Whether building them from scratch or just driving them around, remote control (RC) vehicles are a fun activity for many. RC planes, in particular, are one of the coolest vehicles to make. Just be sure to choose a design with aerodynamics in mind to get the best and most controlled flight!

You can 3D print your own DIY remote control plane and make replacement parts quickly if a component breaks, and we’ve got the best projects for you!

If there’s a plane or two you’d like to 3D print, but you don’t have a printer available, try Craftcloud for excellent quality, a huge range of materials, and delivery to your door.

Beginner

Before you learn to fly, you first have to learn… also to fly but with a simpler and smaller aircraft. The same goes for printing RC planes, so check out one of these beginner-friendly designs.

GASB One

As one of the most popular items on this list, the GASB One is a favorite plane among hobbyists of all skill levels. It’s known for its simple design, easy printability, and assembly, as well as its low cost, with the electronics and materials required costing around $30.

Just like most planes featured here, you can print it completely in PLA. All you’ll need is a motor, servo motors, a propeller, and an ESC.

- Who designed it? Carletto73

- How printable/popular is it? The creator has dubbed the GASB One “The most printed plane in the world,” and rightfully so. It has 77 makes and 25 remixes on Thingiverse alone!

- Where to find it? Thingiverse

Caracara

When discussing RC planes, a glider design isn’t typically the first thing that pops to mind. However, gliders are some of the most unique aircraft around today, and it’s possible to 3D print your own! This RC motor glider is based on the original Crobe design by Franck Aguerre.

With a wingspan of 930 mm and a ready-to-fly weight of 260 g, it offers a balance of agility and stability. A test-flight video showcases its performance.

The model can be easily printed with standard PLA, and its design allows for a layer thickness of 0.2 mm and a single 0.4-mm wall. No supports are required, but a brim is advised.

- Who designed it? LaurentL

- How printable/popular is it? This classic-looking glider has 10 makes and 4 remixes.

- Where to find it? Thingiverse

Stingray

Designed by Qromer, the Stingray is perfect for aviation enthusiasts who want to explore the world of FPV flying without complications. This model is built with Depron or foam board, which are lightweight materials that make the plane agile and responsive in the air. It also has the ability to slow down to the point of almost hovering, allowing pilots to perform incredible maneuvers, such as flying between trees or exploring tight spaces with full control.

Controlling the center of gravity (CG) is essential for flight stability, and users report that a simple hand launch is enough to get the Stingray airborne with ease. Feedback highlights the simplicity of the assembly process and the versatility of the design, which allows for adjustments and modifications according to the pilot’s experience.

Here, 3D printing is used for small parts and pieces that reinforce the plane’s structure. While unfortunately there are no printing instructions, it’s good to be careful to maintain a good balance between infill and resistance.

- Who designed it? Qrome

- How printable/popular is it? There are almost 700 downloads between the repositories, and 2 makes shared on Printables show that anyone can have fun with these!

- Where to find it? Thingiverse, Printables

SU-29

The SU-29 is a great way for beginner fliers to learn the ropes of a 3D printed aircraft without the risk of breaking an expensive model. Additionally, the wings are detachable for transportation, making it easy to fly on-the-go.

The designer of this plane opted to print the fuselage with LW-PLA, a lighter version of traditional PLA for applications such as RC planes. The tires were printed in TPU and the motor mount is PETG. A complete bill of materials is included on Cults.

- Who designed it? 3DBlackbox

- How printable/popular is it? This unique and awesome plane has over 65,000 views on YouTube. The video is a wonderfully detailed assembly guide. Additionally, there are seven posted makes on Cults.

- Where to find it? Cults

Gö 1 Wolf

The Gö 1 Wolf is an aviation classic brought to life in a 3D printed, motorized version, ideal for those who are venturing into the world of printed aircraft for the first time. Inspired by the 1935 German glider, the Wolf offers a smooth and safe flying experience with its huge 1,200-mm wingspan and docile behavior.

It is perfect as a training model, especially when printed with LW-PLA. This filament is recommended to obtain a lighter weight of approximately 270 g, as with common PLA the weight is a little more robust and reaches 440 g. The stall speed is 24 km/h for LW-PLA and 32 km/h for common PLA.

The printing profile included is for a 0.4-mm nozzle and requires a printer with a minimum build volume of 150 x 150 x 200 mm. There’s a tutorial that’s worth checking out before printing, and if you want to avoid having to source the hardware and electronics separately, a standard kit from Eclipson is available at around $70.

- Who designed it? Eclipson

- How printable/popular is it? This recent project has already been downloaded 216 times on MakerWorld and 16 shared prints.

- Where to find it? Eclipson, MakerWorld

Eclipson Model T (Free Version)

The Eclipson Model T is a popular remote control seaplane, but it costs around $20 for the full design. This model is the official free version, and it leaves out the floating landing gears of the plane. You can still fly it, it’ll just need to be hand launched.

Even if it can’t function as a seaplane, the Eclipson Model T is an excellent RC plane project. The plane has a single propeller and uses 29 different 3D printable parts, along with a long list of other hardware (e.g. screws and motors, among other parts).

Although the designer didn’t provide any printing tips, one recorded maker shared a few of the settings they used to make a great print. These settings include a raft activated, no supports, and a 0.2-mm layer height.

- Who designed it? Eclipson

- How printable/popular is it? The designs for the free version of the Eclipson Model T have over 111,000 downloads and 23 recorded makes.

- Where to find it? Thingiverse

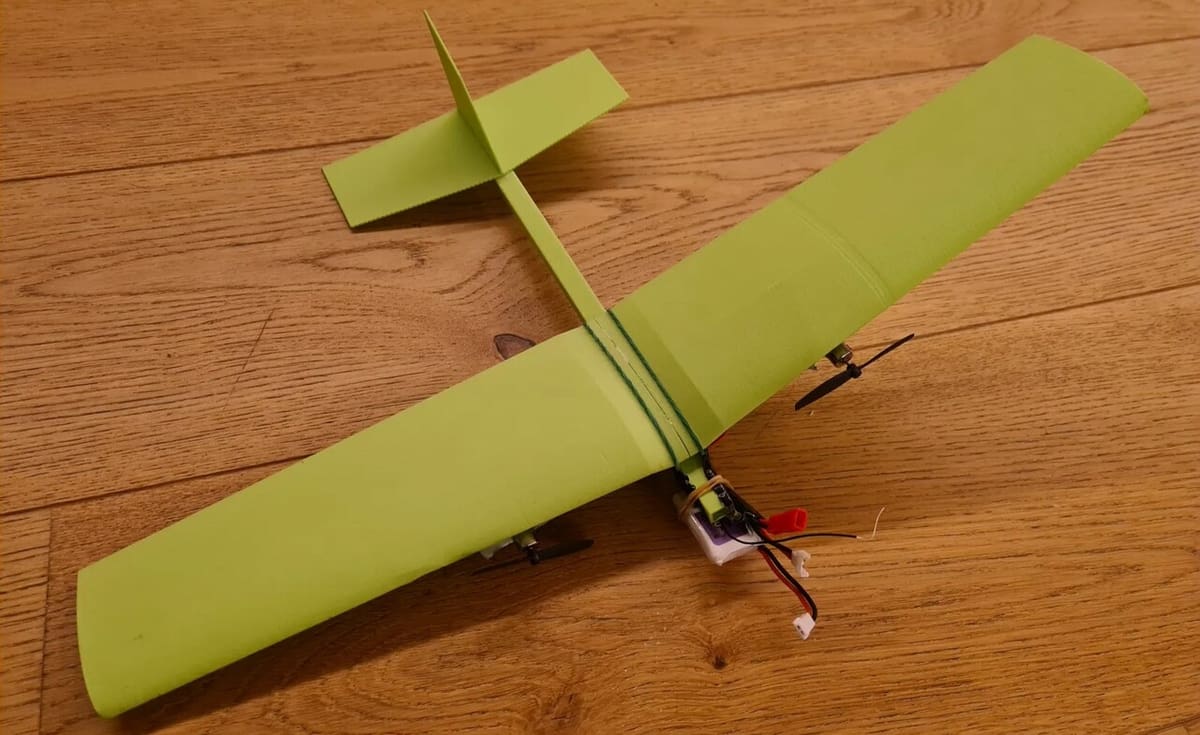

Easy

The Easy RC Plane is a budget-friendly option designed with simplicity and affordability in mind. While the small size might make it harder to fly for beginners, its emphasis on 3D printed parts aims to minimize costs and assembly complexity. With straightforward printing and assembly procedures, users can quickly construct the aircraft without extensive technical expertise. The model is so basic that motors, controllers, and batteries are mounted externally and secured with tape or rubber bands, simplifying maintenance and modifications.

The model requires LW-PLA and a 0.6-mm nozzle, although alternative parts tailored for a 0.4-mm nozzle are available in the repository. Consisting of only six 3D printed parts, the designer says neither supports nor infill are necessary. Assembly involves basic gluing.

- Who designed it? Dongle

- How printable/popular is it? This highly affordable plane has 270 downloads, and at least one maker is enjoying budget flight.

- Where to find it? Printables

Ranger V2

The Ranger V2 by Craycle is an RC aircraft model ideal for beginners in 3D printing and airplane building.

It offers two versions: one with three channels (no ailerons, no FPV) and another with four channels (with ailerons and FPV compatible), along with detailed instructions in PDF format. The Ranger V2 provides a great flying experience, and even if there are mishaps while you’re getting your bearings, it’s easy to rebuild thanks to its structure made of PLA.

To build the Ranger V2, recommendations include opting for a 0.4-mm nozzle, 0.2-mm layer height, no supports, and a heated bed with a minimum size of 150 x 150 mm. Avoid printing with double walls to prevent altering the weight and balance of the model. If you want to go straight to the FPV version, the files are sold separately for ~$35. And if you want to skip the sourcing of materials and parts, you can also buy a power kit from Craycle, also priced at ~$35.

Piper J-3 Cub

The Piper J-3 Cub is an excellent RC plane for beginners because anyone of any age can assemble it. It has a wingspan of 1,068 mm and is extremely lightweight, as the designer printed it using lightweight PLA (LW-PLA). A max takeoff weight of around 0.7 kg was reported.

The most unique feature of this plane is that you can swap its landing gear with 3D printed floats, allowing your plane to take off or land on water. However, make sure to waterproof your float so that water does not seep in; you can easily do this with water-resistant paint or spray.

By following the designers’ detailed user guide, you can build your Piper in no time. Alternatively, you can also watch an assembly video posted by another maker, which includes a flight test.

- Who designed it? 3DLabPrint

- How printable/popular is it? A maker on YouTube has printed, assembled, and tested the plane. With these resources, you can easily build the plane.

- Where to find it? 3DLabPrint

Pusher Propeller

This is a simple Pusher Propeller (PProp) plane with a wingspan of about 1,165 mm. It can be printed in vase mode using LW-PLA for the best flight performance. To find out what components you require for your PProp, check out the detailed shopping list, which includes quantity, purchase links, and an approximate cost of the components.

To put this all together, you can follow the assembly videos, but to view them, you’ll first need to join the Discord server made by the designer. Here, you’ll also find additional build and flight videos, along with support for queries. However, if you’re curious to see how well the aircraft flies, take a look at this flight video.

- Who designed it? dbm0926

- How printable/popular is it? There are over 1,500 downloads but no reported makes. If you’d like to be the first, an easy-to-follow assembly video will help you build your own PProp.

- Where to find it? Printables

Intermediate

If you’re down to put in a bit more effort (and materials) into a plane, one of these models can get you off the ground.

Northern Pike

The Northern Pike is both very popular and well-documented. This plane is built for first-person view (FPV) and includes a built-in camera mount on the nose to stream the video feed as you control the vehicle.

The designer 3D printed this plane on a Prusa i3 MK2S printer with PETG and PLA filament. In total, the printed models for this design consumed around 0.70 kg of filament and took 40 hours to make. The creator of this design listed that they used a 0% infill density, with a 0.1 to 0.25-mm layer height.

- Who designed it? localfiend

- How printable/popular is it? The Northern Pike has 27 recorded makes as well as 7 remixes.

- Where to find it? Thingiverse

Hawk Modular Wing

Crafted by a team of students comprising engineers, 3D printing enthusiasts, and RC hobbyists, the Hawk Modular RC Wing Airplane offers a blend of innovation and practicality.

Designed as a flying wing concept, it aims to provide RC enthusiasts with a flying experience comparable to traditional RC planes. Extensive aerodynamic simulations conducted using XFLR5 software contribute to its flight characteristics.

Comprehensive build instructions are available in the files section to assist users in assembly. Its modular design facilitates effortless 3D printing on various machines, with motor mounting possible either in the front nose or in the rear. It’s advised to use LW-PLA filament, and parts are designed to be printed in vase mode with a 0.6-mm nozzle.

- Who designed it? NeuesFliegene

- How printable/popular is it? This professionally designed plane has over 1,450 downloads and a make so far.

- Where to find it? Printables

Lukisegler

Lukisegler is an electric glider suitable for RC pilots with flight experience. It’s 3D printed using LW-PLA and has a span width of almost 1,700 mm. Because of this material choice, the plane weighs around 0.65 kg, making it a fast-flying aircraft.

You can find all the information regarding the plane’s specifications, required components, assembly instructions, and some helpful tips on Arts Modelle. However, the project page is in German, so you might have to use Google Chrome to translate the page or navigate to Printables instead, where most of the instructions can be found in English.

To avoid stringing, the designer recommends printing the plane’s parts individually with a layer height of 0.2 mm for the best results.

- Who designed it? C-Arts-Modelle

- How printable/popular is it? This glider has over 1,500 downloads and 174 likes on Printables. Even though there are no makes yet, there’s a detailed guide on exactly how to construct and fly this amazing plane!

- Where to find it? Printables, C-Arts-Modelle

E1000 Streamer Combat

The HB1 E1000 RC Streamer Combat Airplane offers versatility and durability. Designed specifically for E1000 streamer combat but adaptable for sport wing use, it combines a modular 3D printed fuselage with a foam wing, optimizing both construction time and weight efficiency. The no-glue modular fuselage design enables quick and easy field repairs by allowing damaged parts to be swiftly replaced.

Detailed test flight and assembly videos provided by the designer offer valuable insights into the aircraft’s performance and construction process. In addition to the 3D printed parts and foam wings, assembly requires wood dowel rods, rubber bands, and other small hardware components. Although the designer recommends a 0.8-mm nozzle with a 0.8-mm layer height, printing with a 0.4-mm nozzle and 0.2-mm layer height is also possible, albeit with increased printing time.

- Who designed it? HB_Aircraft

- How printable/popular is it? This fighter plane has four makes as well as a couple of remixes.

- Where to find it? Thingiverse

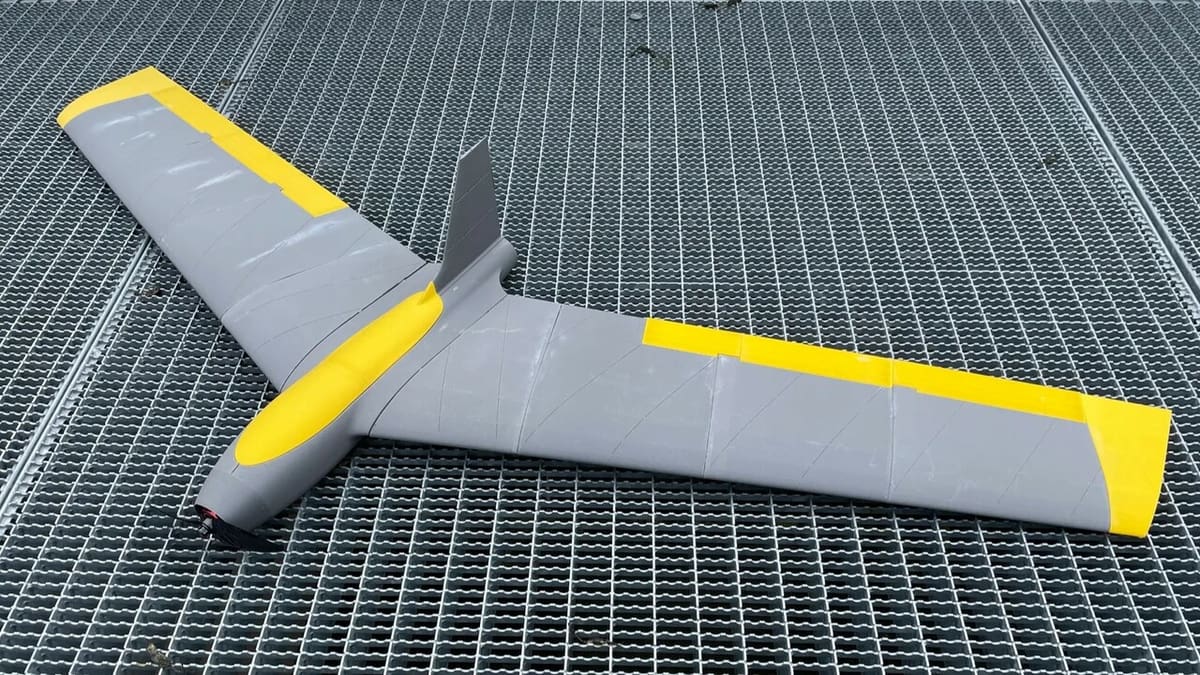

Flying Wing

The Flying Wing is a Y-shaped plane that’s almost entirely 3D printable. Despite its simplistic look, this plane isn’t for beginners and can be challenging to fly, according to the designer.

The plane uses 15 different 3D printable models for the frame and many electronic parts like an ESC for the motor, a 5-V regulator, two servos, and more. The creator of this design listed some print settings to make a few of the different 3D printable models. These settings include a 0.5-mm wall thickness, 0.2-mm layer height, and a 0-15% infill density based on the part.

- Who designed it? TomStanton

- How printable/popular is it? The Flying Wing has 24 recorded makes, 6 remixes, and over 57,000 downloads. As so many users have made this plane, you should be able to do so, too!

- Where to find it? Thingiverse

Red Mini Wing

This RC plane is a smaller, more agile variation of the designer’s previous RC plane project, the Red Duck. Although similar in name, the smaller model is “speedy and pretty maneuverable” and therefore recommended for those with some previous flight experience.

With a wingspan of just 794 mm, the parts can be printed fairly quickly and don’t require supports or rafts, so you can be ready for takeoff in no time! Check out some videos on how this plane glides through the air: an FPV flight and the maiden voyage.

For those up for a challenge, the same maker has a similar model, the Red Swan, with a massive wingspan of 1,950 mm. It needs nearly 1.8 kg of filament to print. Its name reflects the improved elegance of design compared to the original Red Duck.

- Who designed it? wersy

- How printable/popular is it? The Red Mini Wing plane has 19 recorded makes, 4 remixes, and lots of community support.

- Where to find it? Thingiverse

AirCombat

This menacing RC plane is modeled after the combat-style airplanes used in many wars. It features a wide wingspan of 114 cm and is ready to take down whatever dangers you may find in the sky!

Keep in mind that you’ll need to purchase some extra parts besides RC equipment, such as carbon fiber rods and hinges. The creator of this plane chose to print all the parts in PLA, with most printed at a 0.25-mm layer height and the canopy printed at 0.1-mm layer height.

- Who designed it? MMenz

- How printable/popular is it? This combat plane has 4 makes and over 21,000 downloads.

- Where to find it? Thingiverse

Pilatus PC-21

This RC model is a replica of the Pilatus PC-21, a single-engine turboprop advanced trainer produced in Switzerland since 1997. Its main characteristics are its sleek design and speed, and this version weighs around 820 g and has an 860-mm wingspan.

The designer aimed for the model to behave similarly to a jet, and believes it is a good candidate for 3D printing due to its long nose and short wings. These make weight balancing and assembly easier. For those interested in replicating the RC model of the Pilatus PC-21, it’s important to keep in mind some tips shared in the Cults comments, as there are no printing recommendations or instructions provided.

Using LW-PLA can assist with printing, especially for more delicate parts. For those using Cura, the setting under “Special Modes > Surface Mode” should be set to “Both”, in order to avoid issues with missing surfaces, particularly on the fuselage. Adjusting the print speed to around 50-60 mm/s is recommended for shorter print times. Finally, special attention should be paid to the choice of propeller: The designer suggests trying a 10 x 9 3-blade propeller or smaller, as bigger diameters won’t fit and perform correctly.

SuperNova

This 3D printable RC plane is inspired by the rcFoamFighters SuperNova foam pusher plane. On top of looking cool, you can see for yourself how this plane soars through the air!

The plane was 3D printed on a modified RepRap Mendelmax, with 100% infill and 0.25-mm resolution. The fully assembled plane weighs 1.42 kg, including electronics.

- Who designed it? Itek

- How printable/popular is it? The SuperNova has seven recorded makes and two remixes, so it’s safe to say that this project is printable.

- Where to find it? Thingiverse

ASK14

This glider is modeled after the ASK14, which first flew in 1967. The design contains many innovative features, such as a spring-loaded retractable wheel, scale airbrakes, a TPU wing fastening system, and others. However, the STL files for this plane will set you back around $40. Note that slicing will only work with Cura.

- Who designed it? Troy McMillan

- How printable/popular is it? The detailed assembly guide for this glider on YouTube has over 343,000 views.

- Where to find it? Planeprint

Advanced

Experienced RC pilots may be interested in these impressive planes. Don’t worry – the hard work will pay off!

Extra 300s Park Flyer

The Extra 300s Park Flyer embodies classic craftsmanship with laser-cut wing ribs, film-covered wings, carbon rod reinforcements, and a vacuum-formed bubble, along with cutting-edge 3D printed parts such as the fuselage. With a wingspan of 1,000 mm and a takeoff weight of 600 g, it strikes a balance between size and performance.

A full build video provided by the designer offers valuable insight into the assembly process, catering to builders of all skill levels. Not only the STL files for 3D printing are available, but also DXF files for the laser-cut parts.

- Who designed it? Marko Roolaid

- How printable/popular is it? This exquisite plane has over 2,000 downloads but still no documented makes.

- Where to find it? GrabCAD

Aurora

The Aurora is an FPV fixed-wing model that stands out for its high speed, agility, and modern design. Inspired by iconic aircraft such as the IJN J7W Shinden and the XP-55, it’s capable of reaching cruising speeds between 70 km/h and 110 km/h, and up to 130 km/h during more daring maneuvers of up to 3-4 gravity force. The flight experience is engaging and challenging, taking full advantage of the dynamic control provided by the servo gimbal, which is ideal for head tracking with systems like the DJI 03.

The designer recommends printing the fuselage with a 0.2-mm layer height, one wall, and an infill between 2% to 5%. Other parts that require greater strength, such as structural components, need up to two walls and 100% infill, and the designer suggests opting for tough PLA or PETG.

User feedback emphasizes the importance of precise calibration of temperature and flow rate to avoid imperfections on external layers, especially with parts like the wings and fuselage.

- Who designed it? xuhao3e8

- How printable/popular is it? With almost 1,000 downloads and over 520 prints according to MakerWorld, it is clear that it is a worthwhile challenge.

- Where to find it? MakerWorld

Melusine

This Melusine is a 3D printed twin tail electric glider and FPV platform, with a weight of around 2.3 kg and a massive wingspan of 2,320 mm; the STLs cost ~$4.

It’s a twin tail pusher prop electric glider with interchangeable noses for FPV cameras and optional tricycle landing gear with a steerable nose wheel. The Melusine also has 3D printable folding props that make it look like an eagle in the sky when it flies.

The designer recommends using PLA filament to 3D print the parts for the glider and a flexible material (e.g. TPU) for the tires.

- Who designed it? tahustvedt

- How printable/popular is it? The Melusine plane has 2 makes and over 240 downloads. The maker has provided plenty of instructions and even more tips in the comments.

- Where to find it? Cults

Windex

Inspired by the Radab Windex, a single-seat aerobatic glider, the Windex is a 3D printed RC model that weighs roughly 2.25 kg with a wingspan of 2,500 mm.

The designer has printed the aircraft’s fuselage using LW-PLA and covered it with carbon fiber vinyl. He also used balsa wood for different parts of the plane, especially the wings, to make it as lightweight as possible.

To help you build your Windex, there is a complete YouTube playlist that includes its various development stages and assembly, as well as a 5-minute time lapse that gives you a quick overview of the entire build. However, assembling this RC model can take some time before it’s ready to take to the skies.

- Who designed it? Roolaid

- How printable/popular is it? There are more than 2,200 downloads, 360 likes, and quite a few positive comments on Thingiverse and GrabCAD combined.

- Where to find it? Thingiverse, GrabCAD

PLA Moose

The PLA Moose is a DIY plane whose design was inspired by the Yak-54 aircraft and Mr. Burns’ Spruce Moose from The Simpsons. According to the creator of this plane, the PLA Moose has a wingspan of 1,000 mm, and the prototype (printed in PLA) flew successfully. Also, check out the glow-in-the-dark print of this plane from the creator!

This RC plane uses a brushless motor, two servos, and a 4S 3,300 mAh battery to fly – all contained in its 25-part 3D printed frame. It’s worth noting that the plane weighs a fair amount, around 1.6 kg, but the design was updated to make it lighter. The designer lists that they printed the pieces for the PLA Moose with a 5% infill density with supports activated, but no raft is required.

- Who designed it? the_crack_fox

- How printable/popular is it? The PLA Moose plane has six recorded makes and over 14,000 downloads on Thingiverse. Multiple users have confirmed that this plane can fly, so give this DIY build a try!

- Where to find it? Thingiverse

RC Shark

Modeled after the real Shark.Aero airplane, this 1/8 scale model is an easy-to-assemble build for more experienced fliers. It has a wingspan of 990 mm and is built for speed.

The creator of this model chose to print it with PLA on a Flashforge 2s. For assembling the plane, they recommend using regular CA glue such as Loctite. OEM CA adhesives can cause parts to eventually break apart.

- Who designed it? SharkAero

- How printable/popular is it? This plane has 26 makes, not to mention a great, informative video.

- Where to find it? Thingiverse

Bell P-39 Airacobra

Weighing around 600 grams without electronics and with a wingspan of 885 mm, the Airacobra is agile and surprisingly stable, ideal for recreational flights and even casual displays. Recent updates, such as split wings and a redesigned rear fuselage, allow all parts to be printed on standard 3D printers, without the need for special setups or especially large build plates.

To replicate the Bell P-39 Airacobra, PLA or PLA+ is recommended with a 0.4-mm nozzle and a single perimeter for a balance between weight and strength. The designer also recommends 2-3 bottom layers and 3-5 top layers, and setting the temperature between 220 to 230 °C for good layer adhesion. Printing without fan ventilation (0% speed) increases the robustness of the parts, according to the author.

- Who designed it? Gnat666

- How printable/popular is it? This classic plane has more than 1,300 downloads and 2 makes between the two repositories.

- Where to find it? Thingiverse, Cults

Swift S1

A prototype modeled after the aerobatic glider of the same name, the Swift S1 is a RC model with a wingspan of 2,000 mm and a flying weight of about 2.08 kg.

The Swift’s entire body is made up of components that were 3D printed using various materials, including ASA for the fuselage, PETG for the wings and tail surface, and TPU for the attachment hinges. For a durable and lightweight construction, the body also includes carbon tubes inside.

To test the aircraft’s flight ability, the maker took it for a spin at the beach, and he noticed only one drawback: The ASA fuselage got pretty dirty by landing on the sand and grass. Other than that, it flies exceptionally well!

- Who designed it? TomvH

- How printable/popular is it? This model has over 2,000 downloads and over 280 likes. So far, the only make is the designer’s own.

- Where to find it? Printables

FPV Plane

This design is 400 mm wide and has only three printed parts. There’s a place to hold a camera, allowing for FPV capability. Plus, it flies very well.

This model was created in Tinkercad. According to the listed settings, it should be printed with two walls (each 0.4 mm thick), a grid infill pattern, and no bottom and top layers.

- Who designed it? drcameron

- How printable/popular is it? This project has over 27,300 views and more than 2,250 downloads.

- Where to find it? MyMiniFactory

EL-39 Jet Plane

This RC plane stands out from the other selections on this list. Why? It has a mini jet-like engine!

Of course, the EL-39 doesn’t use the same jet as a commercial plane, but it has an electric ducted fan (EDF). The EDF functions similarly to real jet engines but uses electricity and functions at a much smaller scale. It allows the EL-39 to fly very fast.

This RC jet is almost entirely 3D printed, including the EDF unit and landing gear. The EL-39 also has a length of 1,858 mm, a wingspan of 1,451 mm, and weighs roughly 7.5 kg.

The designer of this plane 3D printed the larger parts with a JGAurora A5 and the smaller parts on a Wanhao Duplicator i3. Any machine with a print area of 300 × 300 mm will work for the larger parts, and many of the other parts fit on a 200 × 200 mm bed (or even smaller). It’s important to note that the main tires, nose tire, and a few of the fan components should be 3D printed in a flexible material like TPU.

Be sure you want to take on the project before you get started – the STLs have a tag of ~$17.

- Who designed it? tahustvedt

- How printable/popular is it? This plane is super popular, with over 170,000 views. The designs have been downloaded over 560 times, and despite the complexity of the project, there are four posted makes of the plane.

- Where to find it? Cults

License: The text of "3D Printed RC Plane: The Best Models" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.