete hand for Liam, which was the first prosthetic hand created by e-Nable. Realizing that Liam would quickly outgrow the prosthetic, Ivan began exploring the use of 3D printing to create lighter, more adjustable devices. The collaboration with MakerBot (now part of UltiMaker) resulted in the donation of 3D printers, allowing the production of customizable and affordable prosthetics.

e-Nable has grown exponentially, especially after the creation of a community on Google Plus in 2013 by Jon Schull. The community has expanded to thousands of volunteers around the world, including teachers, students and professionals from different fields. Events such as conferences and “Hand-a-thons” helped spread knowledge and production of prosthetics.

By 2019, e-Nable had more than 10,000 members and had distributed nearly 7,000 prosthetics in more than 100 countries, with continuous development and sharing of new open-source designs. The community produces hand and arm prosthetics of different models. For example, the Unlimbited Arm v2.1 was developed together with Team UnLimbited, which we’ll read more about below. Whether looking for assistance or to volunteer, there are many community chapters all over the globe.

- Where to find it? e-Nable

- What stage is it at? Available to DIY or request one from a volunteer

- Who made it? e-Nable Community

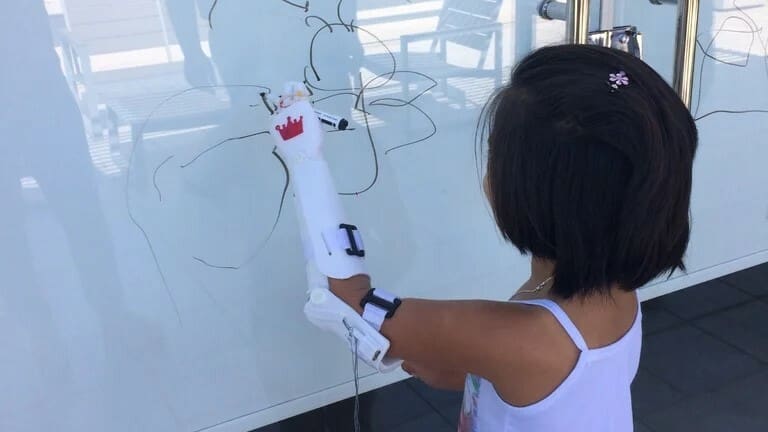

Team UnLimbited

UnLimbited is a British initiative that emerged from the same philosophy of collaborative and open innovation that drives e-Nable; however, it specifically focuses on developing and distributing personalized arm prostheses. Founded by Drew Murray and Stephen Davies, both active members of e-Nable, UnLimbited stands out for its commitment to providing high-quality, low-cost prostheses using 3D printing technologies. The UnLimbited Arm v2.2 is one of the organization’s most notable creations, designed to be functional, personalized, and accessible.

UnLimbited’s story is inspiring and goes back to 2015. Drew Murray, a 3D printing enthusiast, and Stephen Davies, an e-Nable prosthetics beneficiary, joined forces to create an organization that could meet the growing demand for personalized prosthetics. The UnLimbited Arm has become a symbol of innovation and hope by becoming the world’s first thermo-formed 3D printable arm. With a modular and adjustable design, the UnLimbited Arm allows for easy and quick adaptation to each user’s individual needs. It’s also possible to find dozens of free decorations to give a special and personal touch to the UnLimbited Arm. Its first version was the Isabella Edition in honor of its first recipient in September 2015.

Although UnLimbited operates independently, it maintains a close relationship with e-Nable, frequently collaborating on projects and sharing technological advances. This synergy allows both organizations to leverage their respective strengths to maximize social impact. UnLimbited continues to expand its reach by participating in community and educational events and to promote the importance of accessibility and open innovation in the field of prosthetics.

- Where to find it? Team UnLimbited

- What stage is it at? Available to download (The UnLimbited Phoenix Hand and UnLimbited Alfie Edition Arm V. 2.2) and DIY

- Who made it? Team UnLimbited

Leg

Our mobility can affect our independence. 3D printing can show its power by increasing and allowing the customization of solutions that can help overcome challenges.

Exo

The Exo is a prosthetics project from William Root, an industrial designer who managed through his own efforts to develop an affordable solution that uses a scanner and 3D printing to create and adapt a prosthesis to his own measurements and style.

In addition to the cost, a significant challenge when creating a tailored solution is the time needed to adapt a prosthesis to the patient so as to eliminate any discomfort. This process for traditionally manufactured prostheses involves many time-consuming and complicated steps. Root aims to streamline the process and increase access with the Exo prosthesis.

In addition to the complexity that the traditional process involves, there’ s also the aesthetic and maintenance aspect that would again depend on expensive procedures and resources through traditional means. Designing his own prosthetic leg allowed William to opt for a solution he found more aesthetically pleasing, which at the same time met expectations of resistance and comfort.

In Root’s case, a 3D scanner and MIT’s FitSocket technology were used to obtain the necessary measurements, but readily available projects, such as Rijido by oscarovira, can be used to achieve personalized results.

The manufacturing of prostheses can be carried out in different materials, thanks to 3D printing. Due to its resistance and light weight, Root went with titanium for this project.

- Where to find it? Exo Prosthetic Leg

- What stage is it at? Contact the designer to request information

- Who made it? Will Root

Letizia

The Italian company Isinnova developed Letizia, a low-cost leg prosthesis that promises to meet the basic needs of daily routines. This solution was created to meet the demands of a non-profit medical organization that volunteers in Ukraine, where more than 3,000 civilians, including children, lost their legs because of the war.

While similar prostheses can cost more than €5,000, the project’s device is around €500, thus allowing more people to benefit from it. The prosthetic leg is modular, which means it can be adjusted to different needs, such as transfemoral, knee disarticulation, transtibial, and foot amputation.

Letizia was developed as an emergency support, accessible and suitable for any amputation, but thanks to the feedback received from the initial prototypes, Isinnova has made improvements. The new version also has silicone support for the limb.

Currently, around 152 prostheses have been donated and can have their covers customized in up to four different styles.

- Where to find it? Isinnova

- What stage is it at? Contact to request information

- Who made it? Isinnova

CRE-004 DIY

The CRE-004 is an innovative leg prosthesis developed and designed by Agung Dwi Junianto to provide a more affordable and customizable solution for patients. This prosthesis uses materials such as ABS, PLA, and, preferably, HIPS, due to its impact resistance. The main proposal is to allow users with access to 3D printers to produce their own prostheses at a significantly lower cost than traditional options, which can range from $5,000 to $50,000 and need to be replaced every 4 to 5 years.

The design of the CRE-004 was carefully planned to be practical and functional, even with the limitations of home 3D printers. Some larger parts, such as the 250-mm model, can be challenging to print on standard home printers, but in this case, it’s recommended to look for a larger printer and not divide the model into parts to avoid structural failure of the part. The prosthesis was tested on real patients, receiving positive feedback and direct suggestions from users, which helped to further improve the design and functionality. In addition to STL files, there is also a STEP file that allows modifications, as well as assembly instructions in a PDF.

In the comments, while some recommend ABS and HIPS for their strength, others argue that PLA can also be effective, citing examples of robust components made from this material. The project is open to improvements and adaptations, such as modifying components to adjust to different diameters of prosthetic pins and the possibility of printing personalized parts to meet specific patient needs. In addition to the printed parts, some others are needed, such as an aluminum tube with a diameter of 3.175 cm, spring, nut, and screws.

- Where to find it? Thingiverse

- What stage is it at? Available to download and DIY

- Who made it? crewolprint3d

Feet

Supporting our body and allowing a good balance demands an efficient solution. Here are some more projects in which 3D printing is an ally.

Upya

Upya represents a notable advancement in the field of lower limb prosthetics, offering a unique and affordable solution for people with mobility disabilities. Developed by Exoneo, a company specialized in biomechanical engineering, this polyarticulated prosthesis seeks to replicate the natural movement of the human foot, providing comfort and stability to users. Its innovative design includes a spring and damping system that simulates tendons and muscles, offering a walking sensation that is as close to natural as possible.

In addition to its performance, Upya stands out for its affordability. Through the use of 3D printed parts and cost-effective materials, the prosthesis is significantly cheaper than conventional alternatives. This low-cost approach allows a greater number of people, especially in regions with limited resources, to have access to a quality prosthesis that can improve their mobility and quality of life.

Since its founding in 2017, Exoneo has worked to develop universal solutions that meet the needs of people with mobility disabilities around the world. With a committed team of professionals and collaborators, the company is determined to provide products that not only restore the feeling of having a natural limb but also promote sustainable development. By adopting a biomechanical design approach, Exoneo is paving the way for a more accessible orthopedic industry.

- Where to find it? Exoneo

- What stage is it at? Available to request pricing

- Who made it? Exoneo

DIY Prosthetic foot

The 3D prosthetic foot shared on Thingiverse is a design that adopts modular architectural principles and is available for download, testing, and improvements. Although a video shows an amputee performing a walking test with the prosthetic foot, the author warns that this is still a prototype.

3D printing materials that you might have lying around will likely fail after a few uses due to fatigue stress. The designer used ABS but suggests testing with polycarbonate, nylon, carbon fiber, ULTREM, or other materials to increase safety and durability.

To assemble the prosthetic foot, both 3D printed componentsn and non-printed components are required. The latter include heel springs as well as M4 and M5 screws. The height of the foot can be adjusted by scaling the Z dimension of the upper adapters, and the length can be modified by adjusting the position of the sole. The stiffness of the springs or their quantity can also be adjusted according to the user’s preference.

The modularity of the design and the possibility of customization make this prosthetic foot a potentially affordable solution for amputees, although the assistance of a prosthetist is essential to ensure the safety and effectiveness of the device. The designer highlights the importance of obtaining strong springs, as the deformation of the springs must support the user’s weight.

- Where to find it? Thingiverse

- What stage is it at? Available to download and DIY

- Who made it? JVargas_3D

DIY Prosthetic Foot for Yoga

The “Prosthetic Foot for Yoga” aims to improve the balance of prosthetic users who practice yoga. It was developed by Ruei Kao, Samantha McClary, and Yingyi Wu in a course led by Vishal Sachdev at the University of Illinois. Inspired by Jenna Fesemyer, an above-knee amputee who uses a C-Leg prosthesis, the team created an accessory that can be swapped out for her regular prosthetic foot while practicing yoga. The design is modular, fully 3D printable, and uses a sheet of cork at the base to prevent slipping.

To create the prosthetic yoga foot, you need a basic knowledge of Autodesk Fusion to customize the file according to the necessary dimensions, as well as access to a 3D printer. The recommended material is PLA, although it’s noted that nylon is a more resistant option for long-term use. The team used an UltiMaker 2+ Extended printer for the print due to the height required, and they opted for an infill density of 25% in a grid pattern.

The approximate cost of the impression was $115 – much more affordable compared to other prosthetic feet that can cost up to $20,000. The project offers an affordable and customizable solution for amputees who want to practice yoga with more balance and safety.

- Where to find it? Instructables

- What stage is it at? Available to download and DIY

- Who made it? SamanthaM177

License: The text of "3D Printed Prosthetic Limb: 12 Promising Projects" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.