Are 3D Printed Shoes Fashion or Function?

3D printing enables designers to break the boundaries of traditional shoe design, so there has been plenty of innovative footwear fashion in the past decade. 3D printed midsoles, such as those on the Adidas 4WRD, also have shown to actually propel runners forward, so there’s definitely function.

Add to the mix the fact that 3D printing enables footwear manufacturers to make shoes on-demand instead of keeping them in stock, thus reducing the tremendous waste issue that plagues the industry. Plus, several companies are now 3D printing shoes in eco-friendly materials that, they say, can be returned for recycling, which brings a new and needed focus on sustainability to the market.

This combination of fashion, function, and sustainability has attracted major brands to dip their toes into 3D printing, while hoping they can be the next Adidas — with millions of pairs of 3D printed shoes sold worldwide.

Major Brands 3D Printing (or have 3D printed) Shoes

- Adidas

- Nike

- New Balance

- Dior

- Peak

- ECCO

- ACIS

- ATHOS

- Fendi

- Puma

- Decathlon

- Columbia

- Under Armour

- Reebok

- Givenchy

- Balenciaga

Several (actually most) of the brands above no longer offer a 3D printed shoe. Either their product was an experiment disguised as a limited edition or a concept shoe that proved the technology application but perhaps didn’t find its niche or wasn’t applicable on a large scale. That doesn’t mean they’ve abandoned the technology, but for large global brands, moving from one way of making shoes to an entirely different way of making shoes, is not like flipping a switch.

With a few exceptions, 3D printing technology is not ripe for the large volumes big brand’s want.

For this reason, some of the most prominent companies offering 3D printed shoes today are start-ups born digital. They can capitalize on the freedom of design 3D printing allows and also bake in other key benefits, such as sustainability, customizability, and on-demand production.

Upstart footwear design and manufacturing companies, such as Zellerfeld, and the influential shoe designers it partners with, including Heron Preston, KidSuper, Rains, and Kitty, are using 3D printing to create uniquely designed footwear — and gaining a following. According to Footwear News magazine, celebrities such as Justin Bebiber, Jennifer Lopez, J Balvin, and even Elon Musk’s baby have been see about town recently in 3D printed shoes.

3D printing was once restricted to customized high-performance shoes for professional athlete and those willing to pay thousands for unique haut couture footwear. But now, additive manufacturing and footwear brands are seeing new opportunities to address some of the industry’s top challenges, and deliver for consumers looking for a custom, eco-friendly, and aesthetic pair.

Why Big Brands 3D Print Shoes

Adidas

Adidas is the marque success story of 3D printing in footwear. It launched its first 3D printed shoe, known as the Adidas Futurecraft 3D, in 2017 as a limited edition concept shoe that featured a 3D printed midsole tailored to the individual wearer’s foot. Although Adidas doesn’t customize shoes anymore, it was a leap forward in the use of additive manufacturing for custom footwear.

Since then, and millions of shoes later, Adidas has continued to develop and release 3D printed shoe models and has integrated 3D printing technology into other aspects of their footwear design and production processes.

In 2023, Adidas launched new designs of its most popular 3D printed shoe line is the “Adidas 4D” series, which features a 3D printed midsole from a printer and material maker based in the US called Carbon. Adidas has a factory in China full of Carbon 3D printers churning out high-volumes of the $200+ shoe.

The design of the midsole, which involves complex bow-tie lattice structure, transforms vertical pressure into a horizontal force. This gives runners a non-stop smooth forward transition, the company says. Why 3D print? Because this midsole can not be produced with traditional manufacturing methods.

Fendi

Fashion House Fendi tapped influential architect Kengo Kuma to collaborate on footwear in 2023 that would bring Kuma’s distinctive style to your feet.

The collection’s low-top footwear is mean to reflect Kuma’s innovative use of materials in his architecture. The shoes evoke Waranshi paper and cork supported by 3D printed soles that look like the traditional Yatara bamboo knitting technique, according to Fendi.

There’s no sustainability or function here, just pure style. The complex sole design could not be manufacturing with any other technology but 3D printing.

Fendi says Kuma’s approach to design centers around the interplay between nature and craft, an ethos that permeates his work as both an architect and designer. Fendi’s invitation to collaborate allowed Kuma to infuse his architectural sensibilities into fashion, resulting in a collection that embodies his creative vision.

Dior

Fashion house Dior sent models strutting down the runway during the 2023 Paris Fashion Week in 3D printed version of its classic Derby shoe.

3D printed in one piece, save for the laces, the chunky shoe is actually lightweight and breathable. The brand shared a video detailing the design and production process, which appears to show the shoe 3D printed with a powder bed fusion process, seemingly HP’s Multi Jet Fusion.

The TPU material gives the Derby flexibility and strength. No longer available on Dior’s website, hopefully the brand will be experimenting more.

Start-Ups & Designers Pushing the Envelope

Zellerfeld

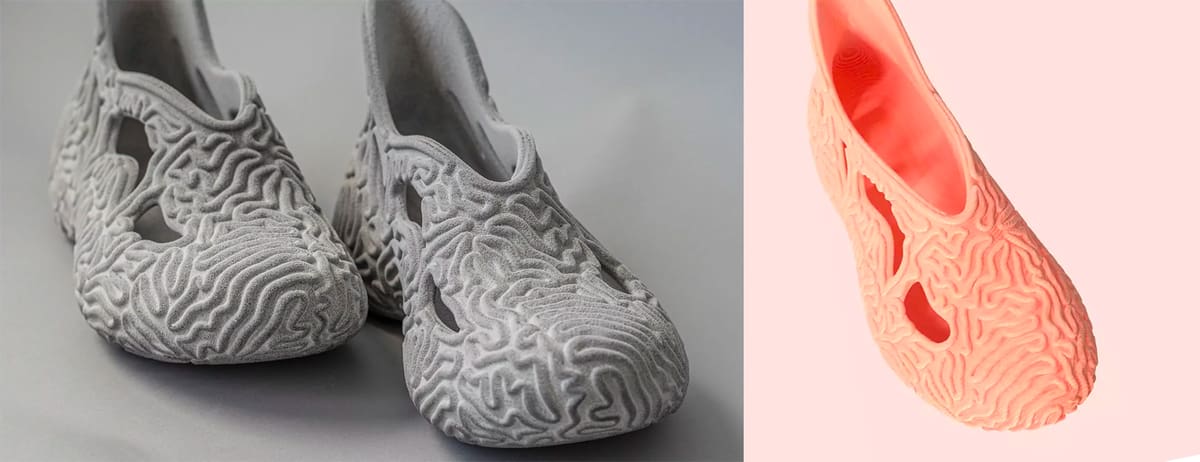

Start-up Zellerfeld may be the biggest 3D printing footwear company you’ve never heard of because they mostly make shoes for other designers. Zellerfeld is an enabler of innovation in the industry with its new partnership platform.

Launched in early 2023, the Zellerfeld platform has 3D printed limited edition shoes for influential shoe designers, including Moncler, Heron Preston, White Lotus, and Rains. They offer a farm of custom-built FDM 3D printers running nearly non-stop.

Zellerfeld doesn’t keep inventory, and customers can return their shoes for recycling. Each pair is custom fit and printed for the shape of your feet. Simply upload a scan of your feet using your smart phone.

Koobz

Koobz, is another shoe-printing start-up platform, which offers a turn-key solution to “democratize access to footwear manufacturing,” it says.

The company says it has designed the most efficient factory to “transform footwear manufacturing across America” and enable creators and designers to launch their own shoes.

Only featuring one shoe at the moment, Koobz’ concept is similar to Zellerfeld. They only print when a order is placed to reduce waste, the shoes are made from one material for easier recycling, and the boast that they’re made in the USA so there’s no carbon footprint from overseas shipping.

Hilos

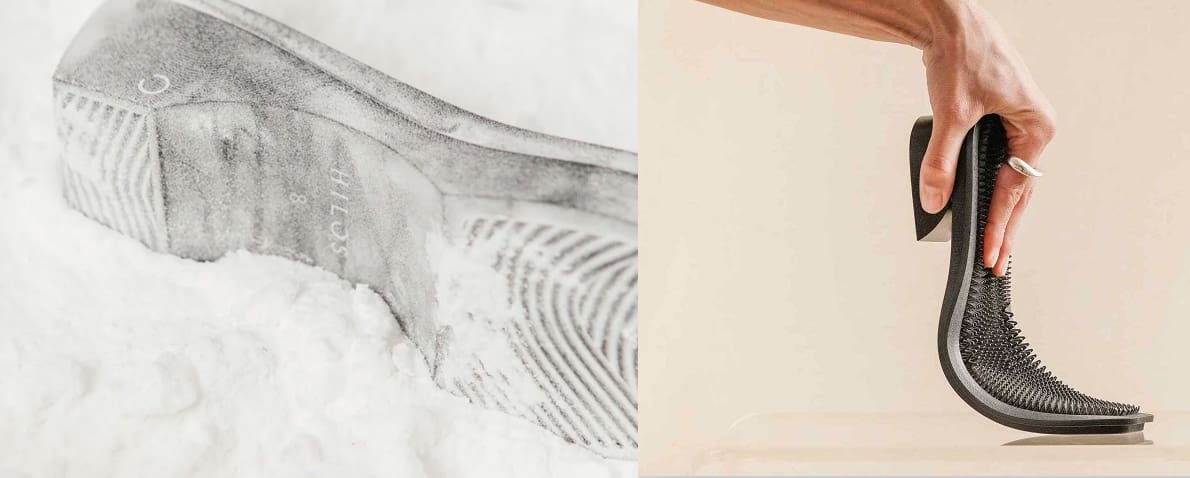

Portland-based Hilos, funded by longtime Nike executives, is yet another start-up hoping to additively manufacture shoes for other brands in the name of sustainability.

Their on-demand 3D printing, without inventory or waste, will enable them to reverse the trend of overstock shoes (that end up in landfills unworn) while offering more sizes and styles. Their shoe designs are all disassemble-able, without glue, making them easier to recycle.

Hilos currently offers more than a dozen styles, all featuring 3D printed soles (some resembling wood) and mostly leather uppers. The soles are printed on HP multi jet fusion 3D printers in nylon.

Elastium

An emerging UAE-based 3D printed footwear startup called Elastium offers a fully 3D printed sneakers made from 100% recyclable foam. The company says its shoe is a break from the limitations of traditional manufacturing and creates a sustainable, personalized, and comfortable 3D printed shoe.

Elastium’s sneakers feature lattice-structured low-density thermoplastic elastomer (TPE) foams fabricated by a proprietary 3D printing technology making their sneakers soft like Crocs, yet providing cushioning and resilience comparable to high-performance sneakers from Nike and Adidas, the start-up claims.

The focus is on rapid, on-demand, localized production. Each pair of Elastium sneakers is printed on-demand, which eliminates the costs associated with traditional footwear manufacturing, including the myriad in-between steps of mold making, sewing, gluing, storage, etc., and significantly reduces carbon emissions. In

addition, the sneakers are made from TPU foam that can be recycled into a new pair.

Like Zellerfeld and Hilos, Elastium also plans to grow into a footwear production platform for other designers.

Shoe Product Development & Prototyping

3D printing is well-established for footwear prototyping. The technology used during product development vastly accelerates product development and time to market for new designs.

3D printing, especially the full-color material jetting technology from companies like Stratasys, enable brands to go directly from digital file to life-size product.

Individual parts of shoes, such as midsoles and soles, can be 3D printed in flexible materials on a wide range of 3D printers in a matter of hours.

Lead image source: Lead image clockwise Decathlon with HP, Pangaia with Zellerfeld, Dior with HP, Adidas with Carbon.

License: The text of "3D Printed Shoes: The Cream of the Crop" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.