While wind power is a growing industry, it still often accounts for a relatively low percentage of the overall power supply. However, this reality is shifting thanks to innovations by brilliant tinkerers and engineers. It’s no surprise that 3D printing has enabled several neat projects and brought new ideas to the scene. Read on as we check out some of the most interesting wind-powered projects available!

If you’re inspired by one of the prints on the list but don’t have the means or desire to print it yourself, check out Craftcloud. You’ll have total control over how you want the final print to look, and with a few clicks, a model will be on its way.

With that, let’s get ready to be blown away by these wind-powered designs!

Horizontal Axis

50-Watt

This simple wind turbine is capable of producing up to 50 watts of power! If you can find the right generator, you might be able to achieve that yourself. The stepper motor the creator used only generates 20 watts, but that’s still impressive for a homemade wind turbine.

If you want to increase the scale and use a larger generator, you can print larger blades with the same architecture. The turbine is also designed to minimize waste, with 95% of the parts requiring no post-processing. Print settings vary by part, so check out the diagrams and assembly videos on the project page to see how to put it together.

- Who designed it? 3dprintable1

- How printable/popular is it? It’s extremely popular with around over 100,000 downloads and 21 makes. Most users reported that they enjoyed printing this turbine; however, some reported lack of clarity on its electronics.

- Where to find it? Thingiverse

Windturer Portable

The Windturer Portable is, as its name implies, a foldable turbine that houses a brushless DC electric motor (BLDC motor) as an electric generator. The designer has provided several updates to the design, including a new articulation system for the tail. This allows the tail to rotate 180 degrees without needing to unscrew and screw. It’s now also possible to use the BLDC motors from camera stabilizers for greater efficiency.

With 17 printable STL files, this turbine is rather complicated to make, and you’ll need to purchase a few more components as well. After successfully printing the parts, don’t forget to smooth out their imperfections and bumps with a sandblast. You can optimize the blade design with QBlade software before printing. You can also watch this YouTube video to become more familiar with this turbine.

- Who designed it? adriancubas

- How printable/popular is it? This model has around 340 likes, 423 followers, and 80 comments so far.

- Where to get it? Hackaday

Solar

If you’re fascinated by wind turbines, this model is for you. It’s the perfect sustainable and renewable resource to display on your desk. This model features a small DC motor driven by power from the solar panels embedded in the design. It’s a remix of an earlier design by Ivalio, and it was originally intended as a 1:87 wind turbine for model train setups.

Users have found the most success printing with PLA and 25% infill. In addition, because this model can support two different DC motors, with each motor requiring different printed parts, the designer provided different STL files for each motor, as well as files for using one or two solar panels. After printing the necessary parts to support your chosen motor, you’ll need to do some soldering and apply hot glue to keep the parts together.

- Who designed it? PhilipHee

- How printable/popular is it? This model has 66 likes, over 380 downloads, and 4 shared makes.

- Where to get it? Printables

Small Lightweight

This easy-to-print turbine is ideal for your backyard garden or balcony greenery. Weighing only 45 grams, it uses PLA filament material and takes only four hours to finish. Quick printing is its primary advantage.

You can either print it whole from a single print file or assemble it after printing four different parts, available in both OBJ and STL file formats.

- Who designed it? volt64bolt

- How printable/popular is it? This light design has more than 2,300 views, over 400 downloads, and 23 likes. Three people have successfully made it and have shared their own photos and experience. One user mentioned adding some bearings to make it work in very low winds.

- Where to find it? Printables

Airplane-Shaped

Believe it or not, this model was made by a 3D printing enthusiast with no engineering background! After trying out some designs, they researched, experimented, and finally designed this wind turbine. Since it’s a horizontal-axis turbine, it might be a little louder than the vertical-axis models, but there are other advantages, like higher efficiency, which might make you want to try this model.

As with some of the other models, it goes without saying that you’ll need some hardware, such as bearings, screws, and super glue. You’ll also need to pause the print to add nuts to one part. Pay close attention to the printing instructions, which suggest varying layer heights for the parts and 15% infill.

- Who designed it? plaszlonet

- How printable/popular is it? This turbine has plenty of fans with four makes and a remix.

- Where to find it? Thingiverse

Vertical Axis

Darrieus

If you’re looking for a first model to get into printing and assembling wind turbines, look no further. This model, inspired by the Darrieus wind turbine invented by French engineer Georges J.M. Darrieus in 1931, is a small vertical-axis wind turbine (VAWT) using three airfoil blades. The creator designed it to make with his students, so it should be fairly straightforward to put together.

The designer reports printing the parts with PLA, 10% cubic infill, and a raft to provide adhesion. While most of the pieces shouldn’t take long to print, the NACA 0018 airfoil blades took about 8 hours each. After printing, you’ll need to secure the parts together with pencils and a silicone hot glue gun.

- Who designed it? adriancubas

- How printable/popular is it? This model has over 380 likes and 2 shared makes. Some of the comments provide recommendations on how to increase the design’s efficiency.

- Where to get it? Instructables

Simple Vertical

This model is a vertical-axis wind turbine because of its vertical blade configuration. These types of wind turbines have advantages, including fewer breakable parts. The style is ideal if you’re looking for something for your home or backyard.

To assemble this simple vertical windmill, follow the detailed directions on the model page. You’ll need glue and some hardware like threaded rods and screws. You’ll also need to make sure to sand the surface of the blades to a smooth finish. The creator suggests printing the “JointTest” pieces, then adjusting settings accordingly to ensure that the joints fit.

- Who designed it? miiiike

- How printable/popular is it? This model is highly popular, with 25 makes and 5 remixes. Most users loved the design but some encountered issues such as confusion with the amount of power generation.

- Where to get it? Thingiverse

Helix Vertical

Another vertical-axis wind turbine, this design is both lightweight and highly stable since it can withstand high winds as well as operate at low wind speeds. These turbines are a perfect addition to your rooftop or the top of an RV to produce power while camping.

You’ll want to print this turbine at a low speed, with 100% infill. No supports or rafts are needed, and you may want to print it turned 180°.

- Who designed it? karete

- How printable/popular is it? This turbine is pretty popular and replicable with over 10,000 downloads and 22 makes.

- Where to find it? Thingiverse

Mini Vertical

This model is a mini turbine that’ll work no matter the direction of the wind, and it’s small enough to use as a learning tool. You can easily pass it around a classroom to demonstrate wind power in action. While this small turbine can only produce enough power to light an LED or two, micro-power generators in general can be great for remote areas.

This model will require some bearings, but there are no special printing instructions.

Modular Vertical

This turbine is special because of its modular design, and it can be scaled up. Another reason to try a vertical-axis turbine is that they tend to be quieter than horizontal-axis designs due to their slower rotation.

This model was printed with a 15% infill with rafts and supports. You’ll need some rods, screws, a thrust bearing, and clamping collars.

- Who designed it? Hashtag_Mike

- How printable/popular is it? This popular design has 6 makes shared and over 20,000 downloads.

- Where to find it? Thingiverse

Multi-Generator Vertical

The multi-generator vertical-axis wind turbine has a high RPM and can rotate pretty fast. We suggest using PLA for the stationary parts and ABS, nylon, or polycarbonate for the moving parts, since they’re subject to friction.

This turbine can generate 20 to 100 watts of power, depending on the number of DC motors and turbine blades. The design features 28 printable STL files. In addition, you’ll need to purchase 13 bearings and the DC motor.

- Who designed it? Oscar-AliB

- How printable/popular is it? This cool design has over 24,000 views and 154 likes.

- Where to find it? Instructables

Contra-Rotating

This wind turbine model is simple but effective in allowing you to stack multiple turbines and have them rotate in whatever direction you like. The ability to use contra-rotating rotors (blades of a wind turbine) means that you might get slightly higher efficiency in certain situations. This model is great if you’re interested in experimenting with stacks of rotors or placement before going all out on a larger model.

This model doesn’t have special printing instructions, but you’ll need some hardware, such as nuts, washers, screws, and a threaded rod for assembly.

Balcony

This vertical-axis wind turbine is ideal for your balcony when there’s low or moderate wind. PETG is recommended for all parts given its higher resistance to weather conditions compared to PLA, even if it may be trickier to print. And to see this model in action, watch this YouTube video.

The components feature printable 15 STL files, and you’ll need some bolts, nuts, bearings, and rods of specific dimensions for assembly.

- Who designed it? Tobias Gabathuler

- How printable/popular is it? This model has over 50,000 downloads combined from both sites, and 24 makes and 7 remixes have been shared on Thingiverse.

- Where to find it? MyMiniFactory, Thingiverse

Ugrinsky

Ugrinsky and Savonius are two types of wind turbines that are similar in appearance and design, but studies have shown that the Ugrinsky design is more efficient. It has an efficiency of 41 to 46%, while the Savonius is 10 to 20%. Other positive features include its simple design and low noise while operating. You can see how these two wind turbines further compare in this YouTube video.

The Ugrinsky components include five printable STL files. To generate extra torque, you can stack two of these turbines together, as seen in the picture above.

- Who designed it? TanyaAkinora

- How printable/popular is it? This printable turbine has seven makes and three remixes.

- Where to find it? Thingiverse

Specialty

Nautilus Mini

Based on “The Archimedes” wind turbine, this design is inspired by a nautilus shell. It’s meant to spin at low wind speeds and be highly efficient. While this model isn’t going to power your home, it’s a great example of how we can visualize new and innovative ideas with 3D printing and maybe even improve on them ourselves!

The creator recommends printing this model slowly. This model comes with a base, but one user commented that there appeared to be a scaling issue with respect to a few of the parts. Be advised that you may have to make adjustments before printing!

- Who designed it? jorgenunobravo

- How printable/popular is it? This project has five makes shared and a remix so far.

- Where to find it? Thingiverse

Gravity-Storing

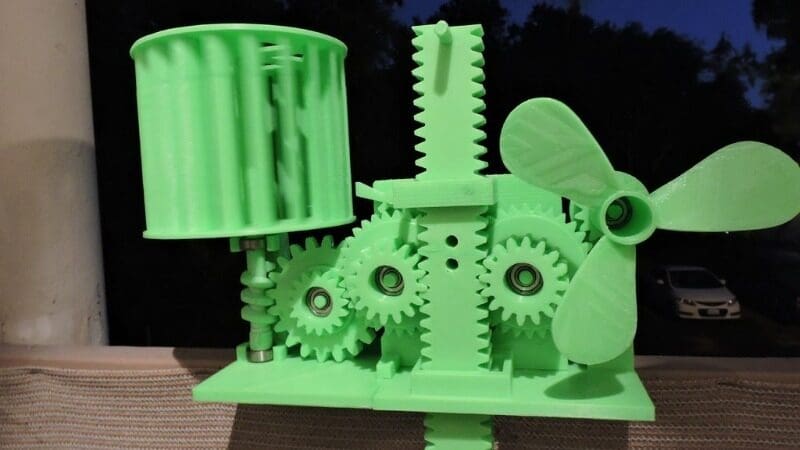

This neat model shows how we can harness the power of the wind without expensive batteries for energy storage. It works by lifting a weight, releasing it, and using the energy created to turn gears to drive the mechanism.

As with other models, you’re going to need some bearings for it, too. The maker of this model printed in ABS with a 30% infill, while other makers have mentioned using supports.

- Who designed it? hyperplanemike

- How printable/popular is it? With eight makes and four remixes, this turbine is causing a stir.

- Where to find it? Thingiverse

Bubble Blower

Ever wanted a bubble blower machine? Now’s your chance! This design works by the wind turning the wand that blows the bubbles, so there’s no need for batteries or power cords. It’s a great piece of portable party gear!

The creator released an animation detailing assembly and a short video of it in action, in case you need some convincing that it’s worth the overhang-printing hassle (it is!).

- Who designed it? Pikkle

- How printable/popular is it? It has over 8,000 views, 600 downloads, and 79 likes.

- Where to find it? MyMiniFactory

License: The text of "The Best 3D Printed Wind Turbines for Your Backyard" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.