A New Wave Of Innovation

In recent years, 3D printing has made its way into wheel production, for several reasons.

3D printed wheels are still few and far between. As such, making them is a perfect opportunity for manufacturers to stand out. They grab the public’s attention and push the boundaries even further — a winning combo.

Another reason is waste reduction. Normally, car wheels are produced by machining a solid block of aluminum. This technique, called CNC milling, can produce a material waste of up to 80%, which is not ideal. With 3D printing, the material waste is typically no more than 5%.

Compared to CNC milling, 3D printing wheels also allows for the production of much more complex designs.

The concept has a great deal of potential thanks to today’s advanced 3D printing technologies, such as metal 3D printing, which enable the simple production of both prototypes and functional parts.

Furthermore, mass customization is considered to be the next big thing across all industries, and 3D printing does it better than any other manufacturing technique.

In the following, we present some of the best 3D printed wheels we’ve seen to date.

HRE's Titanium Wheel

At the end of the last year, California-based high-end wheel manufacturer HRE unveiled their 3D printed wheel, made in collaboration with GE Additive.

The project, called the HRE3D+, was carried out using the Arcam Q10 and Q20 electron beam melting (EBM) systems, which are capable of 3D printing parts out of titanium.

Though the rim is made of carbon fiber, the rest of the wheel consists of five titanium spokes converging at a titanium core. The parts are secured in place using titanium fasteners.

HRE and GE additive produced two different sizes of the wheel, a 20-inch front wheel and a 21-inch rear wheel. And while they may not be for sale, the companies have demonstrated what’s possible, giving us a small glimpse of what the future holds.

BigRep's Prototype Rim

BigRep, a German manufacturer of large-format 3D printers, 3D printed a wheel rim to highlight the possibilities of large-scale customization.

While not a wheel, per se, the project presents a complex structure that would be extremely hard or even impossible to produce with conventional manufacturing techniques.

Because Audi and BMW are mentioned on BigRep’s website, we can only guess that the two German companies are using 3D printing as a wheel prototyping method.

The wheel pictured above was printed on the BigRep ONE v3.

Replica Lamborghini Wheel

As a bit of fun, employees of UK-based Dream3D created a 3D printed replica of a 19-inch Lamborghini Gallardo wheel.

The wheel was printed in two parts. The first features five spokes and a central piece with a 3D printed Lamborghini badge, and the second is the wheel’s rear component. The printer used for the task was the Builder Extreme 1500, and the material was black PLA.

The goal of the project was to as accurately as possible achieve the look of an actual Lamborghini Gallardo wheel. As such, the Dream3D team put a lot of effort into post-processing.

After printing, the wheel was sanded twice, before and after a coating of XTC-3D resin. They then applied three coats of primer followed by three coats of matte black spray paint.

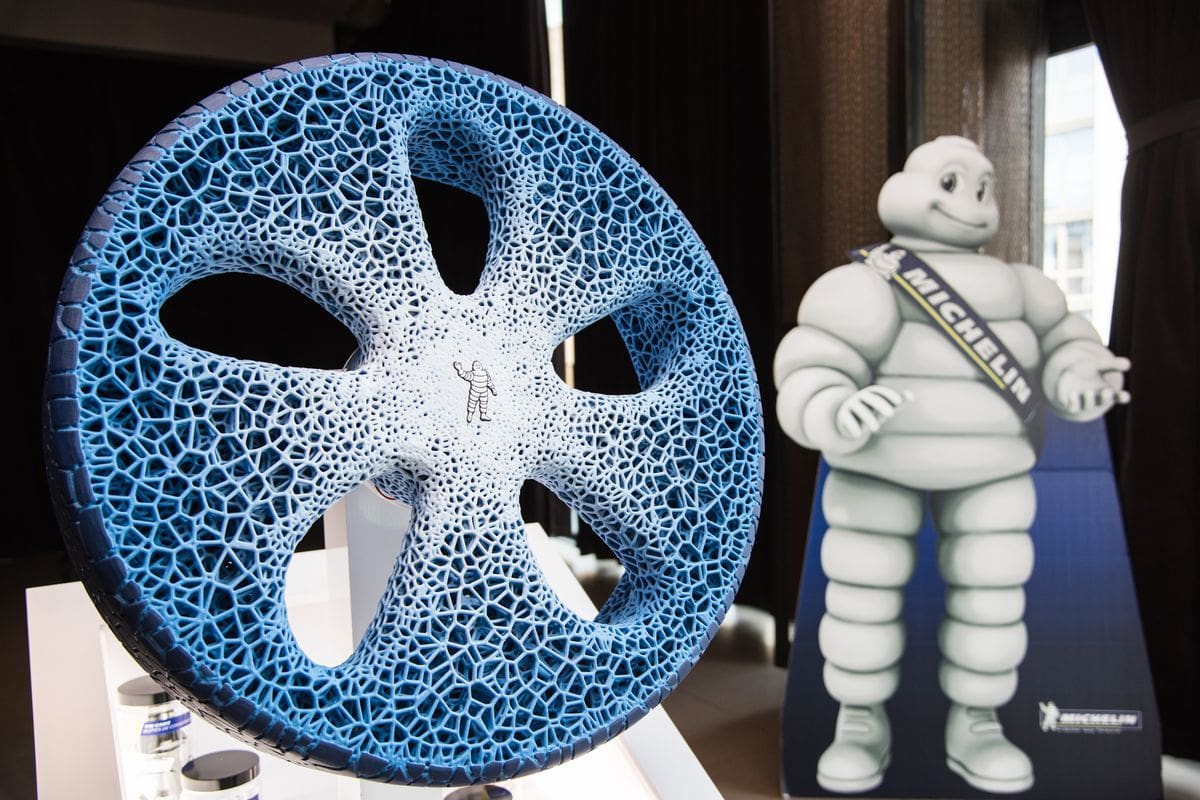

Michelin's Airless Wheel

In 2017, Michelin unveiled its airless wheel, which clearly illustrates the company’s goals for the future. Although the first wave of the industry’s 3D printed wheels will probably be “normal”, this concept can’t be ignored. Who knows? It could even be the future of driving!

Apart from being airless, the wheel’s design features a complex structure that laughs in the face of punctures.

Michelin’s next step is to put various sensors into the 3D printed body to predict weather conditions and report them to the driver. They’ve also presented the concept of “treads on demand”, a system where treads would be printed at a drive-through station.

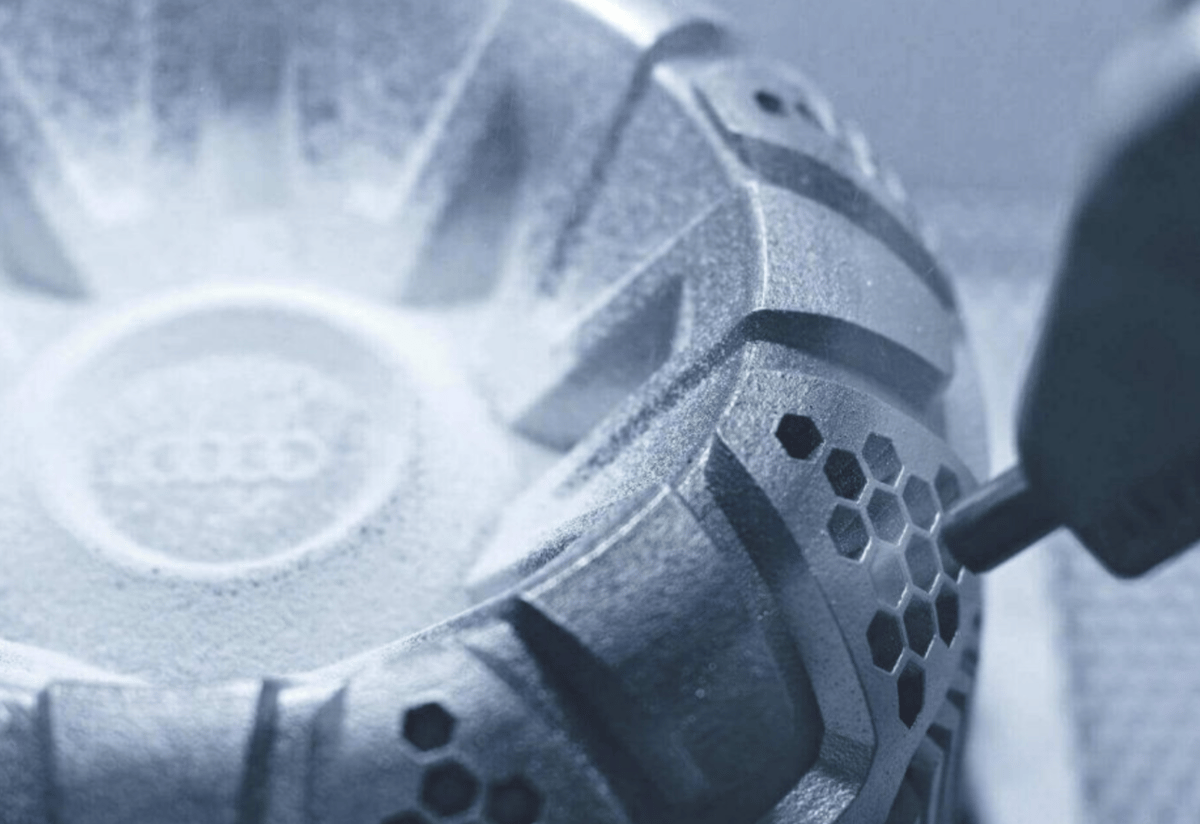

Audi's Lunar Rover Wheels

A few years back, Audi started developing its Lunar Quattro rover, in which they’ve used 3D printing to produce various components, including the wheels.

They’re made of a special aluminium alloy. It, in combination with an innovative inner structure and thin walls, significantly reduces the rover’s weight. Each wheel weighs just 1.6 kg and takes about 32 hours to print.

This project shows us that 3D printing even has advantages when applied to space exploration vehicles!

License: The text of "3D Printed Wheels – The 5 Most Promising Projects" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.